Introduction

In the world of manufacturing and engineering, milling machines stand as pivotal tools that shape materials into precise components. These machines come in various forms, from robust industrial milling machines to compact mini milling machines, catering to a wide range of production needs. Whether you’re looking for a Bridgeport milling machine or a small milling machine for hobby projects, understanding the essence and functionality of these devices is crucial.

What Are Milling Machines?

Milling machines are versatile tools used to cut and shape materials like metal, wood, and plastic through rotary motion. They utilize various cutting tools to remove material from a workpiece, allowing for intricate designs and precision engineering. From vertical milling machines that offer excellent depth control to miniature milling machines suited for delicate tasks, these devices are essential in transforming raw materials into finished products.

Importance of Industrial Milling Machines

Industrial milling machines play a significant role in enhancing productivity across numerous sectors. Their ability to operate continuously while delivering high precision makes them invaluable in large-scale manufacturing environments. By investing in quality machinery like the Bridgeport milling machine or other industrial models, businesses can achieve higher efficiency and maintain competitive advantages in their respective markets.

Applications in Various Industries

The applications of milling machines span an impressive array of industries including aerospace, automotive, electronics, and even jewelry making. In aerospace manufacturing, for instance, precision is non-negotiable; hence industrial milling machines are employed to create complex components with exact tolerances. Similarly, small milling machines find their niche in craft industries where detailed work is paramount—proving that no matter the scale or scope of production needs, there’s always a suitable milling machine for sale ready to meet those demands.

Overview of Milling Machines

Milling machines are versatile tools used in various industries to shape and cut materials into desired forms. These machines operate by removing material from a workpiece through rotary cutters, allowing for precise engineering and manufacturing. Understanding the different types of milling machines and their components is crucial for selecting the right one for specific applications.

Definition and Functionality

At its core, a milling machine is designed to perform machining operations on materials such as metal, wood, or plastic. The functionality of these machines involves rotating cutting tools that remove material from the workpiece to create complex shapes and features. Whether you’re using a mini milling machine for intricate designs or an industrial milling machine for heavy-duty tasks, the fundamental principle remains the same: precision cutting.

Types of Milling Machines

There are several types of milling machines available on the market, each tailored to specific needs and applications. The most common include vertical milling machines, which feature a vertically oriented spindle; horizontal milling machines with horizontally mounted spindles; and specialized options like bridgeport milling machines known for their versatility in small-scale production. For those with limited space or smaller projects, miniature milling machines offer compact solutions without sacrificing functionality.

Key Components Explained

To fully appreciate how a milling machine operates, it’s essential to understand its key components. The primary parts include the spindle that holds the cutting tool, the table where the workpiece is mounted, and various control mechanisms that guide movement during operation. Additionally, features such as coolant systems help maintain temperature during machining processes while ensuring optimal performance in both industrial and small milling machine setups.

The Role of Industrial Milling Machines

Industrial milling machines play a pivotal role in modern manufacturing, significantly transforming how products are created and refined. By utilizing advanced technology, these machines streamline production processes and enhance the overall efficiency of operations. As industries evolve, the importance of milling machines becomes increasingly evident, making them indispensable tools in various sectors.

Enhancing Production Efficiency

One of the most significant advantages of industrial milling machines is their ability to enhance production efficiency. With the capability to perform multiple operations simultaneously, a single milling machine can drastically reduce production time compared to traditional methods. Whether it's a bridgeport milling machine or a small milling machine, these devices are designed for high-speed operation, allowing businesses to meet growing demands without sacrificing quality.

Moreover, the automation features found in many modern mini milling machines further optimize workflow by minimizing human intervention. This not only speeds up production but also reduces labor costs associated with manual machining processes. As companies seek to maximize productivity while maintaining competitive pricing, investing in an efficient vertical milling machine becomes essential for success.

Improving Precision and Accuracy

Precision and accuracy are paramount in manufacturing, especially when dealing with intricate designs or tight tolerances. Industrial milling machines excel in this area through their advanced control systems and robust engineering designs that ensure consistent results across various applications. A miniature milling machine can achieve remarkable precision levels that are often unattainable with manual tools.

The integration of CNC (Computer Numerical Control) technology into many industrial milling machines allows for precise programming of cutting paths and parameters. This technological advancement minimizes human error, ensuring that each component produced is identical and meets stringent specifications. Consequently, businesses can rely on these machines for high-quality output while minimizing the risk of costly mistakes.

Reducing Material Waste

In today’s economy where sustainability is key, reducing material waste has become more critical than ever before. Industrial milling machines contribute significantly to this goal by optimizing cutting processes and ensuring efficient use of raw materials. With accurate machining capabilities offered by devices like the bridgeport milling machine or various small milling machine options, manufacturers can minimize scrap material effectively.

Furthermore, advancements in tooling technology have allowed for better chip removal during machining operations which contributes to less wastage overall. By employing techniques such as adaptive machining available on some CNC systems, companies can adjust their processes dynamically based on real-time data feedback—leading to even less waste generation throughout production cycles. In an era where every bit counts towards profitability and environmental responsibility, investing in quality industrial milling machines is undoubtedly a step forward.

Types of Milling Processes

When it comes to industrial milling machines, understanding the various milling processes is crucial for selecting the right machine for your needs. Each process serves a different purpose and can significantly impact production efficiency and output quality. In this section, we'll delve into end milling versus face milling, horizontal versus vertical milling, and the advantages of CNC milling.

End Milling vs Face Milling

End milling and face milling are two primary types of cutting processes utilized in industrial milling machines. End milling uses a cylindrical cutting tool that cuts along the axis of rotation, making it ideal for producing complex shapes and contours on materials like metals or plastics. On the other hand, face milling employs a flat cutting tool to remove material from the surface of a workpiece, which is perfect for achieving smooth finishes on larger surfaces.

Both processes have their unique applications; end mills are often used in small milling machines or miniature milling machines due to their versatility in tight spaces. Conversely, you might find face mills more frequently employed on larger setups like Bridgeport milling machines that handle bigger workpieces. Understanding these differences can help you choose between an end mill or face mill based on your project requirements.

Horizontal vs Vertical Milling

The orientation of the spindle is another critical factor that distinguishes different types of industrial milling machines: horizontal versus vertical. In horizontal milling machines, the spindle is aligned horizontally, allowing for efficient chip removal and greater stability when working with large materials. This design makes them particularly effective for heavy-duty tasks such as slab cutting or creating slots.

Vertical milling machines feature a vertically oriented spindle that allows for more flexibility in terms of movement and access to intricate designs. They are often favored in prototyping environments where precision is paramount; think about how many times you've seen a small milling machine being used to create detailed parts! Both configurations have their strengths; thus, selecting between horizontal and vertical models depends largely on your specific machining needs.

CNC Milling Advantages

CNC (Computer Numerical Control) technology has revolutionized industrial machining by offering enhanced precision and automation compared to traditional methods. With CNC mills, operators can program complex designs directly into the machine's software—resulting in consistent output without manual intervention! This capability not only improves accuracy but also reduces human error during production runs.

Moreover, CNC mini milling machines offer an accessible entry point for smaller workshops looking to harness advanced machining capabilities without breaking the bank. These compact solutions deliver high-quality results while occupying less floor space compared to their larger counterparts like Bridgeport models. Ultimately, embracing CNC technology allows businesses to scale operations efficiently while maintaining top-tier quality across various applications.

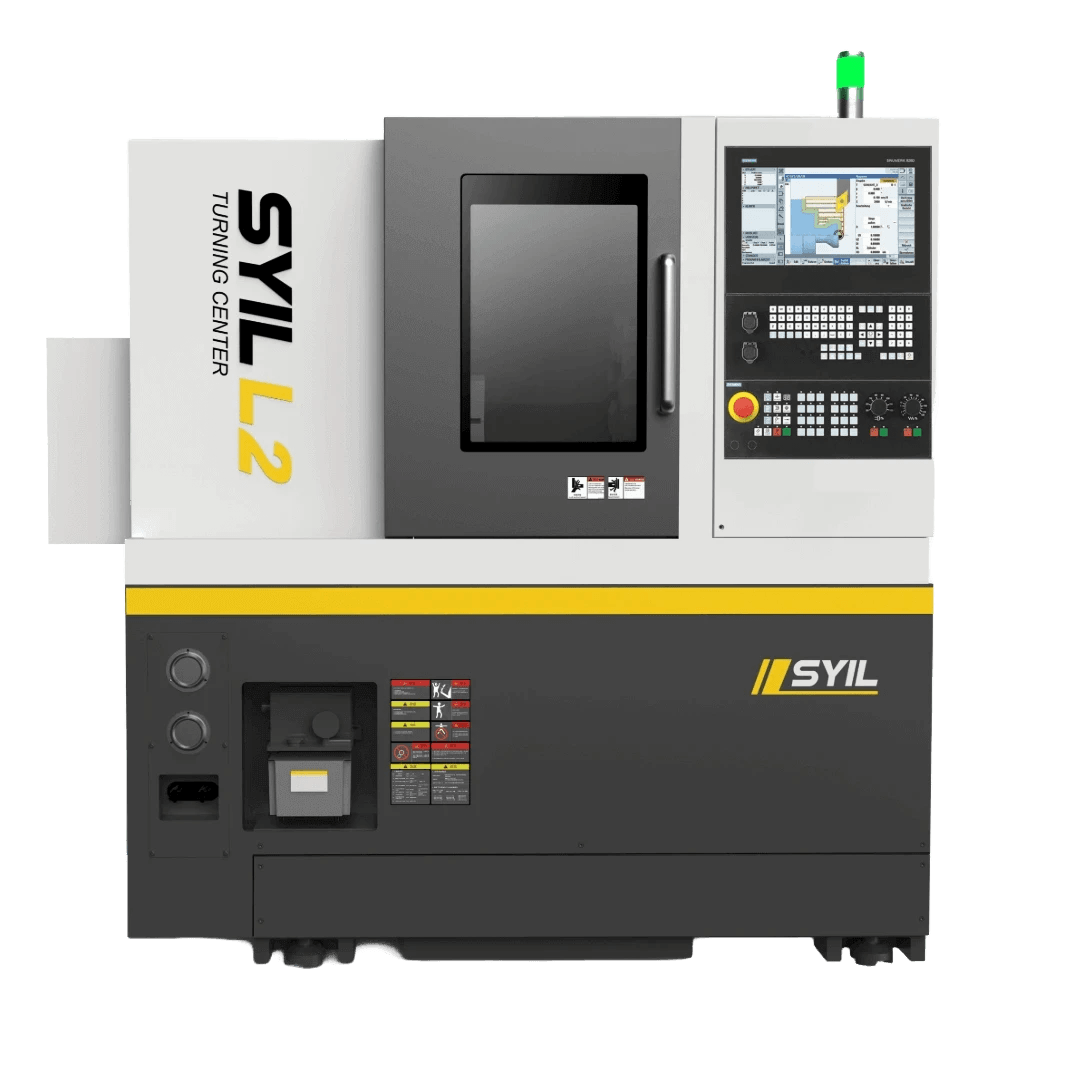

Understanding SYIL CNC Machines

When it comes to precision and versatility in the realm of industrial milling machines, SYIL CNC machines stand out, particularly the SYIL X5 Mini CNC Machine. This miniature milling machine is designed for small-scale applications while still packing a punch in terms of performance. With its compact size and robust features, it’s an ideal choice for hobbyists and professionals alike who need a reliable vertical milling machine without sacrificing quality.

Features of the SYIL X5 Mini CNC Machine

The SYIL X5 Mini CNC Machine boasts several impressive features that make it a top contender among small milling machines. Its rigid construction ensures stability during operation, which translates to enhanced accuracy in machining processes. Additionally, this mini milling machine comes equipped with a user-friendly interface that simplifies programming and operation, making it accessible even for those new to CNC technology.

Moreover, the SYIL X5 offers high-speed spindle options that allow for efficient material removal across various applications. Its ability to handle multiple materials—from metals to plastics—makes it versatile enough for different industries seeking a reliable bridgeport milling machine alternative. With a footprint small enough to fit into compact workspaces, this machine is perfect for anyone looking for an effective yet space-saving solution.

Applications in Prototyping and Jewelry Making

The capabilities of the SYIL X5 Mini CNC Machine extend far beyond basic machining; it's particularly well-suited for prototyping and jewelry making applications. In prototyping, designers can quickly create accurate models that help visualize concepts before moving into full production, saving both time and resources in the development process. For jewelry makers, this miniature milling machine allows intricate designs to be crafted with precision that traditional methods simply cannot achieve.

Additionally, its compact size makes it easier for artisans to work on detailed projects without needing large industrial milling machines that occupy significant workspace. Whether creating custom pieces or producing limited runs of jewelry items, users find this mini milling machine indispensable in bringing their creative visions to life efficiently. The adaptability of the SYIL X5 helps bridge the gap between artisanal craftsmanship and modern manufacturing techniques.

Precision Engraving Capabilities

One of the standout features of industrial milling machines like the SYIL X5 is their precision engraving capabilities. This small milling machine can handle intricate patterns and designs on various surfaces with remarkable accuracy—ideal for applications ranging from decorative engraving on metal parts to personalized gifts made from wood or acrylics. The fine detail achievable with this equipment positions it as an essential tool not just for manufacturers but also artists looking to elevate their craft.

Moreover, precision engraving opens up additional avenues within industries such as signage creation or custom parts fabrication where detail matters most. Users appreciate how easy it is to switch between different tasks on this vertical milling machine without compromising quality or speed—making it a versatile addition to any workshop setup focused on high-quality output at reduced costs compared to larger alternatives like bridgeport milling machines.

In summary, understanding what the SYIL CNC Machines bring to the table highlights their importance in modern manufacturing practices while showcasing how they can enhance productivity across various sectors.

Choosing the Right Milling Machine

Choosing the right milling machine can feel like navigating a labyrinth of options, especially with the plethora of industrial milling machines available on the market. From mini milling machines that fit in your garage to robust Bridgeport milling machines designed for heavy-duty tasks, understanding your specific needs is crucial. Whether you're looking for a vertical milling machine or a miniature milling machine, making an informed decision will save you time and money in the long run.

Factors to Consider for Your Needs

When selecting an industrial milling machine, consider factors such as size, power, and functionality. Are you working on large-scale projects that require a sturdy Bridgeport milling machine, or do you need something more compact like a small milling machine for hobbyist tasks? Additionally, think about whether you need advanced features like CNC capabilities or if a simpler model will suffice for your applications.

Another essential factor is material compatibility; different milling machines excel at machining various materials. If you're primarily working with metals, ensure that the mini milling machine you choose has appropriate specifications to handle those materials effectively. Don’t forget about ease of use and maintenance—some models are designed with user-friendliness in mind while others may require more technical know-how.

Comparing Industrial Milling Machines

With so many options available, comparing industrial milling machines becomes paramount in finding the right fit for your workshop. Start by evaluating key specifications such as horsepower, spindle speed, and cutting capacity; these aspects directly influence performance and efficiency. Don’t overlook customer reviews and testimonials—they can provide valuable insights into real-world performance beyond what manufacturers claim.

When comparing models like vertical vs horizontal milling machines, consider how each design affects accessibility and versatility in your work environment. For instance, a vertical milling machine may offer better visibility while performing intricate cuts compared to its horizontal counterpart. Furthermore, if space is limited in your shop or studio, exploring compact options like small or miniature milling machines might be beneficial without sacrificing capability.

Cost vs Quality Analysis

In the world of industrial milling machines, there’s often a delicate balance between cost and quality that must be navigated carefully. While it might be tempting to opt for cheaper models when searching for a milling machine for sale, remember that lower prices sometimes come at the expense of durability and precision. Investing slightly more upfront could lead to better performance over time—especially important when considering high-stakes projects that demand accuracy.

Conducting thorough research on brands known for their reliability can help mitigate risks associated with poor-quality machinery. For example, brands offering well-reviewed Bridgeport milling machines typically have established reputations based on years of engineering excellence in this field. Ultimately, it's about finding value—selecting an industrial milling machine that meets both budget constraints and operational needs will yield long-term benefits.

Conclusion

In the world of manufacturing and craftsmanship, industrial milling machines stand as a testament to precision and efficiency. As we look to the future, advancements in technology promise even greater capabilities for these machines, enabling them to tackle increasingly complex tasks with ease. From mini milling machines perfect for intricate projects to robust Bridgeport milling machines designed for heavy-duty applications, the versatility of these tools will continue to shape industries.

The Future of Milling Technology

The future of milling technology is bright and brimming with innovation. With the rise of automation and smart manufacturing, we can expect features like enhanced CNC capabilities in both large-scale industrial milling machines and miniature milling machines. These advancements will not only improve production speeds but also ensure that every cut is executed with unmatched accuracy, making vertical milling machines more efficient than ever before.

How to Leverage Milling Machines Effectively

To truly benefit from your investment in a milling machine for sale, it's essential to understand how best to utilize its features. Leveraging advanced programming techniques can maximize the potential of your small milling machine or industrial-grade counterpart. Additionally, regular maintenance and operator training are vital; they enhance performance while extending the lifespan of your equipment.

Final Thoughts on Industrial Milling Machines

Industrial milling machines are indispensable tools in various sectors, from automotive to jewelry making. Their ability to produce high-quality parts with minimal waste makes them invaluable assets for any workshop or factory floor. Whether you're considering a Bridgeport milling machine or exploring options for a miniature milling machine, investing wisely will pave the way for future success in your projects.