Introduction

CNC lathe machines play a crucial role in the manufacturing industry, and the operators who handle them are essential for efficient production. In this article, we will explore the responsibilities and skills required for a CNC lathe operator role and the significance of these machines in manufacturing processes. Additionally, we will introduce SYIL Machine Tools and their innovative CNC mill, highlighting their commitment to quality and sustainability.

Overview of CNC Lathe Operator Role

A CNC lathe operator is responsible for setting up and operating computer numerical control (CNC) lathe machines. These highly skilled professionals ensure the machines run smoothly and efficiently to produce precise components used in various automotive, aerospace, and electronics industries.

Importance of CNC Lathe Machines in the Manufacturing Industry

CNC (Computer Numerical Control) lathe machines are crucial in the manufacturing industry, providing numerous advantages contributing to efficiency, precision, and productivity. Here are some key reasons highlighting the importance of CNC lathe machines:

- Precision and Accuracy: Ensure consistent and precise results, meeting tight tolerances.

- Complex Part Production: Can create intricate parts that are challenging for manual methods.

- Versatility: Suitable for various materials and shapes, offering flexibility in manufacturing.

- Efficiency and Productivity: Operate continuously, reducing downtime and optimizing resource use.

- Reduced Manual Labor: Automation minimizes errors and allows skilled operators to focus on more complex tasks.

- Faster Production Times: Complete machining operations faster than manual methods.

- Cost-Effective Batch Production: Efficient for producing large quantities of identical parts.

- Customization and Prototyping: Facilitate quick and precise prototyping for design development.

- Integration with CAD/CAM Systems: Streamline the design-to-production workflow.

- Quality Control and Consistency: Contribute to enhanced quality control through automated processes.

CNC lathe machines are integral to modern manufacturing, offering precision, efficiency, versatility, and the ability to produce complex parts at scale. Their role in automating processes and improving overall productivity makes them indispensable in various industries, including aerospace, automotive, medical, and electronics.

Introduction to SYIL Machine Tools and Their CNC Mill

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC mill is known for its advanced features, such as multi-axis capabilities, high-speed machining, and user-friendly interfaces. It empowers operators to achieve exceptional precision while optimizing production efficiency.

Highlighting SYIL's Commitment to Quality and Sustainability

SYIL Machine Tools stands out in the industry due to its unwavering commitment to quality craftsmanship and sustainable manufacturing practices. They ensure their CNC machines are built with durable materials to withstand rigorous operations while minimizing environmental impact through energy-efficient designs.

Job Responsibilities

CNC lathe operators play a crucial role in manufacturing by operating and maintaining CNC lathe machines. Their responsibilities include setting up the machines for operation, loading and unloading workpieces, programming and selecting appropriate tooling, and monitoring machine operations.

1. Setting Up CNC lathe Machine For Operation

Setting up a CNC lathe machine involves preparing it for production. This includes ensuring that all necessary tools and materials are available, checking the machine's calibration, and making any necessary adjustments to ensure optimal performance. The operator must also ensure that safety protocols are followed during setup.

2. Loading And Unloading Workpieces Into The Machine

Once the machine is set up, the CNC lathe operator is responsible for loading and unloading workpieces into the machine. This requires careful handling of materials to avoid damage or accidents. The operator must also ensure that the workpiece is securely fastened to prevent movement during machining.

3. Programming And Selecting Appropriate Tooling

Programming is a critical aspect of a CNC lathe operator's job. They must understand programming languages and software to input instructions into the machine's computer system. This includes specifying tool paths, speeds, feeds, and other parameters necessary for precise machining operations. Additionally, operators must select appropriate tooling based on the requirements of each job.

4. Monitoring Machine Operations And Making Adjustments As Needed

While the CNC lathe machine operates, operators must closely monitor its performance to ensure everything runs smoothly. They must monitor cutting tools, coolant levels, chip accumulation, and other factors affecting machining quality or efficiency. Operators must make timely adjustments or stop production if any issues arise during operation.

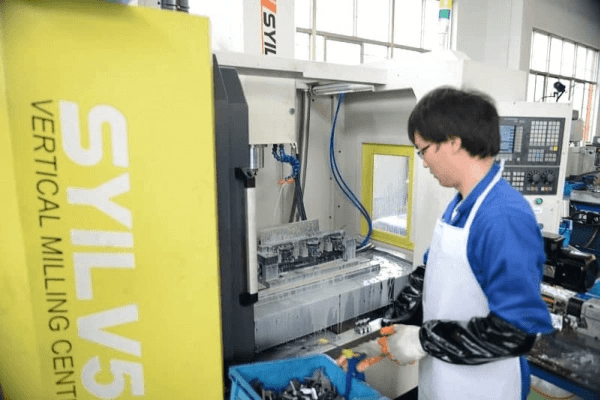

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC mills, like the one shown in the image, offer advanced features and reliability to meet the demands of modern manufacturing.

Becoming a skilled CNC lathe operator requires technical knowledge, attention to detail, problem-solving abilities, and familiarity with programming languages and software. Safety procedures are crucial in CNC operations to protect operators from potential hazards. Quality control is essential to ensure the production of accurate and reliable parts. The field of CNC machining offers promising career opportunities for growth and advancement.

Explore the world of CNC machining with SYIL Machine Tools and discover how you can contribute to the manufacturing industry while benefiting from their commitment to quality and sustainability.

Skills and Qualifications

1. Technical Knowledge Of CNC Lathe Machines

As a CNC lathe operator, it is crucial to possess a strong technical understanding of CNC lathe machines. This includes knowledge of machine components, functions, and operations. A skilled operator should be familiar with spindle speed settings, tooling requirements, and the ability to troubleshoot any technical issues that may arise during operation.

2. Proficiency In Reading Blueprints And Schematics

Reading blueprints and schematics is an essential skill for a CNC lathe operator. These documents provide detailed instructions on each part or component's dimensions, tolerances, and specifications. Being able to interpret these plans accurately ensures that the machine operates precisely according to the design requirements.

3. Strong Attention To Detail And Problem-Solving Abilities

Attention to detail is paramount in CNC lathe operations, as even minor errors can lead to significant consequences in the manufacturing process. A skilled operator must possess keen observational skills to detect deviations from specifications or abnormalities during machining. Additionally, problem-solving abilities are necessary for troubleshooting issues that may arise during operation.

4. Familiarity With Programming Languages And Software

CNC lathe operators should have a basic understanding of programming languages and software used in CNC machining. While they may not be responsible for creating complex programs from scratch, familiarity with coding languages such as G-code enables them to make adjustments or modifications when necessary. Proficiency in using software interfaces specific to the CNC lathe machine is also vital for efficient operation.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Safety Procedures

CNC machining operations require strict adherence to safety guidelines to ensure operators' well-being and the machines' proper functioning. Proper usage of personal protective equipment (PPE), handling hazardous materials, waste disposal, and machine maintenance are all crucial aspects of maintaining a safe working environment.

Importance Of Following Safety Guidelines In CNC Operations

Following safety guidelines is paramount when operating CNC machines. These guidelines are put in place to protect operators from potential hazards and accidents that can occur during the machining process. By adhering to these guidelines, operators minimize the risk of injuries and ensure smooth operations.

Proper Usage Of Personal Protective Equipment (PPE)

Personal protective equipment (PPE) safeguards CNC lathe operators from potential hazards. PPE includes safety glasses, gloves, ear protection, and steel-toed boots. Wearing appropriate PPE shields operators from flying debris, loud noises, and other occupational risks.

Handling Hazardous Materials And Waste Disposal

In CNC machining operations, there may be instances where operators come into contact with hazardous materials such as coolant fluids or metal shavings. CNC lathe operators must handle these materials cautiously and dispose of them properly according to established protocols to avoid environmental contamination or health risks.

Ensuring Machine Maintenance And Inspection For Safety

Regular machine maintenance and inspection are crucial for ensuring the safe operation of CNC lathes. Operators should perform routine checks on the machines to identify potential issues or malfunctions that could compromise safety. By addressing these concerns promptly, operators can maintain a safe working environment for themselves and their colleagues.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's CNC mill is designed with safety features to ensure the well-being of operators during machining operations.

Remember, safety should always be the top priority in CNC operations. CNC lathe operators can create a safe working environment while maximizing productivity by following guidelines, using proper PPE, handling hazardous materials responsibly, and conducting regular machine maintenance.

Explore the exciting career opportunities in CNC machining and consider joining the industry as a skilled professional. SYIL Machine Tools offers high-quality CNC machines to help you excel in your career while contributing to the manufacturing industry's growth and development.

Quality Control

Quality control ensures that products meet the required standards and specifications in the manufacturing industry. As a CNC lathe operator, understanding quality standards and specifications is crucial to producing high-quality finished products.

Understanding Quality Standards And Specifications

CNC lathe operators must thoroughly understand their company's or industry's specific standards and specifications to maintain consistent quality. This includes knowledge of dimensional tolerances, surface finish requirements, and material properties.

By following these standards, operators can ensure that each workpiece meets the necessary criteria for functionality and performance. This attention to detail is essential in industries where precision is paramount, such as aerospace or medical device manufacturing.

Conducting Inspections And Measurements Of Finished Products

CNC lathe operators are responsible for inspecting and measuring finished products to ensure they meet the required specifications during production. This involves using various measuring tools such as calipers, micrometers, and gauges.

By conducting thorough inspections, operators can identify deviations from the desired dimensions or surface finishes. They can then take corrective actions to address these issues before the products are sent for further processing or assembly.

Implementing Corrective Actions For Non-Conforming Parts

Inevitably, there may be instances where certain parts do not meet the required specifications during inspections. CNC lathe operators must implement corrective actions to rectify these non-conforming parts in such cases.

This may involve adjusting machine settings, replacing tooling or workpieces, or making programming modifications. By promptly addressing non-conforming parts, operators minimize waste and ensure that only high-quality products move forward in the production process.

Continuous Corrective Actions For Non-Conforming Parts

CNC lathe operators should actively participate in continuous improvement initiatives to enhance quality control processes. This includes providing feedback on potential improvements to machine settings or programming techniques that could enhance product quality.

Operators should also maintain comprehensive records of quality inspections and any corrective actions taken. These records serve as valuable references for identifying trends, analyzing root causes of quality issues, and implementing long-term solutions to prevent recurrence.

By prioritizing quality control practices, CNC lathe operators contribute to the overall success of their organization. They ensure that each workpiece meets the required standards and specifications, ultimately leading to customer satisfaction and trust in the products they manufacture.

Remember, when it comes to precision CNC machines for milling and drilling, SYIL Machine Tools is a trusted name in the industry. With over 12k machines supplied globally, SYIL prioritizes quality and sustainability in CNC mills. Explore career opportunities in CNC machining today!

Career Opportunities and Advancement

CNC lathe operators have promising growth prospects and high demand in the manufacturing industry. As technology advances, the need for skilled operators to efficiently operate CNC lathe machines is rising. With their ability to produce precise and complex parts, CNC lathes are essential in various aerospace, automotive, and electronics industries.

Becoming a CNC programmer is a natural progression for CNC lathe operators looking to specialize in their field. By gaining proficiency in programming languages and software, they can take on more advanced roles that involve creating and optimizing programs for CNC machines. This specialization opens up opportunities to work on intricate projects and collaborate with engineers and designers.

Moreover, CNC lathe operators can potentially advance into supervisory or managerial roles within manufacturing companies. With experience and expertise, they can oversee a team of operators, ensuring smooth operations and maintaining quality standards. These roles require strong leadership skills, problem-solving abilities, and a deep understanding of CNC machining processes.

Continuing education and training options are essential for the professional development of CNC lathe operators. They can pursue additional certifications or attend workshops to stay updated with the latest advancements in CNC technology. By continuously improving their skills and knowledge, operators can enhance their career prospects and remain competitive.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their state-of-the-art CNC mill offers excellent opportunities for aspiring CNC lathe operators to expand their skill sets.

Conclusion

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC mill plays a vital role in the industry by enabling efficient and precise machining processes.

There are numerous opportunities for growth and advancement for those interested in a career in CNC machining. The demand for CNC lathe operators is rising, with possibilities for specialization or becoming a CNC programmer. Advancement opportunities to supervisory or managerial roles are also available.

Continuing education and training options are essential for professional development in this field. Staying updated with the latest programming languages and software is crucial to excelling as a CNC lathe operator.