Introduction

Industrial milling machines are the backbone of modern manufacturing, transforming raw materials into precise components with remarkable efficiency. Whether you're a seasoned machinist or a curious newcomer, understanding what industrial milling is and how these machines operate can open up a world of possibilities in various industries. From automotive to aerospace, the applications are vast, making it essential to grasp the key components and features that define these powerful tools.

Understanding Industrial Milling Machines

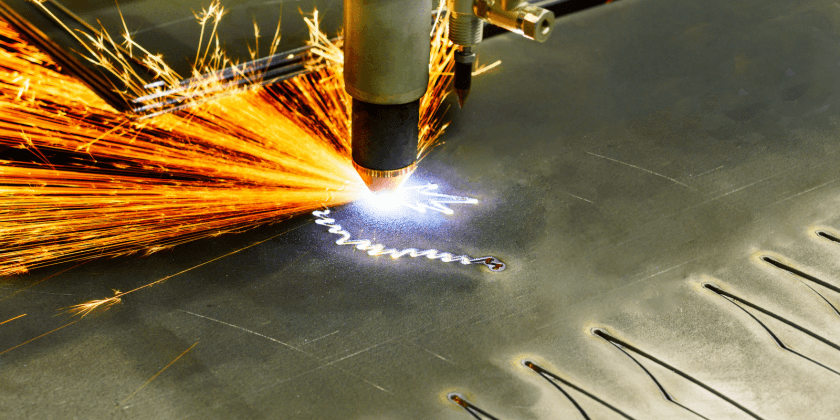

So, what is industrial milling? Simply put, it's a machining process that uses rotary cutters to remove material from a workpiece. The process allows for intricate designs and high precision, which is why industrial milling machines are indispensable in sectors where accuracy is paramount. With roots tracing back to the late 18th century, the evolution of these machines has led us to highly sophisticated models capable of handling complex tasks.

Key Components and Features

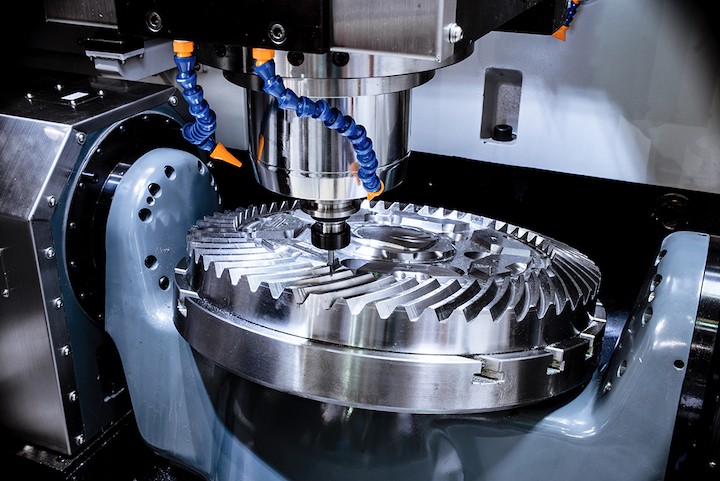

An industrial milling machine typically comprises several key components: the spindle, table, tool holder, and feed mechanisms. Each part plays a crucial role in ensuring smooth operation and precision cutting. Additionally, features like digital readouts and automatic tool changers enhance functionality and user experience, making it easier for operators to achieve their desired results.

Safety Protocols for Operation

Operating an industrial milling machine requires rigorous adherence to safety protocols to prevent accidents and ensure efficient workflows. Proper training on machine operation is vital as it equips users with knowledge about potential hazards linked with machinery use. Wearing appropriate personal protective equipment (PPE) such as goggles and gloves also plays an essential role in maintaining safety while working with these powerful tools.

What is Industrial Milling?

Industrial milling is a crucial manufacturing process that involves the removal of material from a workpiece to create desired shapes and sizes. This technique utilizes various types of industrial milling machines, which can perform complex cuts with precision and efficiency. Understanding what industrial milling is can help businesses optimize their production processes and improve product quality.

Definition and Purpose

At its core, industrial milling refers to the machining process that uses rotary cutters to remove material from a workpiece. The primary purpose of this method is to shape or finish parts with high accuracy, making it essential in industries such as aerospace, automotive, and manufacturing. By employing an industrial milling machine, manufacturers can achieve intricate designs that would be difficult or impossible to accomplish using manual methods.

Historical Overview

The history of industrial milling dates back to the late 18th century when innovative thinkers began developing machines that could automate cutting processes. Early versions of the industrial milling machine were simple but laid the groundwork for more advanced models we see today. Over time, advancements in technology have led to the creation of CNC (Computer Numerical Control) milling machines, which revolutionized how industries operate by increasing precision and reducing human error.

Applications in Various Industries

Industrial milling machines find applications across numerous sectors due to their versatility and efficiency. In aerospace manufacturing, they are used for creating complex components like turbine blades; in automotive production, they help produce engine blocks with tight tolerances; while in electronics, they assist in fabricating circuit boards. With such diverse applications, it's clear why understanding what industrial milling is essential for anyone involved in manufacturing or engineering.

What are the Three Basic Types of Milling Machines?

When it comes to industrial milling machines, understanding the three basic types is crucial for selecting the right one for your needs. Each type has its own unique features and applications, making them suitable for different tasks in various industries. Let's dive into these categories to see how they stack up against each other.

Vertical Milling Machines

Vertical milling machines are a staple in many workshops and factories due to their versatility and ease of use. In this type of machine, the cutting tool is mounted vertically, allowing for precise control over depth and angle during operations. This design makes vertical mills particularly effective for tasks like drilling, slotting, and contouring, which are common in industrial milling.

What is industrial milling without some good ol' vertical machining? These machines can handle both light-duty and heavy-duty tasks, depending on their size and configuration. With a variety of attachments available, operators can expand their capabilities further—making vertical milling machines a popular choice among industrial milling machine manufacturers.

Horizontal Milling Machines

Horizontal milling machines take a different approach by positioning the cutting tool horizontally rather than vertically. This design allows for more extensive workpieces to be machined at once, making it ideal for larger components often found in heavy industries like aerospace or automotive manufacturing. The horizontal orientation also facilitates better chip removal during operations.

One of the key advantages of horizontal milling is its ability to perform multiple operations simultaneously—think face-milling or slab-milling—while maintaining high precision levels. If you're wondering what are the three basic types of milling machines that can tackle hefty projects efficiently, horizontal mills definitely make that list! Plus, they tend to be more rigid than their vertical counterparts due to their structure.

CNC Milling Machines

CNC (Computer Numerical Control) milling machines represent a leap into modern technology within industrial milling processes. These machines utilize computer programs to control movement and operation with incredible precision; it's almost like having a robot do your machining! What is CNC milling? It's essentially taking traditional techniques up a notch by automating processes that were once manual.

The benefits of CNC mills over traditional machinery include improved accuracy, reduced human error, and increased production speed—all critical factors when considering industrial milling machine price points from various manufacturers. However, it's essential to understand what is the difference between CNC mill and machine as you explore your options: while CNC mills automate tasks with software-controlled systems, non-CNC machines require manual adjustments which can slow down production significantly.

In conclusion, whether you're leaning towards vertical or horizontal models or considering diving into CNC technology, knowing what are the three basic types of milling machines will help you make an informed decision tailored to your specific needs in manufacturing environments.

What is CNC Milling?

CNC milling represents a significant evolution in the realm of industrial milling machines, streamlining processes and enhancing precision. Unlike traditional methods, CNC (Computer Numerical Control) milling utilizes computer software to control the movement of cutting tools and machinery. This modern approach not only increases efficiency but also enables manufacturers to achieve intricate designs that would be challenging with manual techniques.

Definition and Advantages

CNC milling is defined as a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. The primary advantage of this method lies in its ability to produce complex shapes with high precision, which is often unattainable with conventional milling machines. Additionally, CNC milling reduces human error, enhances repeatability, and allows for faster production times—making it an indispensable tool for many industrial applications.

Comparison with Traditional Milling

When we compare CNC milling to traditional milling, the differences become strikingly clear. Traditional milling relies heavily on manual operation, requiring skilled machinists to control the machine's movements directly. In contrast, CNC mills operate autonomously based on programmed instructions; this not only minimizes labor costs but also increases production speed while maintaining consistent quality—a crucial factor for industries looking to optimize their operations.

Common Uses in Manufacturing

CNC milling finds application across various sectors due to its versatility and precision. Industries such as aerospace, automotive, and medical device manufacturing frequently utilize CNC mills for creating complex components that demand exact specifications. Furthermore, as businesses seek reliable solutions from industrial milling machine manufacturers, they often turn to CNC technology for its ability to handle both small-scale prototypes and large production runs efficiently.

What is the Difference Between CNC Mill and Machine?

When diving into the world of milling, a common question arises: what is the difference between a CNC mill and a traditional milling machine? The distinction lies primarily in technology and functionality. CNC, or Computer Numerical Control, represents a leap forward from manual operation, allowing for precision and automation that traditional machines simply can't match.

Understanding CNC Technology

CNC technology revolutionizes industrial milling machines by integrating computer systems to control their movements. Instead of manual inputs, operators can program specific designs directly into the machine’s software. This shift not only increases efficiency but also enhances accuracy—making it easier to produce complex shapes that would be nearly impossible with conventional methods.

Benefits of CNC Milling

The advantages of CNC milling are numerous and compelling for any manufacturer considering an upgrade in their operations. Firstly, CNC mills offer unparalleled precision; they can execute intricate designs with minimal human error, which is crucial in industries where tolerances are tight. Additionally, they improve productivity by allowing for continuous operation without fatigue or downtime often associated with manual machines—resulting in faster turnaround times on projects.

Limitations of Non-CNC Machines

While traditional milling machines have their place in certain applications, they come with limitations that can hinder production efficiency. For one, non-CNC machines require skilled operators who must constantly monitor and adjust settings—a process that can lead to inconsistencies over time. Furthermore, these machines are often slower than their CNC counterparts; they may struggle to keep up with modern manufacturing demands where speed and precision are paramount.

Choosing the Right Industrial Milling Machine

Selecting the right industrial milling machine is a pivotal decision that can significantly impact your manufacturing processes. With numerous types, features, and manufacturers to consider, it’s essential to assess your specific needs carefully. By understanding what is industrial milling? and evaluating various options, you can make an informed choice that enhances productivity.

Key Factors to Consider

When choosing an industrial milling machine, several key factors come into play. First, consider the type of materials you'll be working with; different machines cater to varying material hardness and thicknesses. Additionally, think about the precision required for your projects—whether you need a CNC milling machine for intricate designs or a more traditional setup may influence your selection.

Another important factor is the machine's operational capabilities; some machines offer more versatility than others in terms of speed and complexity. You should also evaluate the available space in your facility since larger machines require more room for operation and maintenance. Lastly, don’t overlook the importance of user-friendliness; a machine that’s intuitive can save time during training and boost overall efficiency.

Overview of Industrial Milling Machine Manufacturers

The market is brimming with reputable industrial milling machine manufacturers offering diverse products tailored to various industries. Notable names include Haas Automation, DMG Mori, and Mazak—each known for their innovation and reliability in CNC milling technology. These manufacturers often provide comprehensive support services including training programs on what is CNC milling? ensuring that operators are well-equipped to maximize their equipment's potential.

In addition to established brands, there are also emerging companies focusing on niche markets or specialized applications within industrial milling machines. Researching customer reviews and case studies from these manufacturers can provide valuable insights into their performance in real-world scenarios. Ultimately, selecting a manufacturer with a solid reputation will contribute significantly to achieving desired outcomes in your operations.

Assessing Industrial Milling Machine Price

Price plays a crucial role when evaluating different industrial milling machines available for sale today. While it's tempting to go for budget-friendly options, it's vital to remember that quality often correlates with price; investing in a higher-quality machine might save money on repairs or replacements down the line. Additionally, consider ongoing costs like maintenance services and parts availability when assessing overall value.

Comparing prices across different models helps identify competitive offerings within the market but be wary of deals that seem too good to be true—they could indicate subpar quality or hidden costs later on. Furthermore, check if any financing options are available from manufacturers or dealers which could ease immediate financial burdens while still allowing access to high-quality machinery needed for efficient production processes.

Conclusion

In wrapping up our exploration of industrial milling machines, it’s clear that these versatile tools play a pivotal role in modern manufacturing. Understanding the nuances of what is industrial milling? and the various types available can significantly impact production efficiency and quality. By adhering to best practices for operation, maintaining equipment properly, and knowing where to find industrial milling machines for sale, businesses can optimize their machining processes.

Best Practices for Operation

When operating an industrial milling machine, safety should always be the top priority. Familiarize yourself with the specific features of your machine and ensure you follow all manufacturer guidelines. Additionally, implementing proper setup procedures and tool selection will enhance both precision and productivity—key components in answering what are the three basic types of milling machines?

Tips for Maintenance and Care

Regular maintenance is crucial to prolonging the lifespan of your industrial milling machine. This includes routine checks on lubrication systems, cleaning debris from work areas, and ensuring tools are sharp and properly aligned. By adhering to these maintenance tips, operators can avoid costly downtime while also improving operational efficiency—essentially addressing what is the difference between CNC mill and machine?

Exploring Industrial Milling Machines for Sale

When searching for industrial milling machines for sale, it's essential to consider your specific needs alongside budget constraints. Researching various industrial milling machine manufacturers will provide insights into product reliability and customer satisfaction ratings. Remember that understanding factors like industrial milling machine price can help you make informed decisions that align with your manufacturing goals.