Introduction

In today's fast-paced world of manufacturing, precision is key. And when it comes to achieving unparalleled accuracy and efficiency, CNC milling and turning techniques are at the forefront. Whether you're a seasoned professional or just starting in the industry, understanding the basics of CNC milling and turning is essential for success.

Understanding the Basics of CNC Milling and Turning

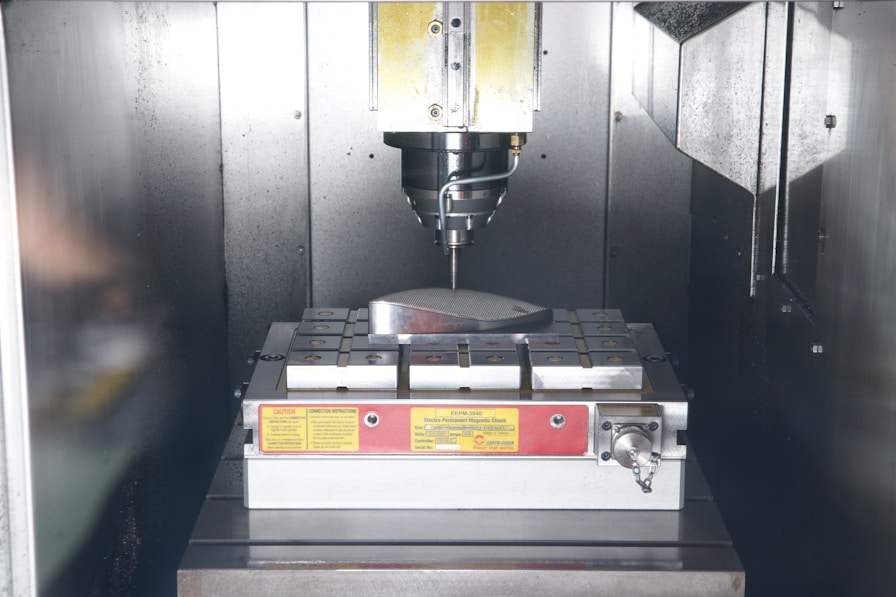

CNC, which stands for Computer Numerical Control, refers to using computer software to control machine tools. In milling and turning, this technology allows for precise movements and cuts on a variety of materials such as metal, plastic, or wood. By utilizing advanced programming and automation, CNC machines can accurately produce complex shapes.

The Power of Precision: Exploring CNC Milling and Turning Techniques

The power of precision that CNC milling and turning offer is truly remarkable. With these techniques, manufacturers can achieve tight tolerances that were once thought impossible. From intricate components for aerospace applications to customized parts for medical devices, CNC milling and turning techniques have revolutionized precision manufacturing.

Meet the Experts: SYIL Machine Tools - Your Go-To for CNC Milling and Turning

When choosing a reliable partner in CNC milling and turning, look no further than SYIL Machine Tools. With over 12k machines supplied globally, SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. They prioritize quality and sustainability in their products, ensuring that their customers receive top-notch equipment that meets their specific needs.

Whether you're a seasoned professional looking to enhance your skills or a newcomer eager to explore the world of CNC milling and turning, this guide will equip you with the knowledge and expertise needed to unleash your potential. Let's dive in!

Getting Started with CNC Milling and Turning

CNC milling and turning are two essential processes in precision manufacturing. Understanding the terminology associated with these techniques is crucial for beginners. CNC is Computer Numerical Control, which uses computerized systems to control machine tools. Milling involves removing material from a workpiece using rotary cutters while turning involves rotating the workpiece against a cutting tool.

Over the years, CNC milling and turning technology have evolved significantly. Automated processes that offer higher precision and efficiency have replaced traditional manual methods. With advancements in computer technology and machine controls, manufacturers can now easily achieve complex shapes and intricate designs.

SYIL Machine Tools is revolutionizing precision manufacturing with its range of CNC machines. These machines combine cutting-edge technology with robust construction to deliver exceptional performance and accuracy. With over 12k machines supplied globally, SYIL prioritizes quality and sustainability, making it a reliable partner for all your CNC milling and turning needs.

Choosing the Right CNC Milling Machine

There are various types of CNC milling machines available on the market. Each type has unique features and benefits, so it's crucial to understand the differences before making a decision.

Exploring Different Types of CNC Milling Machines

CNC milling machines are powerful tools used to create precise parts from various materials. They come in different configurations, each offering distinct advantages for specific projects. Here's a breakdown of some common types of CNC milling machines:

- Vertical Milling Machine: This workhorse of the CNC milling world features a vertically oriented spindle, allowing for easy up-and-down movement of the cutting tool. Vertical mills are known for their precision and versatility, making them ideal for various applications.

- Horizontal Milling Machine: Unlike the vertical setup, horizontal mills have a horizontal spindle. This configuration allows for heavy-duty cutting and easy handling of larger workpieces.

- Universal Milling Machine: As the name suggests, this machine offers the best of both worlds. It combines vertical and horizontal capabilities, providing flexibility for various operations and complex projects.

Understanding the strengths of each type of CNC milling machine allows you to select the one that best suits your specific needs and project requirements.

Factors to Consider When Selecting a CNC Milling Machine

When selecting a CNC milling machine, several factors should be considered. First, you need to determine the size and weight capacity required for your specific projects. Then, consider the dimensions and weight of your typical workpieces to ensure compatibility with the chosen machine.

SYIL: Your Reliable Partner in CNC Milling Machine Selection

When choosing a reliable partner for your CNC milling machine, look no further than SYIL Machine Tools. With over 12k machines supplied globally, SYIL is a trusted name in the industry.

With its commitment to quality and sustainability, SYIL prioritizes customer satisfaction. It offers comprehensive support throughout the selection process and provides ongoing technical assistance to ensure the smooth operation of its CNC machines.

Choose SYIL as your partner in CNC milling machine selection and experience the power of precision manufacturing at its finest.

Mastering CNC Turning Techniques

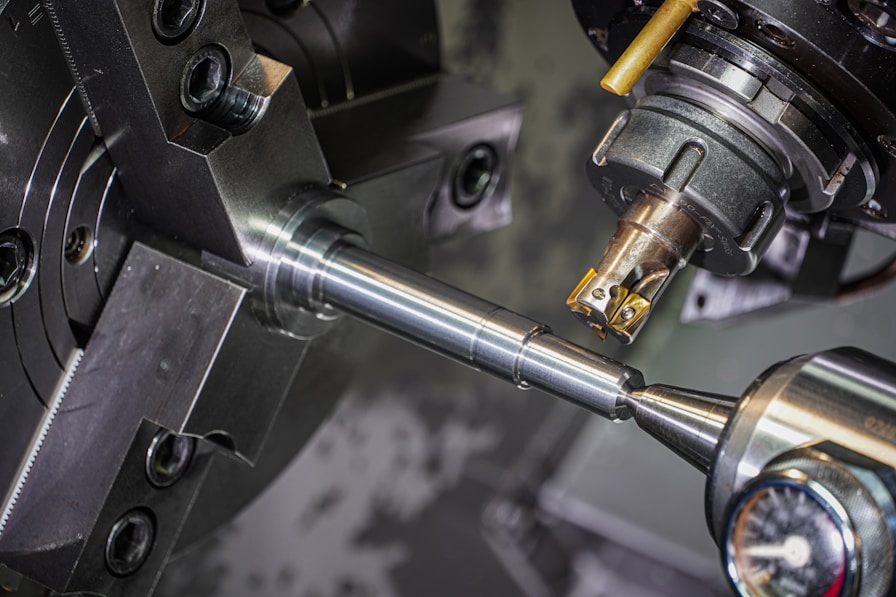

CNC turning is a fundamental machining process that involves rotating a workpiece while a cutting tool removes material to create cylindrical parts. To truly master CNC turning, it's crucial to understand its principles, the tools and techniques required for success, and the solutions available to optimize efficiency.

Understanding the Principles of CNC Turning

CNC turning operates on the principle of rotational motion. The workpiece is securely clamped in a chuck and rotated at high speeds while a cutting tool removes material from its surface. This process allows for precise shaping and finishing of cylindrical components.

Tools and Techniques for CNC Turning Success

The key to success in CNC is selecting the right tools and implementing effective techniques. High-quality cutting tools made from durable materials such as carbide or high-speed steel are essential for achieving precise cuts and extended tool life.

Proper tool selection includes considering geometry, coatings, and chip control capabilities. Depending on the desired outcome, different types of inserts, such as round-nose or grooving inserts, can be used.

SYIL's Turn Mill Center: Optimizing CNC Turning Efficiency

When it comes to optimizing CNC turning efficiency, SYIL Machine Tools offers an exceptional solution: the Turn Mill Center. This innovative machine combines milling and turning capabilities in one compact unit.

The SYIL Turn Mill Center allows simultaneous machining operations, significantly reducing cycle times. Its advanced features include live tooling options, multiple spindle configurations, and automatic tool changers, which enable complex parts to be produced with exceptional precision and efficiency.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and turning. With over 12k machines supplied globally, they prioritize quality and sustainability. By offering innovative solutions like the Turn Mill Center, SYIL empowers manufacturers to elevate their machining capabilities and stay ahead in today's competitive market.

The Art of Precision Turn Milling

Precision turn milling is a cutting-edge technique combining the best CNC milling and turning to achieve unparalleled accuracy and efficiency in manufacturing processes. By integrating milling and turning operations into a single machine, this innovative approach allows for creating complex parts with intricate features and tight tolerances.

Combining the Best of CNC Milling and Turning

The art of precision turn milling combines the advantages of CNC milling and turning processes. With CNC milling, intricate shapes can be achieved by removing material from a workpiece using rotating cutting tools. On the other hand, CNC turning involves rotating a workpiece while a stationary cutting tool shapes it into the desired form.

Key Considerations for Precision Turn Milling

Precision turn milling combines the capabilities of turning and milling to create complex, high-tolerance parts. Several factors require careful attention to achieve optimal results in this process.

- Machine Selection: The right machine is paramount. Evaluate factors like spindle speed, tool capacity, and axis movement to ensure the machine can handle your specific job requirements.

- Cutting Tool Selection: Don't underestimate the impact of cutting tools. High-quality tools with sharp edges and appropriate coatings are crucial for achieving precise machining accuracy and a smooth surface finish.

By carefully considering these key factors, you can ensure your precision turn milling projects are completed successfully and efficiently.

SYIL's CNC Turn Mill Machine: Redefining Precision Engineering

SYIL Machine Tools has revolutionized precision engineering with its state-of-the-art CNC turn mill machines. These machines seamlessly integrate turning and milling operations into one powerful unit, offering unparalleled precision and efficiency.

SYIL's turn mill machines have advanced features such as high-speed spindles, multi-axis capabilities, and automatic tool changers. These features ensure fast and accurate machining of complex parts, reducing production time and costs.

With over 12k machines supplied globally, SYIL Machine Tools prioritizes quality and sustainability. Their commitment to excellence is evident in the precision and reliability of their CNC turn mill machines.

Unleashing the Potential of CNC Milling and Turning

CNC milling and turning have revolutionized the manufacturing industry, opening up a world of innovative applications. From aerospace to automotive, these advanced techniques have found their way into various sectors, pushing the boundaries of what is possible. With precision at its core, CNC milling and turning have become essential tools for creating complex components with utmost accuracy.

Innovative Applications of CNC Milling and Turning

One of the most exciting aspects of CNC milling and turning is its versatility in creating intricate designs. Whether producing complex shapes for medical implants or crafting precise gears for high-performance engines, these techniques offer endless possibilities. The ability to work with a wide range of materials, such as metals, plastics, and composites, further expands the potential applications.

CNC milling and turning play a vital role in industries like aerospace, where lightweight yet strong components are crucial. These techniques enable manufacturers to create reduced-weight intricate structures while maintaining structural integrity. Precision-turned parts contribute to safer and more efficient flying machines from aircraft to satellite components.

Automotive manufacturers also benefit greatly from CNC milling and turning technology. Precision machining ensures optimal performance and reliability, from engine components to suspension parts. Producing complex geometries with tight tolerances enhances fuel efficiency and overall vehicle performance.

Maximizing Efficiency and Productivity in Milling and Turning Operations

Efficiency is key in today's fast-paced manufacturing environment, where time is money. CNC milling and turning machines are designed to maximize productivity by automating once labor-intensive processes. With advanced software controls and tooling options, operators can achieve higher throughput without compromising quality.

By utilizing the multi-axis capabilities offered by turn mill centers, manufacturers can significantly reduce setup times. These machines combine milling and turning operations into one process, eliminating the need for multiple setups on different machines. This seamless integration improves efficiency, reduced lead times, and cost savings.

SYIL's Commitment to Quality and Sustainability

When it comes to CNC milling and turning machines, SYIL Machine Tools stands out as a trusted partner. With over 12,000 machines supplied globally, they have established themselves as industry leaders in precision manufacturing. SYIL's commitment to quality is evident in its state-of-the-art machines, which deliver exceptional accuracy and reliability.

Elevate Your Manufacturing Game with CNC Milling and Turning

In conclusion, CNC milling and turning have revolutionized the precision manufacturing industry. With the power of computer-controlled machines, intricate designs can be brought to life with unparalleled accuracy and efficiency. SYIL Machine Tools, a leading manufacturer in this field, offers a wide range of CNC machines designed to meet manufacturers' diverse needs.

By embracing CNC milling and turning techniques, manufacturers can elevate their game and stay ahead of the competition. The precision and speed offered by these machines enable businesses to produce high-quality products in a shorter amount of time. With SYIL's CNC machines, you can take your manufacturing capabilities to new heights.

Embrace the Future of Precision: SYIL's CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their state-of-the-art turn mill centers and turnmill machines are designed to optimize efficiency in CNC turning operations.

With SYIL's CNC machines, you can embrace the future of precision engineering. These advanced machines combine the best of both worlds—milling and turning—allowing for complex geometries to be achieved with utmost accuracy. Whether you're in automotive, aerospace, or any other industry that demands precision-turned components, SYIL's turn mill centers are your go-to solution.

Unleash Your Potential with CNC Milling and Turning Mastery

To truly unleash your potential as a manufacturer, you must master the art of CNC milling and turning. By understanding the principles behind these techniques and utilizing the right tools, you can unlock endless possibilities for innovation.

SYIL's CNC turn mill machine is at the forefront of this mastery journey. Its cutting-edge technology and user-friendly interface empowers operators to achieve optimal results in every machining operation. Whether you're a seasoned professional or just starting, SYIL's CNC machines provide the platform for you to excel in precision manufacturing.