Introduction

In the world of jewelry making, the choice of tools can elevate an artisan's craft from ordinary to extraordinary. High-quality CNC (Computer Numerical Control) machines have revolutionized the way jewelers create intricate designs, particularly in crafting stunning CNC earrings. By harnessing precision technology, jewelers can achieve remarkable detail and consistency that traditional methods often struggle to replicate.

Why Choose High-Quality CNC for Jewelry

High-quality CNC machines offer unparalleled accuracy, allowing for intricate designs that are simply unattainable with manual techniques. This precision is especially beneficial when creating CNC earrings, where even the smallest detail can make a significant impact on overall aesthetics. Additionally, using these advanced tools reduces production time and minimizes material waste, making them a smart choice for both new and seasoned jewelers.

The Rise of CNC in Earring Design

The rise of CNC technology has transformed earring design into an art form that blends creativity with engineering prowess. Many jewelers now ask themselves: Do jewelers use CNC machines? The answer is a resounding yes! As more artisans embrace this technology, they unlock new possibilities for creating diverse styles and types of earrings that cater to various tastes and trends.

Exploring Sterling Silver for Earrings

When it comes to materials for crafting stunning earrings, sterling silver stands out as a popular choice due to its beauty and versatility. Making earrings on the CNC mill using sterling silver allows jewelers to explore endless design options while ensuring durability and elegance in their creations. Whether you're designing minimalist studs or elaborate chandelier pieces, sterling silver provides a perfect canvas for your next masterpiece.

Understanding CNC Technology in Jewelry

In the world of jewelry making, CNC technology has become a game-changer, especially for crafting stunning pieces like earrings. But what exactly is CNC in jewelry? It stands for Computer Numerical Control, a method that uses computer software to control machine tools for precise cutting and shaping of materials. This technology allows jewelers to create intricate designs with unparalleled accuracy and efficiency, leading to the rise of unique and customizable CNC earrings.

What is CNC in Jewelry?

CNC in jewelry refers to the use of computer-controlled machines that automate the process of designing and manufacturing pieces from various materials, including metals like sterling silver. With this technology, artists can input their designs into specialized software, which then directs the machinery to carve out or shape the material with remarkable precision. Essentially, it transforms creative ideas into tangible jewelry by streamlining the production process while ensuring consistency across multiple pieces.

Advantages of Using CNC Machines

The advantages of using CNC machines in jewelry making are numerous and compelling. First off, they offer incredible precision; even the most intricate designs can be replicated flawlessly every time you make a new piece—perfect for those looking to produce popular styles or custom orders alike! Additionally, CNC machines significantly reduce production time compared to traditional handcrafting methods; this means more time for creativity and less time spent on repetitive tasks when making earrings on the CNC mill.

Another major benefit is scalability; once a design is perfected, jewelers can easily produce large quantities without sacrificing quality or detail. This capability opens up opportunities for businesses looking to expand their product lines while maintaining high standards—an essential factor when considering how many types of earrings there are today! Finally, using CNC technology allows artisans to experiment with innovative designs that might be too complex or labor-intensive if done by hand.

Do Jewelers Use CNC Machines?

Absolutely! Many jewelers have embraced this cutting-edge technology as it enhances their craftsmanship while allowing them greater flexibility in design execution. The question “Do jewelers use CNC machines?” often leads to discussions about how these tools can complement traditional techniques rather than replace them entirely. While some artisans still prefer handcrafting certain elements for a personal touch, others find that incorporating a reliable CNC model for earrings enables them to push boundaries creatively without compromising on quality.

Moreover, as more jewelers recognize the benefits of incorporating these machines into their workflow, we see an increasing number experimenting with unique styles made possible through advanced capabilities offered by modern equipment.

The Perfect CNC Model for Earrings

Finding the right CNC model for earrings is crucial for any jewelry maker looking to elevate their craft. With the rise of CNC technology, creating intricate designs has never been easier or more efficient. In this section, we will explore top machines suited for jewelry making and what features you should prioritize when selecting your equipment.

Top CNC Machines for Jewelry Makers

For jewelers wondering Do jewelers use CNC machines?—the answer is a resounding yes! Many professionals have adopted these tools not only for efficiency but also for their ability to create unique pieces that might be impossible with traditional methods. Investing in a high-quality CNC machine can dramatically enhance your earring production capabilities while keeping costs manageable.

Features to Look for in CNC Equipment

When selecting a CNC model for earrings, certain features are essential to ensure optimal performance. First and foremost, look for precision; a machine with high-resolution capabilities will enable you to create intricate designs that stand out from the crowd. Additionally, consider the software compatibility; user-friendly design software can streamline your workflow and make it easier to bring your creative visions to life.

Another important aspect is spindle speed; faster spindle speeds allow you to work with various materials effectively, including sterling silver—a popular choice when making beautiful earrings on the CNC mill. Lastly, check if the machine offers versatility; being able to handle different types of projects beyond just earrings can provide added value over time.

SYIL CNC Machine: A Solid Choice

Among various options available in the market, the SYIL CNC machine stands out as a solid choice for jewelry makers focusing on creating exquisite cnc earrings. Known for its reliability and precision engineering, this machine allows you to tackle complex designs with ease while maintaining consistency across batches of production.

The SYIL model also boasts advanced features such as customizable tooling options and robust software integration that further enhances its usability—perfectly aligning with your needs as a jeweler exploring What is CNC in jewellery?. By investing in a SYIL machine, you're not just purchasing equipment; you're gaining an ally that empowers your creativity while ensuring top-notch quality in every piece you produce.

Designing Sterling Silver Earrings

Designing sterling silver earrings is an exciting venture that allows for creativity and craftsmanship to shine through. With CNC technology, the process becomes more precise and efficient, making it easier for jewelers to create intricate designs that stand out. Let’s delve into the aspects of choosing the right silver, mastering design techniques, and the actual making of earrings on the CNC mill.

Choosing the Right Silver for CNC Earrings

Look for silver that has a purity of at least 92.5%, which is standard for sterling silver; this ensures your earrings not only look beautiful but also withstand daily wear. Additionally, consider sourcing from reputable suppliers who provide information about their silver's origin and quality standards—this can make all the difference in your final product.

Techniques for Designing Earring Styles

Creating unique earring styles using CNC technology opens up a world of possibilities! Start by sketching out ideas or using CAD software to visualize your designs before moving to production; this helps streamline your workflow significantly. Incorporating different textures or patterns can add depth to your cnc earrings—think about combining polished finishes with matte textures or even engraving intricate details that will catch the eye.

Making Earrings on the CNC Mill

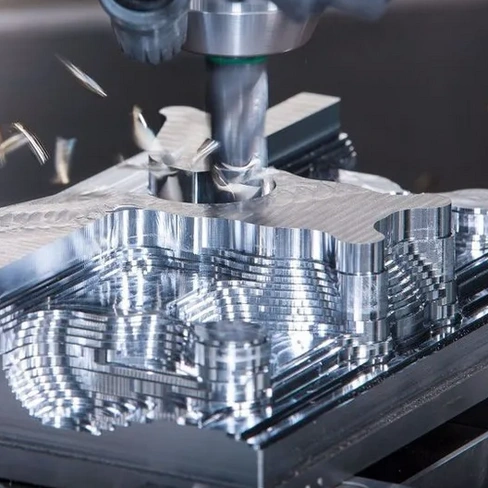

Making earrings on the CNC mill is where artistry meets precision engineering! Once you have your design ready, it's time to set up your machine according to specifications; ensure that you have selected a suitable CNC model for earrings tailored specifically for jewelry-making tasks. After securing your sterling silver piece in place, simply initiate the machining process—watch as it transforms from raw material into stunning finished pieces of jewelry with remarkable accuracy.

Types of Earrings You Can Create

How Many Types of Earrings Are There?

The world of earrings is a treasure trove, boasting a variety that caters to every taste and occasion. Common types include studs, hoops, drop earrings, and ear cuffs, each offering a unique flair. So, how many types of earrings are there? The answer is: more than you can count! With CNC earrings, you can even blend styles or create entirely new designs tailored to your personal aesthetic.

Popular Earring Designs with CNC Technology

CNC technology has revolutionized jewelry making by allowing for intricate designs that were once difficult or impossible to achieve by hand. Popular earring designs created using this innovative method include geometric shapes, floral motifs, and personalized engravings that showcase individuality. Jewelers often ask themselves: do jewelers use CNC machines? The answer is an enthusiastic yes! This technology enables them to produce stunning pieces efficiently while maintaining high-quality standards.

Customization Options for Unique Earrings

One of the most exciting aspects of creating CNC earrings is the ability to customize each piece according to individual preferences. Whether it's choosing specific materials like sterling silver or adding personalized engravings and textures, customization options abound for unique earrings that tell your story. By utilizing a reliable CNC model for earrings, you can transform your creative vision into reality—ensuring that every pair is as distinctive as its wearer.

The CNC Production Process

Creating stunning CNC earrings is an art that marries technology with creativity. Understanding the production process can help aspiring jewelers navigate the complexities of CNC jewelry making. From design to final touches, each step is crucial in achieving a polished end product.

Steps to Create CNC Earrings

The journey of making earrings on the CNC mill begins with designing a digital model using CAD software. This model serves as a blueprint for the machine, guiding it to carve out intricate details in sterling silver or other materials. Once the design is finalized, it's time to set up the CNC machine, load the material, and let technology do its magic—transforming raw metal into beautiful cnc earrings.

After the initial carving process, jewelers often refine their work by sanding and polishing to achieve that perfect shine and finish. This attention to detail is what sets high-quality cnc earrings apart from mass-produced alternatives. Finally, any additional features like hooks or embellishments are added before the earrings are ready for sale or personal use.

Quality Control in CNC Jewelry Making

Jewelers typically implement several checks during various stages of production to ensure everything meets their high standards. These include measuring dimensions against specifications and inspecting surface finishes for any imperfections.

Additionally, some jewelers may choose to conduct stress tests on their finished products to verify durability—because nobody likes losing an earring after just one wear! By prioritizing quality control throughout the production process, jewelers can confidently answer questions like Do jewelers use CNC machines? with pride in their craftsmanship.

Innovations in CNC Technology for Earring Production

As technology advances, so too does the world of jewelry-making; innovations in CNC technology have made it easier than ever to create unique designs efficiently. Newer models boast enhanced precision and speed, allowing makers more freedom when experimenting with complex shapes and styles for their cnc earrings.

Moreover, advancements like automated tool changers mean less downtime during production—a crucial factor when you're racing against trends in earring styles! With these cutting-edge developments paving the way forward, it's exciting to think about how many types of earrings will be possible through this innovative approach.

Conclusion

In the world of jewelry making, embracing CNC technology can significantly elevate your craftsmanship and creativity. As you explore the potential of CNC earrings, you'll find that this innovative approach not only enhances precision but also opens up a realm of design possibilities. Whether you're a seasoned jeweler or just starting out, integrating CNC into your workflow can transform your jewelry game.

Elevate Your Jewelry Game with CNC

CNC technology allows for intricate designs and flawless finishes that are hard to achieve with traditional methods. With the ability to create stunning CNC earrings, you can experiment with various styles and materials without compromising on quality. The precision offered by CNC machines ensures that each piece is uniform and meets high standards, making them perfect for both personal collections and commercial sales.

Finding the Right Equipment for Your Needs

Do jewelers use CNC machines? Absolutely! Many professionals rely on these powerful tools to streamline their production processes while maintaining artistic integrity in their designs. Researching different models will help you identify which equipment aligns best with your specific needs and budget.

The Future of CNC Earrings in Jewelry Making

As technology continues to advance, the future of making earrings on the CNC mill looks promising. Innovations in software and machinery will further enhance customization options for unique earrings that cater to individual tastes and trends. With more jewelers adopting these technologies, we can expect an exciting wave of creativity in earring design that pushes boundaries like never before.