Introduction

In the dynamic world of aviation, aerospace sheet metal fabrication plays a pivotal role in ensuring that aircraft are both lightweight and structurally sound. The precision required in this industry is not just a luxury; it’s a necessity that directly impacts safety and performance. As technology evolves, innovations in the sheet metal process continue to push the boundaries of what’s possible in aerospace manufacturing.

The Role of Fabrication in Aerospace

Fabrication is the backbone of the aerospace industry, providing essential components that make flight possible. From fuselage frames to wing structures, every piece must be meticulously crafted to withstand extreme conditions while maintaining optimal performance. Aerospace sheet metal fabrication stands out as a critical area where precision engineering meets cutting-edge technology.

Importance of Precision Engineering

Precision engineering is paramount in aerospace CNC machining, where even the tiniest error can have catastrophic consequences. This meticulous focus on accuracy ensures that components fit perfectly and function reliably under pressure, contributing to overall safety and efficiency in flight operations. With advancements in technology, engineers can now achieve levels of precision previously thought unattainable.

Innovations in Sheet Metal Process

The landscape of aerospace sheet metal fabrication is rapidly evolving with innovative techniques and technologies reshaping traditional processes. CNC machining for the aerospace industry has introduced automated systems that significantly enhance productivity while reducing human error. These innovations not only streamline production but also allow for more complex designs that were once impossible to create efficiently.

Understanding Aerospace Sheet Metal Fabrication

Aerospace sheet metal fabrication is a crucial process in the aviation industry, where precision and reliability are non-negotiable. This technique involves shaping and assembling metal sheets into components that meet stringent specifications for aircraft design and functionality. The importance of aerospace sheet metal fabrication cannot be overstated, as it directly impacts the safety, performance, and longevity of aircraft.

Definition and Importance

Aerospace sheet metal fabrication refers to the production of parts from thin sheets of metal using various techniques such as cutting, bending, and assembly. This process is vital because it allows manufacturers to create lightweight yet strong components that can withstand the extreme conditions encountered during flight. The precision achieved through CNC machining for the aerospace industry ensures that every part fits seamlessly within complex assemblies, contributing to overall aircraft performance.

The significance of this fabrication method extends beyond mere component creation; it plays a critical role in ensuring compliance with rigorous aviation standards. Each piece produced through aerospace CNC machining must adhere to strict regulations set by organizations like the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency). Thus, understanding what is CNC machine used in aerospace industry contexts becomes essential for maintaining safety protocols while enhancing operational efficiency.

Common Materials Used

In aerospace sheet metal fabrication, several materials are commonly utilized due to their unique properties suited for aviation applications. Aluminum alloys are among the most popular choices because they offer an excellent strength-to-weight ratio along with corrosion resistance—ideal characteristics for aircraft components exposed to harsh environments. Additionally, titanium is gaining traction due to its superior strength at high temperatures, making it suitable for engine parts and other critical applications.

Other materials include stainless steel and composites which are increasingly being integrated into designs thanks to advancements in technology. Stainless steel provides durability while resisting fatigue under varying stress conditions; meanwhile, composites allow for innovative designs without compromising weight or integrity. The choice of material significantly influences how effective the sheet metal fabrication in the aerospace sector can be.

Typical Applications in Aircraft

The applications of aerospace sheet metal fabrication span a wide range within aircraft construction and maintenance processes. Components such as fuselage skins, wing structures, and engine casings are all products of this intricate manufacturing process—each requiring high levels of precision achieved through advanced CNC machining techniques. Moreover, interior elements like brackets or panels also benefit from this form of fabrication by ensuring both aesthetics and functionality.

Furthermore, aviation & aerospace CNC machining capabilities extend beyond new builds; they also play a critical role in repair operations where existing parts need modification or replacement without compromising quality or safety standards. The ability to cut sheet metal with a CNC machine ensures that repairs can be performed quickly while maintaining adherence to original specifications—essentially minimizing downtime during maintenance cycles.

As industries continue evolving toward more efficient practices, understanding what an aerospace CNC machinist does becomes increasingly important—they are not just operators but skilled craftsmen who ensure each part meets stringent requirements vital for safe air travel.

The Advantages of CNC Machining for the Aerospace Industry

CNC machining has revolutionized aerospace sheet metal fabrication, offering an array of benefits that are crucial for the industry's demanding standards. In a sector where precision and efficiency are paramount, CNC machining for the aerospace industry stands out as a game changer. From enhancing accuracy to optimizing production processes, this technology is reshaping how we approach sheet metal fabrication in the aerospace field.

Enhanced Precision and Accuracy

One of the most significant advantages of aerospace CNC machining is its unparalleled precision and accuracy. Traditional methods often struggle to achieve the tight tolerances required in aviation & aerospace CNC machining capabilities; however, CNC machines excel in this area by utilizing computer-controlled processes that minimize human error. This level of precision is essential when working with materials like aluminum and titanium, where even minor deviations can lead to catastrophic failures.

The ability to cut sheet metal with a CNC machine ensures that components fit together seamlessly during assembly, reducing rework and enhancing overall quality. In an industry where safety is non-negotiable, having accurate parts means fewer risks and greater reliability in aircraft operations. As such, enhanced precision not only improves product quality but also instills confidence among manufacturers and operators alike.

Streamlined Production Processes

CNC machining significantly streamlines production processes within the realm of aerospace sheet metal fabrication. By automating various tasks—from cutting to drilling—these machines reduce manual labor while increasing throughput rates. This efficiency allows manufacturers to meet tight deadlines while maintaining high-quality standards across their product lines.

Moreover, advanced programming capabilities enable quick adjustments to designs without extensive downtime or retooling costs, making it easier to adapt to changing project requirements or specifications. The result is a more agile manufacturing environment that can respond swiftly to market demands or client requests while ensuring consistency in output quality across all components produced through aerospace CNC machining.

Reduction of Material Waste

Another critical advantage offered by CNC machining for the aerospace industry is its ability to significantly reduce material waste during production processes. Traditional methods often involve excessive cutting away of materials, leading not only to increased costs but also environmental concerns regarding resource usage. However, with precise cutting techniques employed by CNC machines, manufacturers can optimize their material usage effectively.

This reduction in waste translates into lower operational costs—an attractive proposition for any business looking to enhance profitability without compromising on quality or safety standards essential in aviation & aerospace applications. Additionally, minimizing waste aligns with sustainability goals increasingly prioritized by companies within the industry today; thus contributing positively towards environmental stewardship efforts as well.

Key Technologies in Aerospace CNC Machining

In the realm of aerospace sheet metal fabrication, technology plays a pivotal role in enhancing efficiency and precision. The integration of advanced CNC machining for the aerospace industry has revolutionized how components are designed and manufactured, ensuring that they meet stringent safety and performance standards. This section delves into key technologies that are shaping the future of aerospace CNC machining, including an overview of SYIL CNC machines, advanced software integration, and automation in fabrication.

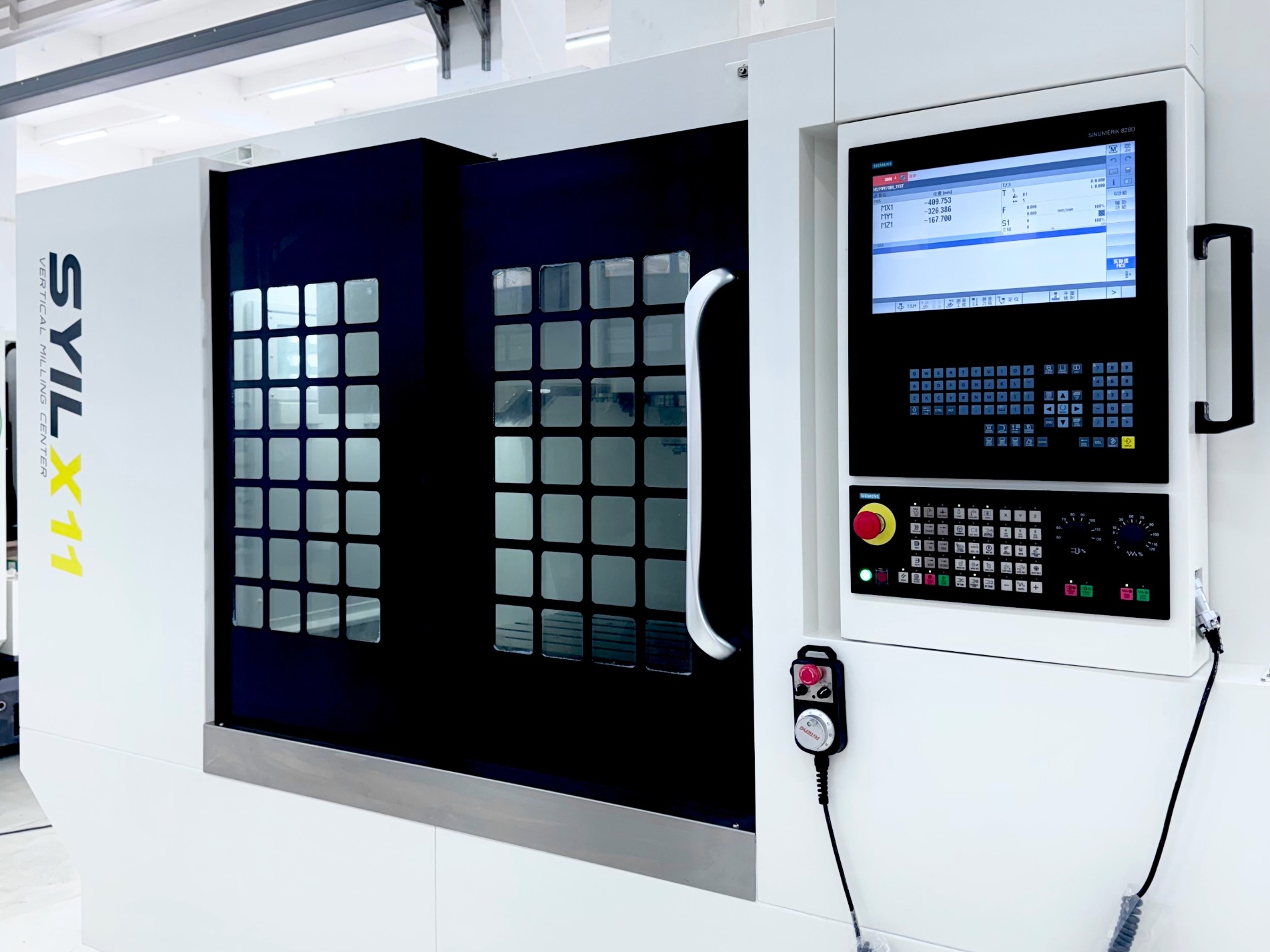

Overview of SYIL CNC Machines

SYIL CNC machines stand out in the world of aerospace sheet metal fabrication for their ability to deliver high precision and reliability. Designed specifically for intricate tasks required in aviation & aerospace CNC machining capabilities, these machines offer a range of features tailored to meet the industry's demands. With their robust build quality and user-friendly interfaces, SYIL machines have become a go-to choice for many aerospace manufacturers looking to streamline their production processes.

What is a CNC machine used in the aerospace industry? Primarily, these machines cut, shape, and finish materials with incredible accuracy—essential when producing components that must withstand extreme conditions. Furthermore, SYIL's commitment to innovation ensures that their models are always equipped with the latest technology to enhance productivity while minimizing waste.

Advanced Software Integration

The backbone of effective aerospace CNC machining lies not only in hardware but also in advanced software integration. Cutting-edge software solutions allow engineers to design complex geometries with ease while optimizing workflows throughout the manufacturing process. By leveraging software tools specifically developed for sheet metal fabrication in the aerospace sector, manufacturers can achieve unprecedented levels of accuracy and efficiency.

These programs enable seamless communication between design teams and machinists by converting CAD models directly into machine instructions—eliminating potential errors associated with manual input. As a result, what is an aerospace CNC machinist's role has evolved; they now focus on overseeing operations rather than merely executing them manually. This shift underscores how vital software has become in modernizing traditional practices within the industry.

Automation in Fabrication

Automation is transforming sheet metal fabrication in the aerospace sector by increasing production speed while maintaining high-quality standards. With advancements such as robotic arms working alongside CNC machines, manufacturers can automate repetitive tasks—from cutting to assembly—freeing up skilled workers for more complex duties that require human oversight or creativity. This shift not only enhances operational efficiency but also reduces labor costs associated with manual handling.

Moreover, automated systems improve consistency across batches of parts produced through precision engineering techniques inherent to aviation & aerospace CNC machining capabilities. As such innovations continue to evolve within this domain, questions like Can you cut sheet metal with a CNC? receive affirmative answers as automated systems handle various materials effortlessly without compromising quality or safety standards.

Challenges in Sheet Metal Fabrication in the Aerospace

In the world of aerospace sheet metal fabrication, challenges abound, but they are not insurmountable. The industry must navigate material limitations, stringent compliance standards, and a growing skill gap within the workforce. Addressing these challenges is essential for maintaining efficiency and innovation in aerospace CNC machining.

Material Limitations and Solutions

Lightweight yet durable materials such as aluminum and titanium are frequently used; however, these materials can pose challenges during fabrication due to their unique properties. To counteract these limitations, advancements in CNC machining for the aerospace industry have introduced innovative techniques that optimize cutting processes and enhance material handling—allowing manufacturers to achieve precision without compromising on quality.

For instance, specialized CNC machines can effectively cut sheet metal with minimal distortion, ensuring that even complex designs meet rigorous specifications. Additionally, implementing advanced coatings and treatments can enhance material performance while reducing wear during machining processes. As a result, the industry is continuously evolving to find solutions that mitigate material-related challenges while maximizing efficiency in aerospace CNC machining.

Compliance with Industry Standards

Compliance with industry standards is non-negotiable in aviation & aerospace CNC machining capabilities; any oversight can lead to catastrophic consequences. Regulatory bodies such as the Federal Aviation Administration (FAA) impose strict guidelines on manufacturing processes to ensure safety and reliability in aircraft components produced through sheet metal fabrication in the aerospace sector. Companies must invest time and resources into understanding these regulations and integrating them into their workflows.

To stay compliant, manufacturers often turn to advanced software systems that help track quality control measures throughout production stages. These systems enable real-time monitoring of processes—ensuring adherence to standards while minimizing errors or defects associated with human oversight. Ultimately, a commitment to compliance not only safeguards public safety but also enhances a company's reputation within the competitive landscape of aerospace manufacturing.

Skill Gaps in the Workforce

One of the more pressing issues facing sheet metal fabrication in the aerospace industry today is a notable skill gap among workers. As technology advances—especially with innovations like CNC machines—the demand for skilled operators who understand both traditional techniques and modern capabilities has surged dramatically. Unfortunately, educational institutions often struggle to keep pace with this rapid evolution of skills required for roles such as an aerospace CNC machinist.

To bridge this gap, companies are increasingly investing in training programs tailored specifically for their needs—fostering talent from within rather than relying solely on external hires. This approach not only equips employees with valuable skills but also cultivates loyalty by demonstrating an investment in their professional growth. By addressing skill gaps proactively through targeted education initiatives, businesses can ensure they remain competitive while upholding high standards of excellence in aviation & aerospace CNC machining capabilities.

Future Trends in Aviation & Aerospace CNC Machining

The landscape of aviation and aerospace CNC machining is rapidly evolving, driven by technological advancements and the need for efficiency. As the industry strives for lighter, stronger, and more efficient components, several key trends are emerging that will shape the future of aerospace sheet metal fabrication. Understanding these trends is crucial for manufacturers looking to stay competitive in a dynamic market.

Adoption of Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is making waves in aerospace sheet metal fabrication. This innovative approach allows for the creation of complex geometries that traditional methods struggle to achieve, significantly enhancing design flexibility. By integrating additive manufacturing into their processes, aerospace companies can reduce lead times and production costs while maintaining high standards of precision.

Moreover, this technology supports rapid prototyping and customization—two essential elements in the fast-paced aerospace industry. As manufacturers seek to optimize their CNC machining for the aerospace industry, incorporating additive techniques can lead to lighter components without sacrificing strength or durability. Ultimately, embracing additive manufacturing will redefine how we think about what is possible in aerospace CNC machining.

Increased Use of Composite Materials

The shift towards composite materials represents another significant trend within aviation and aerospace CNC machining capabilities. Composites offer remarkable strength-to-weight ratios compared to traditional metals used in sheet metal fabrication in the aerospace sector. This change not only improves fuel efficiency but also enhances overall aircraft performance.

As composite materials become more prevalent, there will be an increased demand for specialized machinery capable of handling these advanced materials effectively. Aerospace CNC machinists must adapt their skills to work with composites while ensuring that production processes remain streamlined and efficient. The combination of composites with precise CNC machining techniques will pave the way for innovative designs and improved aircraft longevity.

Innovations in Robotics and Automation

Robotics and automation are transforming how we approach sheet metal fabrication in the aerospace industry by enhancing precision and efficiency on production lines. With advancements like collaborative robots (cobots) working alongside human operators, tasks such as welding or assembly can now be performed with greater accuracy than ever before. This shift not only speeds up production but also reduces human error—a critical factor when it comes to safety in aviation.

Furthermore, integrating robotics into Aerospace CNC machining processes allows companies to scale operations without compromising quality standards or increasing labor costs significantly. As automation continues to evolve within this sector, manufacturers must remain agile and open-minded about new methodologies that can streamline operations while ensuring compliance with stringent industry regulations. The marriage between robotics and sheet metal fabrication heralds a new era where efficiency meets innovation seamlessly.

Conclusion

In the ever-evolving realm of aerospace, innovation stands as a cornerstone for success. The integration of advanced technologies such as CNC machining has revolutionized aerospace sheet metal fabrication, enabling manufacturers to meet the rigorous demands of the industry. As we look to the future, it is clear that continuous improvement in processes and materials will be essential for maintaining a competitive edge.

The Critical Role of Innovation

Innovation is not just a buzzword; it is the lifeblood of aerospace sheet metal fabrication. With each technological advancement, from enhanced CNC machining for the aerospace industry to cutting-edge materials, manufacturers can achieve unprecedented levels of precision and efficiency. This relentless pursuit of innovation ensures that companies can adapt to changing regulations and customer needs while pushing the boundaries of what is possible in aviation.

The Future of Aerospace Fabrication

The future of aerospace fabrication looks promising, driven by advancements in automation and material science. We are likely to see an increased emphasis on Aerospace CNC machining capabilities that incorporate additive manufacturing techniques alongside traditional methods. By leveraging new technologies and materials, manufacturers can create lighter, stronger components that enhance aircraft performance while reducing costs—a win-win scenario for all stakeholders involved.

How to Choose the Right Machining Partner

Choosing the right machining partner is crucial for any organization involved in sheet metal fabrication in the aerospace sector. Look for a partner with proven expertise in CNC machining specifically tailored for the aerospace industry; this includes understanding what CNC machines are used in aerospace applications and their capabilities. Additionally, consider factors such as compliance with industry standards, material handling expertise, and their ability to innovate—after all, your partner should be as committed to pushing boundaries as you are.