Introduction

Understanding the Importance of CNC Technology

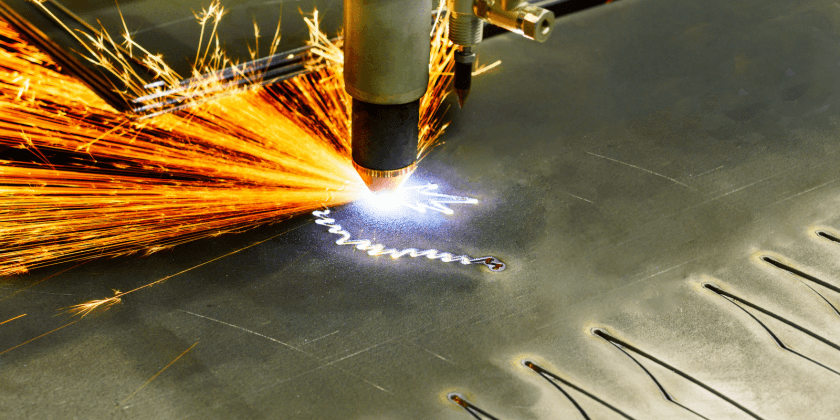

CNC technology, or Computer Numerical Control, has transformed how we approach manufacturing and machining tasks. This technology automates tools and machinery using computer programming, which enhances precision while reducing human error. As industries evolve and demand increases for complex components made from challenging materials like titanium, understanding how a CNC titanium mill operates becomes essential for any manufacturer looking to stay competitive.

Key Attributes of a Quality CNC Titanium Mill

When searching for a quality CNC titanium mill, several key attributes come into play that can make or break your machining experience. First and foremost are power and torque; these attributes ensure that the machine can handle the unique challenges presented by milling titanium effectively. Additionally, features such as RPM capabilities—essential for determining what RPM is needed for milling titanium—play a crucial role in achieving optimal results without compromising material integrity.

Why Titanium is a Challenge to Mill

Milling titanium is not without its difficulties; in fact, many engineers often wonder: can you CNC mill titanium? The answer is yes—but with caveats! Titanium's strength-to-weight ratio makes it incredibly tough to machine compared to other metals; this means that not all machines are equipped to handle its unique properties effectively. Furthermore, understanding what materials cannot be CNC machined helps highlight why specialized equipment is necessary when dealing with such challenging substances as titanium.

Essential Specifications of a CNC Titanium Mill

Motor Power and Torque Requirements

The motor power and torque of a CNC titanium mill are paramount when considering its capability to cut through tough materials like titanium. High torque is essential because milling titanium requires significant force, especially during the initial cut and when working with thicker stock. Without adequate motor power, you may find yourself asking, Can you CNC mill titanium? while staring at an unresponsive machine—definitely not the ideal scenario!

A powerful motor ensures that your CNC mill can maintain consistent performance without stalling or overheating during operation. This becomes particularly important as different types of titanium alloys have varying hardness levels, which can put additional strain on your equipment. Therefore, investing in a CNC titanium mill with robust motor specifications will pay off in terms of efficiency and durability.

RPM Requirements for Milling Titanium

When it comes to determining what RPM is needed for milling titanium, it's essential to strike a balance between speed and feed rate for optimal cutting performance. Generally, higher RPMs are necessary to achieve clean cuts without damaging the tool or workpiece; however, too high of an RPM can lead to excessive heat buildup and tool wear. A well-calibrated spindle speed allows for effective chip removal while minimizing friction—an absolute must when working with such a demanding material.

Most experts recommend operating within the range of 600-1200 RPM for milling titanium depending on factors like tool diameter and specific alloy being used. This range helps ensure that you're neither rushing into cuts nor dragging through them at too low of a speed—a sweet spot that maximizes both efficiency and longevity of your tools. So remember: finding that perfect RPM is vital if you want to avoid costly mistakes down the line!

Size and Weight Considerations

The size and weight considerations of a CNC titanium mill can significantly impact its performance capabilities as well as its installation requirements in your workspace. A larger machine often means greater stability during operation but also requires ample floor space and structural support—something worth considering before making any purchases! Additionally, heavier mills typically absorb vibrations better than their lighter counterparts, leading to improved precision during machining.

However, don’t let size alone dictate your choice; portability might be just as important depending on your shop layout or project needs! If you're frequently moving equipment around or need flexibility in setup locations, consider compact models that still offer robust features suitable for milling titanium effectively yet remain lightweight enough for easy relocation. Ultimately, balancing size with functionality will help ensure you choose the right CNC mill tailored specifically for working with tough materials like titanium.

Material Compatibility and Limitations

Why Not All Materials Can Be CNC Machined

The question What materials cannot be CNC machined? is more common than you might think! Generally speaking, metals like titanium require specific conditions for successful milling; otherwise, you might end up with a pile of shavings instead of precision parts. For instance, softer metals may deform under pressure while harder ones can quickly dull your tools—neither scenario is ideal for a quality CNC titanium mill operation.

Moreover, material thickness and density also play crucial roles in determining machinability. If a material is too thick or dense for the machine's capabilities, it may simply refuse to cooperate during the milling process. This means that understanding material compatibility is key when considering what types of parts you can produce with your CNC titanium mill.

Titanium Alloys and Their Milling Challenges

Now let’s dive into the world of titanium alloys—these beauties can present their own set of challenges when it comes to milling. You might ask yourself: Can you CNC mill titanium? The answer is yes! But be prepared; working with titanium alloys requires specialized knowledge about their properties and how they react under various machining conditions.

Titanium alloys tend to be tough on tooling due to their high strength-to-weight ratio and low thermal conductivity. This means you'll need robust cutting tools capable of handling high RPMs without overheating—a critical factor since What RPM is needed for milling titanium? often hovers around 3000-6000 RPM depending on the specific alloy being used. Additionally, chip formation in titanium can lead to issues like built-up edge (BUE), which complicates the milling process further.

Understanding CNC Mill Material Requirements

To successfully operate a CNC titanium mill, it's essential to grasp its material requirements fully. Each machine has specific limitations on what materials it can handle effectively; thus knowing these specs will save you from costly mistakes down the line! For instance, if you're planning on using your machine primarily for titanium alloys but haven't considered its motor power or torque capabilities beforehand, you could find yourself in a tight spot—or worse yet—a broken machine.

Furthermore, understanding feed rates and cutting speeds tailored specifically for different materials will enhance both efficiency and output quality in your projects. Remember that investing in a good-quality CNC mill means you'll also need compatible tooling designed specifically for tougher materials like titanium—not all tools are up for this job! So make sure you're well-informed before diving headfirst into your next project!

Precision and Accuracy Levels

Importance of Precision in CNC Milling

Precision in CNC milling is paramount, especially when dealing with materials like titanium that have specific tolerances and performance requirements. Can you CNC mill titanium? Absolutely, but it requires a machine that can maintain tight tolerances throughout the entire milling process. A high level of precision ensures that each component fits perfectly within its intended assembly, reducing the likelihood of costly rework or failure down the line.

Measuring Tolerance for Titanium Parts

Measuring tolerance for titanium parts is a meticulous process that demands attention to detail and advanced technology. The question often arises: What RPM is needed for milling titanium? Generally, higher RPMs are necessary to achieve optimal results while maintaining proper feed rates and cutting depths. However, achieving precise tolerances in titanium requires not only the right RPM but also specialized tooling designed to withstand its hardness without compromising accuracy.

Features that Enhance Accuracy

Several features can enhance accuracy in a CNC titanium mill, making them invaluable investments for manufacturers working with this challenging material. Advanced feedback systems, such as linear encoders and closed-loop control mechanisms, help ensure real-time adjustments during machining operations. Additionally, high-quality spindle assemblies capable of maintaining stable RPMs contribute significantly to achieving consistent results—essential when considering how expensive a CNC mill can be compared to its capabilities.

Software and Control Systems

In the world of CNC milling, the software and control systems are akin to the conductor of an orchestra, harmonizing all elements for a seamless output. For a CNC titanium mill, choosing the right software is crucial because it directly impacts not only efficiency but also precision when milling titanium. This section will dive into the essential aspects of CNC software that help operators navigate through their projects with ease and accuracy.

CNC Software—The Brain of Your Mill

CNC software serves as the brain behind your CNC titanium mill, translating design files into actionable commands for the machine to execute. The ability to efficiently process complex geometries is vital when asking yourself, Can you CNC mill titanium? The answer is a resounding yes, but only if your software can handle the intricacies involved in working with this challenging material.

With various options available on the market, it’s essential to choose software that not only meets industry standards but also has robust features tailored for milling titanium. Advanced algorithms can optimize tool paths and minimize cutting time while maximizing tool life—a necessity given titanium's notorious toughness. Ultimately, investing in quality CNC software can significantly enhance your operational capabilities and lead to more successful outcomes.

User-Friendly Interfaces for Efficient Operation

A user-friendly interface makes all the difference when operating a CNC titanium mill. Operators should be able to navigate through settings without feeling like they’re deciphering hieroglyphics; after all, time spent fumbling with controls is time lost on production. Intuitive layouts allow users to quickly adjust parameters such as feed rate and RPM requirements—critical factors when considering What RPM is needed for milling titanium?

Moreover, modern interfaces often come equipped with tutorials or guided workflows that simplify complex tasks. This not only enhances productivity but also reduces errors during operation—something that’s particularly important when dealing with materials that cannot be easily replaced or reworked like titanium. A smooth user experience ensures that even less experienced operators can achieve high-quality results consistently.

Compatibility with Design Programs

Compatibility between your CNC software and design programs is another vital consideration for effective operation of a CNC titanium mill. Many manufacturers utilize CAD/CAM systems to create intricate designs before they are translated into machine language; thus, ensuring seamless integration between these platforms can save significant time and hassle down the line. When evaluating options, always ask yourself if your chosen system supports popular design formats widely used in engineering circles.

Additionally, having robust import/export capabilities allows you to work flexibly across different projects without being locked into one ecosystem—an essential feature in today's fast-paced manufacturing environment where adaptability reigns supreme. If you're wondering about what materials cannot be CNC machined effectively due to their properties or compatibility issues, make sure your chosen software provides insights or warnings about potential pitfalls during milling processes.

Finally, integrating advanced simulation tools within your control system helps visualize how designs will perform before actual machining begins—an invaluable asset when working with challenging materials like titanium where every detail counts! By prioritizing compatibility with design programs alongside robust functionality in both hardware and software systems, you'll set yourself up for success in any project involving a CNC titanium mill.

Cost Considerations for CNC Titanium Mills

How Expensive is a CNC Mill?

The cost of a CNC titanium mill is influenced by various factors, including its capabilities and the materials it can handle. Entry-level mills may be attractive due to their lower price but often lack the necessary power and precision required for effectively milling titanium. On the other hand, premium models come packed with advanced features that justify their hefty price tags—often providing greater efficiency in machining titanium.

Long-Term Investment vs. Initial Cost

While the initial cost of a CNC titanium mill may seem daunting, it's essential to view this purchase as a long-term investment rather than just an upfront expense. A high-quality machine can yield significant returns through increased productivity and reduced material waste over time. Additionally, if you’re asking yourself Can you CNC mill titanium?, remember that investing in a robust machine opens doors to lucrative projects involving this challenging material.

Evaluating Cost-Effectiveness

To truly assess whether you're making a wise investment in a CNC titanium mill, consider both its operational costs and potential revenue generation capabilities. Not all materials can be CNC machined effectively; hence choosing the right machine will save you from costly mistakes down the line when dealing with difficult materials like titanium alloys. Evaluate how much time you'll save on setups and adjustments—this efficiency can make even an expensive model worth every penny.

Conclusion

In wrapping up our exploration of CNC titanium mills, it’s clear that selecting the right machine is not just about picking a shiny new tool; it’s about understanding the unique challenges and requirements of milling titanium. From motor power to RPM specifications, each feature plays a crucial role in achieving precision and efficiency. As you consider your options, remember that investing in quality can pay off in the long run.

Recap of Key Features for Buyers

When contemplating whether to invest in a CNC titanium mill, several key features demand your attention. First, ensure that the motor power and torque requirements align with the demands of milling titanium—this material is notoriously tough. Additionally, pay close attention to RPM requirements for milling titanium; lower speeds can lead to better results and longer tool life.

Another essential aspect is material compatibility; not all materials can be CNC machined effectively. Understanding what materials cannot be CNC machined will help you avoid costly mistakes down the line. Lastly, consider software capabilities—user-friendly interfaces and compatibility with design programs are vital for smooth operation.

Importance of Choosing the Right Machine

Choosing the right CNC titanium mill is akin to finding a partner in crime; it needs to mesh well with your specific needs and production goals. The wrong choice could lead to inefficiencies or even damage to both your machine and materials—no one wants that drama! Plus, when you're tackling challenging materials like titanium alloys, having a reliable machine makes all the difference.

With so many options on the market, taking time to evaluate features such as precision levels and software capabilities will save you headaches later on. Remember also that understanding what RPM is needed for milling titanium will help ensure you select a machine designed for this demanding task. Ultimately, making an informed decision now will set you up for success in your machining endeavors.

Investing Wisely in CNC Technology

Investing wisely in CNC technology means balancing initial costs against long-term benefits—how expensive is a CNC mill really? While upfront costs may seem daunting, consider them as part of an investment strategy aimed at boosting productivity and output quality over time. A high-quality CNC titanium mill may demand more from your wallet initially but can significantly enhance efficiency and reduce waste over its lifespan.

Moreover, think about how much time you'll save by choosing a reliable machine that minimizes downtime due to maintenance or repairs—time is money! In conclusion, whether you're asking Can you CNC mill titanium? or wondering about material limitations like What materials cannot be CNC machined?, remember that thorough research leads to better investments in technology tailored specifically for your needs.