Introduction

In today's fast-paced manufacturing industry, CNC machine cutting has revolutionized how metal is shaped and formed. Understanding the basics of CNC machine cutting metal is crucial for anyone involved in metalworking. From their role in the metal cutting industry to their ability to maximize efficiency with cutting techniques, CNC machines have become indispensable tools for precision and sustainability.

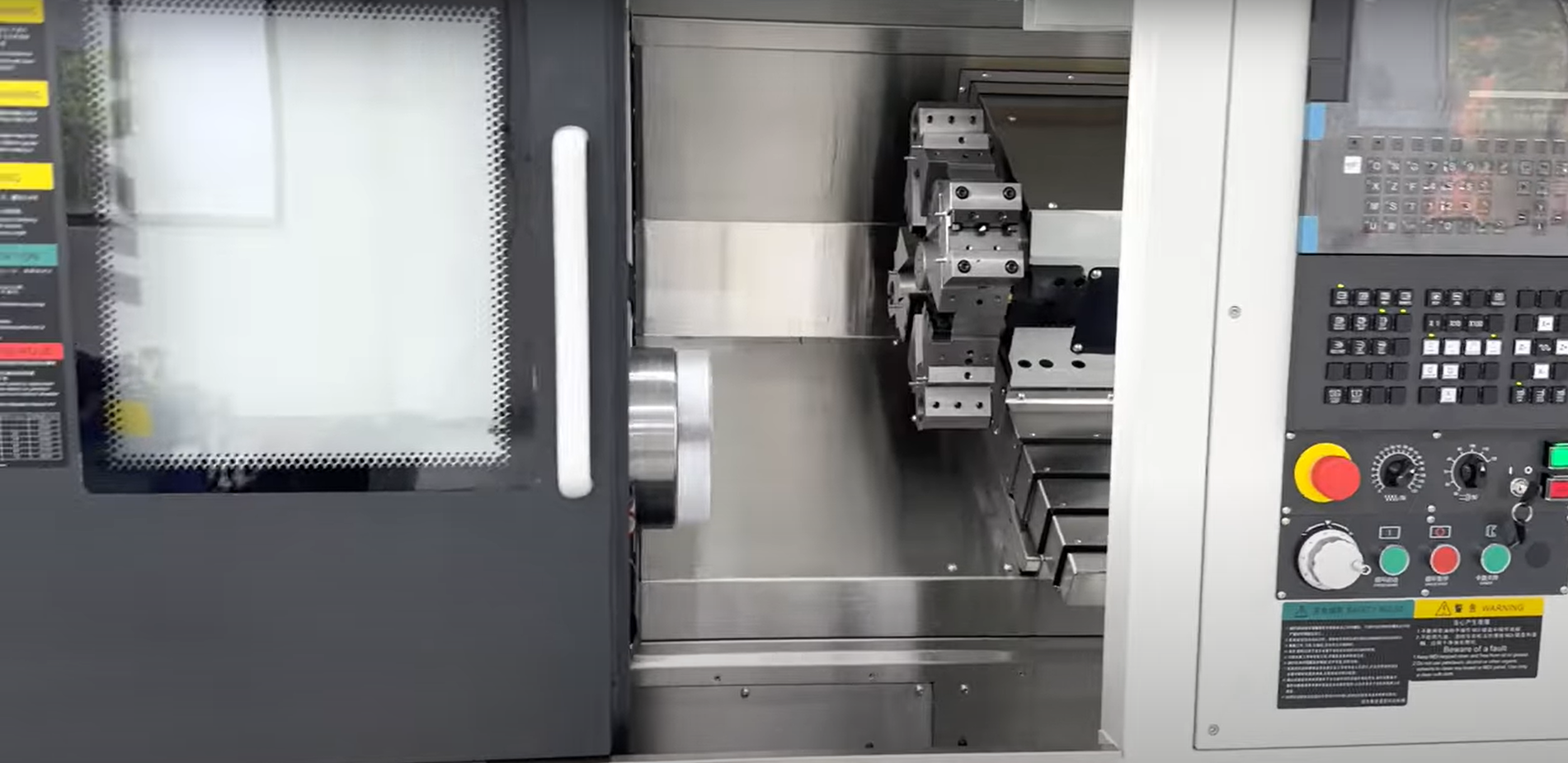

Understanding the Basics of CNC Machine Cutting Metal

CNC machine cutting metal involves using computer-controlled systems to shape and cut various types of metals precisely. These machines utilize advanced technology to execute complex designs with speed and accuracy. By following programmed instructions, CNC machines can produce intricate cuts and shapes that would be nearly impossible to achieve manually.

The Role of CNC Machines in the Metal Cutting Industry

CNC machines have become the backbone of the metal cutting industry, offering many advantages over traditional methods. Here's how CNC technology has transformed this sector:

- Unmatched Precision and Accuracy: CNC machines eliminate human error by following computer-controlled instructions. This ensures consistent, high-quality parts, even for complex designs.

- Increased Efficiency and Productivity: Automation allows CNC machines to operate continuously, significantly reducing production times compared to manual processes.

- Reduced Material Waste: CNC machines can precisely cut intricate shapes, minimizing scrap material and lowering production costs.

- Versatility for Diverse Applications: CNC machines can handle a wide range of metals and produce various parts, making them ideal for various industries.

CNC technology has revolutionized the metal cutting industry by offering superior precision, efficiency, and versatility. This has allowed manufacturers to create complex parts faster, with less waste, and at a higher quality.

Maximizing Efficiency with CNC Machine Cutting Techniques

To maximize efficiency in metal cutting processes, operators must employ various techniques specific to CNC machines. These techniques include optimizing feed rates, selecting appropriate tooling options, and utilizing advanced software features for automatic tool changes and material handling. By implementing these techniques effectively, manufacturers can minimize production time while maintaining high-quality results.

Choosing the Right CNC Machine for Metal Cutting

When it comes to metal cutting, choosing the right CNC machine is crucial for achieving precision and efficiency in your operations. Evaluating the different types of CNC metal cutting machines and considering key factors will help you make an informed decision.

Evaluating the Different Types of CNC Metal Cutting Machines

Various types of CNC machines are available for metal cutting, each with its own strengths and capabilities. Some popular options include CNC milling machines, lathes, and plasma cutters. Understanding the differences between these machines will help you determine which one is best suited for your specific metal cutting needs.

Key Considerations when Selecting a CNC Machine for Metal Cutting

Choosing the right CNC machine for metal cutting is crucial for efficient and precise production. Here are some key considerations to guide your selection:

- Machine Capacity: The size and thickness of the metals you'll be cutting dictate the machine's minimum work envelope and cutting force. Ensure the CNC machine has enough travel and power to handle your materials.

- Spindle Speed and Power: Spindle speed and power determine how fast the cutting tool can rotate and the force it can exert. Harder metals or deeper cuts necessitate a machine with a high-power spindle for efficient material removal.

- Accuracy Requirements: The precision needed for your parts will influence your machine selection. High-tolerance parts may require a CNC machine with superior rigidity and advanced control systems.

- Software Compatibility: Consider the Computer Aided Manufacturing (CAM) software you plan to use. Ensure compatibility with the machine's control system for seamless program transfer and machine operation.

By carefully evaluating these factors, you can select a CNC machine that optimizes your metal cutting operations for precision and productivity.

SYIL CNC Machine: Precision and Sustainability Combined

In your search for a reliable CNC machine for metal cutting, look no further than SYIL Machine Tools. SYIL develops and manufactures precision CNC machines for milling and drilling; over 12k machines are supplied globally. They prioritize quality and sustainability in their designs, ensuring that their machines deliver exceptional performance while minimizing environmental impact.

By choosing a SYIL CNC machine, you can trust that you are investing in top-notch technology that combines precision with sustainable manufacturing practices. With their commitment to quality and innovation, SYIL is your trusted partner in achieving optimal efficiency in metal cutting operations.

Enhancing Precision in CNC Metal Cutting

Precision is paramount in metal cutting processes, as even the slightest error can lead to significant consequences. CNC machines have revolutionized metal cutting by offering advanced techniques that ensure accuracy and precision.

Importance of Accuracy in Metal Cutting Processes

Metal cutting processes are fundamental to many industries, and achieving precise cuts is critical for success. Here's why:

- Ensures Product Quality and Functionality: Accurate cuts directly impact the final product's quality and functionality. Inaccurate cuts can lead to misalignment, improper assembly, and compromised performance.

- Enables Intricate Designs: Modern metal cutting allows for the creation of highly detailed and intricate designs. Precise cuts are essential for achieving these complex shapes and features.

- Maintains Tight Tolerances: Many industries, like aerospace and medical device manufacturing, require parts to meet exact dimensional specifications (tolerances). Accurate metal cutting ensures these tolerances are achieved, guaranteeing proper fit and function.

- Customer Satisfaction and Industry Standards: Meeting customer requirements and adhering to industry standards rely heavily on precise metal cutting. Inaccurate cuts can lead to product rejection, delays, and potential safety hazards.

By prioritizing accuracy in metal cutting processes, manufacturers can ensure they produce high-quality, functional parts that meet customer expectations and industry regulations.

Advanced Techniques for Achieving Precision in CNC Metal Cutting

To achieve precision in CNC metal cutting, advanced techniques are employed. These include high-speed machining, which utilizes rapid tool movements to minimize vibrations and improve accuracy. Additionally, multi-axis machining allows for complex cuts from multiple angles, resulting in precise and intricate shapes.

Another technique is laser cutting, which uses a focused laser beam to accurately melt or vaporize the material. This method offers exceptional precision with minimal material distortion or damage.

SYIL CNC Machine: Delivering Unparalleled Precision in Metal Cutting

When it comes to precision metal cutting, SYIL CNC machines stand out from the competition. With their state-of-the-art technology and innovative features, SYIL machines offer unparalleled accuracy and reliability.

SYIL's CNC metal cutting machines are equipped with high-precision linear guides and ball screws that ensure smooth movements with minimal backlash. This reduces errors caused by mechanical play and guarantees precise cuts every time.

Moreover, SYIL's machines incorporate advanced control systems that optimize tool paths for maximum precision. These systems utilize real-time feedback to adjust cutting parameters on the fly, compensating for any variations or deviations during the process.

With SYIL CNC machines' exceptional precision capabilities, manufacturers can confidently tackle complex projects while maintaining superior quality standards.

Optimizing Speed and Efficiency in CNC Metal Cutting

In CNC machine cutting metal, speed plays a crucial role in determining efficiency. The faster the machine can cut through the metal, the more productive and cost-effective the process becomes.

The Impact of Speed on CNC Metal Cutting Efficiency

CNC metal cutting machines rely on a critical balance: speed versus precision. Here's how cutting speed affects efficiency in your workflow:

- Increased Throughput: Faster cutting speeds directly translate to shorter production times. This allows you to complete more jobs in a shorter timeframe, boosting your overall output and profitability.

- Reduced Costs: Faster machining minimizes labor and energy consumption. This translates to lower operational costs, improving your bottom line.

Finding the Optimal Speed

It's crucial to find the sweet spot between speed and precision. Pushing the limits of speed can compromise the accuracy and quality of the final product. This is where advanced CNC machines like SYIL excel. They deliver high-speed cutting while maintaining exceptional precision, ensuring efficiency and a flawless finish.

Understanding the impact of cutting speed allows you to optimize your CNC machining process for maximum efficiency and quality.

Strategies for Increasing Efficiency in CNC Metal Cutting Operations

To optimize efficiency in CNC metal cutting operations, several strategies can be employed:

- Utilize high-quality cutting tools: Investing in premium-grade cutting tools ensures clean cuts, reduces tool wear, and minimizes downtime for tool replacement.

- Implement efficient programming techniques: By optimizing tool paths and reducing unnecessary movements, programming techniques can significantly improve cutting time while maintaining precision.

- Optimize machine parameters: Fine-tuning machine parameters such as feed rates, spindle speeds, and depth of cut can help achieve faster cutting speeds without compromising quality.

- Implement automation features: Advanced CNC machines like SYIL offer automation features such as tool changers and robotic loading systems that further enhance efficiency by reducing manual intervention.

SYIL CNC Machine: Cutting-Edge Technology for Faster and More Efficient Metal Cutting

SYIL Machine Tools develops precision CNC machines to optimize speed and efficiency in metal cutting processes. With their state-of-the-art technology, SYIL machines deliver exceptional performance while ensuring accuracy and reliability.

Equipped with high-speed spindles and advanced control systems, SYIL CNC machines offer rapid cutting speeds without compromising precision. The machines are also designed sustainably, utilizing energy-efficient components to reduce environmental impact.

By investing in a SYIL CNC machine, manufacturers can significantly enhance their metal-cutting efficiency, increase productivity, and ultimately improve their bottom line.

Overcoming Challenges in CNC Metal Cutting

CNC metal cutting processes can present various challenges that must be addressed for optimal efficiency and precision. Understanding these common issues and implementing proven solutions is crucial to successful metal cutting operations. The SYIL CNC Machine is specifically designed to tackle complex metal cutting projects, providing advanced solutions to overcome these challenges.

Common Issues Faced in CNC Metal Cutting Processes

CNC metal cutting offers a precise and efficient way to create complex parts. However, several factors can affect the quality and efficiency of the process. Here are some of the most common issues encountered in CNC metal cutting:

- Tool Wear: Over time, cutting tools become dull due to friction and contact with the metal. This can lead to reduced accuracy, poor surface finish, and increased cutting forces.

- Chip Evacuation: Metal chips are a byproduct of the cutting process. If these chips are not effectively removed from the cutting zone, they can accumulate and cause tool breakage, overheating, and poor cutting performance.

- Maintaining Consistent Speeds and Feeds: CNC machining relies on precise control of spindle speeds and feed rates. Inconsistent speeds can lead to vibrations, chatter marks, and a compromised cut quality.

By understanding and addressing these challenges, machinists can ensure smooth operation, high-quality parts, and efficient CNC metal cutting processes.

Proven Solutions for Overcoming Challenges in CNC Metal Cutting

To address tool wear, high-quality cutting tools with proper coatings and geometries can significantly improve tool life. Implementing effective chip evacuation strategies, such as chip breakers or coolant systems, helps prevent chip buildup and ensures smooth machining operations. Furthermore, adaptive control systems that adjust feed rates and spindle speeds based on real-time conditions enhance process stability.

SYIL CNC Machine: Designed to Tackle Complex Metal Cutting Projects

SYIL Machine Tools understands the challenges faced in CNC metal cutting processes and has developed its machines with innovative features to overcome them. Their machines have advanced tool monitoring systems that detect tool wear and automatically adjust machining parameters for optimal performance. With efficient chip evacuation mechanisms and integrated coolant systems, SYIL machines ensure uninterrupted production without compromising accuracy or surface finish.

By addressing common challenges faced in CNC metal cutting processes through proven solutions, SYIL Machine Tools offers a reliable solution for precision metal cutting. Their CNC machines are designed to optimize efficiency and accuracy, providing sustainable and high-quality results. Embrace the future of metal cutting with SYIL CNC Machine Tools and experience the difference in performance and reliability.

Exploring Advanced CNC Metal Cutting Techniques

Innovation is key to staying ahead in the ever-evolving world of metal cutting. This section will delve into the latest CNC metal cutting technology advancements and highlight cutting-edge techniques that maximize efficiency. SYIL CNC Machine, a leading manufacturer of precision CNC machines, is at the forefront of embracing these advancements.

Innovations in CNC Metal Cutting Technology

The field of CNC metal cutting has witnessed remarkable innovations that have revolutionized the industry. One such innovation is the development of laser technology for metal cutting. Laser-cutting machines, such as the SYIL CNC Machine, utilize high-powered lasers to cut through various metals with incredible speed and accuracy precisely. This advancement has significantly increased productivity and reduced material waste.

Additionally, computer software advancements have enhanced CNC machines' capabilities for metal cutting. With sophisticated algorithms and real-time data analysis, these machines can optimize tool paths and adjust cutting parameters on the fly for improved efficiency and precision.

Cutting-Edge Techniques for Maximizing Efficiency in CNC Metal Cutting

Several cutting-edge techniques have emerged to achieve optimal efficiency in CNC metal cutting operations. One such technique is high-speed machining (HSM), which involves using higher spindle speeds and feed rates to remove material rapidly while maintaining accuracy. HSM reduces cycle times and increases productivity without compromising quality.

Another technique gaining traction is multi-axis machining. By utilizing multiple axes simultaneously, complex geometries can be achieved in a single setup, eliminating the need for additional operations or setups. This technique saves time, reduces errors, and enhances overall efficiency.

SYIL CNC Machine: Embracing the Latest Advancements in Metal Cutting Technology

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling while prioritizing quality and sustainability. Their range of advanced CNC metal cutting machines incorporates the latest innovations to deliver exceptional performance.

The SYIL LaserCut 3015 is a prime example of their commitment to embracing cutting-edge technology. This CNC laser cutting machine for metal utilizes high-powered lasers to achieve precise and efficient cuts. Its advanced software and intelligent control system optimize cutting paths, resulting in faster production times and reduced material waste.

In conclusion, exploring advanced CNC metal cutting techniques is crucial for maximizing efficiency and productivity. Innovations such as laser technology and multi-axis machining have transformed the industry, while SYIL CNC Machine continues to lead the way by embracing these advancements. With their precision and sustainability-focused approach, SYIL machines are ideal for businesses seeking optimal results in metal cutting operations.

Conclusion

Harnessing the Power of CNC Machine Cutting for Optimal Efficiency

In conclusion, CNC machine cutting has revolutionized the metal cutting industry by offering precision, speed, and efficiency. By utilizing advanced techniques and state-of-the-art technology, these machines have become essential tools for maximizing productivity in metal cutting operations. By consistently delivering accurate results, CNC machines ensure optimal efficiency in every project.

SYIL CNC Machine: Your Partner in Precision Metal Cutting

When it comes to precision metal cutting, SYIL CNC Machines stands out as a reliable partner. With their commitment to quality and sustainability, SYIL Machine Tools have developed a range of precision CNC machines specifically designed for milling and drilling tasks. These machines offer unparalleled accuracy and efficiency, making them the ideal choice for any metal cutting project.

Embrace the Future of Metal Cutting with SYIL CNC Machine Tools

As technology advances, it is crucial to embrace the future of metal cutting with innovative solutions like SYIL CNC Machine Tools. These machines incorporate cutting-edge features, such as laser technology, that enable precise and efficient metal cutting. By investing in SYIL CNC machines, you can stay ahead of the competition and unlock new possibilities in your metal cutting endeavors.

By harnessing the power of CNC machine cutting for optimal efficiency and partnering with SYIL CNC Machine Tools, you can elevate your metal cutting capabilities to new heights. Say goodbye to manual labor and inefficiency and embrace the precision and speed of CNC machines. With SYIL's commitment to quality and sustainability, you can trust their CNC machines to deliver exceptional results in every metal cutting project. Don't miss out on the future of metal cutting - choose SYIL CNC Machine Tools today!