Introduction

In the realm of modern manufacturing, understanding the CNC milling process is essential for anyone looking to delve into precision machining. CNC, or Computer Numerical Control, has revolutionized how we create intricate parts and prototypes, making it a cornerstone of contemporary production methods. Whether you’re a hobbyist or a seasoned engineer, knowing what a milling machine is used for can help you navigate the vast landscape of machining technologies.

Understanding the CNC Milling Process

At its core, the CNC milling process involves removing material from a workpiece using rotary cutters, allowing for high-precision shaping and finishing. But how does a milling machine work? By translating digital designs into physical components through automated movements guided by computer software, these machines can achieve remarkable accuracy and repeatability in production runs. This level of control not only enhances efficiency but also opens doors to complex geometries that traditional methods might struggle to replicate.

Significance of CNC Machines in Manufacturing

The significance of CNC machines in manufacturing cannot be overstated; they have transformed industries by enabling faster production times and reducing human error. As companies strive to meet increasing demands for customization and precision, understanding the types of milling machines available becomes crucial in selecting the right tool for specific tasks. From creating intricate parts for aerospace applications to crafting custom jewelry designs, these machines are indispensable across various sectors.

Overview of Milling Machine Types

When it comes to types of milling machines, there’s an impressive variety tailored to different applications and requirements. The two primary categories are vertical milling machines and horizontal milling machines, each with distinct characteristics that cater to specific machining needs. Additionally, exploring concepts such as milling machine vs lathe highlights their unique functionalities—while both are vital in shaping materials, their operating principles differ significantly.

What is a Milling Machine?

Milling machines are essential tools in the realm of manufacturing, designed to remove material from a workpiece using rotary cutters. They can perform various operations, including drilling, boring, and shaping, making them incredibly versatile. Understanding what a milling machine is and how it functions is crucial for anyone venturing into machining or manufacturing.

Definition and Functionality

A milling machine is a sophisticated piece of equipment that utilizes rotary motion to cut and shape materials such as metal, wood, or plastic. Essentially, it works by feeding the workpiece against a rotating cutter that removes material in precise dimensions. So, how does a milling machine work? It operates on principles of mechanical engineering where the interplay between speed, feed rate, and cutting tool geometry determines the quality of the finished product.

Key Components Explained

The anatomy of a milling machine includes several vital components that contribute to its functionality. The most prominent parts are the spindle, which holds the cutting tool; the table that supports the workpiece; and the base that provides stability during operation. Additionally, control systems and motors play significant roles in determining how effectively different types of milling machines operate—be it vertical milling machines with their up-and-down motion or horizontal milling machines featuring side-to-side movements.

Applications in Various Industries

Milling machines have found applications across numerous industries due to their versatility and precision capabilities. From automotive manufacturing to aerospace engineering and even jewelry making—what is a milling machine used for? The answer spans from creating intricate prototypes to producing complex components with high tolerances. As we explore further into types of milling machines, you'll discover specialized designs tailored for specific tasks within these diverse fields.

How Does a Milling Machine Work?

When it comes to understanding how does a milling machine work, it's essential to grasp the fundamental principles behind its operation. A milling machine utilizes rotary cutters to remove material from a workpiece, effectively shaping and finishing it according to precise specifications. This process can be performed on various materials, including metals, plastics, and wood, making it incredibly versatile across industries.

Basic Operating Principles

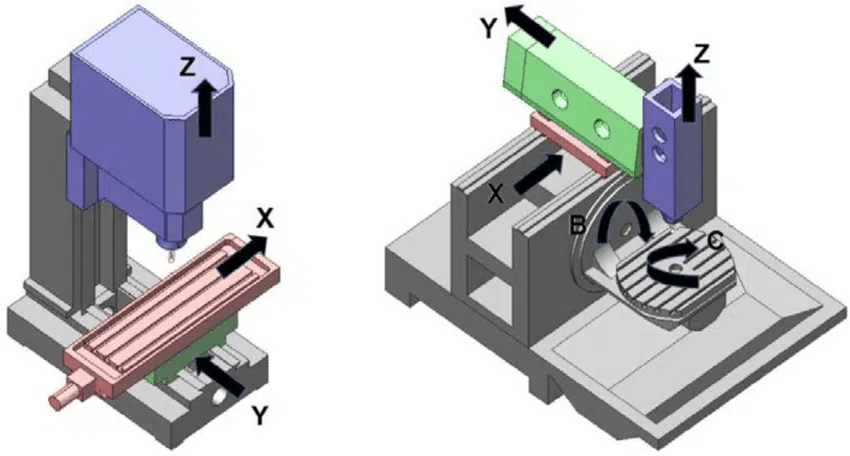

At its core, a milling machine operates by moving the workpiece against a rotating cutter. The cutting tool can move in multiple axes depending on the type of milling machine being used—be it vertical or horizontal. In vertical milling machines, the spindle is oriented vertically, allowing for more intricate designs and features; while in horizontal milling machines, the spindle is positioned horizontally for more substantial material removal.

Understanding what a milling machine is used for also involves recognizing that its applications range from creating prototypes to producing complex components in various sectors such as automotive and aerospace. The precision of this equipment allows manufacturers to achieve tight tolerances that are critical in many applications. Thus, whether you're working with a bed type or turret type milling machine, knowing how does a milling machine work ensures optimal performance.

Control Mechanisms and Software

Modern CNC (Computer Numerical Control) machines incorporate sophisticated control mechanisms that enable them to execute complex tasks with minimal human intervention. These systems rely on software programs that dictate the movement of both the cutting tools and the workpiece based on pre-defined parameters set by engineers or operators. This level of automation not only enhances productivity but also reduces errors commonly associated with manual operation.

The integration of CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software allows users to design parts digitally before they are manufactured physically using these machines. By simulating how does a milling machine work through software visualizations, operators can predict potential issues and optimize machining strategies beforehand. As technology advances further into intelligent automation systems, understanding control mechanisms becomes vital for anyone involved in manufacturing.

Importance of CNC Technology

CNC technology has revolutionized how we perceive traditional machining processes like those found in various types of milling machines—including vertical and horizontal variants—and even when comparing milling machines vs lathes. With CNC capabilities, manufacturers can produce high-quality parts at an unprecedented speed while maintaining consistency across production runs. This is particularly important when dealing with large orders where every piece must meet exact specifications.

Moreover, CNC technology has opened doors for creativity within manufacturing environments by enabling intricate designs that were once thought impossible with manual machinery alone. For instance, engraving delicate patterns or creating detailed models is now achievable thanks to advancements in CNC capabilities within SYIL CNC machines and others alike. As we look toward the future of manufacturing technologies—especially regarding 5 types of milling machines—the role of CNC will undoubtedly continue to expand.

Types of Milling Machines

When it comes to milling machines, variety is the spice of life! Understanding the different types of milling machines can help you choose the right tool for your specific project needs. From vertical to horizontal designs, each type offers unique features and capabilities that cater to various manufacturing processes.

Vertical Milling Machine Features

Vertical milling machines are characterized by their vertically oriented spindle, which holds the cutting tool. This design allows for precision in cutting and shaping materials, making it an excellent choice for intricate tasks such as engraving or detailed model creation. The versatility of a vertical milling machine also means it can be used for a wide range of applications, from prototyping to mass production.

One key feature of vertical milling machines is their ability to perform various operations like drilling, boring, and tapping. This multifunctionality makes them essential in industries where precision is paramount. If you're wondering what a milling machine is used for, look no further than the vertical variant; it’s perfect for everything from simple tasks to complex projects!

Horizontal Milling Machine Characteristics

Horizontal milling machines are known for their horizontal spindle orientation, which allows them to handle larger workpieces more efficiently than their vertical counterparts. This design often enables faster material removal rates and better chip clearance during operation—perfect when you're dealing with heavy-duty tasks! Additionally, horizontal mills typically come equipped with multiple cutting tools that can be changed out quickly based on the job requirements.

Another standout characteristic is their stability; horizontal milling machines tend to be heavier and more robust than vertical ones due to their construction. This stability translates into enhanced accuracy during machining operations—a crucial aspect when considering how does a milling machine work effectively in industrial settings! With these characteristics in mind, it's clear why many manufacturers opt for horizontal designs.

Differences Between Milling Machine vs Lathe

When comparing a milling machine vs lathe, it's essential first to understand their primary functions: while both are pivotal in machining processes, they serve different purposes. A lathe primarily rotates the workpiece against a stationary cutting tool, ideal for creating cylindrical shapes or detailed designs on round materials like metal rods or wood dowels. On the other hand, a milling machine uses rotating cutting tools on fixed workpieces—perfect for producing flat surfaces or complex geometries.

Another significant difference lies in versatility; while lathes excel at turning operations (think cylindrical forms), milling machines offer far greater adaptability across various tasks—from drilling holes to intricate engraving patterns! If you’re exploring 5 types of milling machines beyond just lathes—like bed type or turret mills—you'll discover how each contributes uniquely within manufacturing environments.

In summary, understanding these differences helps clarify what each machine excels at and why they might be suited for your specific needs—whether you require precision cuts from a vertical mill or robust performance from a horizontal one!

The Versatility of SYIL CNC Machines

When it comes to the world of CNC machining, the SYIL X5 Mini CNC Machine stands out as a versatile powerhouse. Designed for both hobbyists and professionals, this machine showcases how does a milling machine work in a compact format. Its size doesn't compromise its capabilities; instead, it opens up numerous applications across various industries.

Overview of the SYIL X5 Mini CNC Machine

The SYIL X5 Mini CNC Machine is an ideal representation of modern milling technology, blending efficiency with precision. This vertical milling machine allows users to engage in intricate tasks ranging from prototyping to detailed model creation. With its user-friendly interface and robust construction, it serves as a perfect entry point for those exploring what is a milling machine used for in practical scenarios.

Equipped with advanced control mechanisms and software, this mini-mill ensures that even complex designs can be executed flawlessly. The compact design makes it suitable for small workshops without sacrificing performance or versatility—an essential quality when considering the types of milling machines available today. Whether you're crafting prototypes or engaging in detailed projects, the SYIL X5 proves that size isn't everything when it comes to capability.

Prototyping and Detailed Model Creation

Prototyping is one area where the SYIL X5 truly shines, showcasing its strengths compared to other types of milling machines like horizontal milling machines or traditional lathes. By leveraging computer numerical control (CNC) technology, users can create highly accurate models tailored to specific requirements—perfectly demonstrating how does a milling machine work in real-world applications. This precision allows engineers and designers to iterate quickly on their ideas without breaking the bank or wasting materials.

The ability to produce detailed models also opens doors for various industries such as automotive and aerospace engineering, where accuracy is paramount. With features tailored for rapid prototyping, users can transition from concept sketches to tangible products seamlessly—a game-changer when considering what is a milling machine used for today. It's not just about making parts; it's about bringing innovative ideas into reality with speed and efficiency.

Engraving and Jewelry Making Applications

In addition to prototyping capabilities, the SYIL X5 excels in engraving and jewelry making applications—a niche yet highly rewarding sector within manufacturing. The fine control offered by this mini CNC machine allows artisans to create intricate designs that would be nearly impossible using manual methods or less sophisticated machines like traditional lathes—a clear advantage when weighing milling machine vs lathe options.

Jewelry makers can take full advantage of this technology by producing custom pieces that reflect personal style while maintaining high standards of quality—showcasing yet another facet of what is a milling machine used for today! From personalized engravings on rings to detailed pendants that require finesse, the versatility offered by this vertical milling machine enables artisans to push creative boundaries like never before.

For those looking into 5 types of milling machines available on the market today, understanding how each type functions—including their specific advantages—will empower you in choosing the right tool for your creative endeavors.

5 Types of Milling Machines You Should Know

When diving into the world of milling machines, it’s essential to understand the various types available and their unique functionalities. Each type has its own set of advantages and applications, making them suitable for different tasks in manufacturing and prototyping. Let’s explore five types of milling machines that every machinist or hobbyist should be familiar with.

Bed Type Milling Machine

The bed type milling machine is a robust and versatile piece of equipment designed for heavy-duty operations. It features a stationary bed that supports the workpiece while the milling head moves vertically or horizontally, allowing for precise cuts on large components. This type is particularly effective for high-volume production where stability and accuracy are paramount, showcasing how does a milling machine work at its best.

In terms of functionality, the bed type milling machine excels in producing flat surfaces and intricate shapes with minimal vibration. Its design allows it to accommodate larger workpieces than other types, making it an ideal choice when dealing with substantial materials or complex geometries. If you're wondering what is a milling machine used for in industrial settings, this machine often takes center stage due to its capabilities.

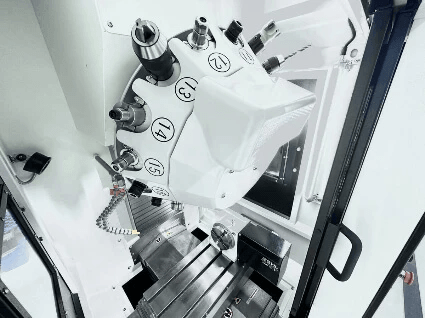

Turret Milling Machine

Turret milling machines are known for their flexibility and ease of use, making them popular among small workshops and educational institutions. Unlike bed type machines, turret mills feature a movable turret that holds the cutting tool, allowing operators to perform various operations without repositioning the workpiece frequently. This design highlights one key difference when comparing milling machine vs lathe; turret mills can handle multiple setups more efficiently.

The turret's ability to swivel facilitates drilling at different angles and depths, providing versatility in machining tasks such as contouring or creating intricate designs on metal parts. These machines are excellent for prototype development where customization is frequently required because they allow quick adjustments between tasks without losing precision. Thus, understanding how does a milling machine work can significantly enhance your productivity when using turret models.

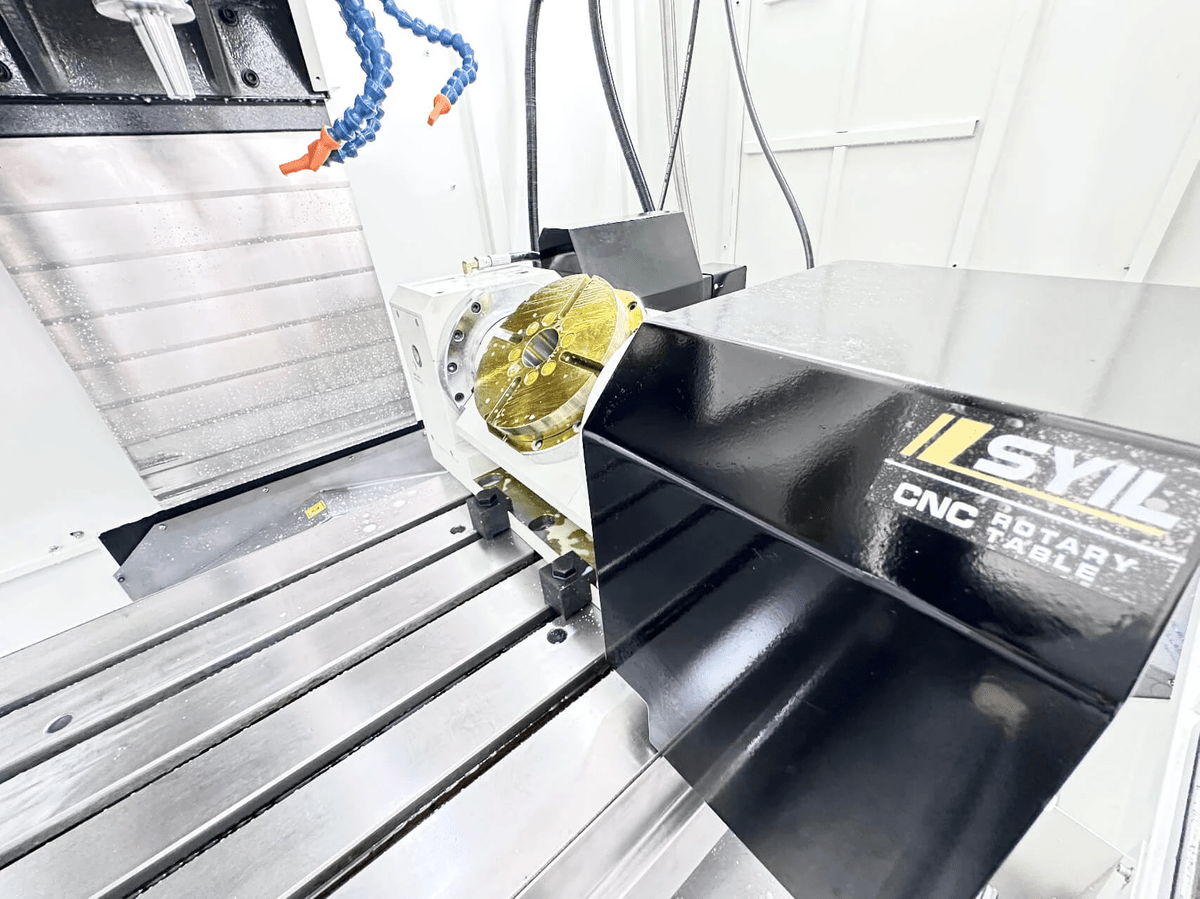

CNC Milling Machines and Their Benefits

CNC (Computer Numerical Control) milling machines represent the pinnacle of modern machining technology by automating processes through computer programming. These advanced devices offer unparalleled precision by following programmed instructions down to minute details—far surpassing manual techniques in both speed and accuracy. When exploring types of milling machines today, CNC models stand out due to their ability to produce complex parts consistently with minimal human intervention.

The benefits of CNC technology extend beyond mere efficiency; they also include reduced material waste through optimized cutting paths and enhanced safety features that mitigate operator risk during operation. Moreover, CNC systems can handle multiple operations simultaneously—making them indispensable in industries ranging from aerospace to jewelry production where precision matters most! So if you're pondering what is a milling machine used for today’s manufacturing landscape? Look no further than CNC options!

In summary, understanding these 5 types of milling machines—bed type mills, turret mills, CNC machinery—will equip you with knowledge essential for selecting the right tool based on your specific needs or projects ahead!

Conclusion

In conclusion, understanding the milling machine's capabilities and applications is crucial for making informed decisions in manufacturing and prototyping. With various types of milling machines available, including vertical and horizontal milling machines, it's essential to evaluate your specific needs to find the perfect fit. As we move forward, CNC technology continues to evolve, enhancing the precision and efficiency of these machines.

Choosing the Right Milling Machine for Your Needs

When it comes to choosing a milling machine, first consider what you intend to use it for—this will guide you in selecting from the 5 types of milling machines available. For example, if your projects involve intricate designs or detailed model creation, a vertical milling machine may be more suitable due to its versatility and ease of operation. On the other hand, if you're focusing on heavy-duty tasks requiring robust materials, a horizontal milling machine might be your best bet.

Moreover, understanding how does a milling machine work is vital in making this choice; knowing its functions can help you determine which type aligns with your production goals. Don't forget to weigh factors like space availability and budget constraints while exploring options like CNC milling machines that offer advanced features. Ultimately, selecting the right machine can significantly impact your productivity and creativity in manufacturing processes.

The Future of CNC Milling Technologies

The landscape of CNC technologies is continuously changing with advancements that promise even more precision and efficiency in how does a milling machine work today compared to just a few years ago. Innovations such as AI integration and improved software control mechanisms are set to redefine what these machines can achieve across various industries. The future holds exciting possibilities where automation will not only enhance productivity but also reduce human error significantly.

As we explore new frontiers in manufacturing techniques through these technologies, businesses must stay informed about emerging trends within different types of milling machines that could offer competitive advantages. From smart sensors that monitor performance in real-time to advanced materials tailored for specific applications, the next generation of CNC mills will likely push boundaries further than ever before. Embracing these changes will be critical for manufacturers looking to thrive in an increasingly demanding market.

Enhancing Creativity with CNC Capabilities

CNC technology has revolutionized how we approach design and creativity within manufacturing sectors by allowing unprecedented freedom when it comes to what is a milling machine used for today. Whether you're creating intricate jewelry pieces or detailed prototypes using tools like the SYIL X5 Mini CNC Machine, there's little doubt that these capabilities empower creators at every level—hobbyists included!

The ability for designers to visualize their concepts digitally before executing them physically has transformed traditional workflows into something far more dynamic than what was previously possible with manual methods or even basic machinery like lathe systems—a comparison that's often made when discussing milling machine vs lathe functionalities. Consequently, as creative minds continue exploring all avenues offered by modern machining techniques—including various types of milling machines—they unlock new potentials limited only by their imagination.