Introduction

Welcome to the fascinating world of watch making, where precision and craftsmanship come together to create timeless pieces of art. In this guide, we will explore the artistry and history of watch making, as well as the intricate craft behind it.

The Art of Watch Making

Watch making is a delicate art that requires skill, patience, and an eye for detail. From designing intricate dials to assembling tiny gears, every step in the process is a testament to the dedication of watch makers.

The History of Watch Making

The history of watch making dates back centuries, with early timepieces evolving from sundials and water clocks. Over time, advancements in technology and craftsmanship have led to the creation of some of the most exquisite watches in existence.

Understanding the Craft of Watch Making

To truly appreciate the craft of watch making, one must understand the meticulous process involved in creating a timepiece. From selecting high-quality materials to mastering intricate techniques, watch makers dedicate themselves to perfecting their craft.

Getting Started in Watch Making

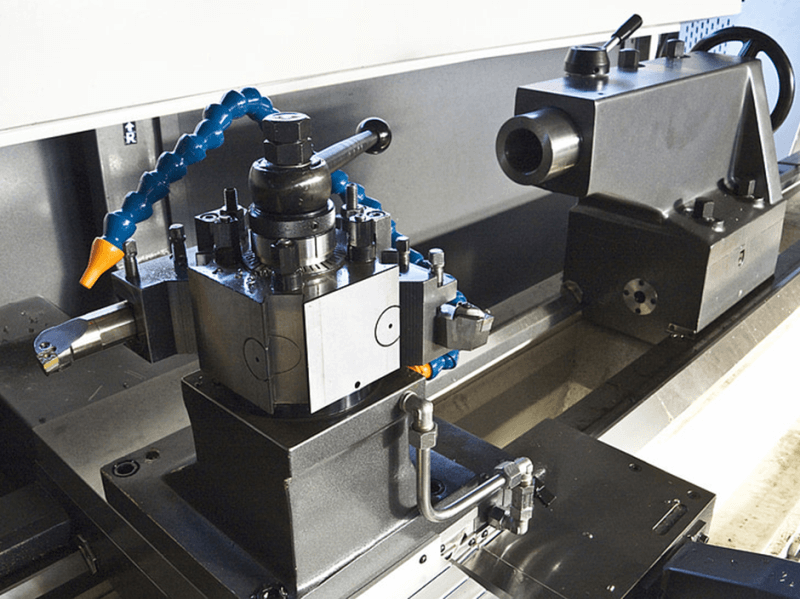

When starting out in watch making, having the right tools and equipment is crucial. A good quality set of precision screwdrivers, tweezers, and a loupe are essential for intricate work. A watchmaker's lathe and a bench vise are also important for holding parts securely while working on them.

Tools and Equipment for Watch Making

To begin your journey into watch making, you'll need to invest in specialized tools such as hand removers, hand setters, case openers, and movement holders. These tools are designed to handle the delicate nature of watch components with precision and care. Additionally, investing in a high-quality ultrasonic cleaner can help keep your workspace tidy and free from debris.

Once you have acquired the necessary tools and equipment for watch making, it's important to familiarize yourself with basic techniques such as disassembling and reassembling watch components, adjusting movement mechanisms, and properly sealing watch cases to ensure water resistance. Understanding these fundamental skills will lay a strong foundation for your journey into the intricate world of watch making. Additionally, honing your fine motor skills and attention to detail will be crucial in mastering the art of assembling and repairing timepieces.

Basic Watch Making Techniques

Learning basic watch making techniques is fundamental to mastering this craft. It's essential to understand the intricacies of each component and how they work together to create a functioning timepiece. Additionally, developing a keen eye for detail is crucial when working with small, delicate parts. This attention to detail will ensure that every aspect of the watch is assembled and regulated with precision.

The Importance of Precision in Watch Making

Precision is at the heart of watch making; every tiny gear or component must fit together perfectly for a timepiece to function flawlessly. This requires attention to detail and an unwavering commitment to accuracy throughout the entire process. From measuring components to assembling intricate parts, precision is non-negotiable in this craft.

Precision in watch making is not just about the physical components; it also extends to the aesthetic design and finishing of the timepiece. The intricate engravings, delicate hands, and polished surfaces all require meticulous attention to detail to achieve the desired look. Even a slight imperfection can detract from the overall beauty of the watch, making precision an essential aspect of its visual appeal.

Advanced Techniques in Watch Making

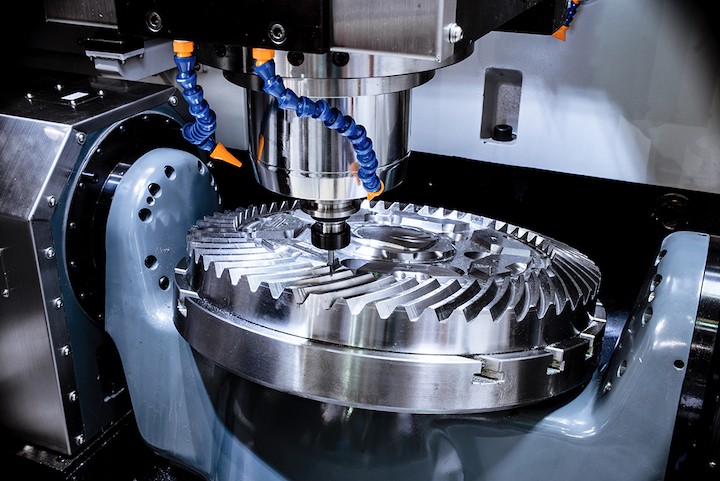

When it comes to advanced techniques in watch making, CNC milling machines play a crucial role. These machines are specifically designed for the intricate and precise work required in watch making, allowing for unparalleled accuracy and detail. With CNC milling machines, watchmakers can create complex components with ease and efficiency, revolutionizing the way watches are crafted.

CNC Milling Machines for Watchmaking

CNC milling machines are indispensable tools in the world of watch making. These machines use computer numerical control to precisely remove material from a workpiece, resulting in highly detailed and accurate components. With their ability to work with a wide range of materials, including metals and plastics, CNC milling machines have become an essential part of the modern watchmaker's toolkit.

CNC milling machines have revolutionized the art of watchmaking by allowing for the precise and intricate fabrication of watch components. This level of precision is essential in creating the delicate gears, springs, and other parts that make up a high-quality timepiece. Additionally, CNC machines can produce these parts at a much faster rate than traditional methods, increasing efficiency in the manufacturing process. As a result, watchmakers are able to meet the demands of their customers while maintaining the highest standards of craftsmanship.

Watchmaking with CNC Machining

Watchmaking with CNC machining has transformed the industry, allowing for the creation of intricate parts that were once impossible to produce by hand. The precision and repeatability of CNC machining have elevated the quality and complexity of watches, opening up new possibilities for design and innovation. As technology continues to advance, watchmakers are embracing CNC machining as an integral part of their craft.

CNC Milling a Custom Watch

One of the most exciting developments in watch making is the ability to CNC mill custom watches. With this advanced technique, watchmakers can bring unique designs to life with unparalleled precision and accuracy. From intricate dials to custom cases, CNC milling allows for endless creativity and customization in creating one-of-a-kind timepieces that truly stand out.

Furthermore, CNC milling opens up a world of possibilities for watchmakers to experiment with different materials and textures. Whether it's wood, metal, or even plastic, the precision of CNC milling ensures that even the most unconventional materials can be crafted into stunning timepiece components. This level of versatility allows for truly unique and innovative designs that push the boundaries of traditional watchmaking.

Building a Watch Making Business

As you venture into the world of watch making, starting your own business can be an exciting and rewarding endeavor. With the rise of CNC Milling Machines for Watchmaking, you have the opportunity to create unique timepieces that stand out in the market. By investing in high-quality CNC machines and assembling a skilled team, you can lay the foundation for a successful watch making business.

Starting a Watch Making Business

To start a watch making business, you'll need to research and invest in the right machines to make watches. CNC Milling Machines for Watchmaking offer precision and efficiency in producing watch components, making them essential tools for your workshop. Additionally, understanding the intricacies of Watchmaking with CNC Machining will be crucial in creating high-quality timepieces that meet industry standards.

After investing in the right machines and understanding the intricacies of watchmaking with CNC machining, it's essential to develop a strong marketing strategy for your watch making business. One effective approach is to focus on the craftsmanship and precision that goes into creating each timepiece. Emphasizing the attention to detail and quality materials used in your watches will appeal to discerning customers who appreciate fine craftsmanship.

Marketing Strategies for Watch Makers

In today's digital age, marketing your watch making business is essential for reaching potential customers. Utilize social media platforms to showcase your craftsmanship and engage with watch enthusiasts online. Consider creating captivating content that highlights the process of CNC Milling a Custom Watch to attract attention from both casual consumers and serious collectors.

Finding Success in the Watch Making Industry

Finding success in the competitive watch making industry requires dedication, innovation, and strategic planning. By leveraging advanced techniques such as Can you CNC a watch?, you can push boundaries and offer customers something truly unique. Embrace modern technology while preserving traditional craftsmanship to set yourself apart from competitors and establish your brand as a leader in the field of watch making.

In addition to embracing modern technology, it's essential to prioritize customer satisfaction and feedback. By actively seeking out and implementing customer input, you can ensure that your watches meet the needs and desires of your target audience. This customer-centric approach will not only help you build a loyal customer base but also differentiate your brand from others in the industry.

The Future of Watch Making

Innovations in Watch Making Technology

The future of watch making is being shaped by exciting technological advancements. From 3D printing to nanotechnology, the industry is constantly evolving to produce more precise and durable timepieces. These innovations are revolutionizing the way watches are designed and manufactured, ensuring that watch making remains a dynamic and forward-thinking craft.

The integration of CNC (Computer Numerical Control) technology in watch making has opened up new possibilities for creating intricate and complex designs with utmost precision. CNC machines can carve out watch components with incredible accuracy, allowing for the production of highly detailed and customized timepieces. This technology has streamlined the manufacturing process, reducing lead times and increasing production efficiency, ultimately leading to a wider range of innovative designs in the market. As CNC technology continues to advance, we can expect to see even more groundbreaking developments in the world of watch making.

Can You CNC a Watch?

Absolutely! CNC (Computer Numerical Control) machines have become an integral part of modern watch making. These machines allow for incredibly precise and intricate designs to be created with ease, revolutionizing the production process. By utilizing CNC technology, watch makers can achieve unparalleled levels of precision and detail in their timepieces.

Furthermore, the use of CNC machines in watch making has also opened up new possibilities for customization and personalization. With the ability to program intricate designs and patterns into the machines, watch makers can now offer bespoke timepieces to their customers, allowing for a level of individuality and uniqueness that was previously unattainable. This shift towards personalized craftsmanship is reshaping the industry and providing consumers with a more tailored and exclusive experience when it comes to purchasing a watch.

SYIL CNC Machine and its Role in Watch Making

The SYIL CNC machine has emerged as a game-changer in the world of watch making. This cutting-edge technology enables watch makers to create custom components with unparalleled precision and efficiency. With its user-friendly interface and advanced capabilities, the SYIL CNC machine has become an indispensable tool for those looking to elevate their craft and produce exceptional watches.

By embracing these technological advancements, the future of watch making is brighter than ever before. With innovations like 3D printing, nanotechnology, and advanced CNC machines leading the way, the possibilities for creating exquisite timepieces are truly limitless. Watch makers who harness these cutting-edge tools will undoubtedly shape the future of this timeless craft.

Conclusion

Mastering the Art of Watch Making

As we wrap up our exploration of watch making, it's clear that mastering this craft requires dedication, precision, and a deep understanding of the intricate details involved. From choosing the right materials to assembling the delicate components, becoming a master watch maker is no small feat.

Embracing Technology in Watch Making

With the advent of CNC Milling Machines for Watchmaking and Watchmaking with CNC Machining, it's evident that technology has become an integral part of watch making. Embracing these advancements allows for greater precision and efficiency in creating timepieces that stand the test of time.

The Enduring Legacy of Watch Making

Despite technological advancements, the enduring legacy of watch making lies in its rich history and timeless artistry. From intricate designs to precise movements, the tradition of crafting exquisite timepieces continues to captivate enthusiasts and collectors alike.

Can you CNC a watch? Yes! The future of watch making is undoubtedly intertwined with CNC technology. Aspiring watch makers can now explore new possibilities in creating custom watches using CNC Milling Machines for Watchmaking. This opens up exciting opportunities for innovation and creativity in the industry.