Introduction

CNC metal cutting machines have played a pivotal role in revolutionizing the manufacturing industry, offering increased efficiency and precision in metal cutting operations. This has improved productivity, cost savings, and reduced material waste. One company at the forefront of advancing metal cutting technology is SYIL CNC Machines. With their commitment to quality and sustainability, SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they have established themselves as a trusted partner in the industry.

The Evolution of CNC Metal Cutting Machines

The evolution of CNC metal cutting machines has been remarkable. From their humble beginnings as simple numerical control (NC) machines to the sophisticated computer-controlled systems we have today, they have come a long way. Computer programming has allowed for greater automation, accuracy, and flexibility in metal cutting operations.

The Role of SYIL CNC Machines in Advancing Metal Cutting Technology

SYIL CNC Machines has been at the forefront of advancing metal cutting technology with their innovative solutions. Their precision CNC machines utilize state-of-the-art technology to deliver exceptional performance and accuracy in milling and drilling operations. With a focus on quality and sustainability, SYIL Machine Tools ensures their machines meet the highest standards while minimizing environmental impact.

Understanding CNC Metal Cutting Machines

CNC metal cutting machines have revolutionized the manufacturing industry with their ability to automate and streamline the metal cutting process. These machines utilize computer numerical control (CNC) technology to cut and shape various types of metals precisely.

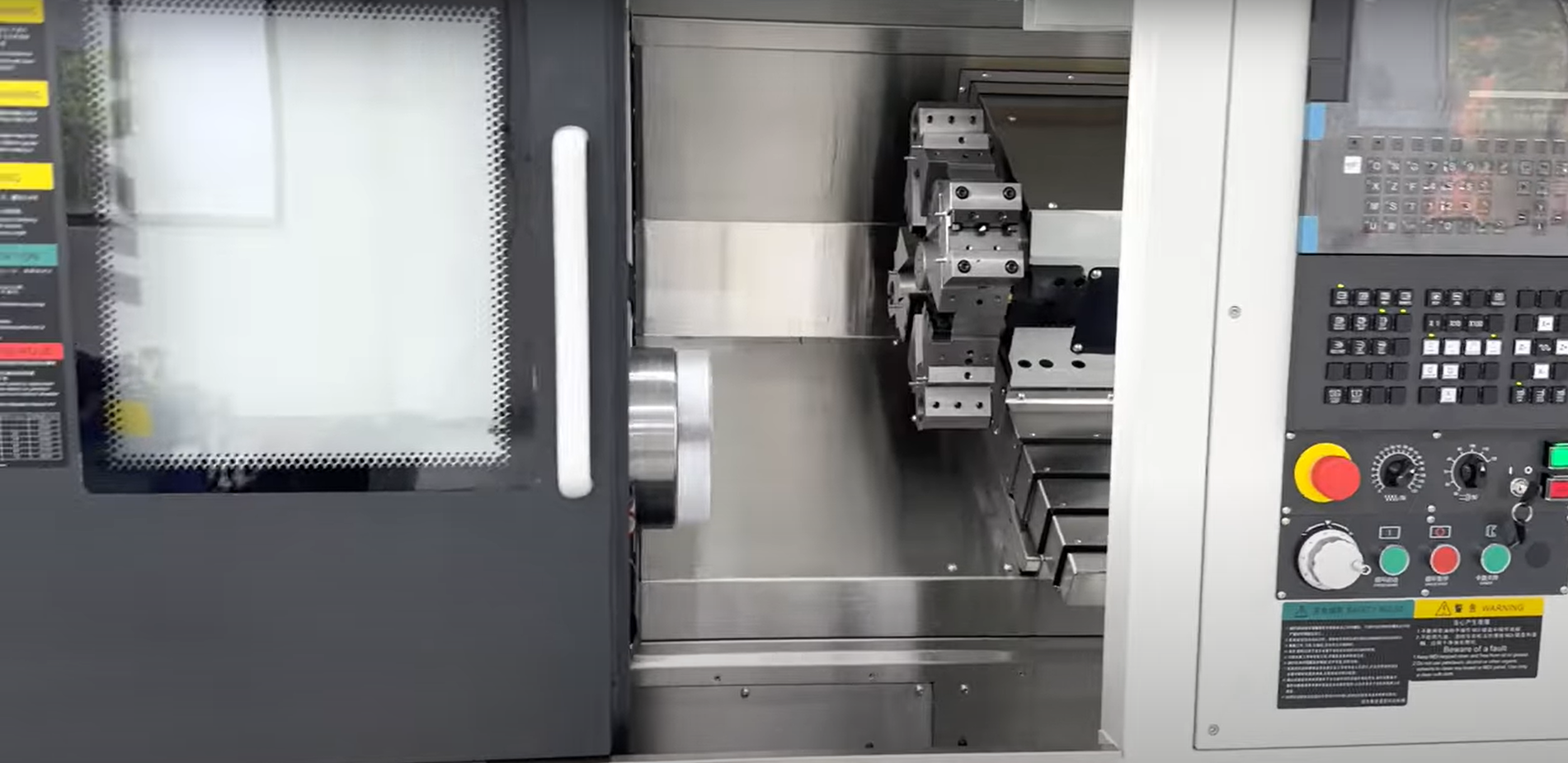

What is a CNC Metal Cutting Machine?

A CNC metal cutting machine is a sophisticated piece of equipment that uses computer programming to control the movement of the cutting tools. It replaces manual labor and allows for precise, repeatable cuts in metals such as steel, aluminum, and titanium. These machines have various cutting tools, including drills, mills, lathes, and lasers, to accommodate different cutting requirements.

How CNC Machines Increase Efficiency and Precision in Metal Cutting

CNC machines have revolutionized metal cutting, offering unparalleled precision and efficiency. Here's how CNC technology elevates metal fabrication:

- Boosted Efficiency: CNC machines eliminate human error and streamline production times. Precise programming ensures consistent accuracy in every cut, leading to fewer rejects and high-quality finished products.

- Tackling Complex Cuts: CNC machines excel at intricate designs, unlike manual methods. They can execute complex patterns and shapes with minimal effort, making them ideal for tight tolerances and intricate components.

CNC machines are game-changers in metal cutting. Their ability to combine precision with efficiency makes them a cornerstone of modern manufacturing.

Exploring the Different Types of CNC Metal Cutting Machines

There are several types of CNC metal cutting machines available in the market today:

- CNC milling machines: These machines use rotary cutters to remove material from a workpiece by advancing it against a rotating cutter.

- CNC lathes: Lathes rotate the workpiece while stationary tools shape it symmetrically.

- CNC laser cutting machines: Laser technology provides precise and clean cuts on various materials like metal sheets or tubes.

- 3D printers: While not exclusively used for metal cutting, 3D printers can create intricate metal components layer by layer using additive manufacturing techniques.

Each type has its unique benefits and applications, allowing manufacturers to choose the most suitable machine for their specific needs.

Benefits of CNC Metal Cutting Machines

1. Improved Productivity and Throughput Rates

CNC metal cutting machines significantly improve productivity and throughput rates compared to traditional manual methods. These machines can perform complex cutting operations much faster, resulting in increased production output. With automated processes and advanced programming, CNC machines can efficiently execute repetitive tasks without constant human intervention. This allows manufacturers to meet tight deadlines and fulfill large orders in less time.

2. Enhanced Precision and Accuracy in Metal Cutting

One key advantage of CNC metal cutting machines is their ability to deliver exceptional precision and accuracy in every cut. These machines are equipped with advanced control systems that ensure consistent results, eliminating human error and variability. Computer-aided design (CAD) software enables operators to create intricate designs with intricate details that the CNC machine can flawlessly execute. This level of precision is crucial, especially when dealing with complex components or parts that require tight tolerances.

3. Cost Savings and Reduced Material Waste

By using CNC metal cutting machines, manufacturers can achieve significant cost savings and reduce material waste. These machines optimize the cutting process by minimizing errors, leading to less generated scrap material. Additionally, the precise nature of CNC machining allows for tighter nesting of parts on raw materials, maximizing material utilization and reducing waste. This saves money on raw material costs and reduces environmental impact by minimizing waste disposal.

3. Versatility and Flexibility in Metal Cutting Operations

CNC metal cutting machines offer unparalleled versatility and flexibility in various metal cutting operations. They can handle a wide range of materials, including steel, aluminum, brass, and titanium. With different tools such as drills, mills, lathes, or lasers integrated into these machines' systems, they can perform multiple operations seamlessly without requiring manual tool changes or reconfiguration. This versatility allows manufacturers to adapt quickly to changing production needs and take on diverse projects.

SYIL Machine Tools, a leading manufacturer in the CNC industry, understands the importance of these benefits and has developed precision CNC machines that excel in delivering productivity, accuracy, cost savings, and versatility. With over 12k machines supplied globally, SYIL Machine Tools prioritizes quality and sustainability while providing cutting-edge solutions for milling and drilling needs.

Applications of CNC Metal Cutting Machines

1. Aerospace Industry: Achieving Complex Metal Cutting Requirements

In the aerospace industry, precision is crucial for producing aircraft components. CNC metal cutting machines are vital in achieving complex metal cutting requirements, ensuring the highest accuracy and consistency. These machines can handle materials like aluminum, titanium, and stainless steel, enabling manufacturers to create intricate parts with tight tolerances. With their advanced capabilities and versatility, CNC machines have revolutionized the aerospace industry by streamlining production processes and reducing lead times.

2. Automotive Industry: Streamlining Production Processes

The automotive industry relies heavily on CNC metal cutting machines to streamline production processes and meet the increasing demand for high-quality components. These machines enable manufacturers to efficiently cut and shape various metals used in automobile manufacturing, such as steel and aluminum alloys. By utilizing CNC technology, automotive companies can achieve precise cuts, intricate designs, and consistent quality throughout their production lines. This not only improves efficiency but also ensures safety and reliability in vehicles.

3. Medical Industry: Creating Precise Components for Medical Devices

In the medical industry, precision is paramount when creating components for medical devices. CNC metal cutting machines offer unmatched accuracy and repeatability, making them indispensable in manufacturing critical parts like surgical instruments, implants, and prosthetics. With their ability to work with a wide range of materials including stainless steel and titanium alloys, these machines ensure that medical professionals have access to precise tools that meet stringent quality standards.

4. Energy Sector: Meeting the Demands of Renewable Energy Technologies

As renewable energy technologies continue to gain momentum globally, CNC metal cutting machines play a crucial role in meeting the demands of this evolving sector. From wind turbine components to solar panel frames, these machines cut various metals required for renewable energy infrastructure projects. Their precision allows for efficient assembly and installation while ensuring optimal energy system performance.

SYIL CNC Machines: Leading the Way in Metal Cutting Technology

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL CNC machines offer advanced features like laser cutting technology, enabling finer precision and smoother edges. Their commitment to customer success is evident through numerous testimonials from satisfied clients who have experienced increased productivity and efficiency with SYIL machines. Choose SYIL for your metal cutting needs and unlock the full potential of CNC technology.

SYIL CNC Machines: Leading the Way in Metal Cutting Technology

Introduction to SYIL Machine Tools

SYIL Machine Tools is a renowned manufacturer specializing in developing and manufacturing precision CNC machines for milling and drilling. With a global presence and over 12,000 machines supplied worldwide, SYIL has established itself as a leader in the industry. Its commitment to quality and sustainability sets it apart from competitors, making it the go-to choice for businesses seeking reliable and efficient metal cutting solutions.

Key Features and Capabilities of SYIL CNC Machines

SYIL CNC machines are known for their precision, efficiency, and versatility in metalworking projects. Here's a breakdown of their key features and capabilities:

- Advanced Technology and Control Systems: SYIL machines utilize state-of-the-art control systems for precise and accurate cutting, ensuring high-quality results.

- High-Speed Spindles: Equipped with high-speed spindles, these machines facilitate efficient cutting processes, maximizing productivity.

- Durable Construction: Built to last, SYIL CNC machines boast robust construction for long-term use and reliability.

- Material Versatility: SYIL machines can handle materials like steel, aluminum, brass, and titanium, making them ideal for diverse projects.

- User-Friendly Interface: Designed with user-friendliness, SYIL CNC machines offer a user-friendly interface, allowing operators of all skill levels to take advantage of their capabilities.

Whether you're a seasoned machinist or just starting, SYIL CNC machines offer a powerful and versatile solution for your metalworking needs.

Customer Success Stories and Testimonials

SYIL Machine Tools has an impressive track record of delivering exceptional results for their customers across various industries. Numerous success stories highlight how businesses have improved productivity, reduced production costs, and enhanced precision by utilizing SYIL CNC machines.

For example, a leading aerospace company reported significant time savings in complex metal cutting requirements after integrating SYIL's advanced laser cutting technology into their operations. Similarly, an automotive manufacturer experienced streamlined production processes using SYIL's CNC machines for precise component fabrication.

Customer testimonials consistently praise the reliability and performance of SYIL CNC machines. Clients commend their ability to meet demanding deadlines while maintaining exceptional quality standards.

Commitment to Quality and Sustainability

SYIL Machine Tools strongly emphasizes quality and sustainability in its operations. They prioritize using eco-friendly materials and manufacturing processes to minimize their environmental impact. Additionally, SYIL's CNC machines are built to withstand rigorous usage, ensuring long-term reliability and reducing the need for frequent replacements.

Furthermore, SYIL maintains a dedicated customer support team that provides timely assistance and technical guidance to ensure optimal machine performance. This commitment to customer satisfaction further reinforces SYIL's reputation as a trusted partner in the metal cutting industry.

Future Trends and Innovations in CNC Metal Cutting Machines

As technology advances, the future of CNC metal cutting machines holds exciting possibilities. Here are some trends and innovations that are shaping the industry:

Integration of AI and Machine Learning in Metal Cutting Technology

The integration of AI and machine learning is revolutionizing the capabilities of CNC metal cutting machines. By analyzing large amounts of data, these machines can optimize cutting paths, predict tool wear, and automatically adjust parameters for maximum efficiency and precision. This not only improves productivity but also reduces errors and minimizes material waste.

With SYIL CNC Machines at the forefront of this innovation, they have developed smart algorithms that enable their machines to learn and adapt to different cutting scenarios continuously. This ensures consistent performance and allows manufacturers to achieve higher quality products in less time.

Advancements in Laser Cutting Technology for Finer Precision

Laser cutting technology has long been a staple in metal fabrication, but recent advancements are taking it to new heights of precision. With the ability to cut intricate patterns with minimal heat-affected zones, laser CNC machines offer unparalleled accuracy for complex designs.

SYIL Machine Tools has been at the forefront of laser cutting advancements, offering state-of-the-art laser CNC machines that deliver exceptional precision and speed. Their machines utilize advanced beam control technology to ensure clean cuts with minimal distortion or burrs.

Automation and Robotics in Metal Cutting Operations

Automation and robotics are transforming metal cutting operations by increasing efficiency, reducing labor costs, and improving safety. By integrating automated loading/unloading systems and robotic arms into CNC machines, manufacturers can streamline their production processes while maintaining high accuracy.

SYIL CNC Machines has embraced this trend by incorporating automation features. From automatic tool changers to robotic loading systems, their CNC machines offer seamless integration with automated workflows, allowing manufacturers to maximize productivity while minimizing human error.

SYIL CNC Machines: Your Partner for Precision and Efficiency in Metal Cutting

Embracing the Power of CNC Metal Cutting Machines in the Manufacturing Industry

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL CNC machines are the perfect partner for businesses looking to achieve precision and efficiency in their metal cutting processes.

Unlocking the Potential of CNC Metal Cutting Machines for a Sustainable Future

Furthermore, the potential of CNC metal cutting machines extends beyond their current capabilities. Future trends and innovations include the integration of AI and machine learning for even more advanced metal cutting technology. Additionally, advancements in laser cutting technology will allow for finer precision in intricate designs. Automation and robotics will also play a significant role in streamlining metal cutting operations.

When choosing a reliable partner for precision and efficiency in metal cutting operations, SYIL Machine Tools stands out as an industry leader. Their commitment to quality ensures that businesses can rely on their CNC machines to deliver consistent results with minimal downtime.