Introduction

Are you a fan of the art of watchmaking? Have you ever wondered how to CNC your own watch case? In this guide, we'll explore the importance of CNC in watch case production and the tools and machines needed for DIY watch case making.

The Art of Watchmaking

Watchmaking is a timeless craft that requires precision, skill, and attention to detail. From intricate movements to elegant designs, watchmaking is a true art form that has captivated enthusiasts for centuries.

Importance of CNC in Watch Case Production

CNC milling machines have revolutionized the way watch cases are produced. With their ability to create complex shapes with precision and accuracy, CNC machines have become an essential tool in modern watchmaking.

Tools and Machines Needed for DIY Watch Case

If you've ever wondered how to make a mechanical watch at home, you'll need more than just traditional hand tools. CNC milling machines for watchmaking are crucial, along with CAD software for design and precision measuring instruments.

Understanding CNC for Watch Case Making

CNC Your Own Watch Case is an exciting project that requires a good understanding of CNC machining. With CNC milling machines for watchmaking, you can achieve precision and accuracy in creating intricate watch cases. The basic principles of CNC machining involve programming a computer to control the movements of the machine, allowing for precise cutting and shaping of materials.

Basic Principles of CNC Machining

To make your own watch case, you need to understand the basic principles of CNC machining. This includes learning how to program the machine to follow specific instructions for cutting and shaping metal or other materials. With the right software and knowledge, you can create intricate designs with precise measurements using a CNC milling machine.

Precision and Accuracy in Watch Case Production

When it comes to watchmaking, precision and accuracy are crucial. A small deviation in measurements can affect the functionality and aesthetics of the watch case. With CNC machining, you can achieve unparalleled precision in creating intricate details and achieving perfect measurements for your DIY watch case.

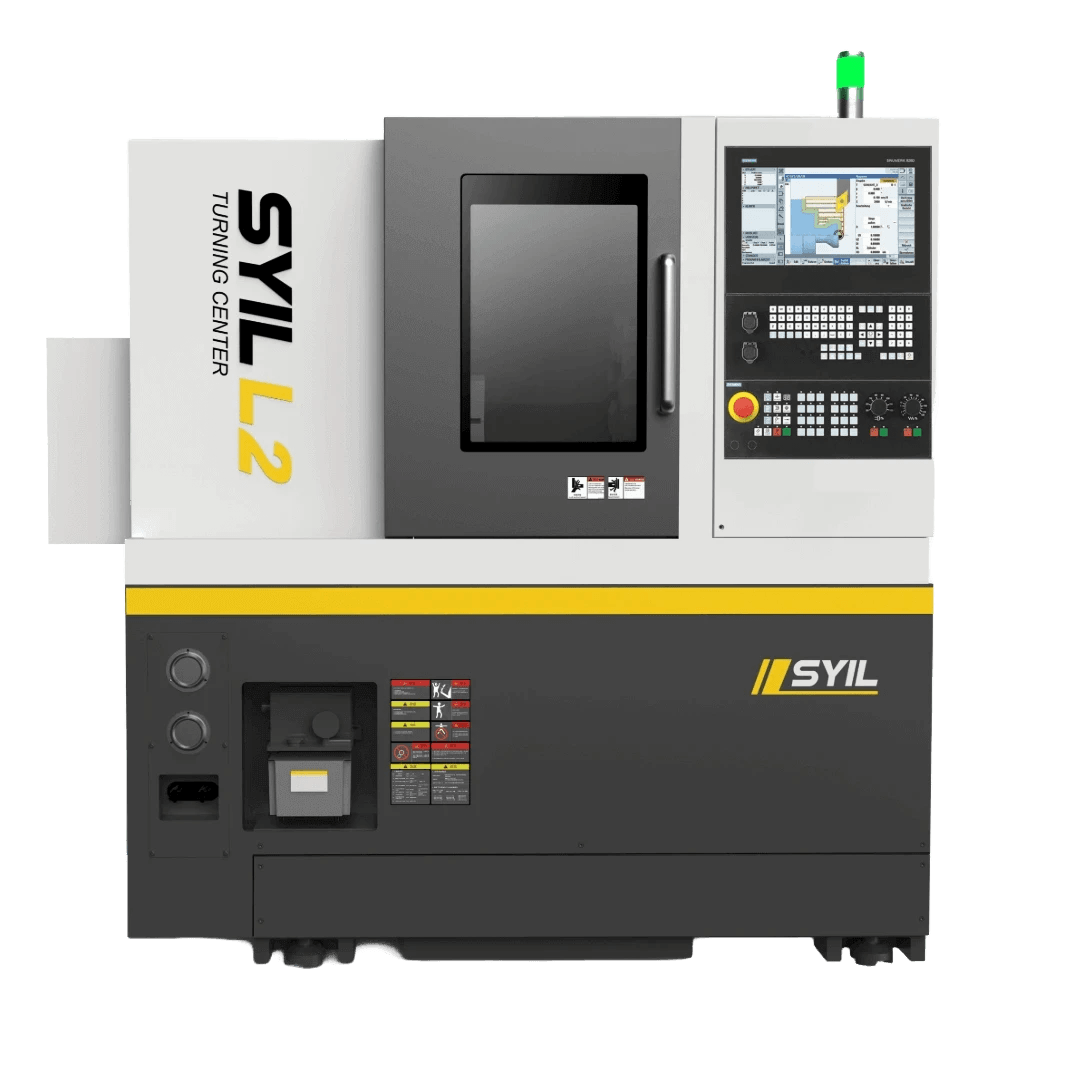

SYIL CNC Machine for Watchmaking

The SYIL CNC machine is an excellent choice for watchmaking with its high precision and reliability. This machine is designed specifically for small-scale manufacturing processes like creating custom watch cases. With its user-friendly interface and advanced capabilities, the SYIL CNC machine is a valuable tool for anyone interested in making their own mechanical watches at home.

Designing Your Watch Case

When it comes to designing your own watch case, CAD software is an essential tool for creating precise and intricate designs. With the use of CAD software, you can easily visualize and customize every detail of your watch case, ensuring that it meets your exact specifications. Whether you prefer a classic round case or a more modern square design, CAD software allows you to bring your vision to life with ease.

CAD Software for Watch Case Design

Utilizing CAD software for watch case design provides you with the ability to create 3D models of your designs, allowing for a more comprehensive understanding of how the final product will look and function. This technology enables you to experiment with different shapes, sizes, and features before committing to the production process, ultimately saving time and resources in the long run. With user-friendly interfaces and powerful design tools, CAD software empowers DIY watchmakers to unleash their creativity and precision.

Customizing Your Watch Case

One of the most exciting aspects of DIY watchmaking is the ability to customize your watch case according to your preferences. Whether you want to incorporate unique engravings, intricate patterns, or personalized details, customizing your watch case allows you to create a timepiece that truly reflects your individual style and personality. By leveraging the capabilities of CAD software and CNC machining technology, you can bring even the most complex designs to life with unparalleled accuracy and craftsmanship.

SYIL CNC Machine and Watch Case Design

The synergy between SYIL CNC machines and watch case design is undeniable – these state-of-the-art machines are specifically engineered for precision manufacturing in watchmaking. With their advanced capabilities in milling and engraving, SYIL CNC machines empower DIY enthusiasts to transform their creative concepts into tangible realities with exceptional accuracy and detail. From intricate dial patterns to unique crown shapes, the combination of SYIL CNC machines and watch case design opens up endless possibilities for crafting bespoke timepieces.

Furthermore, the precision and repeatability of SYIL CNC machines ensure that each watch case is manufactured with consistent quality, meeting the high standards of the watchmaking industry. This level of reliability allows for mass production of watch cases without sacrificing the intricate details and unique designs that set each timepiece apart. As a result, watchmakers can confidently produce a range of custom designs to cater to different tastes and preferences, expanding their market reach and appeal to a wider audience.

CNC Milling Your Watch Case

CNC milling your own watch case is an exciting and rewarding process that allows you to create a truly unique timepiece. To start, you'll need to secure a high-quality CNC milling machine specifically designed for watchmaking. Once you have the right machine, follow a step-by-step guide to set up your design, choose the appropriate cutting tools, and begin the milling process.

Step-by-Step Guide to CNC Milling

To begin CNC milling your watch case, first, load your CAD design into the machine's software and set up the workpiece securely in place. Next, carefully select the appropriate cutting tools and ensure they are properly installed in the machine. Once everything is set up, initiate the milling process and monitor the progress closely to ensure precision and accuracy throughout.

Material Selection for Watch Case

When it comes to material selection for your watch case, consider using high-quality metals such as stainless steel or titanium for durability and aesthetic appeal. These materials are ideal for CNC machining due to their strength and resistance to wear, ensuring that your watch case will stand the test of time.

SYIL CNC Machine and Milling Techniques

The SYIL CNC machine is a game-changer in watchmaking with its advanced capabilities for precise and intricate milling techniques. Equipped with state-of-the-art technology, this machine allows you to achieve unparalleled accuracy in creating intricate designs and details for your custom watch case.

By following this step-by-step guide and utilizing high-quality materials alongside advanced milling techniques with a SYIL CNC machine, you can achieve remarkable results in crafting your own unique watch case that reflects your personal style and creativity.

Finishing and Assembly

When it comes to finishing your DIY watch case, surface finishing is crucial for achieving a professional look. Using CNC milling machines for watchmaking allows for precise and intricate surface finishes, ensuring that your watch case looks sleek and polished. With the right tools and techniques, you can achieve a flawless surface finish that adds a touch of luxury to your homemade timepiece.

Surface Finishing for Watch Case

To achieve a high-quality surface finish for your watch case, you can use techniques such as polishing, brushing, or sandblasting. These methods can be easily executed with the help of CNC milling machines for watchmaking, allowing you to create custom textures and patterns on the surface of your watch case. Whether you prefer a glossy or matte finish, CNC machining gives you the flexibility to achieve the exact look you desire.

Final Assembly of Watch Case

Once the surface finishing is complete, it's time to move on to the final assembly of your watch case. This involves carefully fitting all the components together, including the movement, dial, hands, and crystal. With precision parts made using CNC machining techniques, the assembly process becomes much smoother and more efficient. The result is a professionally assembled watch case that is ready to house its mechanical heart.

Once the surface finishing is complete, it's time to move on to the final assembly of your watch case. This involves carefully fitting all the components together, including the movement, dial, hands, and crystal. With precision parts made using CNC machining techniques, the assembly process becomes much smoother and more efficient. The result is a professionally assembled watch case that is ready to house its mechanical heart.

SYIL CNC Machine and Watch Case Finishing

The SYIL CNC machine plays a crucial role in achieving impeccable finishing for your DIY watch case. Its precision and accuracy ensure that every detail of the design is faithfully reproduced on the final product. By utilizing advanced CNC machining capabilities, you can take your homemade timepiece to the next level with flawless surface finishes that rival those found in luxury watches.

The precision and accuracy of the SYIL CNC machine also ensure consistent quality control and testing throughout the manufacturing process. This means that each watch case produced will meet the highest standards of craftsmanship, giving you peace of mind that your timepiece will stand the test of time. With advanced CNC machining capabilities, you can be confident that every detail, from intricate engravings to smooth edges, will be flawlessly executed, resulting in a finished product that exudes luxury and sophistication.

Quality Control and Testing

When it comes to CNC Your Own Watch Case, ensuring Precision and Accuracy is crucial. Using CNC Milling Machines for Watchmaking allows for incredibly precise cuts and measurements, ensuring that your watch case meets the highest standards of quality. With the right machines and tools, you can achieve the level of precision needed for a flawless watch case.

Ensuring Precision and Accuracy

To achieve the highest level of precision and accuracy in watch case production, it's essential to carefully calibrate your CNC machine, use high-quality materials, and regularly check for any potential errors or deviations in the machining process. This attention to detail will guarantee that your watch case meets the exact specifications required for a perfect fit and finish. Additionally, conducting thorough quality control checks at various stages of production is crucial to ensure that each component meets the required standards. By implementing stringent quality control measures, you can identify and rectify any issues early on, preventing costly rework or product recalls down the line.

Testing for Functionality

After CNC milling your watch case, it's important to thoroughly test its functionality before proceeding with the finishing and assembly process. This includes checking for proper fit with other watch components, assessing water resistance (if applicable), and ensuring that all mechanisms work smoothly. By conducting thorough functionality tests, you can catch any issues early on and make necessary adjustments.

SYIL CNC Machine and Watch Case Quality Control

The SYIL CNC machine plays a critical role in maintaining quality control throughout the watchmaking process. Its precision engineering capabilities allow for consistent results, while its advanced features enable thorough testing of each watch case produced. With the SYIL CNC machine as your partner in watch case production, you can be confident in delivering exceptional quality to your customers or creating a timepiece you can truly be proud of.

The SYIL CNC machine's ability to produce precise and consistent watch cases is unmatched, giving you the confidence to meet the highest standards of quality in the industry. Its advanced features allow for thorough testing of each component, ensuring that every watch case meets your exact specifications. With the SYIL CNC machine as your partner, you can be sure that your timepieces will not only meet but exceed customer expectations, setting your brand apart as a leader in quality and craftsmanship.

Conclusion

In conclusion, mastering the art of DIY watch case making through CNC machining is an attainable goal for any enthusiast. With the right tools and machines, such as the SYIL CNC machine, you can unlock the potential of CNC in watchmaking and create high-quality, custom watch cases from the comfort of your own home.

Achieving Mastery in DIY Watch Case Making

By understanding the principles of CNC machining and utilizing CAD software for design, you can achieve mastery in creating your own watch cases. With precision and accuracy as your guiding principles, you can customize and mill your watch case to perfection using a SYIL CNC machine, resulting in a professional-grade product that rivals those produced by top manufacturers.

Unlocking the Potential of CNC in Watchmaking

The potential of CNC in watchmaking is truly limitless. By harnessing the power of CNC milling machines for watchmaking, you can elevate your craft to new heights and produce intricate designs with unmatched precision. Whether you are a hobbyist or a professional, embracing CNC technology will revolutionize your approach to creating mechanical timepieces.

SYIL CNC Machine: Your Partner in Watch Case Production

The SYIL CNC machine is not just a tool; it is your ultimate partner in watch case production. With its advanced milling techniques and quality control features, this machine empowers you to bring your unique designs to life with ease and efficiency. Embrace the future of watchmaking with SYIL as your trusted ally.