Introduction

CNC Lathe Machines have revolutionized the manufacturing industry with their precision and efficiency. In this article, we will explore the various aspects of CNC Lathe Machines, including their introduction, history, importance in manufacturing, and an overview of SYIL Machine Tools and their expertise in this field.

CNC Lathe Machines play a crucial role in modern manufacturing processes due to their numerous advantages. They offer high levels of accuracy and repeatability, ensuring consistent quality output. These machines also enhance productivity by reducing manual labor requirements and minimizing errors caused by human intervention.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

Understanding CNC Lathe Machines

CNC Lathe Machines are advanced manufacturing tools for precision turning operations in various industries. These machines utilize computer numerical control (CNC) technology to automate and control machining, resulting in efficient and accurate production.

Definition And Basic Principles Of CNC Lathe Machines

CNC Lathe Machines are specialized equipment designed to perform turning operations on a rotating workpiece. They use computer programming to control the movement of the cutting tool, allowing for precise shaping and finishing of the material. The basic principle behind CNC Lathe Machines is the conversion of digital instructions into mechanical actions, ensuring consistent and repeatable results.

Components and working mechanism of CNC Lathe Machines

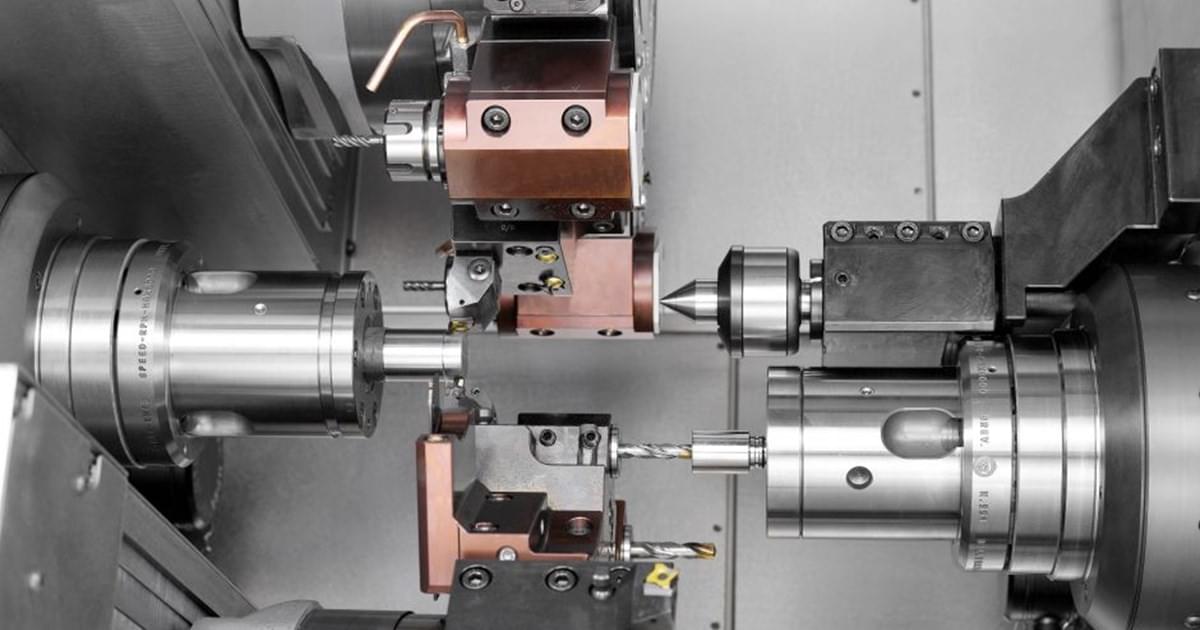

A typical CNC Lathe Machine has several key components that work together seamlessly. These include the spindle, chuck, turret, tailstock, and various motors and sensors. The spindle holds and rotates the workpiece while the chuck securely clamps it. The turret houses multiple cutting tools that can be automatically selected and positioned as needed. The tailstock provides additional support for longer workpieces.

The working mechanism involves precise coordination between these components. The CNC controller receives instructions from a computer program or operator input, translating them into specific movements for each component. Servo motors drive these movements accurately, enabling precise cutting, drilling, threading, and other operations.

Advantages Of Using Cnc Lathe Machines

CNC lathe machines offer numerous advantages over traditional manual lathes, making them indispensable tools in modern manufacturing and production environments. Here are some key advantages of using CNC lathe machines:

- Precision and Accuracy: CNC lathe machines can produce precise and accurate machining operations. With computer-controlled movements and advanced tooling, CNC lathes can achieve tight tolerances and produce high-quality parts with consistency and repeatability.

- Versatility: CNC lathe machines are highly versatile and can manufacture various parts and components. They can perform various machining operations on different materials, such as metals, plastics, and composites, including turning, facing, threading, grooving, drilling, and more.

- Increased Productivity: CNC lathe machines significantly improve productivity compared to manual lathes. They can operate continuously without operator intervention, reducing idle time and maximizing machining throughput. Additionally, CNC lathes can perform multiple operations in a single setup, increasing efficiency and productivity.

- Complex Geometry: CNC lathe machines can produce parts with complex geometries that would be challenging or impossible to achieve with manual lathes. With advanced programming capabilities and multi-axis machining capabilities, CNC lathes can easily create intricate shapes, contours, and profiles.

- Reduced Setup Time: Setting up a CNC lathe machine for a new job is faster and easier than manual lathes. Once the program is created and the tooling is set up, CNC lathes can be quickly reconfigured for different machining tasks, reducing downtime between jobs and increasing overall efficiency.

- Automation and Unattended Operation: CNC lathe machines can be fully automated, allowing unattended operation and lights-out machining. With automatic tool changers, part loaders, and integrated robotics, CNC lathes can run continuously without operator supervision, maximizing uptime and throughput.

- Improved Safety: CNC lathe machines offer improved safety compared to manual lathes. With automated safeguards, interlocks, and emergency stop features, CNC lathes help prevent accidents and injuries in the workplace. Additionally, operators can monitor machining processes from a safe distance, reducing exposure to hazardous environments.

- Quality Control: CNC lathe machines enhance quality control by providing real-time monitoring and feedback during machining operations. With built-in sensors, probes, and inspection systems, CNC lathes can detect deviations from specifications and adjust the fly, ensuring that parts meet stringent quality standards.

- Cost Savings: While the initial investment in a CNC lathe machine may be higher than a manual lathe, the long-term cost savings are significant. CNC lathes reduce labor costs, minimize material waste, improve efficiency, and increase throughput, resulting in a favorable return on investment.

CNC lathe machines offer numerous advantages in precision, versatility, productivity, automation, safety, quality control, and cost savings, making them essential tools for modern manufacturing and production operations.

SYIL's Contribution To The Development Of CNC Lathe Machines

SYIL Machine Tools, a leading manufacturer in the industry, has played a significant role in advancing CNC Lathe Machines. With their expertise and commitment to innovation, they have developed cutting-edge machines that deliver exceptional performance and reliability.

SYIL's CNC Lathe Machines incorporate state-of-the-art technology and advanced features to enhance productivity and precision. Their machines offer seamless integration with computer-aided design (CAD) software, enabling efficient programming and simulation of machining processes.

Furthermore, SYIL prioritizes sustainability in its manufacturing practices. They strive to minimize environmental impact by implementing energy-efficient technologies and using eco-friendly materials.

Applications of CNC Lathe Machines

CNC Lathe Machines are widely used in various industries due to their versatility and precision. They offer a range of applications, including turning operations, ensuring precision and accuracy, and providing customization options. SYIL Machine Tools has also introduced innovative features in their CNC Lathe Machine applications.

Turning Operations Performed By CNC Lathe Machines

CNC Lathe Machines excel at performing turning operations with exceptional efficiency and accuracy. They can handle various metal, wood, and plastic materials, making them ideal for manufacturing components like shafts, rods, and cylinders. Automating the process allows for consistent results and faster production times.

Precision And Accuracy In CNC Lathe Machine Operations

One of the key advantages of using CNC Lathe Machines is their ability to consistently deliver precise and accurate results. The machines are equipped with advanced control systems that ensure precise movements of the cutting tools along the X and Z axes. This level of precision eliminates human error, resulting in high-quality finished products.

Versatility And Customization Options In CNC Lathe Machines

CNC Lathe Machines offer remarkable versatility when it comes to customization options. They can be programmed to create intricate designs, complex shapes, or unique workpiece patterns. With multi-axis capabilities like 2-axis or 3-axis control, these machines can produce a wide range of components with varying levels of complexity.

SYIL's Innovative Features In CNC Lathe Machine Applications

SYIL Machine Tools stands out in the industry by introducing innovative features in their CNC Lathe Machine applications. Their machines incorporate advanced technologies that enhance performance, improve efficiency, and increase productivity. SYIL's dedication to research and development ensures that its customers can access cutting-edge solutions for their manufacturing needs.

Industries that Benefit from CNC Lathe Machines

The versatility and precision of CNC Lathe Machines make them invaluable in various industries. Let's explore how these machines revolutionize manufacturing processes in the automotive, aerospace, and medical device industries and the global impact of SYIL Machine Tools.

1. Automotive Industry And The Role Of CNC Lathe Machines

In the automotive industry, CNC Lathe Machines are crucial in producing high-quality components with exceptional precision. These machines ensure consistent accuracy and tight tolerances, from engine parts to transmission components. Creating complex shapes and contours allows for the efficient production of intricate automotive parts.

One example is using 2-axis CNC Lathe Machines for manufacturing crankshafts and camshafts. These machines accurately shape metal rods into perfectly balanced rotating shafts, ensuring smooth engine operation. The NC Lathe technology enables automated production processes, reducing human error and increasing productivity.

2. Aerospace Industry's Reliance On CNC Lathe Machines

Due to strict safety regulations, the aerospace industry demands the utmost precision and reliability in its components. CNC Lathe Machines are instrumental in meeting these requirements by producing intricate parts with exceptional accuracy.

3-axis CNC Lathe Machines are commonly used to manufacture critical aerospace components like turbine blades, landing gear parts, and hydraulic system elements. The X and Z-axis capabilities allow for multi-dimensional machining operations that result in high-quality finished products.

SYIL Machine Tools has been at the forefront of developing advanced features tailored to the aerospace industry's needs, ensuring compliance with stringent quality standards.

3. Medical Device Manufacturing And CNC Lathe Machine Usage

Precision is paramount when it comes to manufacturing medical devices. CNC Lathe Machines enable the production of highly accurate and intricate components used in medical devices, such as implants, surgical instruments, and prosthetics.

The ability to customize designs and achieve tight tolerances makes CNC Lathe Machines indispensable in this industry. With the use of flatbed CNC Lathe machines for sale, medical device manufacturers can easily create complex shapes and meet each application's specific requirements.

SYIL's Global Presence And Impact On Diverse Industries

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

SYIL's range of CNC Lathe Machines caters to various industries, including automotive, aerospace, and medical device manufacturing. Their commitment to innovation and customer satisfaction has made them a trusted partner for businesses worldwide.

Advancements and Future of CNC Lathe Machines

CNC lathe machines have come a long way since their inception, with continuous advancements pushing the boundaries of precision manufacturing. These technological developments have revolutionized the industry, enabling manufacturers to achieve higher efficiency and accuracy in their operations.

Latest Technological Advancements In CNC Lathe Machines

In recent years, the introduction of advanced control systems has greatly enhanced the capabilities of CNC lathe machines. These systems utilize state-of-the-art software and hardware to optimize machine performance and ensure seamless operation. With features such as real-time monitoring, predictive maintenance, and adaptive control algorithms, manufacturers can now achieve unprecedented levels of productivity and reliability.

Integrating artificial intelligence (AI) into CNC lathe machines is a notable advancement. AI algorithms can analyze vast amounts of data collected during machining processes to identify patterns and make intelligent real-time decisions. This improves overall efficiency and helps detect potential issues before they escalate, minimizing downtime and reducing costs.

Integration Of Automation And Robotics In CNC Lathe Machines

Automation has become a key focus in the development of CNC lathe machines. By integrating robotic arms into machining, manufacturers can achieve higher productivity levels while reducing manual labor requirements. These robots can load and unload workpieces, make tool changes, and perform quality inspections.

The utilization of automation not only increases production speed but also ensures consistent quality throughout the manufacturing process. With precise movements and repeatability, robots eliminate human errors that may occur during manual operations.

SYIL's Commitment To Sustainable And Eco-Friendly Manufacturing

SYIL Machine Tools recognizes the importance of sustainable manufacturing practices today. They are committed to minimizing their environmental impact by developing CNC lathe machines that are energy-efficient and eco-friendly.

By incorporating advanced power management systems into their machines, SYIL ensures optimal energy consumption without compromising performance. This reduces operating costs and contributes to a greener and more sustainable manufacturing industry.

Potential Future Developments In CNC Lathe Machines

Looking ahead, the future of CNC lathe machines holds exciting possibilities. One potential development is integrating Internet of Things (IoT) technology, enabling machines to communicate and share data in real time. This connectivity allows remote monitoring, predictive maintenance, and even autonomous decision-making.

Furthermore, advancements in material science may lead to the development of more durable and lightweight machine components. This would result in increased machine longevity and improved performance.

As the demand for customization grows, CNC lathe machines may also see advancements in their ability to handle complex geometries and intricate designs easily. Incorporating advanced software algorithms and tooling technologies will enable manufacturers to push boundaries and achieve new levels of precision.

SYIL Machine Tools is at the forefront of these potential developments, constantly innovating to meet the evolving needs of manufacturers worldwide.

Choosing the Right CNC Lathe Machine

When selecting a CNC Lathe Machine, several factors need to be considered.

- You need to determine the specific requirements of your manufacturing operations and identify the type of CNC Lathe Machine that will best suit your needs. Factors such as the size and complexity of the parts you will be producing and the desired level of precision and accuracy should all be taken into account.

- Budget considerations also play a crucial role in choosing the right CNC Lathe Machine. It's important to strike a balance between cost-effectiveness and quality. While it may be tempting to opt for a cheaper machine, ensuring that it meets your production requirements and offers reliable performance in the long run is essential. Investing in a high-quality CNC Lathe Machine can save you money on repairs and replacements.

SYIL Machine Tools offers a wide range of CNC Lathe Machines that cater to various manufacturing needs. Their machines are known for their exceptional quality, precision, and durability. With options like 2-axis CNC lathes, 3-axis CNC lathes, and flatbed CNC lathes for sale, SYIL provides flexibility regarding machine capabilities.

But don't just take our word for it! Testimonials from satisfied customers speak volumes about SYIL's CNC Lathe Machines. Customers have praised their reliability, ease of use, and outstanding performance in meeting their production demands. The positive feedback from these testimonials is a testament to SYIL's commitment to delivering top-notch machines.

Conclusion

In conclusion, CNC Lathe Machines are crucial in modern manufacturing processes. They offer precision, efficiency, and versatility in turning operations, making them essential for automotive, aerospace, and medical device manufacturing industries. SYIL Machine Tools has revolutionized the CNC Lathe Machine industry with its expertise and commitment to quality. With its range of innovative features and global presence, SYIL has become a recognized brand in the industry.

Looking toward the future, CNC Lathe Machines are expected to continue advancing technologically. Integration of automation and robotics will further enhance their capabilities and efficiency. SYIL is also committed to sustainable and eco-friendly manufacturing practices, ensuring a greener future for the industry.

If you're looking for precision manufacturing solutions, I encourage you to explore SYIL's CNC Lathe Machines. Their range includes 2-axis and 3-axis options, as well as flatbed CNC lathes for sale. With their proven track record of customer satisfaction and testimonials from happy clients, you can trust SYIL to meet your machining needs.