Introduction

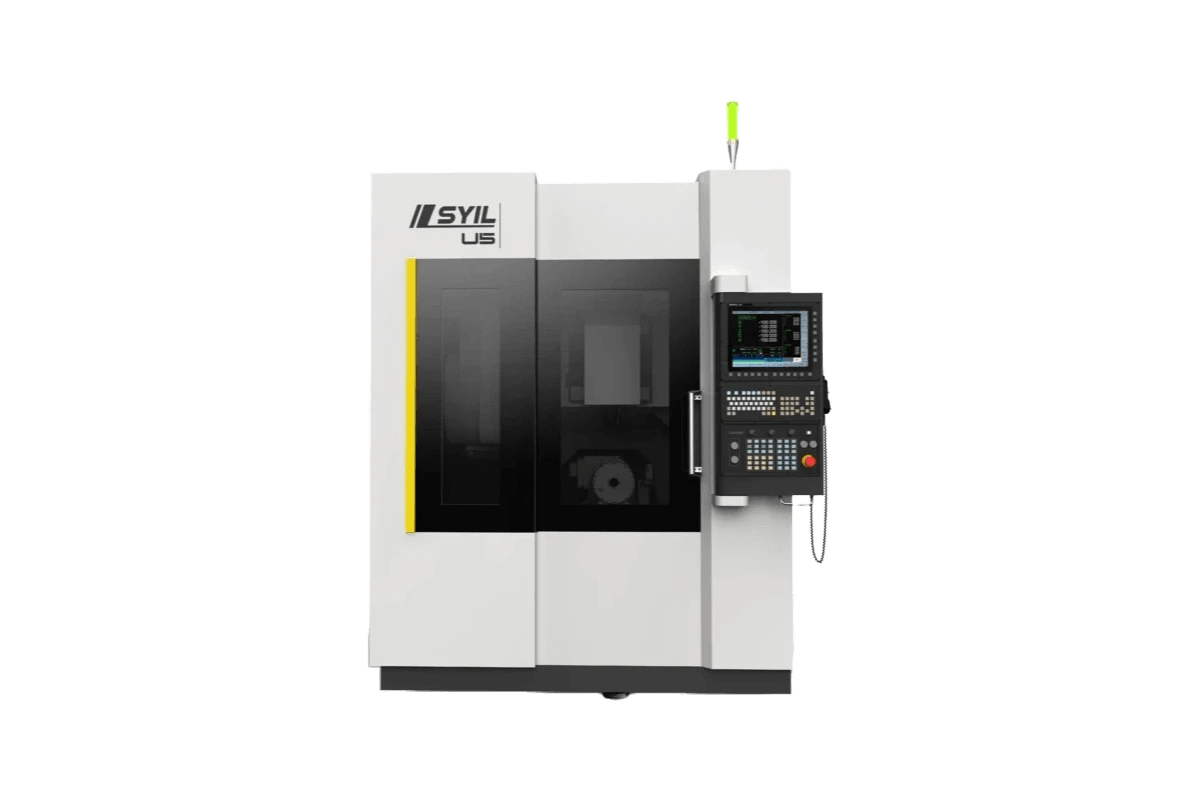

The SYIL U5 Vertical Machining Center is a state-of-the-art CNC vertical machine that revolutionizes industrial machining operations. With its advanced 5-axis capabilities, it enables precise and complex simultaneous machining, making it a game-changer for manufacturing processes. As an essential tool in modern production facilities, CNC vertical machines like the SYIL U5 play a crucial role in enhancing efficiency and productivity.

The SYIL U5 Vertical Machining Center

The SYIL U5 is a cutting-edge 5-axis CNC mill designed for industrial machinists, offering numerous advanced features. It enables simultaneous 5-axis machining for complex, precise operations, allowing the creation of intricate, multi-sided parts. With a spacious work envelope of 500 x 400 x 250 mm, it accommodates various part sizes and shapes, featuring full 360-degree A-axis and 150-degree B-axis rotations for maximum flexibility.

The Benefits of 5-Axis Machining

One of the key advantages of utilizing 5-axis machining is the increased efficiency it brings to manufacturing processes. By allowing for multi-sided machining in a single setup, it reduces the need for multiple operations and minimizes handling time. This results in higher throughput and lower production costs, making it an attractive option for businesses seeking to streamline their operations.

Why CNC Vertical Machines are Essential

CNC vertical machines are essential tools in modern manufacturing due to their ability to perform precise and complex operations with ease. Their versatility makes them indispensable in industries such as aerospace, automotive, and medical device manufacturing. By leveraging advanced technology and innovative design, these machines play a pivotal role in driving progress and innovation across various sectors.

The SYIL U5 Vertical Machining Center

The SYIL U5 vertical machining center is a state-of-the-art 5-axis CNC mill designed to meet the demands of industrial machinists. Its advanced features make it an ideal choice for precision machining operations, offering unparalleled performance and flexibility.

Features of the SYIL U5

The SYIL U5 is equipped with a high-speed spindle that can reach up to 30,000 RPM, ensuring rapid and efficient cutting for high-volume production. Its 32-tool capacity carousel-style automatic tool changer minimizes downtime and maximizes productivity, making it a valuable asset for any manufacturing operation.

The SYIL U5 also features a robust and reliable Siemens 828D CNC control system, providing precision and accuracy in machining operations. This advanced control system allows for seamless integration with CAD/CAM software, streamlining the programming process and ensuring consistent quality in the finished products. With its user-friendly interface and intuitive operation, the SYIL U5 makes complex 5-axis machining accessible to operators of all skill levels.

Simultaneous 5-Axis Machining

One of the key highlights of the SYIL U5 is its ability to perform simultaneous 5-axis machining, allowing for the creation of complex and intricate multi-sided parts with unparalleled precision. This capability opens up a world of possibilities for machinists, enabling them to tackle challenging projects with ease and efficiency.

The SYIL U5's simultaneous 5-axis machining capability not only allows for the creation of complex and intricate multi-sided parts, but also ensures unparalleled precision in every detail. This advanced feature opens up a world of possibilities for machinists, empowering them to take on challenging projects with confidence and efficiency. With the ability to maneuver in multiple directions simultaneously, the SYIL U5 provides a level of flexibility and accuracy that is unmatched in the industry.

Spacious Work Envelope

With a generous work envelope measuring 500 x 400 x 250 mm, the SYIL U5 can accommodate various part sizes and shapes, providing flexibility and versatility in machining operations. Its full 360-degree A-axis and 150-degree B-axis rotations offer maximum maneuverability, allowing machinists to achieve their desired outcomes with ease.

The SYIL U5's spacious work envelope not only accommodates various part sizes and shapes but also provides the flexibility and versatility needed for a wide range of machining operations. With its full 360-degree A-axis and 150-degree B-axis rotations, machinists can easily maneuver the machine to achieve their desired outcomes with precision and efficiency. This level of maneuverability sets the SYIL U5 apart, allowing manufacturers to take on complex machining tasks with ease and confidence.

By incorporating the SYIL U5 into their operations, manufacturers can harness its advanced capabilities to streamline their production processes and achieve superior results in precision machining tasks.

Advantages of 5-Axis Machining

Increased Efficiency

5-axis machining with a CNC vertical machine like the SYIL U5 offers increased efficiency by reducing the need for multiple setups and tool changes. This results in faster production times and higher output, optimizing the overall manufacturing process.

By streamlining the manufacturing process, 5-axis machining with a CNC vertical machine like the SYIL U5 also allows for the production of complex parts with greater ease and precision. This technology enables the machine to access hard-to-reach areas and produce intricate geometries that would be difficult or impossible to achieve with traditional machining methods. As a result, manufacturers can take on more challenging projects and expand their capabilities, attracting a wider range of clients and opportunities.

Complex Part Production

The SYIL U5 vertical machine enables complex part production with its simultaneous 5-axis machining capabilities. This allows for intricate and multi-sided parts to be manufactured with precision, accuracy, and consistency, meeting the demands of diverse industries.

Furthermore, the SYIL U5 vertical machine's advanced technology and innovative design contribute to reduced set-up time, allowing for quick and efficient production of complex parts. This means that manufacturers can streamline their operations, increase productivity, and meet tight deadlines without compromising on quality. With its user-friendly interface and automated features, the machine minimizes human intervention, reducing the risk of errors and ensuring consistent output.

Reduced Set-Up Time

Utilizing a CNC vertical milling machine like the SYIL U5 significantly reduces set-up time due to its advanced features and user-friendly software. This streamlines operations, minimizes downtime, and ultimately increases productivity, making it an essential asset for modern manufacturing facilities.

In addition to reducing set-up time, the SYIL U5 CNC vertical milling machine also offers precise and accurate machining capabilities. This ensures that parts are manufactured with high quality and consistency, reducing the need for rework or adjustments. The machine's ability to produce complex components with tight tolerances further enhances its value in modern manufacturing facilities.

The Importance of Vertical Machine Supplier

When considering a vertical machine supplier, quality and reliability are paramount. A reputable supplier ensures that their CNC vertical machines are built to last, with durable components and precision engineering. This guarantees consistent performance and longevity, reducing the risk of costly downtime and maintenance issues.

Quality and Reliability

A reliable vertical machine supplier invests in top-notch materials and rigorous quality control measures to deliver machines that meet the highest industry standards. By choosing a trusted supplier like SYIL for your CNC vertical machine needs, you can rest assured that you are getting a high-quality, reliable product that will consistently deliver exceptional results.

Customer Support and Service

In addition to the quality of the machines themselves, the level of customer support and service provided by a vertical machine supplier is crucial. SYIL offers comprehensive support, including technical assistance, maintenance services, and training programs to ensure that their customers can maximize the performance of their CNC vertical machines.

Furthermore, SYIL is committed to staying ahead of the curve when it comes to technological advancements and innovation. They continuously invest in research and development to ensure that their CNC vertical machines are equipped with the latest features and capabilities. This dedication to advanced technology allows SYIL's customers to benefit from state-of-the-art equipment that can meet the demands of modern manufacturing processes.

Advanced Technology and Innovation

The best vertical machine suppliers stay ahead of the curve by incorporating advanced technology and innovation into their products. SYIL is at the forefront of technological advancements in CNC vertical milling, continuously improving their machines to meet evolving industry demands for precision, efficiency, and versatility.

SYIL's commitment to innovation and cutting-edge technology has enabled them to produce vertical milling machines that are not only precise and efficient but also incredibly versatile. This versatility allows their machines to be used across a wide range of industries, from aerospace and automotive to medical device manufacturing and beyond. By staying ahead of the curve, SYIL ensures that their vertical turning centers can adapt to the evolving needs of various industries, making them a top choice for businesses looking to invest in advanced machining technology.

Now let's move on to explore the applications of vertical turning centers in various industries.

Applications of Vertical Turning Centers

The versatility and precision of vertical turning centers make them indispensable in various industries, including aerospace, automotive, and medical device manufacturing. In the aerospace industry, CNC vertical machines play a crucial role in producing complex components such as turbine blades and engine parts with high accuracy and efficiency. Similarly, the automotive industry relies on vertical turning centers for manufacturing intricate components like transmission shafts and gearboxes. Moreover, in medical device manufacturing, these machines are used to create precise implants and surgical instruments with intricate geometries to meet the stringent quality standards.

Aerospace Industry

In the aerospace industry, vertical turning centers are used to manufacture critical components such as aircraft engine parts and structural elements. These machines enable the production of complex geometries with tight tolerances required for aerospace applications. The 5-axis capabilities of CNC vertical machines allow for simultaneous machining from multiple angles, ensuring the creation of intricate parts with high precision and efficiency. The use of advanced cutting tools and high-speed spindles further enhances the productivity of vertical turning centers in meeting the demanding requirements of the aerospace sector.

Automotive Industry

In the automotive industry, vertical turning centers are utilized for producing a wide range of components such as engine blocks, cylinder heads, and transmission parts. These machines enable manufacturers to achieve high levels of accuracy and surface finish quality essential for automotive applications. The simultaneous 5-axis machining capability allows for efficient production of complex shapes and contours required in modern vehicle designs. Additionally, CNC vertical milling technology facilitates rapid tool changes and reduces setup times, enabling automotive manufacturers to enhance their production efficiency while maintaining superior part quality.

Medical Device Manufacturing

The medical device manufacturing sector relies on CNC vertical machines to produce intricate components such as orthopedic implants, surgical instruments, and medical devices with complex geometries. Vertical turning centers offer precise multi-axis machining capabilities that are essential for creating customized medical implants tailored to individual patient requirements. With advanced tooling options and high-speed spindles, these machines ensure exceptional surface finishes and dimensional accuracies critical for medical applications.

By leveraging the capabilities of 5-axis machining technology provided by CNC vertical machines from a reliable supplier like SYIL U5 Vertical Machining Center offers unparalleled versatility across diverse industries.

The Future of CNC Vertical Machines

As the demand for precision and efficiency continues to rise, technological advancements in CNC vertical machines are inevitable. Manufacturers are constantly innovating to improve spindle speed, tool capacity, and overall machine performance. These advancements aim to enhance productivity and reduce production costs, making CNC vertical machines even more indispensable in modern manufacturing.

Technological Advancements

Technological advancements in CNC vertical machines are focused on enhancing precision, speed, and versatility. This includes the development of more powerful spindles capable of higher RPMs, advanced control systems for seamless operation, and improved tooling options for greater flexibility in machining various materials. These innovations will enable manufacturers to produce even more complex and intricate parts with unmatched accuracy.

Industry 4.0 Integration

The integration of Industry 4.0 principles into CNC vertical machines is becoming increasingly prevalent. This involves the implementation of smart technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and data analytics to optimize machine performance, predict maintenance needs, and streamline production processes. By embracing Industry 4.0, CNC vertical machines can operate with unprecedented efficiency and adaptability.

Market Trends and Demand

The market trends for CNC vertical machines indicate a growing demand for advanced capabilities that can handle a wider range of machining tasks with increased precision and speed. As industries continue to push the boundaries of what is possible in manufacturing, the need for versatile and reliable CNC vertical machines will only intensify. This trend underscores the importance of investing in cutting-edge technology to stay competitive in the evolving market landscape.

Conclusion

Investing in 5-Axis Machining Technology

The SYIL U5 Vertical Machining Center represents the future of CNC vertical machines, offering advanced features like simultaneous 5-axis machining and a spacious work envelope. Investing in this cutting-edge technology allows industrial machinists to achieve complex, precise operations with maximum efficiency and flexibility.

The Versatility of Vertical Machine Centres

Vertical machine centres are essential for various industries, including aerospace, automotive, and medical device manufacturing. Their ability to accommodate different part sizes and shapes, combined with high-speed spindle and automatic tool changer capabilities, makes them versatile and indispensable for modern manufacturing processes.

Choosing the Right CNC Vertical Machine Provider

When selecting a vertical machine supplier, it's crucial to prioritize quality, reliability, customer support, and advanced technology. By choosing a reputable provider with a track record of innovation and excellence, industrial machinists can ensure they have access to the latest advancements in CNC vertical milling technology.