Introduction

In the world of CNC machining, selecting the right material is a crucial step that can make or break your project. The CNC material list is extensive, with options ranging from metals to plastics and wood, each offering unique properties and benefits. Understanding what material is used in CNC processes not only enhances the quality of your output but also influences efficiency and cost-effectiveness.

Understanding CNC Material Selection

CNC machining relies on various materials, making understanding their properties essential for successful projects. Factors such as strength, weight, and machinability should guide your choices when navigating the CNC material list. Whether you're asking yourself What metal is used in CNC? or considering other options like plastics or wood, knowing the characteristics of each material will lead to better decisions.

Why Material Choice Matters

Choosing the right material impacts not just the final product's durability but also its functionality and aesthetic appeal. In many cases, different materials can yield vastly different results; hence understanding common materials used in CNC projects helps streamline this process. Additionally, when you consider questions like What is the material used in CNC fixtures? it becomes clear that every aspect of your project hinges on informed selection.

Overview of Common CNC Materials

A diverse range of materials populate the CNC landscape, each with its own set of advantages and applications. Metals such as aluminum and steel are often favored for their strength and durability, while plastics offer versatility at a lower cost—making them popular choices for prototyping and custom parts. Wood remains a classic choice due to its natural beauty and ease of workability; however, knowing how these materials fit into your project requires a solid grasp of their properties as well as an awareness of questions like What are the 7 major parts of a CNC machine? which further influence material selection.

Exploring the CNC Material List

When diving into the world of CNC machining, understanding the CNC material list is essential for making informed choices. The materials you select can significantly influence not only the performance of your project but also its overall cost and feasibility. Let’s break down some of the most common materials used in CNC projects, focusing on metals, plastics, and wood.

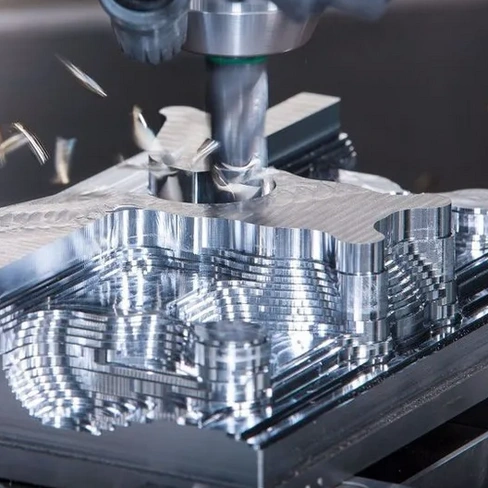

Metals: The Heavy Hitters

Metals are often considered the heavy hitters in the CNC material list due to their strength and durability. Common metals used in CNC include aluminum, steel, brass, and titanium—each offering unique properties suited for various applications. For instance, aluminum is lightweight yet robust, making it a popular choice for aerospace components; meanwhile, steel boasts superior strength and is frequently used in structural applications.

When selecting metal for a project, it's crucial to consider factors like machinability and cost-effectiveness. What metal is used in CNC? This question leads to a broad spectrum of answers depending on specific requirements like tensile strength or corrosion resistance. Ultimately, understanding these properties will guide you toward optimal CNC machining material selection.

Plastics: Versatility and Cost

Plastics are another significant player on the CNC material list due to their versatility and affordability. Materials such as acrylic, polycarbonate, and nylon offer a range of benefits from lightweight structures to vibrant colors that can enhance aesthetic appeal. Additionally, plastics are often easier to machine than metals—making them an attractive option for prototypes or low-volume production runs.

What material is used in CNC projects involving plastics? The answer varies widely; however, acrylic stands out due to its clarity and ease of fabrication while nylon offers excellent wear resistance—ideal for components that undergo frictional forces. As sustainability becomes more critical in manufacturing processes, biodegradable plastics may also find their way into future projects.

Wood: A Classic Choice

Wood remains a classic choice on the CNC material list thanks to its natural beauty and workability. From hardwoods like oak and maple to softer options such as pine or plywood panels, wood brings warmth and character that other materials may lack. It's particularly favored in furniture design but can also be utilized for signage or decorative items.

In terms of what is the material used in CNC fixtures? Often wood serves as an economical solution when creating custom jigs or fixtures tailored specifically for woodworking machines or other applications requiring precision alignment without breaking the bank. However, it’s essential to consider factors such as grain direction when planning cuts since they can affect both aesthetics and structural integrity.

What Material is Used in CNC Projects?

When diving into the world of CNC projects, understanding what material is used in CNC can significantly influence your outcomes. The choice of material not only affects the aesthetics and functionality of the final product but also plays a crucial role in the machining process itself. Let's explore some of the most common materials found on the CNC material list.

Aluminum: Lightweight Champion

Aluminum stands out as a prime candidate on any CNC material list, primarily due to its lightweight nature and excellent machinability. This metal is easy to cut and shape, making it a favorite for various applications, from aerospace components to intricate parts for consumer electronics. Its resistance to corrosion also makes aluminum an appealing choice for outdoor applications, ensuring longevity without heavy maintenance.

Additionally, aluminum is available in various alloys, each offering unique properties that can be tailored to specific project requirements. Whether you need something strong yet light or flexible yet durable, there's likely an aluminum alloy that fits your needs perfectly. As you consider what metal is used in CNC projects, remember that aluminum’s versatility allows it to shine across many industries.

Steel: Strength Meets Durability

Steel has earned its reputation as one of the strongest materials available on the CNC material list—ideal for projects requiring exceptional durability and structural integrity. This metal excels in high-stress environments where reliability is paramount; think automotive parts or heavy machinery components where failure isn't an option. While steel can be more challenging to machine than lighter metals like aluminum, advancements in cutting tools and techniques have made it increasingly accessible.

Moreover, steel comes in various grades and types—such as stainless steel or tool steel—each designed for specific properties like corrosion resistance or hardness. When considering what metal is used in CNC machining processes, it's hard to overlook steel's ability to withstand harsh conditions while providing lasting performance. If you're aiming for strength without sacrificing quality, steel should definitely be at the top of your list.

Acrylic: Color and Clarity

Acrylic might not be your first thought when pondering what materials are commonly used in CNC projects; however, this versatile plastic deserves a spot on any comprehensive cnc material list due to its unique properties. Known for its exceptional clarity and vibrant color options, acrylic offers a visually appealing alternative to glass while being lighter and more shatter-resistant—a win-win! Its ease of machining allows creators to achieve intricate designs that would be difficult with other materials.

In addition to aesthetic advantages, acrylic can also serve functional purposes by being utilized in displays or protective covers where visibility is essential but weight needs reduction. Whether you're designing signage or creating custom enclosures for electronics, acrylic provides both form and function effortlessly. So when considering your next project’s design elements alongside practical considerations like weight or durability—don't underestimate acrylic's potential!

The Role of CNC Fixtures

CNC fixtures play a pivotal role in the world of CNC machining, ensuring that materials are held securely during the machining process. When considering the CNC material list, it’s essential to recognize how fixture materials can influence the overall quality and precision of your projects. With a firm understanding of what material is used in CNC fixtures, you can enhance your machining efficiency and accuracy.

What is the Material Used in CNC Fixtures?

The material used in CNC fixtures is often selected based on its ability to withstand various forces while maintaining dimensional accuracy. Commonly, these materials include aluminum, steel, and high-density plastics, which provide different benefits depending on the application at hand. Knowing what metal is used in CNC fixtures can help you make informed choices from the broader CNC material list for your specific project requirements.

Importance of Fixture Material

Fixture material is crucial because it directly impacts the stability and repeatability of your machining operations. If you choose an inappropriate fixture material, it could lead to vibrations or misalignments that negatively affect precision—something every machinist dreads! Additionally, understanding what material is used in CNC fixtures helps streamline production processes by ensuring compatibility with both machine components and Common Materials Used in CNC Projects.

Types of Fixture Materials

There are several types of fixture materials available for various applications within CNC machining. Metals like aluminum are favored for their lightweight properties and strength; meanwhile, steel offers enhanced durability for more demanding tasks. On the other hand, plastics such as phenolic resins are popular due to their versatility and cost-effectiveness—making them a staple on any comprehensive cnc material list.

Common Materials Used in CNC Projects

When diving into the world of CNC machining, understanding the common materials used in CNC projects is crucial for achieving optimal results. The CNC material list is extensive, featuring a variety of options that cater to different needs and applications. From metals to plastics, each material offers unique properties that can significantly influence the final product's performance and aesthetics.

Comparing Different Material Properties

Different materials exhibit distinct properties that affect their suitability for various CNC applications. For instance, metals like aluminum and steel are known for their strength and durability, making them ideal for structural components. On the other hand, plastics such as acrylic offer versatility and lightweight characteristics, which can be advantageous in projects requiring intricate designs or color variations.

When considering what material is used in CNC projects, it's essential to evaluate factors like tensile strength, machinability, thermal resistance, and cost-effectiveness. These attributes play a pivotal role in determining how well a material will perform under specific conditions or loads during machining processes. Ultimately, comparing these properties within the context of your project will lead to more informed decisions regarding CNC machining material selection.

Application-Specific Material Selection

Choosing the right material often depends on the specific application at hand. For example, if you're designing parts for aerospace applications where weight reduction is critical without sacrificing strength, aluminum becomes a go-to option due to its lightweight nature combined with robust mechanical properties. Alternatively, if you need components that require excellent clarity and aesthetic appeal—think signage or display cases—acrylic would be an ideal choice from the CNC material list.

It's also important to consider what metal is used in CNC when working on applications requiring high corrosion resistance or wear resistance; stainless steel might be your best bet here. Each project has its own unique demands; thus understanding these application-specific requirements allows for better alignment between design goals and material selection strategies.

Sustainability and Material Choices

In today's manufacturing landscape, sustainability plays an increasingly vital role in choosing materials for CNC projects. Many manufacturers are now prioritizing eco-friendly materials that reduce environmental impact while maintaining performance standards—this shift reflects growing consumer awareness regarding sustainability issues within industries using the cnc material list as a reference point.

For instance, recycled metals can serve as viable alternatives without compromising on quality or functionality when considering what metal is used in CNC processes. Additionally, bio-based plastics are emerging as sustainable substitutes that help mitigate reliance on fossil fuels while offering desirable properties such as machinability and durability.

By integrating sustainability into your cnc machining material selection process—from evaluating fixture materials based on their environmental footprint to opting for recyclable options—you not only enhance your project's ecological credentials but also contribute positively toward industry-wide change.

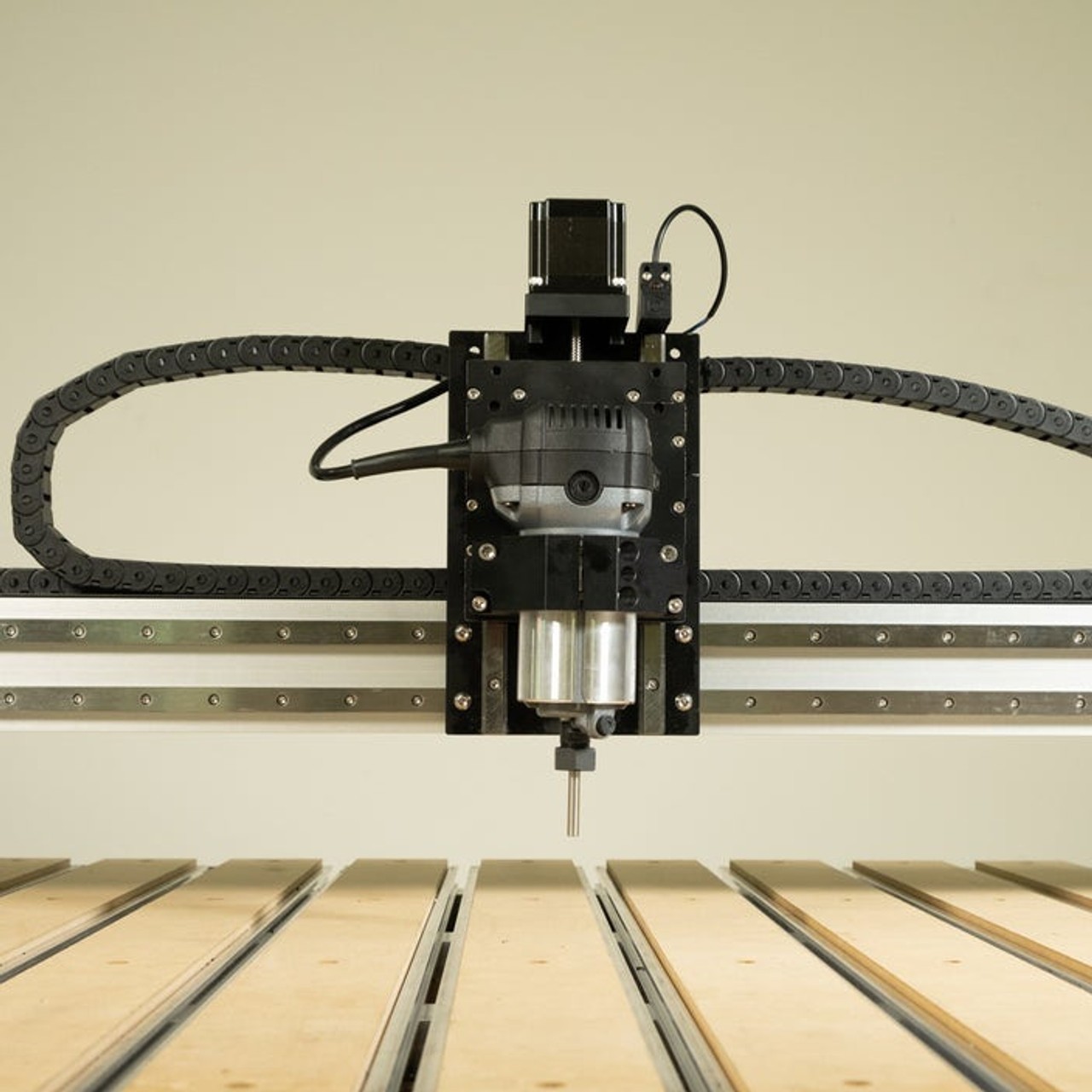

The Anatomy of a CNC Machine

Understanding the anatomy of a CNC machine is essential for anyone venturing into the world of CNC machining material selection. This knowledge not only helps in choosing the right materials from the CNC material list but also influences how these materials are processed. By grasping how each component interacts, you can optimize your projects and ensure precision.

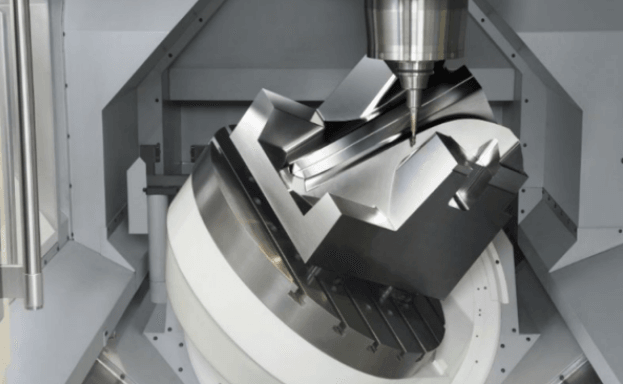

What are the 7 Major Parts of a CNC Machine?

A typical CNC machine consists of seven major parts: the control panel, drive motors, spindle, worktable, tool holder, coolant system, and frame. The control panel is where operators input commands and oversee operations, while drive motors provide movement along various axes. The spindle holds and rotates tools for machining processes, and the worktable secures materials during cutting or milling.

The tool holder is responsible for keeping tools in place with precision to avoid any mishaps during operation. Meanwhile, the coolant system helps maintain optimal temperatures during machining to prevent overheating and extend tool life. Lastly, the frame provides structural integrity to support all components while minimizing vibrations that could impact machining accuracy.

How Parts Influence Material Choices

Each part of a CNC machine plays a pivotal role in determining what material is used in CNC projects. For instance, if you're working with metals like aluminum or steel that require robust cutting forces, you'll need a machine with powerful drive motors and sturdy spindles capable of handling such demands. Conversely, when machining softer materials like plastics or wood from your CNC material list, less intense machinery might suffice.

Moreover, the choice of fixtures also depends on both material properties and machine capabilities; certain metals may require specialized fixtures to ensure stability during complex cuts or intricate designs. Understanding these relationships not only aids in selecting appropriate materials from common materials used in CNC projects but also enhances overall project efficiency by reducing wear on machinery.

Interconnectedness of Machine and Material

The interconnectedness between machines and their materials cannot be overstated when discussing CNC Machining Material Selection. Each type of material has distinct properties—such as hardness or flexibility—that influence how it interacts with various components like spindles or tool holders during processing operations. For example, using high-density plastics might require different tooling than metals due to differences in thermal expansion rates.

Furthermore, understanding what metal is used in CNC applications can guide decisions about necessary modifications to standard machines for optimal performance with specific materials from your CNC material list. In this way, knowing both your machine's anatomy and its operational limits allows you to make informed choices that maximize productivity while minimizing potential issues down the line.

Selecting the Right Metal for CNC

When it comes to CNC machining, metal selection is a crucial aspect that can make or break your project. The right metal can enhance durability, improve functionality, and even impact the aesthetic appeal of the final product. Understanding what metal is used in CNC processes helps in navigating the extensive CNC material list and ensuring optimal results.

What Metal is Used in CNC?

CNC machining utilizes a variety of metals, each chosen for specific properties that align with project requirements. Commonly used metals include aluminum, steel, brass, copper, and titanium—each offering unique benefits tailored to different applications. Knowing what material is used in CNC projects allows designers and engineers to select the best fit based on strength, weight, machinability, and cost.

Pros and Cons of Common Metals

Every metal has its own set of pros and cons that should be carefully weighed during the CNC machining material selection process. For instance, aluminum is lightweight and corrosion-resistant but may not offer the same strength as steel; conversely, steel provides unmatched durability but can be heavier and more challenging to machine. Brass offers excellent machinability but may not be suitable for high-stress applications; understanding these trade-offs will help you navigate your options on the cnc material list effectively.

Future Trends in CNC Metals

The landscape of metals used in CNC machining continues to evolve with advancements in technology and material science. Future trends indicate a growing interest in lightweight alloys and composites that offer improved performance without compromising strength or durability—perfect for industries looking to reduce weight while maintaining structural integrity. Additionally, sustainable practices are gaining traction; expect more eco-friendly materials making their way onto common materials used in CNC projects as manufacturers seek greener alternatives.

Conclusion

In the world of CNC machining, material selection is not just a technical detail; it’s a pivotal decision that can impact the success of your projects. Understanding the CNC material list is crucial, as it encompasses a variety of options tailored for different applications. Whether you’re working with metals, plastics, or wood, knowing what material is used in CNC will help you achieve optimal results.

Key Takeaways for Material Selection

When navigating through Common Materials Used in CNC Projects, remember that each material has its unique properties and applications. For instance, aluminum shines with its lightweight nature while steel stands out for its strength and durability. Always consider factors such as cost, functionality, and project requirements when determining what metal is used in CNC.

Making Informed Choices for Projects

Making informed choices involves understanding not only the materials but also their interactions with the machine itself—what are the 7 major parts of a CNC machine? Each component plays a role in how materials are processed and can influence your final product's quality and precision. Moreover, being aware of what is the material used in CNC fixtures can help ensure stability during machining operations.

The Future of CNC Machining Materials

As technology advances, so too does the landscape of materials available for CNC machining. Innovations may lead to new composites or alloys that enhance performance while being more sustainable—an increasingly important consideration today. Staying updated on trends related to what metal is used in CNC will empower you to make better decisions and keep your projects at the cutting edge.