Introduction

In the world of electronics, PCB drills play a crucial role in the assembly and functionality of printed circuit boards. These specialized tools are essential for creating precise holes that accommodate various electronic components, and understanding their importance can significantly enhance your projects. Whether you're a hobbyist or a professional, mastering the art of PCB drilling can lead to more efficient designs and better-performing devices.

Understanding the Importance of PCB Drills

PCB drills are not just ordinary tools; they are vital for ensuring that your electronic circuits function correctly. The accuracy and precision provided by these drills directly impact the quality of your PCBs, making it essential to choose the right one for your needs. With countless options available, knowing what drill to use for PCB is key to achieving optimal results in your projects.

Overview of PCB Drill Types

From micro drill bits designed for intricate work to larger bits suitable for standard applications, each type serves a unique purpose in the manufacturing process. Familiarizing yourself with these different types will help you select the most effective tool for your specific project requirements.

Selecting Your Ideal Drilling Machine

Choosing the right drilling machine can feel overwhelming given all the choices out there, but it doesn't have to be! Factors such as drilling speed, precision levels, and compatibility with various PCB drill bits should guide your decision-making process. Additionally, exploring whether you can make a PCB with a CNC machine opens up new possibilities for achieving high accuracy and efficiency in your work.

What Are PCB Drills?

PCB drills are specialized tools designed for creating precise holes in printed circuit boards (PCBs). These holes are essential for connecting different components and ensuring the functionality of electronic devices. Understanding the nuances of PCB drills can significantly enhance your PCB manufacturing process.

Definition and Purpose

At their core, PCB drills serve a critical function in electronics fabrication. They create vias and mounting holes that allow for electrical connections between layers of a multi-layered board. The purpose of these drills extends beyond mere hole creation; they also contribute to the overall reliability and performance of the final product.

Common Applications in Electronics

PCB drills find applications across various sectors within electronics, from consumer gadgets to industrial machinery. They are crucial in producing circuit boards used in smartphones, computers, automotive systems, and medical devices. As technology advances, the demand for more intricate designs necessitates the use of high-quality PCB drill bits to achieve precision drilling.

Choosing the Right Drill Bits

When it comes to selecting drill bits for PCBs, several factors come into play—material type, size, and coating all matter significantly. For instance, carbide drill bits are popular due to their durability and ability to maintain sharpness over time. Additionally, understanding what drill to use for PCB depends on your specific project requirements; smaller bits may be necessary for high-density boards while larger ones might suffice for simpler designs.

What Drill to Use for PCB?

Choosing the right drill for PCB manufacturing can feel like navigating a maze, but it doesn't have to be overwhelming. The type of PCB drills you select will significantly impact the quality and precision of your final product. With various options available, understanding what drill to use for PCB becomes crucial for both hobbyists and professionals alike.

Factors Influencing Drill Selection

First and foremost is the thickness of your PCB material; thicker materials often require more robust drill bits that can handle extra pressure without breaking. Additionally, the size and type of holes you need to create will dictate whether you go with standard or micro drill bits—each serving its unique purpose in the realm of electronics.

Another significant factor is the speed and feed rate of your drilling machine; different machines may require specific types of PCB Drill Bits to optimize performance. If you're using a CNC PCB drilling machine, compatibility with various bit sizes can also influence your choice significantly. Finally, consider the material composition of both the drill bit and the board itself, as certain combinations yield better results than others.

Popular Drill Bit Sizes and Types

In the world of PCB manufacturing, not all drill bits are created equal—some reign supreme in popularity due to their versatility and performance. Common sizes include 0.3mm, 0.4mm, and 0.6mm bits; these are often used for standard applications where precision is key but not overly complex designs are involved. For more intricate projects requiring smaller holes, micro-drill bits ranging from 0.1mm up to 0.2mm become essential tools in achieving accuracy.

Beyond size considerations, you'll find various types of drill bits tailored for specific tasks: carbide bits are favored for their durability while HSS (High-Speed Steel) bits offer excellent cutting performance at lower costs. Each type has its strengths depending on what you're trying to accomplish with your PCBs—whether it's mass production or one-off prototypes needing fine details.

Performance Comparison of Different Drills

To truly understand what drill to use for PCB applications, it's beneficial to compare how different drills perform under various conditions. For instance, CNC drilling machines often outperform manual options when it comes to speed and consistency; they can execute multiple drills efficiently without sacrificing quality—a crucial factor if you're asking yourself Can you make a PCB with a CNC machine?

Moreover, accuracy is another area where advanced models shine; modern CNC machines boast tolerances as tight as ±0.01mm compared to traditional methods which may fall short at ±0.1mm or higher—a stark contrast when considering how accurate is a PCB drill? When evaluating performance metrics like longevity and wear resistance among different brands or types of drills, it's clear that investing in high-quality tools pays off in both time saved and improved end results.

Can You Make a PCB with a CNC Machine?

The answer is a resounding yes! The capabilities of CNC technology have revolutionized PCB manufacturing, allowing hobbyists and professionals alike to create printed circuit boards with precision and efficiency. With the right setup, you can transform your designs into tangible PCBs using CNC PCB drilling machines.

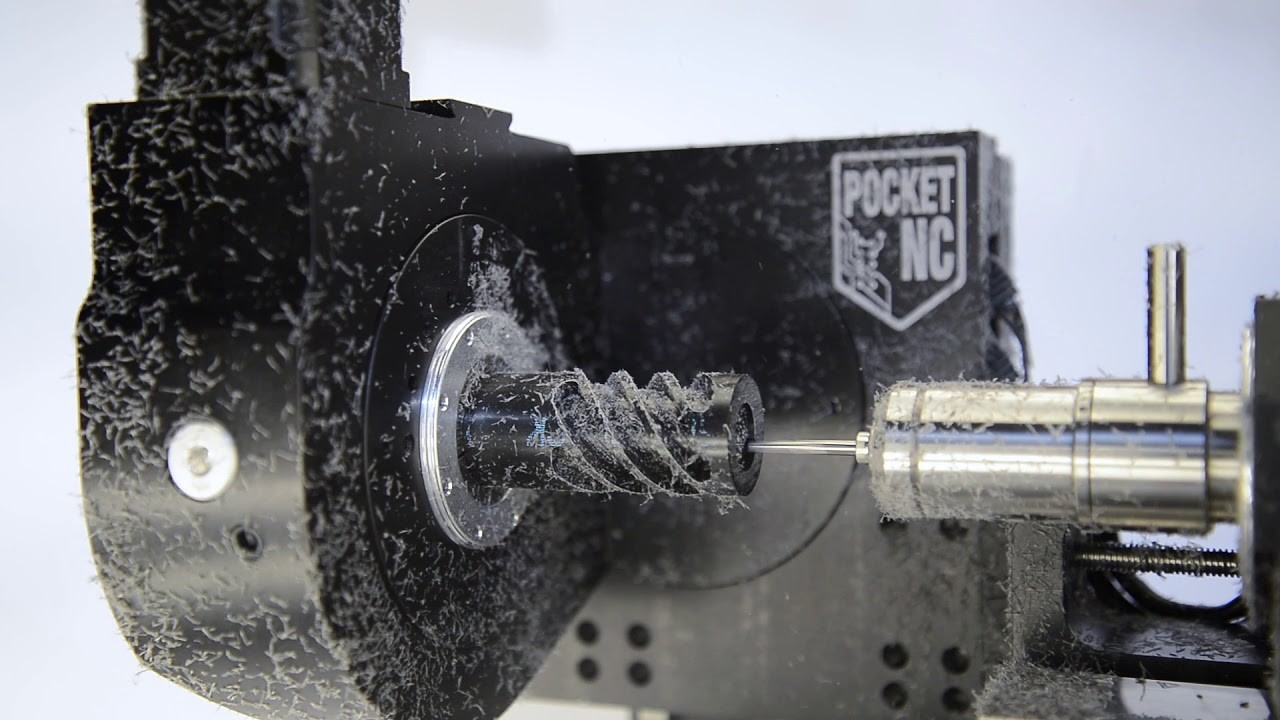

Overview of CNC Technology in PCB Manufacturing

CNC, or Computer Numerical Control, is a technology that automates machining processes through computer programming. In the context of PCB manufacturing, CNC machines can accurately drill holes for components and traces based on digital design files. This level of automation not only speeds up production but also enhances the accuracy of the final product—essential for ensuring that all your pcb drills are perfectly aligned.

Benefits of Using a CNC PCB Drilling Machine

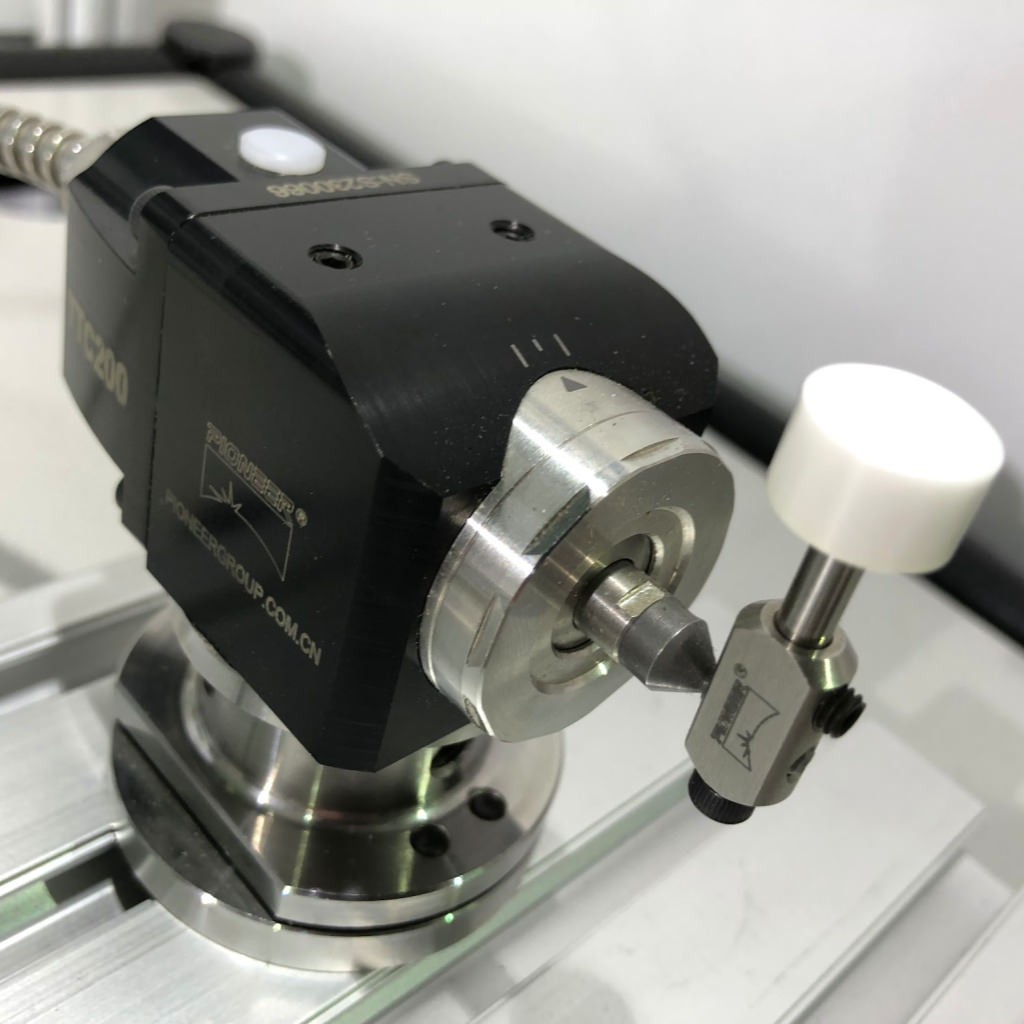

Using a CNC PCB drilling machine offers several advantages over traditional methods. First and foremost, these machines provide unmatched precision, which answers the question: How accurate is a PCB drill? With tight tolerances achievable through advanced programming, you can produce high-quality boards consistently. Additionally, they allow for flexibility in design changes without requiring new setups or tools; simply adjust your digital file and let the machine do its work.

Step-by-Step Guide to CNC PCB Drilling

Creating PCBs with a CNC machine involves several straightforward steps. Begin by designing your circuit board layout using software compatible with your CNC system; this will help determine what drill to use for PCB holes based on component specifications. Once you’ve prepared your design files, load them into the CNC machine’s software and set up the materials—typically FR-4 or similar substrates—and choose appropriate pcb drill bits for different hole sizes.

After setting everything up, start the machining process while monitoring closely to ensure everything runs smoothly; this step is crucial since it directly impacts how accurate your finished product will be! Once drilling is complete, clean up any debris from the board before proceeding to soldering components onto it. And voilà! You've successfully made a PCB using cutting-edge technology.

How Accurate Is a PCB Drill?

Importance of Precision in PCB Manufacturing

Precision in PCB manufacturing cannot be overstated; it’s the backbone that supports complex electronic designs. High-accuracy drills ensure that holes are placed exactly where they need to be, facilitating proper component placement and soldering. Without this precision, you risk creating boards that don’t meet specifications or fail under operational stress.

Moreover, accurate drilling reduces waste and saves time during assembly processes. This efficiency translates into cost savings and faster production cycles—key factors for any manufacturer looking to stay competitive in today’s fast-paced market. Therefore, understanding how accurate is a PCB drill becomes essential for both hobbyists and professionals alike.

Measuring Accuracy and Tolerances

To gauge how accurate a PCB drill is, manufacturers often rely on specific measurements and tolerances defined by industry standards. These standards dictate acceptable limits for hole sizes and placements based on the type of components being used on the board. For instance, if you're working with microcontrollers or small SMD components, tighter tolerances are required compared to larger through-hole components.

Measuring tools such as calipers or laser measurement systems can help verify these tolerances in real-time during production runs. Additionally, regular calibration of your CNC PCB drilling machine ensures that it maintains its precision over time—a critical step if you’re serious about quality control in your projects.

Techniques to Enhance Drilling Accuracy

Enhancing drilling accuracy involves multiple strategies that can significantly improve your results with PCB drills. First off, selecting high-quality PCB drill bits specifically designed for precision work can make all the difference; these bits minimize wobbling during operation while providing clean cuts through various materials used in PCBs.

Another technique involves optimizing feed rates and spindle speeds on your CNC machines based on material type and thickness—this helps reduce thermal expansion which could otherwise affect accuracy during drilling operations. Finally, implementing advanced software solutions that simulate drilling paths can help identify potential issues before actual production begins.

In summary, mastering how accurate is a PCB drill requires an understanding of precision's importance along with effective measuring techniques and enhancement strategies tailored to your specific needs.

What Is the Smallest PCB Drill Size?

Exploring Micro Drill Bits for PCB

Micro drill bits are specifically designed for precision drilling of small holes in PCBs, often measuring as little as 0.1 mm in diameter. These tiny wonders are crafted with specialized materials and coatings that enhance their durability and performance when working with delicate circuit boards. When selecting PCB drills for intricate designs, it’s crucial to consider factors such as material compatibility and expected hole sizes to ensure optimal results.

The variety of micro drill bits available includes spiral, straight flute, and step drills, each offering unique advantages depending on your specific requirements. For instance, spiral micro drills are excellent for creating cleaner holes due to their efficient chip removal capabilities. Understanding these differences will help you choose the right PCB drill bits tailored to your project needs.

Applications for Small Drill Sizes

Small drill sizes find applications across various electronic sectors, including mobile devices, medical equipment, and aerospace technologies where compactness is essential. In these fields, precision is paramount; therefore, using appropriately sized PCB drills ensures that even the most intricate designs can be fabricated without compromising functionality or reliability.

Moreover, as electronic devices continue to shrink while increasing in complexity, the demand for smaller vias and pads has surged—making tiny drill sizes more important than ever before. From high-frequency RF circuits to multi-layer PCBs requiring precise interlayer connections, small holes play a critical role in ensuring signal integrity and performance stability.

Tips for Handling and Using Tiny Drill Bits

Handling tiny PCB drill bits requires a delicate touch—after all, they’re not just any ordinary tools! To prevent breakage or damage during use or storage, always keep them secured in protective cases when not in operation; this helps maintain their sharpness and integrity over time. Additionally, using a CNC PCB drilling machine can greatly enhance accuracy while minimizing human error associated with manual drilling techniques.

When setting up your CNC machine or manual setup for drilling small holes on PCBs, make sure you're using appropriate feed rates and spindle speeds suited for micro drilling tasks; this will ensure clean cuts without excessive heat buildup that could damage both the bit and the board itself. Lastly—and perhaps most importantly—always wear safety goggles when working with any type of cutting tool; no one wants an unexpected surprise while focusing on precision!

Conclusion

In the world of electronics, mastering the art of PCB drilling is essential for creating efficient and reliable circuit boards. Understanding the intricacies of PCB drills and their various applications can significantly enhance your manufacturing process. Whether you’re a hobbyist or a professional, knowing what drill to use for PCB will elevate your projects to new heights.

Mastering the Art of PCB Drilling

To truly master PCB drilling, one must appreciate both the tools and techniques involved in this precise craft. From selecting the right drill bits to understanding how accurate a PCB drill needs to be, every detail counts in achieving optimal results. Additionally, exploring options like CNC machines can further refine your skills and expand your capabilities in creating intricate designs.

Key Takeaways for Beginners

For those just starting with PCB manufacturing, it’s crucial to grasp some fundamental concepts about what drill to use for PCB projects. Familiarizing yourself with various types of PCB drill bits and their specific uses will save you time and frustration down the line. Remember that accuracy is paramount; thus, investing in quality equipment and understanding how accurate is a PCB drill can make all the difference in your final product.

Using SYIL CNC Machines for Precision Work

When it comes to precision work in PCB manufacturing, SYIL CNC machines stand out as an excellent choice for many professionals and enthusiasts alike. These machines not only simplify the process of drilling but also ensure that you achieve consistent results every time you create a board. So if you're wondering whether you can make a PCB with a CNC machine, rest assured that these tools are designed to meet those needs effectively while handling even the smallest PCB drill sizes with ease.