Introduction

Understanding the Importance of CNC Machine Precision

In today's highly competitive manufacturing industry, precision is paramount. CNC machine precision refers to the ability of a computer numerical control (CNC) machine to consistently produce accurate and reliable results. Whether it's a precision CNC lathe or a high-precision 10-axis CNC machine, the level of accuracy directly impacts the quality and efficiency of machining operations.

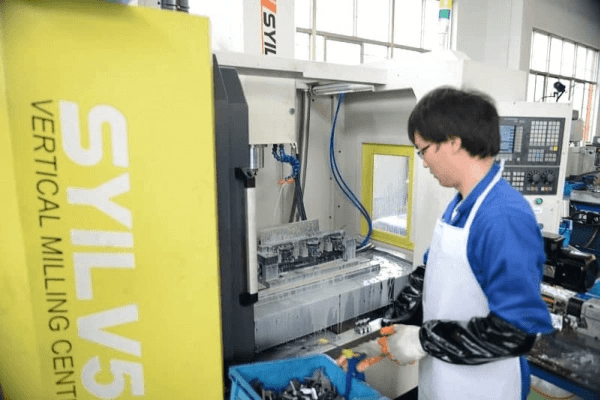

When it comes to precision CNC machines, SYIL Machine Tools stands out as a leading manufacturer and supplier. With over 12k machines supplied globally, SYIL prioritizes quality and sustainability in their designs. Their commitment to delivering accurate CNC machining capabilities has earned them a reputation for excellence in the industry.

The Fundamentals of CNC Machine Precision

CNC machine precision is the ability of a computer numerical control (CNC) machine to consistently produce accurate and reliable results. It involves the tight tolerances and exact measurements required for tasks such as milling, drilling, and cutting. SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Exploring the Basics: What is CNC Machine Precision?

CNC machine precision refers to the level of accuracy that can be achieved in the manufacturing process using computer-controlled machines. These machines are programmed with specific instructions to perform precise movements and operations on various materials. The accuracy of a CNC machine is determined by its ability to consistently reproduce these movements within tight tolerances.

The Role of Precision in Optimizing Performance

Precision plays a crucial role in optimizing the performance of CNC machines. When components are manufactured with high precision, they fit together seamlessly, resulting in smoother operation and reduced wear and tear. This leads to improved overall performance, increased productivity, and decreased downtime.

SYIL Machine Tools understands the importance of precision in optimizing performance. Their CNC machines are designed with advanced features that ensure accurate and repeatable results, even in complex machining tasks.

SYIL's Commitment to Accuracy and Reliability

SYIL Machine Tools is committed to providing CNC machines that deliver exceptional accuracy and reliability. They utilize state-of-the-art technology combined with rigorous quality control measures to ensure that their machines meet the highest standards.

With their focus on precision engineering, SYIL's CNC machines offer outstanding machining capabilities for a wide range of applications. Whether it's a high precision CNC lathe or a 10-axis CNC machine, SYIL's commitment to accuracy remains unwavering.

In the next section, we will explore the factors that can affect CNC machine precision and strategies for maximizing it. Stay tuned!

Factors Affecting CNC Machine Precision

Machine Accuracy: Components and Calibration

To achieve high precision in CNC machining, it is crucial to consider the machine's accuracy, which depends on the quality of its components and calibration. SYIL Machine Tools understands this importance and prioritizes the use of top-notch components in their CNC machines. From robust linear guides to high-precision ball screws, every aspect is designed to ensure minimal backlash and maximum accuracy.

Calibration plays a significant role in maintaining precision over time. SYIL's CNC machines undergo meticulous calibration processes to fine-tune their performance. This includes adjusting parameters such as axis alignment, backlash compensation, and spindle runout. By regularly calibrating their machines, SYIL ensures that they consistently deliver accurate results for various machining applications.

Tooling Considerations for Enhanced Precision

In addition to machine accuracy, tooling considerations also contribute to achieving enhanced precision in CNC machining. The selection of cutting tools, such as end mills or drills, can significantly impact the final result. SYIL Machine Tools provides a wide range of cutting tools specifically designed for high precision applications.

Using advanced coatings and geometries, these tools offer improved wear resistance and reduced cutting forces, resulting in superior surface finishes and dimensional accuracy. By choosing the right tooling options from SYIL's comprehensive range, manufacturers can optimize their CNC machining capabilities for precise operations.

Environmental Factors and Their Impact on Precision

Environmental factors can affect CNC machine precision if not properly managed. Temperature variations can cause thermal expansion or contraction of machine components, leading to dimensional inaccuracies in machined parts. To mitigate this issue, SYIL incorporates temperature compensation features into their CNC machines.

By monitoring temperature changes within the machine's environment and making real-time adjustments to compensate for thermal effects on component dimensions, SYIL ensures consistent precision even under varying conditions.

Additionally, dust and debris accumulation can negatively impact precision by interfering with machine components and affecting their movement. SYIL Machine Tools emphasizes the importance of proper maintenance and cleaning techniques to prevent such issues. Regularly removing debris and lubricating critical parts helps maintain optimal precision throughout the machine's lifespan.

Strategies for Maximizing CNC Machine Precision

Precision in CNC machine operations can be maximized through various strategies. By implementing proper maintenance and cleaning techniques, choosing the right cutting parameters, and leveraging advanced software and technologies, manufacturers can achieve superior levels of accuracy and reliability.

Proper Maintenance and Cleaning Techniques

Maintaining a CNC machine is crucial for ensuring its optimal performance and precision. Regularly cleaning the machine's components, such as the spindle, tool holders, and worktable, helps prevent the accumulation of debris that can affect accuracy. Additionally, lubricating moving parts with high-quality oils or greases reduces friction and enhances smooth operation.

Proper maintenance also involves inspecting critical components for wear and tear. By regularly checking belts, bearings, and guides for any signs of damage or misalignment, manufacturers can address issues promptly before they impact precision. Implementing a preventive maintenance schedule that includes routine inspections and necessary repairs will help prolong the lifespan of the machine while maintaining its accuracy.

Choosing the Right Cutting Parameters for Precision

Selecting appropriate cutting parameters is essential for achieving precision in CNC machining operations. Factors such as feed rate, spindle speed, depth of cut, and tool selection significantly impact the final product's accuracy.

By understanding the material being machined and its specific requirements, manufacturers can adjust these parameters accordingly. For instance, using a slower feed rate when machining delicate materials or reducing depth of cut to minimize vibrations can enhance precision.

Furthermore, utilizing high-quality cutting tools specifically designed for precision machining ensures consistent results. Tools with sharp edges made from durable materials increase cutting efficiency while maintaining dimensional accuracy.

Leveraging Advanced Software and Technologies

In today's digital era, advanced software solutions play a pivotal role in maximizing CNC machine precision. CAD/CAM software enables manufacturers to design intricate parts with high precision and convert them into machine-readable programs.

Simulation software allows for virtual testing of machining processes, identifying potential errors or interferences before actual production. By simulating the entire machining operation, manufacturers can optimize tool paths and minimize material wastage, leading to improved precision.

Additionally, incorporating technologies like laser measurement systems and in-process monitoring further enhances accuracy. These systems provide real-time feedback on dimensional variations during machining, allowing for immediate adjustments to maintain precision.

SYIL Machine Tools understands the importance of these strategies in achieving CNC machine precision. Their commitment to developing cutting-edge software and leveraging innovative technologies ensures their machines deliver exceptional results consistently.

By implementing proper maintenance practices, choosing the right cutting parameters, and harnessing advanced software and technologies, manufacturers can unlock the full potential of CNC machine precision. This not only enhances product quality but also provides a competitive edge in the industry.

Advanced Techniques for CNC Machine Precision

High-Speed Machining: Balancing Speed and Accuracy

In the world of precision manufacturing, speed and accuracy are crucial factors. High-speed machining (HSM) is a technique that allows for faster material removal rates while maintaining precision. By utilizing advanced cutting tools and optimizing tool paths, HSM achieves efficient machining without compromising accuracy.

SYIL Machine Tools recognizes the importance of high-speed machining in today's competitive market. Their CNC machines are equipped with powerful spindles and robust control systems, enabling them to handle high cutting speeds with ease. With SYIL's high-speed machining capabilities, manufacturers can achieve shorter cycle times without sacrificing precision.

5-Axis Machining: Unlocking New Levels of Precision

Traditional CNC machines typically operate in three axes: X, Y, and Z. However, complex parts often require more intricate machining techniques. 5-axis machining provides a solution by allowing simultaneous movement along five axes, enabling manufacturers to achieve intricate geometries and precise angles.

SYIL Machine Tools offers advanced 5-axis CNC machines that push the boundaries of precision engineering. These machines provide unparalleled flexibility and accuracy in manufacturing complex components. With SYIL's 5-axis machining capabilities, manufacturers can achieve exceptional levels of precision in their products.

SYIL's Innovative Approaches to Precision Engineering

SYIL Machine Tools has always been at the forefront of innovation when it comes to precision engineering. They continuously invest in research and development to improve their CNC machines' performance and accuracy.

One notable innovation from SYIL is their development of a 10-axis CNC machine. This groundbreaking technology allows for even greater flexibility and precision in machining operations. With ten axes of movement, manufacturers can achieve highly complex shapes with utmost accuracy.

SYIL's commitment to innovation ensures that their customers have access to cutting-edge technologies that enhance their precision manufacturing capabilities.

Achieving Precision in Specific Applications

Precision Milling Techniques and Best Practices

When it comes to precision milling, SYIL Machine Tools stands out as a leader in the industry. Their CNC machines offer exceptional accuracy and reliability, making them the ideal choice for any milling application. From small-scale projects to large-scale production, SYIL's precision CNC lathe machines deliver outstanding results.

To achieve precision in milling, it is crucial to consider several factors. First and foremost, selecting the right cutting tools is essential. SYIL's CNC machining capabilities allow for the use of high-quality tools that ensure precise cuts and smooth finishes.

Additionally, proper machine calibration plays a crucial role in achieving accuracy. SYIL's machines are meticulously calibrated to guarantee optimal performance. This attention to detail ensures that every milling operation is executed with utmost precision.

Moreover, employing best practices such as maintaining a stable workpiece setup and utilizing advanced software can further enhance precision. SYIL's CNC machines are equipped with innovative technologies that enable operators to monitor and adjust cutting parameters in real-time, resulting in unparalleled precision.

Precision Drilling Strategies for Superior Results

Drilling operations require meticulous attention to detail to achieve accurate results consistently. SYIL Machine Tools understands this need for precision drilling and has developed cutting-edge solutions to meet these requirements.

One of the key aspects of achieving accuracy in drilling is selecting the appropriate drill bits. SYIL's CNC machines offer a wide range of options, including high-speed steel (HSS) and carbide drill bits that deliver exceptional performance.

Furthermore, maintaining proper feed rates and spindle speeds is crucial for precise drilling operations. SYIL's 10-axis CNC machine provides operators with precise control over these parameters, ensuring optimal drilling speed while maintaining accuracy.

Case Studies: Real-World Examples of Precision Achievements

SYIL Machine Tools has an impressive track record of delivering precision achievements across various industries. Let us explore some real-world case studies that highlight their CNC machine's capabilities.

In the automotive industry, SYIL's accurate CNC machines have been used to manufacture complex engine components with tight tolerances. These precision-machined parts contribute to improved engine performance and fuel efficiency.

Additionally, in the aerospace sector, SYIL's high-precision CNC machines have played a crucial role in producing intricate parts for aircraft engines. The accuracy and reliability of these machines ensure that critical components meet stringent quality standards.

Conclusion

Embracing CNC Machine Precision for Competitive Edge

In today's highly competitive manufacturing industry, embracing CNC machine precision is crucial for gaining a competitive edge. By utilizing the advanced capabilities of precision CNC lathes and machines, manufacturers can achieve unparalleled accuracy and efficiency in their operations. With SYIL Machine Tools as your partner in precision manufacturing, you can stay ahead of the competition and meet the demands of the market.

SYIL Machine Tools: Your Partner in Precision Manufacturing

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their commitment to accuracy and reliability ensures that their machines deliver exceptional results every time. By choosing SYIL as your partner, you can rely on their expertise to enhance your production capabilities.

Unlocking the Full Potential of CNC Machine Precision

To unlock the full potential of CNC machine precision, it is essential to explore advanced techniques and strategies. Proper maintenance and cleaning techniques are crucial for ensuring long-term accuracy. Choosing the right cutting parameters tailored to your specific needs further enhances precision. Additionally, leveraging advanced software and technologies can optimize performance and maximize efficiency.

By embracing these strategies along with SYIL's innovative approaches to precision engineering, manufacturers can achieve exceptional results across various applications. Whether it's precision milling or drilling, SYIL's machines provide the accuracy required for superior outcomes.