Introduction

Haas CNC Machines and SYIL CNC Machines are two prominent computer numerical control (CNC) machine brands. CNC machines are crucial in various industries, revolutionizing manufacturing processes with precision and efficiency. This article compares the cost, performance, and features of Haas and SYIL CNC machines to help readers decide when to choose the right machine for their needs.

Overview of Haas CNC Machines

Haas CNC Machines are renowned for their reliability and versatility. They offer a wide range of models, including milling machines and lathes, designed to meet the diverse needs of manufacturers across different industries. Haas has established itself as a leading player in the CNC machine market with a strong emphasis on quality and innovation.

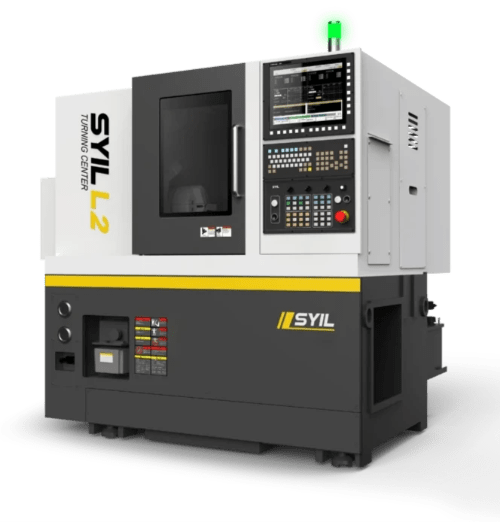

Introduction to SYIL CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's commitment to delivering cutting-edge technology at competitive prices has made it popular among small businesses and hobbyists.

Importance of CNC Machines in Various Industries

CNC (Computer Numerical Control) machines hold significant importance in various industries due to their versatile applications and several advantages. Here's a concise overview of their importance:

- Precision Manufacturing: CNC machines ensure high precision and accuracy in manufacturing processes, meeting stringent quality standards across industries.

- Increased Efficiency: Automation in CNC machines leads to continuous operation, reducing downtime and increasing overall production efficiency.

- Versatility: CNC machines can be used for various materials, allowing their application in diverse industries such as aerospace, automotive, healthcare, and electronics.

- Complex Part Production: The ability to program intricate designs enables the production of complex components, contributing to advancements in technology and product development.

- Cost-Effective Mass Production: CNC machines are well-suited for batch production, offering cost-effective solutions for large-scale manufacturing of identical parts.

- Reduced Manual Labor: Automation minimizes the need for extensive manual labor, ensuring consistency and reducing the risk of human error.

- Customization and Prototyping: CNC machines facilitate rapid prototyping and customization, allowing for quick design and product development iteration.

- Integration with CAD/CAM Systems: Integrating CNC machines with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems streamlines the production process, enhancing workflow efficiency.

- Quick Tool Changes: CNC machines enable rapid tool changes, reducing setup times and enhancing the overall speed of manufacturing processes.

- Quality Control: The automated nature of CNC machines contributes to improved quality control, ensuring consistency and adherence to specifications.

The importance of CNC machines lies in their ability to provide precision, efficiency, versatility, and automation across various industries, ultimately contributing to advancements in manufacturing and technology.

This article aims to provide an unbiased comparison between Haas and SYIL CNC machines in terms of cost, performance, features, customer satisfaction levels, and overall value for money. By examining these factors comprehensively, readers will gain valuable insights into which brand aligns better with their specific requirements.

Cost of Haas CNC Machines

Haas CNC machines are renowned for their precision and reliability in manufacturing. When considering the cost of Haas CNC machines, several factors include specifications, size, and additional features.

Overview of Haas CNC Machine Pricing

Haas offers a wide range of CNC machines to meet various manufacturing needs. The pricing for Haas CNC machines typically starts at around $40,000 for entry-level models and can go up to several hundred thousand dollars for more advanced and specialized machines.

Factors Affecting the Cost of Haas CNC Machines

Various factors can influence the cost of Haas CNC machines, and understanding these factors is essential for businesses considering the purchase of such equipment. Here are key factors affecting the cost of Haas CNC machines:

- Machine Type and Model: Different Haas CNC machines, such as milling machines, lathes, or multi-axis machining centers, come in various models with different capabilities. The specific type and model chosen will impact the overall cost.

- Machine Size and Capacity: The physical size and machining capacity of the CNC machine play a role in determining its cost. Larger machines with higher capacity and capabilities typically come at a higher price.

- Number of Axes: CNC machines with more axes provide greater flexibility and precision in machining. Machines with additional axes, such as 4-axis or 5-axis machines, tend to be more expensive than those with fewer axes.

- Automation Features: Haas CNC machines may have automation features like tool changers, pallet changers, or robotic integration. The level of automation can significantly impact the cost of the machine.

- Tooling and Accessories: The cost of tooling and additional accessories required for specific machining tasks should be considered. Different applications may require specialized tooling, which can contribute to the overall cost.

- Control System and Software: The sophistication of the CNC control system and the included software features influence the cost. Advanced control systems with more features may come at a higher price but can contribute to increased efficiency.

- Brand Reputation: Haas is a well-known brand in the CNC machine industry. The reputation and reliability associated with the brand can influence the cost of Haas CNC machines.

- Service and Support: The availability and quality of customer support, training, and maintenance services provided by the manufacturer can impact the overall cost. A comprehensive service package may be reflected in the machine's price.

- Installation and Training: The cost of installation and training services provided by the manufacturer or a third party may be included in the overall package. This can vary based on the complexity of the machine and the level of training required.

- Market Conditions: Economic factors, market demand, and supply conditions can influence pricing. Prices may fluctuate based on market trends and the availability of specific machine models.

Understanding these factors and carefully evaluating a business's specific requirements can help make informed decisions about purchasing Haas CNC machines and managing associated costs.

Range of Haas CNC Machine Prices

The range of prices for Haas CNC machines is extensive, catering to different budgets and requirements. As mentioned, entry-level models can start at around $40,000, while more sophisticated machines with advanced capabilities can exceed $500,000.

It's important to note that pricing may vary based on geographical location, local taxes or tariffs, customization options, and any additional accessories or tooling required.

Comparison of Haas CNC Machines with SYIL CNC Machines

When comparing Haas CNC machines with SYIL CNC machines in terms of cost-effectiveness, it's important to consider both quality and price. While Haas has established itself as a reputable brand in the industry, SYIL Machine Tools offers competitive alternatives that provide excellent value for money.

SYIL's CNC machines are known for their affordability without compromising precision and performance. With a focus on quality and sustainability, SYIL prioritizes customer satisfaction by delivering reliable and cost-effective CNC machines.

Cost of SYIL CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Overview of SYIL CNC Machine Pricing

SYIL offers a wide range of CNC machines at competitive prices to meet the diverse needs of various industries. Their pricing structure is designed to provide affordable options without compromising on quality.

Factors Affecting the Cost of SYIL CNC Machines

Several factors influence the cost of SYIL CNC machines. The complexity and size of the machine, as well as the specific features and capabilities required, can impact pricing. Additionally, customization options, such as tooling configurations or software upgrades, may affect the overall cost.

Range of SYIL CNC Machine Prices

SYIL provides a range of CNC machine models with varying price points to cater to different budgets. Their entry-level machines start at a cost-effective price point, making them accessible to small businesses or individuals looking to venture into CNC machining. On the other hand, their advanced models offer enhanced capabilities and precision at a higher price range.

Advantages of Choosing SYIL CNC Machines over Haas CNC Machines

When comparing SYIL CNC machines with Haas counterparts, several advantages become evident:

- Cost-effectiveness: SYIL offers competitive pricing without compromising quality or performance, making their machines an attractive option for those on a budget.

- Customization: SYIL provides flexibility regarding machine configuration and optional upgrades, allowing customers to tailor their machines according to specific requirements.

- Ease of use: SYIL's intuitive user interface and user-friendly software make it easier for operators with varying experience levels to operate their CNC machines efficiently.

- After-sales support: SYIL prioritizes customer satisfaction by offering comprehensive after-sales support services, including technical assistance and maintenance guidance.

Performance and Features of Haas CNC Machines

Haas CNC machines are known for their exceptional performance and advanced features that cater to the needs of various industries. These machines offer precise and efficient milling and drilling capabilities, making them a popular choice among manufacturers worldwide.

Overview of Haas CNC Machine Performance

Haas CNC machines are renowned for their high-performance capabilities. With cutting-edge technology and precision engineering, these machines deliver exceptional accuracy, speed, and repeatability results. Whether it's complex machining tasks or simple operations, Haas CNC machines consistently provide superior performance that meets the demands of modern manufacturing.

Key Features of Haas CNC Machines

Haas CNC machines have key features that enhance their performance and efficiency. These features include advanced control systems, high-speed spindles, rigid construction for stability, automatic tool changers for increased productivity, and intuitive user interfaces for easy operation. Additionally, Haas machines incorporate innovative technologies such as wireless probing systems and advanced tool management software to optimize performance.

Comparison of Haas CNC Machine Performance with SYIL CNC Machines

When comparing the performance of Haas CNC machines with SYIL CNC machines, it is important to consider factors such as precision, reliability, and versatility. While both brands offer excellent performance capabilities, Haas stands out with its robust construction and cutting-edge technology advancements. The precision engineering in Haas machines ensures consistent accuracy throughout the machining process, while their reliability allows for uninterrupted production even in demanding environments.

Potential Drawbacks of Haas CNC Machines

Despite their impressive performance, a few potential drawbacks associated with Haas CNC machines should be considered when making a purchasing decision. One drawback is the initial cost investment required to acquire a Haas machine. While they offer exceptional value for money regarding long-term productivity gains, the upfront cost may be a barrier for some businesses. Additionally, Haas machines may require regular maintenance and servicing to ensure optimal performance, which can add to the overall cost of ownership.

Performance and Features of SYIL CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Overview of SYIL CNC Machine Performance

SYIL CNC machines are known for their exceptional performance in various industries. These machines are equipped with advanced technology that ensures precise and efficient operations. Whether milling or drilling, SYIL CNC machines deliver exceptional results with high accuracy and repeatability. They are designed to easily handle complex tasks, making them a reliable choice for professionals.

Key Features of SYIL CNC Machines

SYIL CNC machines have various impressive features that set them apart. One notable feature is their user-friendly interface, which allows operators to program and control the machine's operations easily. These machines also have high-speed spindles that enable fast and efficient cutting processes. The robust construction ensures stability during operation, minimizing vibrations and ensuring optimal performance.

Comparison of SYIL CNC Machine Performance with Haas CNC Machines

When comparing the performance of SYIL CNC machines with Haas CNC machines, it is evident that both brands offer reliable performance. However, SYIL CNC machines have certain advantages, making them a preferred choice for many professionals.

- Due to their advanced technology and high-quality components, SYIL CNC machines provide superior precision and accuracy. This ensures consistent results even when working on intricate designs or complex projects.

- SYIL CNC machines offer faster processing speeds, allowing for increased productivity without compromising on quality. The high-speed spindles enable rapid cutting processes, reducing production time significantly.

- SYIL CNC machines are known for their durability and reliability. These machines are built to withstand heavy-duty usage in demanding industrial environments, ensuring long-term performance without frequent breakdowns or maintenance issues.

Advantages of Choosing SYIL CNC Machines over Haas CNC Machines

Opting for SYIL CNC machines over Haas CNC machines comes with several advantages.

- The cost-effectiveness of SYIL machines makes them an attractive option for businesses looking to invest in high-quality CNC technology without breaking the bank. The competitive pricing of SYIL machines and their exceptional performance make them a cost-efficient choice.

- SYIL Machine Tools prioritizes sustainability in its manufacturing processes. They strive to minimize environmental impact by using energy-efficient components and reducing waste generation. By choosing SYIL CNC machines, businesses can contribute to a greener future while enjoying the benefits of advanced technology.

Regarding performance and features, SYIL CNC machines excel in delivering precise results with speed and reliability. Their advanced technology, user-friendly interface, and competitive pricing make them a top choice for professionals in various industries. Businesses can enhance productivity by choosing SYIL CNC machines while contributing to a sustainable future.

Customer Reviews and Satisfaction

Feedback from Haas CNC Machine Users

Many users of Haas CNC machines have praised the reliability and precision of these machines. They appreciate Haas machines' durability and high performance, making them suitable for a wide range of applications. Some users have mentioned that the cost of Haas CNC machines is justified by their long lifespan and low maintenance requirements.

Feedback from SYIL CNC Machine Users

Users of SYIL CNC machines have expressed satisfaction with the affordability and quality of these machines. They appreciate the competitive pricing offered by SYIL, especially compared to other brands like Haas. Many users have mentioned that despite being budget-friendly, SYIL CNC machines deliver excellent performance and accuracy.

Comparison of Customer Satisfaction Levels

When comparing customer satisfaction levels between Haas and SYIL CNC machine users, it is evident that both brands have a loyal customer base. However, feedback from SYIL CNC machine users often highlights the cost-effectiveness and reliability of these machines, which resonates with many small businesses or hobbyists looking for an affordable yet efficient solution.

Testimonials Highlighting the Benefits of SYIL CNC Machines

Testimonials from satisfied SYIL CNC machine users emphasize various benefits such as cost savings, ease of use, and exceptional precision. Users appreciate how SYIL machines offer advanced features at a fraction of the price compared to other brands. The versatility and reliability of SYIL CNC machines make them a top choice for those seeking high-quality results without breaking the bank.

Conclusion

When comparing the cost of Haas and SYIL CNC machines, it is important to consider several factors. Haas CNC machines are known for their high-quality performance but have a higher price tag. On the other hand, SYIL CNC machines offer competitive pricing without compromising on quality.

Considerations for Choosing the Right CNC Machine

When choosing the right CNC machine, it is crucial to consider your specific needs and budget. Evaluate factors such as the type of machining required, desired performance levels, and available workspace. Additionally, consider long-term maintenance costs and support services provided by the manufacturer.

Benefits of Opting for SYIL CNC Machines

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Opting for SYIL CNC machines offers several benefits, including cost-effectiveness, reliable performance, and excellent customer support.

Final Thoughts on Choosing the Best CNC Machine Brand

Choosing the best CNC machine brand ultimately depends on your requirements and budget constraints. While Haas offers top-notch performance at a higher cost, SYIL provides affordable options without compromising quality or customer satisfaction.