Introduction

Are you fascinated by the intricate details of watchmaking? Do you dream of creating your own custom watch case? Are you curious about the cutting-edge CNC technology that makes it all possible? In this guide, we will delve into the art of making watch cases, from the traditional craftsmanship to the modern CNC techniques.

Exploring the Craft of Watchmaking

Watchmaking is a time-honored craft that has been perfected over centuries. From designing intricate movements to crafting unique cases, every aspect requires precision and skill. Whether you're a seasoned watch enthusiast or a novice hobbyist, there's something truly magical about creating your own timepiece.

The Allure of Custom Watch Cases

Custom watch cases offer a level of personalization and uniqueness that mass-produced watches simply can't match. Imagine designing a case that reflects your individual style and personality, from sleek stainless steel to lightweight titanium. The possibilities are endless when it comes to customizing your own watch case.

Understanding CNC Technology

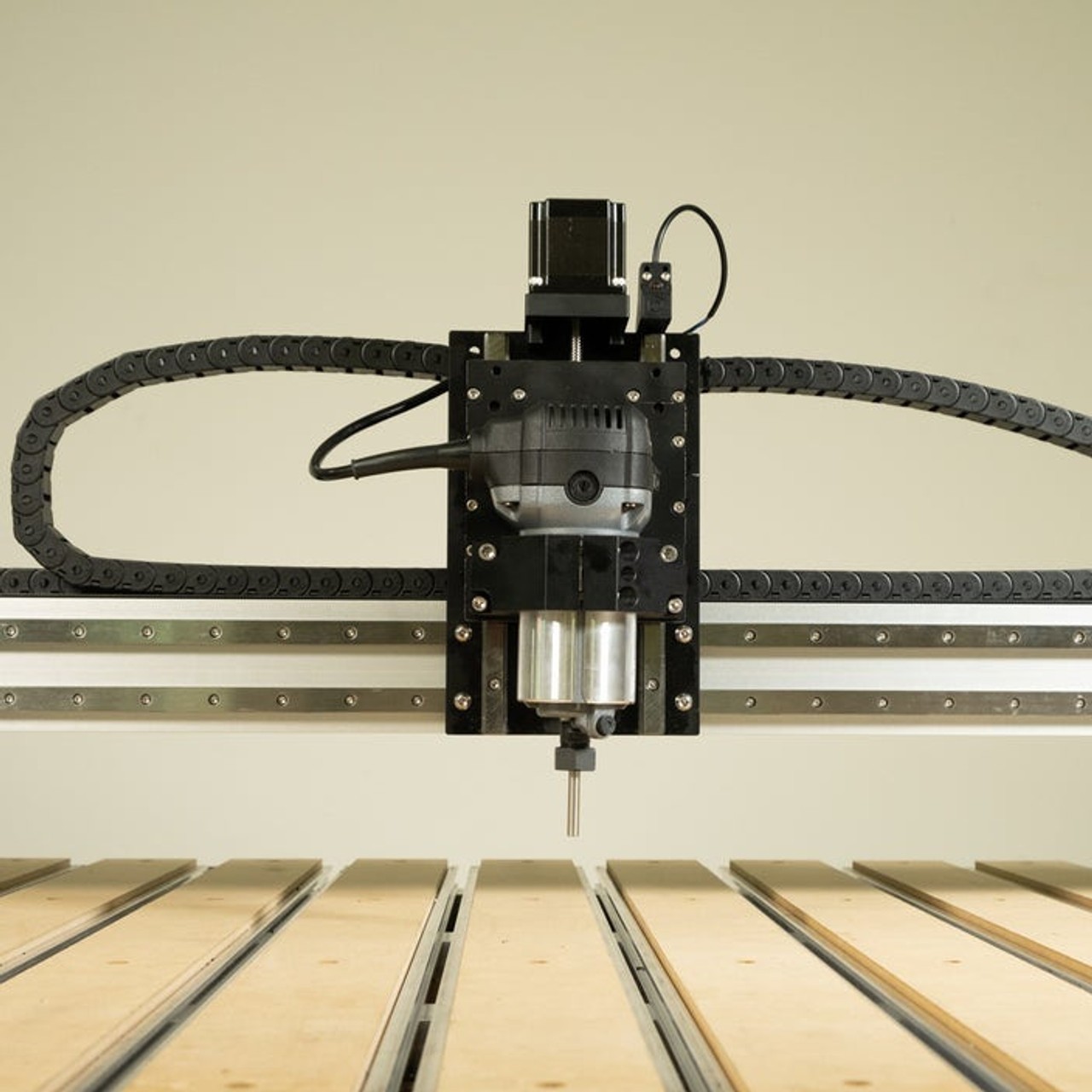

CNC technology has revolutionized the way we create intricate parts and components, including watch cases. With CNC machining, you can bring your designs to life with unparalleled accuracy and efficiency. Whether you're a professional designer or an amateur tinkerer, understanding how CNC technology works is key to realizing your watchmaking dreams.

The Art of Watch Case Design

When it comes to creating a custom watch case, the first step is to sketch your vision. Whether it's a classic round case or a unique geometric shape, sketching allows you to visualize the design and make necessary adjustments before moving on to the next stage.

Utilizing CAD software is essential for turning your sketches into precise digital models. This software enables you to manipulate every detail of the watch case design, ensuring that it meets your exact specifications. From intricate engravings to precise measurements, CAD software brings your vision to life in a virtual environment.

For precision manufacturing of your custom watch case, consider using a SYIL CNC machine. This high-tech equipment ensures that every cut and detail is executed with utmost accuracy, resulting in a flawless final product. With the SYIL CNC machine, you can bring even the most intricate designs to life with ease.

Material Selection for Watch Cases

Exploring Stainless Steel

Stainless steel is a popular choice for watch cases due to its durability and resistance to corrosion. To make a stainless steel watch case, the material is first cut into the desired shape using CNC technology. The pieces are then carefully welded together to form the case, which is then polished to achieve a sleek finish.

Stainless steel watch cases are not only known for their durability and resistance to corrosion but also for their timeless and classic appearance. The sleek finish achieved through careful polishing gives these watch cases a sophisticated and elegant look, making them a popular choice among those who appreciate both style and functionality in their timepieces. Additionally, the versatility of stainless steel allows for various design options, from traditional to modern, catering to a wide range of preferences.

The Appeal of Titanium

Titanium has gained popularity in watchmaking due to its lightweight nature and strength. To make a titanium watch case, the material is milled using CNC technology to create intricate designs and precise dimensions. The result is a durable and stylish watch case that appeals to those seeking a modern and high-quality timepiece.

Steel watch cases are typically made using a process called stamping, where a sheet of steel is cut and then formed into the desired shape using a press. This method allows for mass production of watch cases at a relatively low cost, making steel watches more affordable for consumers. While steel is not as lightweight as titanium, it offers its own set of advantages, including exceptional durability and resistance to corrosion. Many traditional watchmakers continue to use steel in their timepieces, appealing to those who appreciate classic craftsmanship and reliability.

How are steel watch cases made?

Steel watch cases are typically made through a process called stamping, where the metal is pressed into shape using a mold or die. However, with advancements in CNC technology, steel watch cases can now be made with greater precision and customization. By utilizing CNC machines, manufacturers can create unique and intricate designs that were once impossible with traditional methods.

In addition to the precision and customization offered by CNC machines, steel watch cases can also be made more efficiently. With traditional stamping methods, there is often a lot of material waste as the metal is pressed into shape. However, CNC machining allows for more accurate cutting and shaping of the steel, minimizing waste and maximizing the use of materials. This not only benefits manufacturers in terms of cost savings but also contributes to a more sustainable production process.

CNC Machining Process

When learning how to make a watch case, understanding how to design something for a CNC machine is crucial. Utilizing CAD software, designers can create intricate 3D models of their custom watch cases, ensuring precision and accuracy in the machining process. By mastering this skill, watchmakers can bring their unique designs to life with the help of CNC technology.

How to design something for a CNC machine?

Designing something for a CNC machine involves creating a detailed blueprint of the watch case, including precise measurements and specifications. Using CAD software, designers can visualize their ideas in 3D and generate the necessary code for the CNC machine to follow. This step is essential in ensuring that the final product matches the original vision for the custom watch case.

Once the blueprint is complete, the next step is to select the appropriate materials for the custom watch case. This decision will impact the final look and feel of the product, so it's crucial to consider factors such as durability, weight, and aesthetics. Whether opting for stainless steel, titanium, or a precious metal like gold, designers must ensure that the chosen material aligns with their vision for the finished piece.

Precision Cutting with CNC Technology

CNC machines are capable of executing precise cuts and shaping techniques that would be nearly impossible to achieve by hand. The advanced technology allows for intricate details and complex patterns to be accurately reproduced on stainless steel watch cases, resulting in a flawless finished product that meets exact specifications.

CNC machines have revolutionized the watch manufacturing industry by allowing for the production of intricate and complex designs with unparalleled precision. The ability to accurately reproduce detailed patterns on stainless steel watch cases has opened up a world of possibilities for creating unique and custom designs that were previously unattainable. This level of precision has elevated the quality of finished products, ensuring that each watch case meets exact specifications and reflects the highest standards of craftsmanship.

Custom CNC watch case production

With the ability to program specific cutting paths and tool movements, custom CNC watch case production offers unparalleled flexibility and customization options. This process allows for unique designs to be brought to life with ease, while also streamlining production and reducing costs associated with traditional manufacturing methods. Additionally, CNC machining allows for intricate detailing and precision that may not be achievable through other methods, ensuring that every watch case is crafted to perfection. The use of computer-controlled machinery also minimizes the margin for error, resulting in consistently high-quality products that meet the exact specifications of the design.

Finishing Touches for Your Watch Case

Polishing and Brushing Techniques

When it comes to adding the final touches to your custom watch case, polishing and brushing techniques are essential for achieving a flawless finish. Polishing involves using abrasive materials to smooth the surface of the watch case, while brushing creates a textured finish with fine lines. Both techniques require precision and attention to detail to ensure a high-quality result that enhances the overall aesthetics of your stainless steel watch case.

To further enhance the look of your custom watch case, consider the option of PVD coating. This process involves applying a thin film of coating to the surface of the watch case using a vacuum deposition method. PVD coating offers a wide range of color options, including black, gold, rose gold, and more, allowing you to customize the appearance of your stainless steel watch case to suit your personal style. Additionally, PVD coating provides increased durability and resistance to scratches and corrosion, ensuring that your custom watch case maintains its pristine finish for years to come.

PVD Coating Options

PVD (Physical Vapor Deposition) coating offers a range of options for enhancing the appearance and durability of your custom CNC watch case. This process involves depositing a thin film of material onto the surface of the watch case through a vacuum coating technique. PVD coatings can provide your watch case with increased resistance to wear, corrosion, and fading, while also offering a variety of color options to suit your personal style.

In addition to enhancing the appearance and durability of your custom CNC watch case, PVD coating can also provide a smooth and uniform finish, adding a touch of luxury to your timepiece. This coating option allows for precise control over the thickness and composition of the deposited film, ensuring a high-quality result that meets your exact specifications. With PVD coatings, you can achieve the look and feel of premium materials such as gold, rose gold, or black stainless steel at a fraction of the cost.

How to Make CNC Parts Cheaper?

To make CNC parts cheaper without compromising on quality, consider optimizing your designs for cost-effective production. This can involve minimizing material waste, streamlining machining processes, and utilizing standard tooling sizes to reduce manufacturing costs. Additionally, sourcing materials from reputable suppliers and maximizing machine utilization can help lower production expenses without sacrificing the precision and quality of your custom CNC watch case.

Remember that these finishing touches play an integral role in bringing your custom watch case design to life, enhancing its visual appeal and durability. By mastering polishing and brushing techniques, exploring PVD coating options, and implementing cost-saving strategies for CNC parts production, you can create a truly unique stainless steel watch case that reflects your individuality.

Conclusion

Bringing Your Custom Watch Case to Life

With an understanding of material selection, CNC machining processes, and finishing touches, it's time to bring your custom watch case to life. By combining traditional craftsmanship with modern technology, you can create a timeless piece that reflects your individuality and style. The possibilities are endless when it comes to designing your own unique timepiece. Once you have finalized the design and materials for your custom watch case, it's time to consider the intricate details that will truly make it stand out. From personalized engravings to unique dial designs, these finishing touches will add a touch of personality and flair to your bespoke timepiece. Whether it's a special date, initials, or a meaningful symbol, these small details can make a big impact on the overall look and feel of your custom watch.

DIY Watchmaking with CNC Technology

By harnessing the power of CNC technology, DIY watchmaking has become an exciting endeavor for enthusiasts. Whether you're drawn to sleek stainless steel or the allure of titanium, CNC machining allows for precise customization at an affordable cost. Embrace the freedom of creating something truly exceptional that showcases your personal taste. Moreover, with the accessibility of online tutorials and forums, aspiring watchmakers can easily find support and guidance from experienced hobbyists. This sense of community adds an extra layer of enjoyment to the DIY watchmaking process, as you connect with like-minded individuals who share your passion for horology.

How to make a mechanical watch at home?

Embarking on the journey of making a mechanical watch at home is both challenging and rewarding. From sourcing quality components to mastering assembly techniques, this hands-on experience offers an intimate understanding of horology. With dedication and patience, crafting a mechanical timepiece becomes an enriching pursuit that celebrates craftsmanship and precision craftsmanship.

After sourcing the necessary components such as the movement, dial, hands, and case, the next step is to carefully assemble each part with precision and attention to detail. This process requires steady hands and a keen eye for alignment to ensure that the watch functions properly. Assembling a mechanical watch at home also provides an opportunity to customize the design, from choosing the type of movement to selecting unique dial and hand combinations.