Introduction

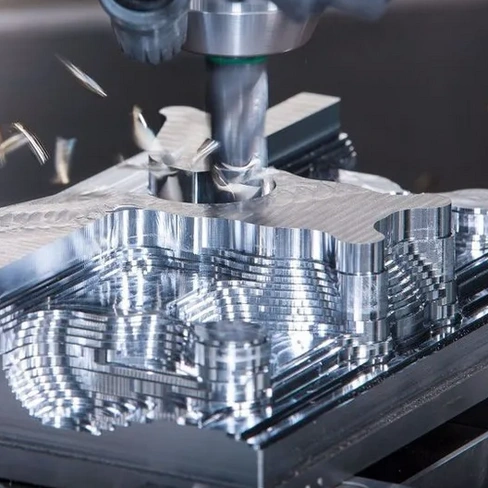

CNC machining is a fascinating process that transforms raw materials into intricate designs through the precision of computer-controlled tools. Understanding CNC machine materials is crucial for achieving the desired results in any project, whether you're crafting delicate jewelry or robust mechanical parts. The right choice of metal and other materials can significantly impact both the quality and efficiency of your work.

Understanding CNC Machine Materials

When diving into the world of CNC machining, one quickly realizes that not all materials are created equal. The variety of CNC machine materials available can be overwhelming, but each has its unique properties that make it suitable for specific applications. From metals like aluminum and steel to plastics and wood, knowing what material is used for CNC machining helps streamline the selection process.

Importance of Choosing the Right Metal

Selecting the appropriate metal cnc machining materials is vital for ensuring durability and performance in your projects. Different metals offer varying levels of strength, machinability, and cost-effectiveness; hence, understanding these factors can save you time and resources down the line. Choosing wisely not only enhances your project's outcome but also minimizes potential issues related to material limitations.

Overview of CNC Material List

To simplify your decision-making process, it's helpful to have a comprehensive CNC material list at hand. This list typically includes common metals like aluminum, brass, steel, and copper alongside various plastics and woods suitable for carving. Additionally, being aware of what materials cannot be CNC machined will prevent unnecessary setbacks in your projects while ensuring you’re equipped with knowledge on what materials can a CNC machine cut effectively.

Essential CNC Machine Materials

When it comes to CNC machine materials, the choices are vast and varied. Selecting the right material can significantly impact the quality and efficiency of your machining projects. Understanding the essential materials used in CNC machining is crucial for both beginners and seasoned professionals alike.

Common Metals in CNC Machining

In the realm of metal CNC machining materials, certain metals stand out due to their unique properties and versatility. Aluminum, steel, brass, and copper are among the most commonly utilized metals in CNC applications. Each of these metals offers distinct advantages that cater to different project requirements, making them staples on any comprehensive CNC material list.

Characteristics of Aluminum and Steel

Aluminum is lightweight yet strong, making it a popular choice for various applications where weight reduction is critical without sacrificing durability. It also boasts excellent corrosion resistance, which prolongs its lifespan in many environments. On the other hand, steel is renowned for its exceptional strength and toughness; it's often used when high durability is paramount—perfect for heavy-duty components that need to withstand significant stress.

Advantages of Brass and Copper

Brass offers a unique combination of machinability and aesthetic appeal; it's often chosen for decorative items or components requiring good corrosion resistance while maintaining a pleasing finish. Copper stands out for its superior electrical conductivity; this makes it ideal for applications like electrical connectors or heat exchangers where performance matters most. Both brass and copper are excellent choices when considering what materials can be CNC machined effectively while adding value through their specialized properties.

Factors to Consider When Selecting Metal

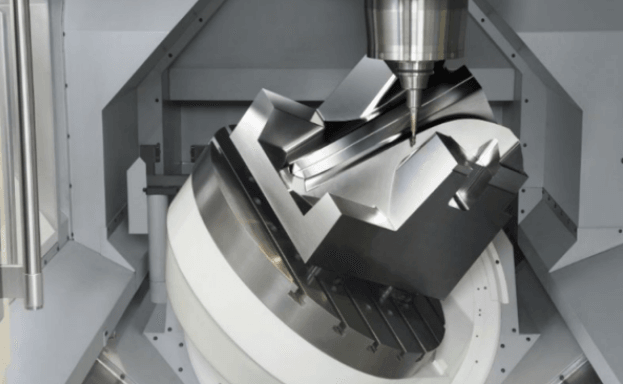

When diving into the world of CNC machine materials, selecting the right metal is crucial for achieving optimal results. Various factors come into play, including strength and durability requirements, machinability and tool wear rates, as well as cost and availability challenges. Understanding these elements will help you navigate the CNC material list more effectively and make informed decisions for your projects.

Strength and Durability Requirements

The strength and durability of metal CNC machining materials are paramount in determining their suitability for specific applications. For instance, if you're working on components that must endure high stress or harsh environments, you'll want to opt for metals with superior tensile strength and resistance to wear. Choosing a material that meets these requirements not only ensures longevity but also enhances the performance of your final product in demanding conditions.

Machinability and Tool Wear Rates

Machinability refers to how easily a metal can be cut or shaped using CNC machines, which directly impacts tool wear rates during machining processes. Some materials are easier to work with than others; aluminum, for example, is known for its excellent machinability compared to harder metals like stainless steel. Selecting a material with favorable machinability can significantly reduce production time and costs while prolonging the life of your cutting tools—an essential consideration when evaluating what materials can a CNC machine cut efficiently.

Cost and Availability Challenges

Cost is always a consideration when deciding on metal CNC machining materials; however, availability can often be just as critical. While you may find an ideal material that meets all your project requirements, it won't do much good if it's hard to source or excessively expensive due to market fluctuations. Balancing quality with affordability means keeping an eye on both the current market trends and potential suppliers so you can avoid delays in your projects due to material shortages.

What Materials Cannot Be CNC Machined?

When selecting CNC machine materials, it’s crucial to understand that not all materials are suitable for CNC machining. Some materials pose challenges that can lead to inefficiencies and poor results. In this section, we’ll explore the limitations of certain plastics, the characteristics of fragile and brittle materials, and evaluate non-metal options that may not be ideal for CNC applications.

Limitations of Certain Plastics

While plastics are often considered versatile in manufacturing, many types cannot be effectively machined using CNC technology. For instance, soft or flexible plastics tend to deform under cutting forces, leading to inaccurate dimensions and poor surface finishes. Moreover, some plastics produce excessive chips or shavings during machining that can obstruct tools and affect the overall efficiency of the process—definitely not what you want on your CNC material list!

Additionally, thermoplastics like polyethylene and polypropylene may melt or warp due to heat generated by cutting tools. This melting can compromise part integrity and dimensional accuracy—two critical factors in metal CNC machining materials. Therefore, when pondering What materials cannot be CNC machined?, it's wise to proceed with caution regarding specific plastic types.

Understanding Fragile and Brittle Materials

Fragile and brittle materials present another set of challenges for CNC machining processes. These materials tend to break or crack under stress during cutting operations, which can lead to wasted resources and increased costs. When considering what material is used for CNC machining, it’s essential to avoid these delicate options unless specifically designed tooling is available.

Glass or ceramics are prime examples of such fragile substances; while they can be machined using specialized techniques, standard CNC processes may not yield favorable results. Furthermore, even some metals can exhibit brittle properties under certain conditions—making them less than ideal candidates for traditional metal CNC machining materials without proper treatment or preparation.

Evaluating Non-Metal Options

When evaluating non-metal options for your next project involving a CNC machine, it’s important to consider their suitability carefully. While wood is a popular choice due to its machinability and aesthetic appeal in projects like furniture making or intricate carvings (the best material for CNC carving), other non-metals may fall short in performance.

For example, while foam might seem appealing due to its lightweight nature and ease of use in prototypes or models, it often lacks the durability needed for functional parts made via CNC methods. Similarly, rubber's flexibility might hinder precision cuts required in more demanding applications—making it a less favorable choice on your list of potential cnc machine materials.

In conclusion, understanding what materials cannot be CNC machined is just as vital as knowing which ones are ideal for your projects! By avoiding unsuitable plastics along with fragile substances while carefully evaluating non-metal choices like wood versus foam or rubber will help ensure successful outcomes every time you fire up that trusty machine.

Best Materials for CNC Carving

CNC carving is an art form that allows creators to transform raw materials into intricate designs. Choosing the right CNC machine materials is crucial for achieving the desired results, especially when looking at a diverse CNC material list. Understanding which materials excel in CNC carving can elevate your projects from ordinary to extraordinary.

Ideal Choices for Intricate Designs

When it comes to intricate designs, wood often reigns supreme among CNC machine materials. Its natural grain patterns and ease of manipulation make it perfect for detailed carvings and artistic expressions. Additionally, softer woods like pine or cedar allow for smoother cuts, making them ideal candidates for those fine details that bring a design to life.

However, plastics also hold their ground as excellent choices in the realm of best material for CNC carving. They offer versatility and come in various colors and finishes that can add an extra flair to your project. Moreover, certain plastics are designed specifically for machining, ensuring they deliver precision without compromising on aesthetics.

Metal CNC machining materials like aluminum can also be utilized effectively in carving applications, particularly when durability is a priority. While more challenging to work with than wood or plastic, aluminum provides strength and longevity that can enhance the final product's value. Therefore, selecting the right material ultimately depends on the project's specific requirements and artistic vision.

Comparing Wood, Plastic, and Metal

Each of these materials—wood, plastic, and metal—brings unique characteristics to the table when assessing what materials can a CNC machine cut effectively. Wood offers warmth and organic beauty but may require more care during machining due to its tendency to splinter or warp under pressure. In contrast, plastics are often easier on tools but may not provide the same level of structural integrity as metal options.

Metal CNC machining materials shine in terms of strength but come with higher costs and increased wear on tools during cutting processes. This makes them less ideal for large-scale projects focused solely on intricate designs unless durability is paramount. Ultimately, understanding these differences helps artisans choose wisely from their available options based on project needs.

Furthermore, considering factors such as cost-effectiveness plays a crucial role in selecting between these materials within your CNC material list. While wood might be more affordable upfront compared to metals like stainless steel or titanium, one must factor in longevity and application suitability over time—especially if you’re looking at high-volume production scenarios.

Unique Applications of Each Material

The unique applications of each material further illustrate why understanding what material is used for CNC machining is essential before starting any project involving a CNC machine. For instance, wood is widely used in furniture making or decorative pieces where aesthetics play a significant role; its ability to be stained or painted adds versatility unseen in other mediums.

Plastics find their niche primarily in signage or prototypes due to their lightweight nature and vibrant color options—perfectly suited for products requiring frequent updates without incurring high costs associated with retooling metal components regularly! Conversely, metal finds its home within industries demanding robust solutions such as aerospace or automotive manufacturing where precision engineering takes precedence over decorative elements.

In conclusion, knowing what materials cannot be CNC machined helps streamline decision-making processes while expanding creative possibilities across various projects! By carefully evaluating each option's strengths alongside specific project requirements—designers will undoubtedly unlock new avenues within their craft using appropriate cnc machine materials tailored just right!

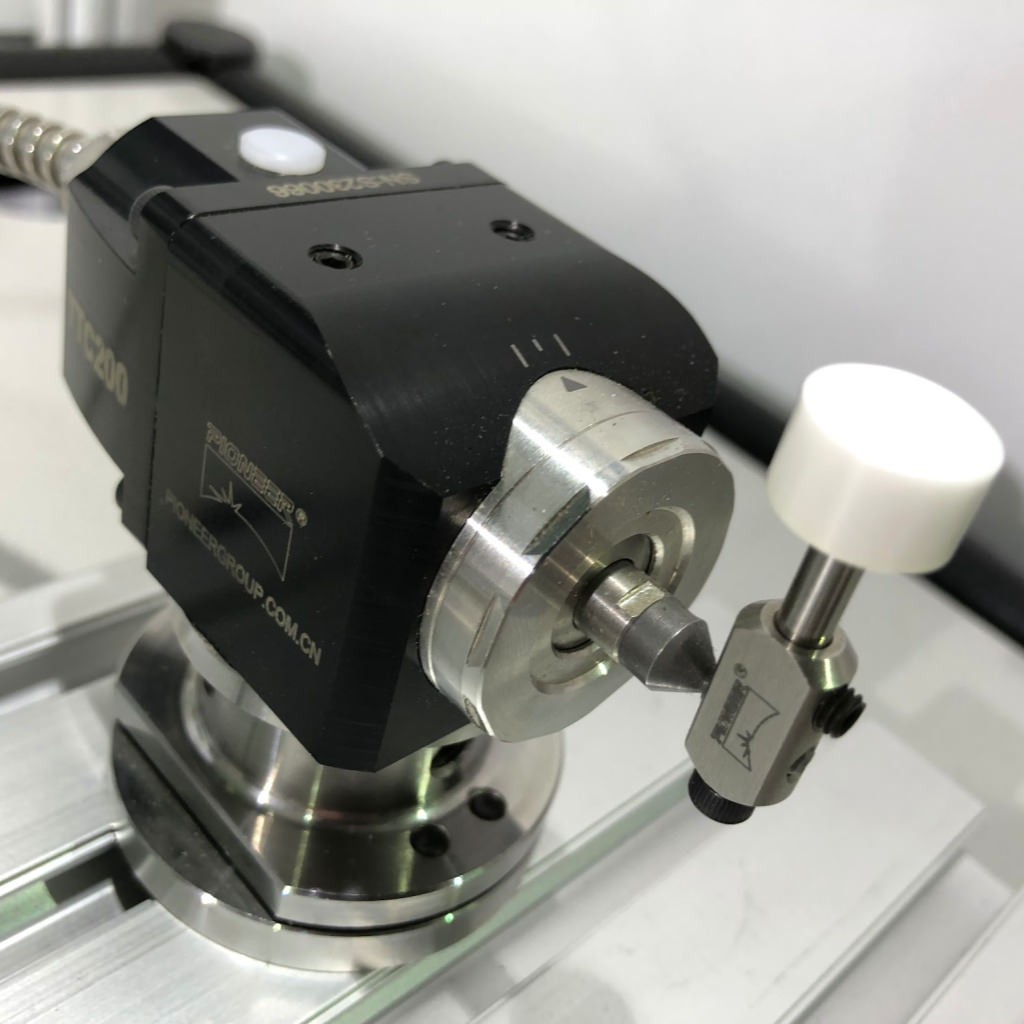

Exploring the SYIL X5 Mini CNC Machine

The SYIL X5 Mini CNC machine stands out as a remarkable tool for hobbyists and professionals alike, offering flexibility across various projects. Whether you're crafting intricate designs or working on prototypes, this machine excels in utilizing diverse CNC machine materials effectively. Its compact size does not compromise its capabilities, making it a popular choice among those who need precision without occupying much space.

Versatility in Various Projects

One of the most appealing aspects of the SYIL X5 is its versatility in handling different types of projects. This mini CNC machine can work with a range of metal CNC machining materials, including aluminum, brass, and even some plastics, giving users the freedom to explore multiple applications. From creating custom parts to artistic pieces, the SYIL X5 adapts effortlessly to meet various demands found in the CNC material list.

Moreover, this machine is designed for both beginners and seasoned machinists. For those asking What materials can a CNC machine cut?—the answer is plenty! The SYIL X5 can handle everything from soft metals to harder materials with ease, ensuring that your project ideas are only limited by your imagination.

Precision in Engraving and Carving

Its advanced technology ensures that every cut is executed with meticulous accuracy, making it ideal for detailed work such as signage or decorative items. Users often rave about how well this mini CNC machine handles fine details without compromising on speed or efficiency.

The ability to work with various CNC machine materials also enhances its engraving capabilities; whether you’re using wood for a rustic look or metal for a sleek finish, results are consistently impressive. If you're searching for what material is used for CNC machining that yields intricate designs, look no further than this versatile tool!

Benefits for Jewelry Makers and Prototyping

Jewelry makers find the SYIL X5 particularly beneficial due to its precision and versatility when working with delicate materials like gold or silver. The ability to create intricate patterns makes it an essential addition to any jeweler’s workshop—allowing them to bring their creative visions to life seamlessly. Moreover, when exploring what materials cannot be CNC machined? Jewelry makers will appreciate how easily they can avoid fragile options while focusing on durable yet beautiful metals.

For prototyping purposes as well, this mini CNC machine shines brightly; it allows designers to quickly produce models from various materials listed in their preferred CNC material list without extensive setup time or costs associated with larger machines. In short, whether you’re crafting unique jewelry pieces or developing prototypes for new products, the SYIL X5 proves itself invaluable.

Conclusion

In the world of CNC machining, selecting the right materials is paramount to achieving optimal results. The choice of CNC machine materials can significantly influence the durability, precision, and overall success of your projects. Understanding the differences among various metals, such as aluminum, steel, brass, and copper, will help you make informed decisions that align with your specific needs.

Key Takeaways for CNC Material Choices

Not all metals are created equal; some are easier to work with than others, affecting tool wear rates and production costs. Remember that while aluminum is lightweight and versatile, steel offers superior strength—so choose wisely based on your project's requirements.

Navigating the CNC Material List

Navigating a comprehensive CNC material list can be daunting but rewarding when you know what you're looking for. Familiarize yourself with what material is used for CNC machining in various applications to streamline your selection process. Additionally, understanding what materials cannot be CNC machined—like certain plastics or fragile substances—can save you time and headaches down the line.

Empowering Your CNC Machining Projects

Equipped with knowledge about the best material for CNC carving and other applications, you're now ready to tackle your projects with confidence! Whether you're venturing into intricate designs or robust components, knowing which materials can a CNC machine cut will empower your creativity and efficiency. So roll up those sleeves; it's time to bring your visions to life using the right CNC machine materials!