Introduction

When it comes to precision machining, the choice of a vertical machining center (VMC) is crucial for achieving optimal results. Understanding the key components of a VMC, such as the toolchanger, coolant delivery system, and chip disposal solutions, is essential for making an informed decision. Additionally, considering factors like spindle speed, axis travel, and workpiece capacity are vital in selecting the right vertical machining center for your production needs.

Understanding Toolchanger, Coolant Delivery, and Chip Disposal

The toolchanger in a vertical machining center plays a critical role in automating the process of swapping out cutting tools during operation. Meanwhile, an efficient coolant delivery system ensures proper lubrication and cooling during high-speed cutting processes. And when it comes to chip disposal solutions, effective evacuation and waste management are key considerations for maintaining a clean and safe working environment.

Importance of Key Factors in Choosing a VMC

The importance of key factors in choosing a VMC cannot be overstated. Factors such as rigidity, accuracy, and thermal stability are crucial for achieving high-quality machined parts. Additionally, considering the reputation and reliability of vertical machining center manufacturers is essential for ensuring long-term performance and support for your equipment.

Considerations for Vertical Machining Centers

When evaluating vertical machining centers, it's important to consider factors such as spindle power and torque capabilities to handle various cutting applications. Furthermore, assessing the machine's control system and programming flexibility can significantly impact productivity and ease of operation.

Toolchanger Capabilities

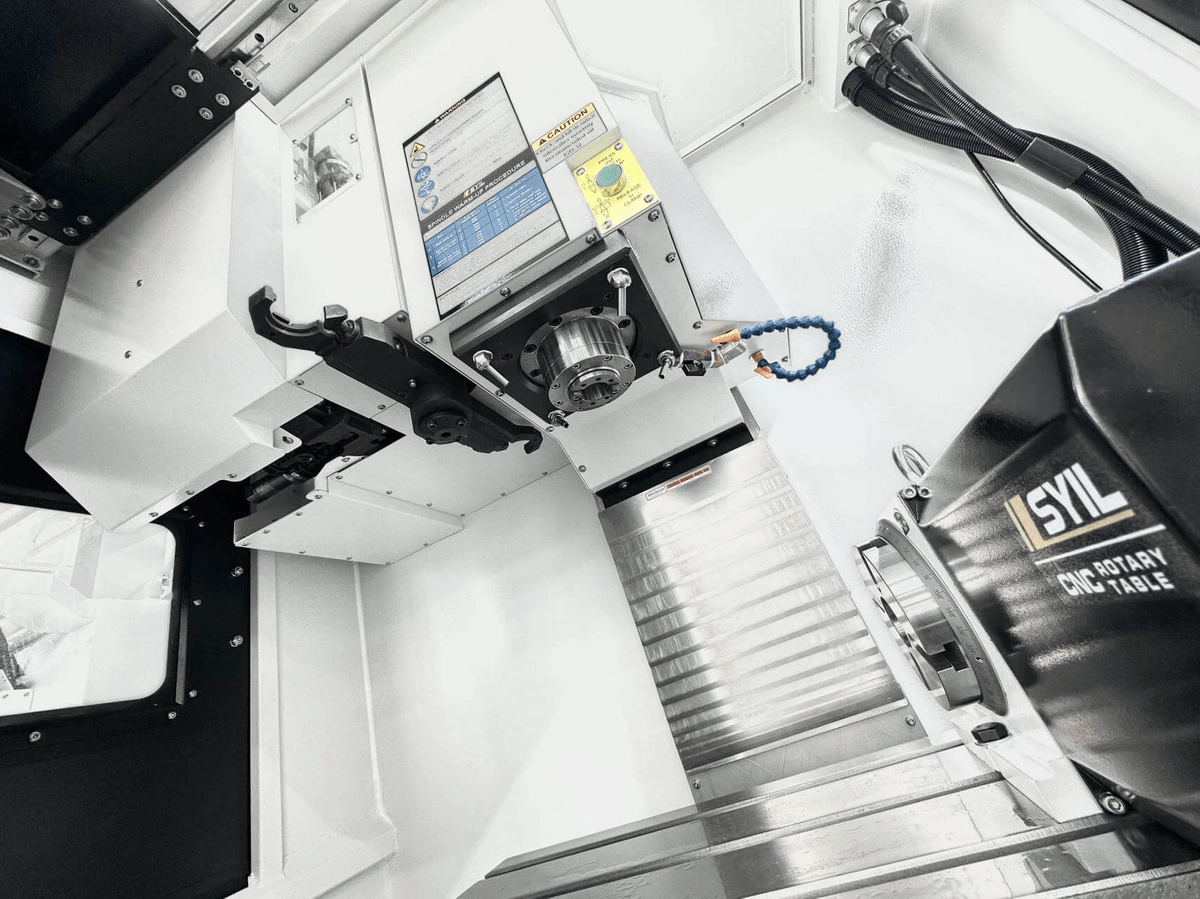

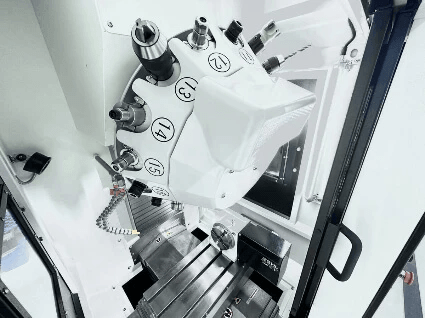

When considering a vertical machining center (VMC), it's crucial to assess the toolchanger capabilities. The automatic toolchanger efficiency of a VMC, such as the one offered by SYIL CNC Machine, is essential for seamless production processes. With rapid and precise tool changes, this feature ensures minimal downtime and increased productivity.

Automatic Toolchanger Efficiency

The automatic toolchanger efficiency of a VMC plays a significant role in optimizing manufacturing operations. SYIL's CNC vertical machining center boasts an advanced automatic toolchanger system that enables swift and accurate tool swaps, reducing setup times and enhancing overall production efficiency. This feature is particularly valuable in high-mix, low-volume production environments.

Tool Storage Capacity

Another key consideration when evaluating VMCs is the tool storage capacity. SYIL's vertical machining centers offer ample storage for various tools, allowing for versatility in machining applications without the need for frequent manual interventions to change tools. This capability contributes to uninterrupted workflow and improved output quality.

In addition to ample storage for various tools, SYIL's vertical machining centers also offer efficient tool changing time optimization. This means that the machines are designed to minimize the time it takes to switch between different tools, further enhancing productivity and reducing downtime. By streamlining the tool changing process, operators can focus on the machining tasks at hand without being slowed down by lengthy tool changeovers. This optimization contributes to a more efficient workflow and ultimately leads to improved output quality.

Tool Changing Time Optimization

Optimizing tool changing time is paramount for maximizing productivity in manufacturing operations. SYIL's CNC vertical machining center excels in minimizing downtime through its efficient tool changing process, ensuring that tools are swapped swiftly and accurately to maintain continuous production flow. This optimization significantly impacts overall operational efficiency.

In conclusion, the toolchanger capabilities of a VMC are pivotal factors to consider when selecting a machining center for your operations. With SYIL's advanced automatic toolchanger efficiency, ample tool storage capacity, and optimized tool changing time, manufacturers can benefit from enhanced productivity and seamless workflow management.

Furthermore, the toolchanger capabilities of a VMC can also impact the overall cost-effectiveness of production. By minimizing tool changing time and maximizing efficiency, manufacturers can reduce downtime and increase output, ultimately leading to cost savings. SYIL's advanced automatic toolchanger not only streamlines operations but also contributes to the bottom line by optimizing resource utilization.

Coolant Delivery System

When it comes to vertical machining centers (VMCs), the coolant delivery system plays a crucial role in ensuring efficient and precise machining operations. High-pressure coolant benefits are evident in the ability to reduce heat build-up during cutting, extend tool life, and improve surface finish. With the use of a vertical machining center, manufacturers can take advantage of high-pressure coolant systems to achieve optimal cutting performance and enhance overall productivity.

High-Pressure Coolant Benefits

The high-pressure coolant system in a CNC vertical machining center offers numerous advantages, including improved chip control, reduced tool wear, and enhanced surface quality. By delivering coolant at high pressure directly to the cutting zone, the vertical machining center ensures efficient heat dissipation and chip evacuation. This results in shorter cycle times and higher production output, making it a valuable feature for manufacturers seeking to maximize efficiency.

In addition to the benefits of improved chip control and reduced tool wear, high-pressure coolant systems also contribute to extended tool life. By effectively dissipating heat from the cutting zone, the coolant helps prevent premature tool failure and ensures consistent performance over time. This not only reduces maintenance costs but also minimizes downtime for tool replacement, further enhancing the overall efficiency of the machining process.

Efficient Chip Removal

In addition to high-pressure coolant benefits, efficient chip removal is another critical aspect of the coolant delivery system in a vertical milling machine. Proper chip evacuation is essential for maintaining consistent cutting performance and preventing tool damage. Vertical machining centers equipped with advanced chip removal systems can effectively manage chips during the machining process, minimizing downtime and improving overall operational efficiency.

Furthermore, efficient chip removal is crucial for preventing the accumulation of chips that can lead to tool wear and breakage. A well-designed chip removal system ensures that chips are effectively cleared from the work area, allowing for uninterrupted machining operations. This not only improves the quality of the finished products but also reduces the need for frequent tool changes, saving time and resources.

Advanced Coolant Filtration

An advanced coolant filtration system is essential for maintaining the quality and effectiveness of the coolant delivery system in a vertical machine center. Quality filtration helps remove contaminants from the coolant, ensuring that it remains clean and free from debris that could compromise cutting performance. With SYIL CNC machines offering state-of-the-art filtration technology, manufacturers can rely on superior coolant management for their VMC operations.

In addition to removing contaminants, advanced coolant filtration systems also help regulate the temperature of the coolant, preventing overheating and ensuring consistent cutting performance. By maintaining the coolant at an optimal temperature, manufacturers can minimize thermal expansion in the machine components, leading to improved accuracy and precision in VMC operations. This level of control over the coolant temperature is a testament to the advanced technology integrated into SYIL CNC machines, providing a comprehensive solution for efficient and reliable machining processes.

By prioritizing high-pressure coolant benefits, efficient chip removal, and advanced filtration capabilities in their selection of a vertical machining center manufacturers can ensure optimal performance and productivity in their manufacturing processes.

Chip Disposal Solutions

When it comes to efficient chip evacuation in a vertical mill, it's crucial to consider the design of the machine's chip management system. SYIL CNC Machine offers a well-designed chip conveyor system that efficiently removes chips from the work area, preventing any interference with machining operations. This ensures uninterrupted production and minimizes downtime for chip removal.

Efficient Chip Evacuation

SYIL's vertical machining centers are equipped with powerful chip conveyors that swiftly remove chips from the work area, maintaining a clean and tidy workspace. The efficient evacuation of chips also prevents tool damage and ensures smooth machining operations, ultimately contributing to higher productivity and reduced maintenance costs.

Waste Management Considerations

In addition to efficient chip evacuation, waste management considerations play a significant role in the overall operational efficiency of a vertical machining center. SYIL CNC Machine emphasizes sustainable waste management practices, offering options for recycling and proper disposal of metal chips generated during machining processes.

Environmental Impact of Chip Disposal

SYIL recognizes the importance of environmentally responsible manufacturing practices, including the disposal of metal chips produced by vertical machining centers. By implementing effective waste management solutions, such as recycling programs and environmentally friendly disposal methods, SYIL minimizes the environmental impact associated with metal chip disposal.

Comparison of Leading VMC Manufacturers

When it comes to vertical machining centers, there are several top manufacturers to consider. One of the standout brands in this category is SYIL CNC Machine. Known for its precision engineering and innovative technology, SYIL offers a range of vertical machining centers that are designed to meet the demands of modern manufacturing processes. With a focus on quality and performance, SYIL has established itself as a leader in the vertical machining center market.

SYIL CNC Machine

SYIL CNC Machine has earned a reputation for excellence in the production of vertical machining centers. The company's commitment to cutting-edge technology and superior craftsmanship is evident in their range of CNC vertical machining centers. From compact models ideal for small workshops to larger machines suited for heavy-duty industrial applications, SYIL offers a diverse selection of vertical machining centers to cater to various production needs.

Other Prominent VMC Brands

In addition to SYIL CNC Machine, there are other prominent manufacturers of vertical machining centers that have made their mark in the industry. Companies such as Haas Automation, Mazak, and Okuma are known for their high-quality VMCs that deliver exceptional precision and reliability. Each brand brings its own unique features and capabilities to the table, catering to different requirements and preferences within the manufacturing sector.

While Haas Automation is known for its user-friendly interface and rugged construction, Mazak stands out for its advanced technology and seamless integration with automation systems. On the other hand, Okuma is recognized for its heavy-duty cutting capabilities and exceptional spindle performance. These distinctions make it clear that manufacturers have a variety of options to choose from when selecting a VMC brand that best suits their specific production needs.

Quality and Performance Differences

When comparing leading VMC manufacturers, it's essential to consider the quality and performance differences between their offerings. While all top brands strive for excellence in their products, there are distinct differences in terms of machine rigidity, spindle speed, tool capacity, control systems, and overall build quality. Prospective buyers should carefully evaluate these factors based on their specific production requirements before making an informed decision.

By weighing the strengths and weaknesses of different VMC brands against their individual needs, manufacturers can make well-informed decisions when selecting a vertical machining center that aligns with their production goals. With its commitment to innovation and precision engineering, SYIL CNC Machine stands out as a leading provider of high-performance VMC solutions that can elevate manufacturing processes across diverse industries.

Conclusion

When it comes to selecting a vertical machining center (VMC), it's crucial to make informed decisions based on the key factors we've discussed. The efficiency of the toolchanger, coolant delivery system, and chip disposal solutions can have a significant impact on production efficiency and overall performance.

Making Informed Decisions for VMC Selection

Choosing the right VMC involves considering various factors such as toolchanger capabilities, coolant delivery system, and chip disposal solutions. It's important to thoroughly evaluate the options available from different vertical machining center manufacturers to ensure that the chosen machine meets the specific needs of your production processes.

Impact of Key Factors on Production Efficiency

The efficiency of the toolchanger, coolant delivery system, and chip disposal solutions directly impacts production efficiency. A well-designed VMC with advanced features can significantly reduce downtime and optimize machining operations, leading to improved productivity and cost savings. Additionally, the precision and speed of the spindle motor play a crucial role in production efficiency. A high-quality spindle motor can ensure accurate and rapid machining, contributing to overall productivity and minimizing lead times. Furthermore, the control system of a VMC is essential for monitoring and adjusting various parameters during machining processes. An intuitive and responsive control system can streamline operations, minimize errors, and maximize output, further enhancing production efficiency.

SYIL CNC Machine: Leading VMC Solution

SYIL CNC Machine stands out as a leading solution for vertical machining centers, offering advanced technology and superior performance. With its innovative toolchanger capabilities, efficient coolant delivery system, and effective chip disposal solutions, SYIL VMCs are designed to enhance production efficiency and deliver exceptional results.

In conclusion, choosing a vertical machining center requires careful consideration of key factors such as toolchanger capabilities, coolant delivery system efficiency, and chip disposal solutions. With SYIL CNC Machine's leading VMC solution, manufacturers can expect enhanced productivity and performance in their machining operations.