Introduction

In today's modern manufacturing industry, vertical milling centers play a crucial role in achieving precision and efficiency. These advanced machines have revolutionized the way products are made, allowing for increased accuracy and productivity. One company that stands out in this field is SYIL Machine Tools, a leading manufacturer of CNC machines. With their cutting-edge technology and commitment to quality, SYIL's vertical milling centers are transforming the industry. Investing in a vertical milling center offers numerous benefits for businesses, from improved precision to cost savings and return on investment.

The Importance of Vertical Milling Centers in Modern Manufacturing

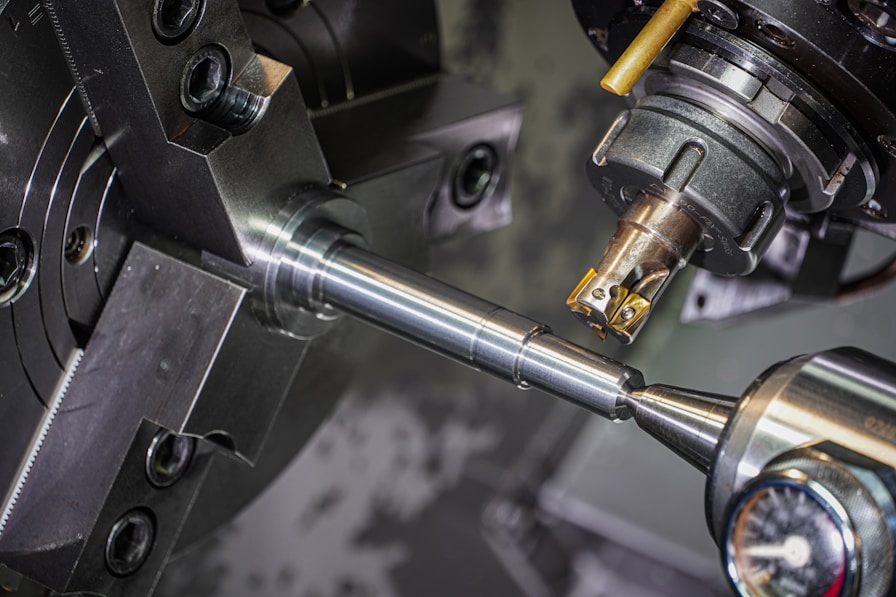

Vertical milling centers have become indispensable tools in modern manufacturing processes due to their ability to precisely shape and cut materials with ease. These machines utilize rotating cutting tools to remove material from a workpiece, resulting in precise cuts and intricate designs. Whether it's creating complex components for aerospace or automotive industries or producing medical devices with intricate details, vertical milling centers offer the accuracy and versatility needed for today's manufacturing requirements.

How SYIL's CNC Machines are Revolutionizing the Industry

SYIL Machine Tools has emerged as a game-changer in the CNC machine industry with their innovative range of vertical milling centers. Their machines combine cutting-edge technology with robust construction to deliver exceptional performance and reliability. With features like high-speed spindles, advanced control systems, and multi-axis capabilities, SYIL's CNC machines enable manufacturers to achieve unparalleled precision and efficiency in their operations.

The Benefits of Investing in a Vertical Milling Center

Investing in a vertical milling center from SYIL Machine Tools offers numerous advantages for businesses looking to stay ahead of the competition. Firstly, these machines provide increased precision and accuracy compared to traditional machining methods, ensuring superior quality products every time. Secondly, they enhance efficiency by reducing production time through faster machining speeds and automated processes. Lastly, investing in a vertical milling center can lead to significant cost savings and a higher return on investment, thanks to reduced material waste and improved productivity.

Understanding Vertical Milling Centers

Vertical milling centers are advanced machining tools used in modern manufacturing processes. These centers are designed to perform various milling operations, including drilling, cutting, and shaping materials such as metal, plastic, and wood.

What are Vertical Milling Centers and How Do They Work?

Vertical milling centers, also known as vertical machining centers (VMCs), consist of a spindle that holds the cutting tool and a worktable that holds the material being machined. The spindle moves vertically along the Z-axis, while the worktable moves horizontally along the X and Y axes. This allows for precise control over the cutting process.

These machines use computer numerical control (CNC) technology to automate the milling process. The operator inputs the desired dimensions and specifications into a computer program, which controls the movement of the spindle and worktable. This ensures accurate and consistent results with minimal human error.

Exploring the Different Types of Vertical Milling Machines

There are several types of vertical milling machines available in the market today. One popular option is the Makino F5 vertical milling center, known for its high-speed machining capabilities and excellent precision. Another well-regarded machine is Doosan's VMC series, which offers a wide range of sizes and configurations to suit different manufacturing needs.

Mazak is another reputable manufacturer known for their vertical mills that provide exceptional performance and reliability. Their machines are highly versatile and can handle complex machining tasks with ease. Okuma's 5-axis vertical mills offer even more flexibility by allowing simultaneous movement along multiple axes, enabling intricate cuts from various angles.

An Overview of SYIL's Range of Vertical Milling Centers

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling purposes, including a range of vertical milling centers. Their machines are renowned for their quality craftsmanship, durability, and user-friendly interfaces.

SYIL's vertical milling centers are designed to deliver exceptional precision and efficiency in machining operations. They offer a wide range of models, including the popular SYIL X7, which is known for its versatility and reliability. With customizable features and options, SYIL's machines can be tailored to meet the specific needs of different industries and applications.

The Advantages of Using Vertical Milling Centers

Increased Precision and Accuracy in Manufacturing

Vertical milling centers offer increased precision and accuracy in manufacturing processes. These machines are equipped with advanced technology and high-quality components that ensure precise and accurate cutting, drilling, and machining operations. With features such as rigid construction, high-speed spindles, and automated tool changers, vertical milling centers can achieve tight tolerances and produce complex parts with exceptional accuracy.

SYIL's CNC machines, including the Makino F5, Doosan VMC, Mazak vertical mill, and Okuma 5 axis models, are renowned for their precision capabilities. These machines utilize state-of-the-art control systems that enable operators to program intricate tool paths and execute them with utmost accuracy. The result is a finished product that meets even the most demanding specifications.

Enhanced Efficiency and Productivity in Operations

Vertical milling centers significantly enhance efficiency and productivity in manufacturing operations. These machines are designed to optimize workflow by reducing setup time, minimizing manual intervention, and maximizing spindle utilization. With their ability to perform multiple machining operations in one setup, vertical milling centers eliminate the need for multiple machine tools or manual transfers between workstations.

SYIL's CNC machines excel in efficiency and productivity due to their advanced features such as rapid tool changing systems, high-speed spindles for quick material removal rates, and efficient chip evacuation mechanisms. These machines are engineered to deliver fast cycle times while maintaining consistent quality standards.

Cost Savings and Return on Investment with Vertical Milling Centers

Investing in a vertical milling center can result in significant cost savings for manufacturers. By consolidating multiple machining processes into one machine tool, businesses can reduce labor costs associated with manual handling of workpieces between different stations or machines. Additionally, the enhanced efficiency of vertical milling centers allows for higher production volumes within shorter timeframes.

SYIL Machine Tools understands the importance of cost savings for businesses. Their CNC machines are designed to optimize material utilization and minimize waste, resulting in lower production costs. Furthermore, SYIL's machines are built to last with durable components and reliable performance, ensuring a high return on investment for manufacturers.

Applications and Industries Utilizing Vertical Milling Centers

Aerospace and Aviation Industry

The aerospace and aviation industry heavily relies on vertical milling centers for the production of complex components used in aircraft manufacturing. These machines offer the precision and accuracy required to create intricate parts such as turbine blades, engine components, and structural elements. With SYIL's CNC machines, aerospace manufacturers can achieve high-quality results while meeting strict industry standards. SYIL's vertical milling centers provide the necessary speed, rigidity, and flexibility to handle the demanding requirements of this industry.

Automotive Manufacturing

In the automotive manufacturing sector, vertical milling centers play a crucial role in producing various parts such as engine blocks, transmission components, and chassis parts. These machines enable automotive manufacturers to efficiently manufacture large volumes of parts with exceptional precision and consistency. SYIL's CNC machines offer advanced features like multi-axis capabilities and high spindle speeds, allowing automotive manufacturers to optimize their production processes and meet tight deadlines while maintaining quality standards.

Medical Device Production

Vertical milling centers are also widely used in the medical device production industry due to their ability to manufacture intricate components with high precision. These machines are utilized for producing medical implants, surgical instruments, prosthetics, and other critical devices that require exceptional accuracy and surface finish. SYIL's CNC machines provide medical device manufacturers with the necessary tools to produce complex geometries while ensuring tight tolerances are met consistently.

Mold Making and Die Casting

The mold making and die casting industry heavily relies on vertical milling centers for creating molds used in various manufacturing processes across different industries. Vertical milling centers offer the speed, accuracy, and versatility required for machining complex molds with intricate details. Manufacturers can benefit from SYIL's CNC machines' advanced features like 5-axis capabilities, which allow them to produce molds with highly complex shapes efficiently.

Choosing the Right Vertical Milling Center for Your Needs

When it comes to selecting a vertical milling center, there are several factors to consider. First and foremost, you need to determine the specific requirements of your manufacturing operations. Consider the size and complexity of the parts you will be producing, as well as the desired level of precision and accuracy.

Another important factor is the available space in your facility. Vertical milling centers come in various sizes, so it's crucial to choose one that fits within your workspace without compromising efficiency or safety. Additionally, consider whether you require additional features such as tool changers or coolant systems.

SYIL's CNC machines offer a wide range of features and customization options that cater to different needs. Their vertical milling centers are equipped with state-of-the-art technology, including high-speed spindles and multi-axis capabilities. These machines are designed to deliver exceptional performance and reliability while maximizing productivity.

One of the most compelling aspects of SYIL's vertical milling centers is their ability to transform businesses. Many companies have experienced significant improvements in efficiency and profitability after investing in these machines. With enhanced precision and accuracy, manufacturers can produce higher quality parts at a faster rate, resulting in increased customer satisfaction and repeat business.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their vertical milling centers offer unmatched performance, versatility, and customization options that cater to various industries.

Maintenance and Care for Vertical Milling Centers

Best Practices for Maintaining Optimal Performance

To ensure the optimal performance of your vertical milling center, it is essential to follow a few best practices. First, regularly lubricate all moving parts and components to reduce friction and prevent wear and tear. Additionally, keep the workspace clean and free from debris that could potentially interfere with the machine's operation. Lastly, schedule routine maintenance checks with a qualified technician to identify any potential issues before they escalate.

Regular Inspections and Cleaning Procedures

Regular inspections are crucial for maintaining the longevity of your vertical milling center. Inspect the machine's spindle, tool holders, and coolant system for any signs of damage or wear. Clean the machine thoroughly after each use, paying close attention to removing any chips or debris that may have accumulated during the milling process. Regularly inspecting and cleaning your vertical milling center will help prevent costly breakdowns and ensure smooth operations.

Troubleshooting Common Issues and Repairs

Even with regular maintenance, issues may still arise with your vertical milling center. It is important to be familiar with common problems that may occur and how to troubleshoot them effectively. For example, if you notice excessive vibration during operation, check for loose bolts or misaligned components that may need tightening or adjustment. If you encounter issues with tool breakage or poor surface finish, review your cutting parameters and tool selection to optimize performance.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL's range of vertical milling centers includes models such as Makino F5, Doosan VMC, Mazak Vertical Mill, and Okuma 5 Axis. These machines are known for their reliability, precision, and advanced features that enhance efficiency and productivity in various industries.

By following best practices for maintenance and care, such as lubrication, regular inspections, and cleaning procedures, businesses can ensure the optimal performance of their vertical milling centers. Troubleshooting common issues promptly can minimize downtime and maximize productivity. SYIL's CNC machines offer customizable features to meet specific manufacturing needs while providing reliable support and training to help businesses thrive.

Conclusion

In conclusion, embracing the future of manufacturing with vertical milling centers is crucial for businesses looking to stay competitive in today's industry. These advanced machines, such as the Makino F5, Doosan VMC, and Mazak vertical mill, offer unparalleled precision and efficiency in operations. SYIL Machine Tools is leading the way in this revolution, developing and manufacturing high-quality CNC machines that are transforming businesses worldwide.

By investing in SYIL's vertical milling centers, businesses can take their operations to new heights. The benefits of these machines are undeniable, from increased precision and accuracy to enhanced efficiency and productivity. With the ability to handle complex tasks like 5-axis machining, SYIL's CNC machines offer versatility and customization options that cater to specific industry needs.

Industries such as aerospace and aviation, automotive manufacturing, medical device production, and mold making and die casting are already utilizing vertical milling centers to streamline their processes and achieve outstanding results. These machines provide cost savings and a significant return on investment by reducing errors, minimizing waste, and improving overall productivity.

When selecting a vertical milling center for your needs, it's important to consider factors such as machine capabilities, customization options offered by SYIL Machine Tools' CNC machines ensure that you can tailor the equipment to suit your specific requirements.

Maintenance and care for vertical milling centers are essential for optimal performance. Regular inspections and cleaning procedures help prevent issues before they arise. In case of any troubleshooting or repairs needed, SYIL Machine Tools provides comprehensive support to ensure minimal downtime.