Introduction

Understanding the basics of CNC machines is essential for anyone interested in the field of machining. These machines have revolutionized the manufacturing industry, offering precision, efficiency, and versatility like never before. With different types of CNC machines available, it becomes crucial to familiarize oneself with their capabilities and applications.

Knowing the various types of CNC machines is important because each machine specializes in specific tasks and materials. By understanding their differences, you can make informed decisions when selecting the right machine for your needs. From milling machines to lathe machines, drilling machines to laser cutting machines, there is a wide range of options to explore.

One leading manufacturer in the CNC machine industry is SYIL Machine Tools. With a commitment to quality and sustainability, SYIL develops and manufactures precision CNC machines for milling and drilling. Their extensive experience and expertise have earned them a reputation as a trusted brand in the industry. Operating globally with over 12k machines supplied worldwide, SYIL continues to innovate and expand its product range.

This comprehensive guide on CNC machines aims to provide valuable insights into each type of machine, highlighting their capabilities and applications. Whether you're a beginner or an experienced machinist, this guide will serve as a valuable resource for understanding the world of CNC machining.

1. Milling Machines

Brief Overview Of Milling Machines

Milling machines are essential tools in the world of CNC machining. They remove material from a workpiece, creating complex shapes and designs with precision and accuracy. Milling machines can perform various operations, including cutting, drilling, and shaping, making them highly versatile in various industries.

Exploring The Versatility Of Vertical Milling Machines

Vertical milling machines are known for their versatility and ability to handle different types of materials. They have a vertically oriented spindle, allowing easy access to the workpiece from multiple angles. This flexibility makes vertical milling machines suitable for simple tasks like drilling holes and more complex operations like contouring and grooving.

Highlighting The Precision And Efficiency Of Horizontal Milling Machines

Horizontal milling machines excel in precision and efficiency due to their horizontally oriented spindles. This orientation allows for precise cuts along the X-axis, resulting in accurate dimensions and smooth finishes on the workpiece. Horizontal milling machines are commonly used in mass production settings where speed and consistency are crucial.

Discussing The Compact And Cost-Effective SYIL Milling Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

SYIL offers a range of compact and cost-effective milling machines that cater to various needs. Their machines are designed with space-saving features without compromising on performance or accuracy. Whether you're a small workshop or an industrial facility, SYIL has options that fit your requirements without breaking your budget.

2. Lathe Machines

Lathe machines are crucial in CNC machining, offering precision and versatility for various applications. From shaping materials to creating intricate designs, lathe machines are essential in machining.

Introduction To Lathe Machines And Their Purpose

Lathe machines rotate a workpiece against a cutting tool, allowing precise shaping and cutting operations. They are commonly used in metalworking, woodworking, and other industries where cylindrical or symmetrical parts must be created.

Emphasizing The Capabilities Of Benchtop Lathe Machines

Benchtop lathe machines are compact and versatile tools that can be easily placed on a workbench or table. Despite their smaller size, they offer impressive capabilities for hobbyists and small-scale production. With variable speed control and adjustable tool rests, benchtop lathes provide excellent precision and control.

Exploring The Advantages Of CNC Lathe Machines

CNC lathe machines take the capabilities of traditional lathes to the next level by incorporating computer numerical control technology. This allows for automated operations, increased accuracy, and enhanced productivity. With CNC programming, complex shapes can be easily achieved with minimal manual intervention.

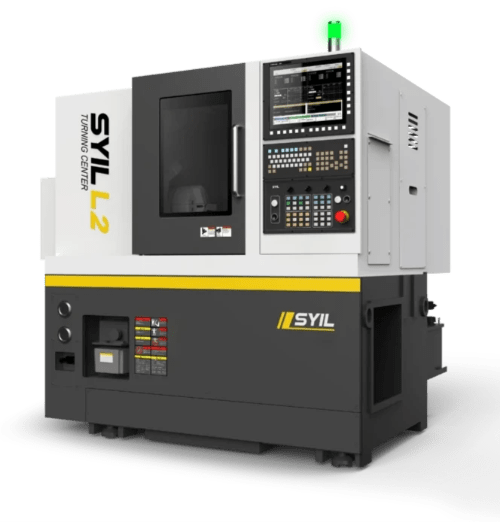

Highlighting SYIL's Range Of High-Quality Lathe Machines

SYIL Machine Tools offers many high-quality lathe machines that cater to various needs and budgets. Their lathe machines are known for their durability, precision, and user-friendly features. Whether you're a hobbyist or a professional machinist, SYIL has the perfect lathe machine to meet your requirements.

3. Drilling Machines

Drilling machines play a crucial role in CNC machining, allowing for the precise and accurate creation of holes in various materials. These machines are essential for various automotive, aerospace, and manufacturing industries. Without drilling machines, achieving the desired specifications and quality in CNC machining projects would be nearly impossible.

Benchtop drilling machines are particularly popular due to their compact size and versatility. They are designed to fit on workbenches or tabletops, making them ideal for small workshops or limited spaces. Despite their smaller size, these machines offer impressive power and precision, allowing users to drill holes easily.

CNC drilling machines take drilling to the next level by incorporating automation and computer control. These machines eliminate manual operation, resulting in increased efficiency and accuracy. With CNC drilling machines, users can create complex hole patterns with consistent precision, reducing human error and saving valuable time.

SYIL Machine Tools offers various drilling machines tailored to various applications. Their drilling machines are known for their exceptional performance and reliability. Whether you need a machine for metalworking or woodworking projects, SYIL has the perfect solution.

4. Laser Cutting Machines

Laser-cutting machines are essential tools in the world of CNC machining. These machines use laser technology to cut through various materials precisely and accurately. They are widely used in manufacturing, automotive, aerospace, and other industries.

Brief Overview Of Laser Cutting Machines

Laser-cutting machines utilize a high-powered laser beam to melt, burn, or vaporize materials, resulting in precise and clean cuts. The process is controlled by computer programming, ensuring accuracy and consistency in every cut. These machines can handle various materials, including metal, wood, plastic, fabric, and glass.

Exploring The Versatility And Precision Of CO2 Laser Cutting Machines

CO2 laser cutting machines are known for their versatility and precision. They use a mixture of carbon dioxide gas as a laser source to cut through various materials easily. These machines are highly efficient and can produce intricate designs with sharp edges. Whether engraving detailed patterns on wood or creating complex metal parts, CO2 laser-cutting machines deliver exceptional results.

Highlighting The Speed And Accuracy Of Fiber Laser Cutting Machines

Fiber laser cutting machines have gained popularity due to their remarkable speed and accuracy. These machines use optical fibers as the laser source to achieve high power density for faster cutting speeds. Advanced technology in fiber lasers can effortlessly cut through thick metals while maintaining precise dimensions. Fiber laser cutting machines offer rapid and precise results from stainless steel sheets to aluminum plates.

SYIL's Range Of Laser Cutting Machines For Diverse Industries

SYIL Machine Tools understands the significance of laser cutting technology in modern manufacturing processes. That's why they offer a comprehensive range of laser cutting machines suitable for diverse industries such as automotive, electronics, signage making, and more.

SYIL's line-up includes CO2 and fiber laser cutting machines that combine versatility with exceptional performance. These machines are designed to meet the demands of various applications, from intricate engraving to heavy-duty metal cutting. With SYIL's commitment to quality and innovation, its laser-cutting machines are trusted by professionals worldwide.

5. Plasma Cutting Machines

Plasma cutting machines are essential tools in CNC machining, offering a range of applications and benefits. Understanding the capabilities and advantages of these machines is crucial for anyone involved in the industry.

Introduction To Plasma Cutting Machines And Their Applications

Plasma-cutting machines utilize a high-velocity jet of ionized gas, known as plasma, to cut through various materials such as metal, steel, and aluminum with precision and ease. These machines are widely used in the automotive, aerospace, construction, and fabrication industries.

Exploring The Capabilities Of CNC Plasma Cutting Machines

CNC plasma cutting machines take precision to a new level by incorporating computer numerical control technology. This allows for automated and highly accurate cuts based on programmed designs. Complex shapes and intricate patterns can be effortlessly achieved with CNC plasma cutting machines.

Highlighting The Precision And Versatility Of SYIL Plasma Cutting Machines

When it comes to precision and versatility, SYIL Machine Tools stands out as a leading manufacturer of plasma-cutting machines. Their state-of-the-art technology ensures consistent quality cuts with minimal errors or deviations. Whether you need straight lines or intricate curves, SYIL's plasma-cutting machines always deliver exceptional results.

Discussing The Cost-Effectiveness And Efficiency Of Plasma Cutting Technology

Plasma cutting technology offers remarkable cost-effectiveness compared to traditional methods like sawing or shearing. It eliminates the need for secondary operations by producing clean edges that require minimal finishing touches. Additionally, its high-speed capabilities ensure efficient production processes, saving both time and money.

6. Other Types of CNC Machines

CNC machines are not limited to milling, lathe, drilling, laser cutting, and plasma cutting machines. Several other CNC machines cater to specific needs and applications in various industries. Let's explore some of these machines below:

Brief Overview Of Other Types Of CNC Machines Like Grinding Machines

Grinding machines are used for precision machining processes that involve removing material from a workpiece using an abrasive wheel. These machines are commonly used in the manufacturing industry to achieve high levels of accuracy and surface finish. They can be used for various applications, such as sharpening tools, shaping metal parts, and creating intricate surface designs.

Exploring The Specialized Applications Of Wire EDM Machines

Wire Electrical Discharge Machining (EDM) is a process that uses electrical sparks to cut through conductive materials with extreme precision. Wire EDM machines are particularly useful for creating complex shapes and contours in hard materials like metal. They are commonly used in aerospace, automotive, and tooling industries.

Discussing The Benefits Of CNC Routers For Woodworking And Engraving

CNC routers are versatile machines that use computer-controlled movements to cut and shape wood, plastic, and foam. They are widely used in woodworking industries for tasks like carving intricate designs, creating furniture components, and producing highly precise decorative items. Additionally, CNC routers find applications in the engraving industry for etching detailed surface patterns.

Introducing SYIL's Commitment To Innovation And Expanding Product Range

SYIL Machine Tools develops and manufactures precision CNC machines for milling, drilling, laser cutting, plasma cutting, grinding, wire EDM machining, woodworking, engraving, and more! With over 12k machines supplied globally, SYIL prioritizes quality, sustainability, and customer satisfaction.SYIL is becoming a recognized brand in the industry due to its commitment to innovation and expanding its product range.

Conclusion

Knowing the various types of CNC machines is crucial for anyone interested in CNC machining. By understanding these machines' different capabilities and applications, individuals can make informed decisions about which type of machine best suits their needs.

SYIL Machine Tools, a leading CNC machine manufacturer, offers many high-quality machines for milling, lathe work, drilling, laser cutting, plasma cutting, and more. With over 12k machines supplied globally, SYIL has built a strong reputation in the industry for its precision and sustainability.

Exploring the world of CNC machining opens up endless possibilities for creativity and innovation. Whether you're a hobbyist or a professional, there is always something new to learn and discover in this field.

To further expand your knowledge and expertise in CNC machining, I encourage you to delve deeper into each type of machine discussed in this comprehensive guide. There are countless resources available online that can provide valuable insights and practical tips.

Remember to stay curious and keep exploring the ever-evolving world of CNC machining. With SYIL Machine Tools by your side, you can trust that you have access to top-notch machinery that will help bring your ideas to life.