Introduction

In today's fast-paced manufacturing industry, the SYIL CNC Vertical Milling Machine is revolutionizing production processes with its cutting-edge technology. This state-of-the-art CNC machine offers unparalleled precision and efficiency, making it a game-changer for businesses seeking to stay ahead of the competition.

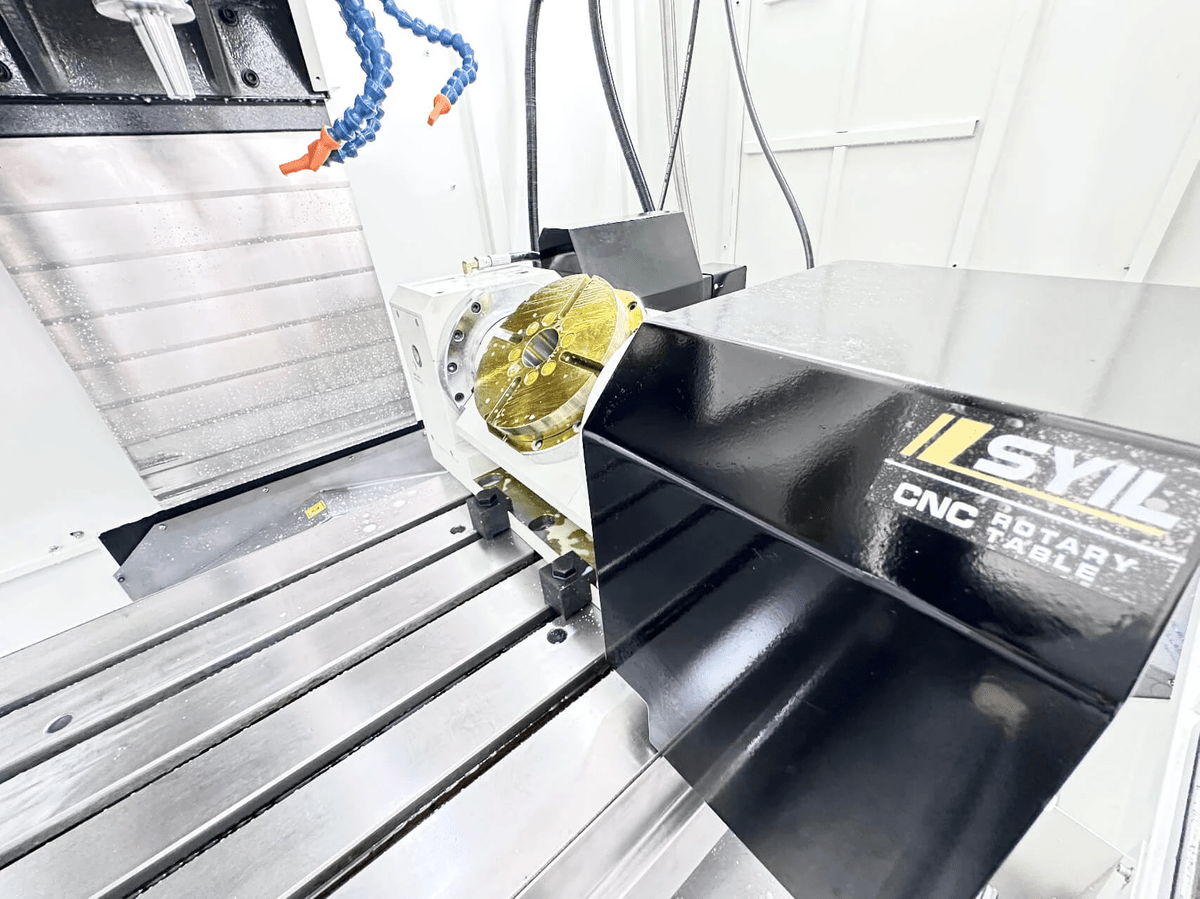

Understanding the SYIL CNC Vertical Milling Machine

SYIL CNC Vertical Milling Machines offer impressive capabilities in a compact design, which is ideal for smaller workshops. Here's what makes them stand out:

- Advanced Engineering: SYIL machines are built with cutting-edge technology, ensuring precision and reliability.

- 5-Axis Machining: This advanced feature tackles intricate and complex projects with ease.

- Compact Design: Despite their power, SYIL machines fit perfectly in smaller workshops, maximizing space efficiency.

- Uncompromised Performance: Don't let the size fool you - SYIL machines deliver high-quality results for demanding tasks.

With advanced engineering, 5-axis capabilities, and a space-saving design, SYIL CNC Vertical Milling Machines empower workshops of all sizes to tackle complex projects and achieve exceptional results.

Benefits of Advanced CNC Technology

With its advanced CNC technology, the SYIL machine delivers unmatched accuracy and consistency in every task, resulting in superior finished products. The 5-axis CNC capabilities allow for multi-sided machining with minimal setup, reducing production time and costs.

Increasing Productivity with Precision Machinery

SYIL's CNC Vertical Milling Machine empowers manufacturers to streamline their production processes, increase throughput, and meet tight deadlines without sacrificing quality. Its precision machinery ensures that every component meets exact specifications, minimizing waste and maximizing productivity.

In addition to boosting productivity, SYIL's CNC Vertical Milling Machine also offers the flexibility to handle a wide range of materials and designs. This versatility allows manufacturers to take on diverse projects without needing multiple machines, saving time and resources. With its user-friendly interface and advanced technology, the machine enables operators to quickly set up and execute complex machining tasks, further enhancing efficiency.

The Evolution of CNC Vertical Milling Machines

From Manual to Automated Processes

Traditionally, traditional milling machines required manual operation, leading to limitations in precision and efficiency. However, with the advent of advanced CNC technology, the industry has witnessed a significant shift towards automated processes. This evolution has revolutionized manufacturing by allowing for more complex designs and faster production times.

SYIL’s Contribution to Industry Advancements

SYIL has played a pivotal role in this evolution by introducing state-of-the-art CNC vertical milling machines that offer unparalleled precision and versatility. With its innovative 5-axis CNC machines, SYIL has set new standards for efficiency and accuracy in manufacturing operations. By constantly pushing the boundaries of technology, SYIL continues to drive industry advancements forward.

The Impact of Advanced CNC Technology

Advanced CNC technology has revolutionized vertical milling machines, offering manufacturers a significant edge. Here's how:

- Unmatched Precision and Complexity: Integrating cutting-edge software and hardware enables these machines to achieve levels of precision and intricate details previously unattainable.

- Exceptional Performance and Reliability: Companies like SYIL are committed to staying at the forefront of this technology and ensuring their machines deliver consistent top performance and reliable operation.

- Unparalleled Versatility: SYIL's 5-axis CNC technology unlocks a world of possibilities for manufacturers. These machines tackle diverse industry demands with unmatched precision and adaptability while maximizing productivity and efficiency.

As the manufacturing landscape continues to evolve, SYIL remains a leader, providing innovative solutions for modern production needs. By embracing SYIL's advanced CNC technology, manufacturers can propel their production processes to new heights.

Precision and Accuracy in Manufacturing

SYIL CNC Vertical Milling Machine Features

Regarding precision and accuracy in manufacturing, the SYIL CNC Vertical Milling Machine offers a range of cutting-edge features. With its advanced 5-axis capabilities, this CNC machine provides unparalleled flexibility and accuracy, allowing for intricate and complex machining tasks with ease. The mini milling machine design also ensures space-saving efficiency without compromising performance, making it an ideal choice for various production needs.

Achieving Consistent Quality and Performance

SYIL's CNC milling machines are known for their precision and reliability, making them a valuable asset for any workshop. Here's what sets them apart:

- Robust Construction & Advanced Technology: SYIL's machines are built with a focus on durability and utilize cutting-edge technology to ensure consistent performance.

- High-Speed Spindle Options: With various spindle speed options, you can optimize machining for different materials and project requirements.

- Advanced Tooling Capabilities: The machines handle a wide range of tooling, allowing for diverse machining tasks and complex designs.

- Unmatched Accuracy & Reliability: 5-axis functionality combined with robust construction guarantees precise results for any project, from prototyping to high-volume production.

- Meeting Demanding Standards: SYIL's machines are built to meet the strictest manufacturing requirements, ensuring consistent quality and minimizing production errors.

SYIL's CNC milling machines offer a powerful combination of precision, versatility, and reliability, making them a perfect fit for workshops seeking to elevate their production capabilities.

Enhancing Workflow Efficiency

You can significantly enhance workflow efficiency by integrating SYIL's CNC vertical milling machine into your production processes. The seamless automation and user-friendly interface streamline operations, reducing setup times and optimizing overall productivity. With its rapid tool changes and high-speed machining capabilities, this CNC machine empowers manufacturers to achieve more in less time while maintaining exceptional precision throughout the manufacturing process.

Streamlining Production Processes

With SYIL’s integration of advanced automation, the CNC vertical milling machine offers unparalleled efficiency and precision. The 5-axis CNC machine allows for complex multi-sided machining, reducing setup time and maximizing production output. This level of automation ensures consistent quality and accuracy in every component manufactured.

SYIL’s Integration of Advanced Automation

SYIL’s CNC milling machines have state-of-the-art automation features, allowing seamless tool changes and uninterrupted production runs. The 5-axis CNC technology enables simultaneous machining from multiple angles, eliminating the need for manual repositioning and significantly reducing production time. This advanced level of automation sets SYIL apart as a leader in the industry, providing manufacturers with a competitive edge in today's market.

Optimizing Time and Resources

The SYIL mini-milling machine is designed to optimize time and resources through its advanced automation capabilities. Manufacturers can maximize operational efficiency while minimizing labor costs with reduced setup times and increased production speeds. The 5-axis CNC machine also allows for machining complex parts in a single setup, further streamlining the manufacturing process.

Improving Overall Manufacturing Operations

By integrating advanced automation into their CNC vertical milling machines, SYIL has revolutionized manufacturing operations across various industries. The precision and speed offered by the 5-axis CNC technology result in improved overall productivity and cost-effectiveness. Manufacturers can rely on SYIL’s machines to consistently deliver high-quality components while enhancing manufacturing processes.

SYIL’s CNC vertical milling machines have set a new standard for precision and speed in manufacturing operations. The 5-axis CNC technology improves overall productivity and cost-effectiveness and ensures consistent delivery of high-quality components. With SYIL’s machines, manufacturers can streamline their processes and achieve superior results, setting them apart in their respective industries.

Investing in a SYIL CNC vertical milling machine means embracing cutting-edge technology that optimizes production processes to achieve maximum efficiency and output while maintaining superior quality standards.

Customization and Adaptability

Regarding versatility, the SYIL CNC Vertical Milling Machine stands out as a game-changer in the industry. Its 5-axis CNC capabilities allow for intricate and complex machining operations, making it a top choice for manufacturers looking to push the boundaries of what's possible with a milling machine. Whether crafting prototypes or producing custom parts, this mini milling machine offers unparalleled flexibility to meet diverse production needs.

SYIL CNC Vertical Milling Machine Flexibility

With its 5-axis CNC technology, the SYIL machine enables multi-sided machining with precision and speed, opening up a world of possibilities for manufacturers. Its compact size makes it ideal for small workshops or tight production spaces without sacrificing performance or quality. This CNC machine's flexibility allows for seamless integration into existing workflows, easily adapting to various manufacturing requirements.

Meeting Diverse Industry Demands

In today's fast-paced manufacturing landscape, the demand for customized parts and products is higher than ever. The SYIL CNC Vertical Milling Machine rises to the challenge by offering a wide range of customization options, from tooling configurations to material compatibility. Whether it's aerospace components or medical devices, this 5-axis CNC machine is designed to meet the diverse demands of different industries, ensuring precision and accuracy in every project.

Tailoring Solutions to Unique Production Needs

Every manufacturing operation has challenges and requirements, which is why the SYIL CNC Vertical Milling Machine is engineered to provide tailored solutions for unique production needs. Whether fine-tuning cutting parameters or adjusting spindle speeds, this mini-milling machine empowers operators to customize their machining processes according to specific project specifications. This level of adaptability ensures that manufacturers can achieve optimal results across a wide range of applications.

In addition to its adaptability, the SYIL CNC Vertical Milling Machine also prioritizes safety and maintenance considerations. With built-in safety features and easy-to-follow maintenance protocols, operators can feel confident in the machine's reliability and longevity. This peace of mind allows manufacturers to focus on their production processes without worrying about unnecessary downtime or safety hazards, ultimately contributing to increased efficiency and productivity.

Safety and Maintenance Considerations

SYIL’s Commitment to Equipment Safety

SYIL CNC Vertical Milling Machines are designed strongly emphasizing safety features, ensuring a secure working environment for operators. With built-in emergency stop buttons, protective enclosures, and automatic tool changers, SYIL machines prioritize users' well-being without compromising productivity.

SYIL CNC Vertical Milling Machines are designed strongly emphasizing safety features, ensuring a secure working environment for operators. With built-in emergency stop buttons, protective enclosures, and automatic tool changers, SYIL machines prioritize users' well-being without compromising productivity. In addition to these safety features, SYIL conducts regular maintenance checks and provides comprehensive training for operators to ensure long-term reliability and optimal equipment performance. This commitment to ongoing support and maintenance sets SYIL apart as a leader in equipment safety and customer satisfaction.

Ensuring Long-Term Reliability

When it comes to CNC machines, uninterrupted production is key. SYIL machines deliver this reliability through several key features:

- Durable Construction: SYIL machines are built with high-quality materials and meticulous assembly processes, ensuring long-term reliability.

- Rigorous Quality Control: Stringent quality checks guarantee consistent performance and minimize downtime, keeping your production running smoothly.

- Predictive Maintenance: Advanced features allow you to anticipate potential issues before they become costly breakdowns. This proactive approach extends the machine's lifespan and reduces the need for unscheduled maintenance.

By prioritizing long-term reliability, SYIL CNC machines empower manufacturers to focus on what matters most – their core operations – with complete peace of mind. Invest in SYIL and experience the difference reliable machinery can make.

Maximizing Machine Lifespan

By implementing regular maintenance schedules and offering comprehensive support services, SYIL enables users to maximize the lifespan of their CNC vertical milling machines. From timely lubrication to expert troubleshooting assistance, SYIL is committed to ensuring its equipment operates at peak efficiency throughout its extended service life.

In conclusion, investing in a SYIL CNC Vertical Milling Machine unlocks enhanced productivity and efficiency. It provides the peace of mind that comes with top-notch safety features and long-term reliability. Embracing advanced manufacturing solutions has never been more accessible or beneficial than with SYIL's innovative 5-axis CNC technology.

Conclusion

Investing in SYIL CNC Vertical Milling Machines is a strategic move for any manufacturing operation looking to stay ahead. With SYIL's commitment to innovation and precision, their CNC machines offer unparalleled performance and reliability, making them a valuable asset for any production facility.

Unlocking enhanced productivity and efficiency is effortless with SYIL's CNC Vertical Milling Machines. The advanced 5-axis technology ensures intricate and complex parts can be easily manufactured, while the mini milling machine option provides flexibility for smaller-scale projects. This level of adaptability allows for increased output without compromising on quality.

Embracing advanced manufacturing solutions has never been easier with SYIL's range of CNC machines. From their precision engineering to their user-friendly interface, these machines streamline production processes and empower manufacturers to confidently meet diverse industry demands.

Investing in SYIL's CNC Vertical Milling Machines means investing in the future of manufacturing. The seamless integration of advanced automation, coupled with the precision and accuracy of these machines, ensures that production processes are optimized for maximum output and efficiency.

Unlocking enhanced productivity and efficiency has never been more achievable than with SYIL's cutting-edge technology. Manufacturers can significantly improve their workflow efficiency while maintaining consistent quality across all operations by harnessing the power of advanced automation and 5-axis capabilities.

Embracing advanced manufacturing solutions through SYIL's CNC Vertical Milling Machines is about staying competitive and leading the way in innovation. With a focus on customization, adaptability, safety, and reliability, these machines are designed to meet the unique production needs of any industry.

By choosing SYIL as your partner in manufacturing excellence, you're not just investing in a piece of equipment; you're investing in a complete solution that will elevate your production capabilities to new heights.