Introduction

Are you curious about the role of CNC machines in jewelry making? Wondering if you can actually make jewelry with a CNC machine? In this article, we'll explore the fascinating world of CNC-made jewelry and the benefits of using CNC machines in jewelry production.

The Role of CNC Machines in Jewelry Making

CNC machines play a crucial role in modern jewelry manufacturing, offering precision and efficiency in crafting intricate designs. From cutting and shaping metals to engraving detailed patterns, these machines have revolutionized the art of jewelry making.

Benefits of Using CNC Machines in Jewelry Production

Using a CNC machine for jewelry production comes with numerous benefits, including enhanced precision, faster production times, and the ability to create intricate designs that were once impossible by hand. This technology allows jewelers to push the boundaries of creativity and craftsmanship.

Exploring the Craft of CNC-Made Jewelry

With advancements in CNC technology, jewelers can now create stunning pieces that were previously unattainable. From delicate filigree work to complex geometric patterns, the possibilities are endless when it comes to making jewelry with a CNC machine.

Understanding CNC Machines in Jewelry Making

CNC machines, or Computer Numerical Control machines, are revolutionizing the way jewelry is manufactured. These machines use computer programs to control the movement and operation of the machinery, allowing for precise and intricate designs to be created with ease.

What is CNC in jewelry manufacturing?

CNC in jewelry manufacturing refers to the use of computer-controlled machines to create intricate and detailed jewelry pieces. These machines are programmed to follow specific design patterns, allowing for consistent and precise production of various jewelry items.

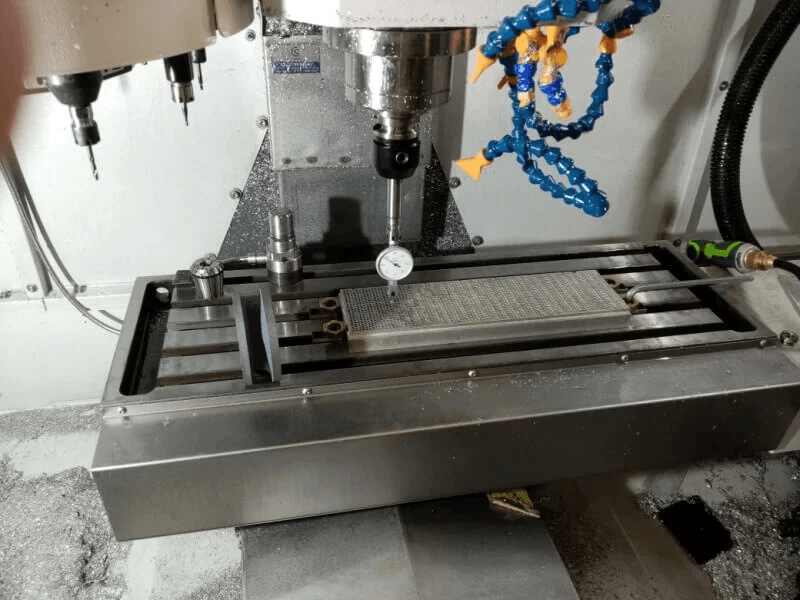

Once the design pattern is inputted into the CNC machine, it uses a variety of tools such as drills, lathes, and mills to shape and carve the jewelry piece from a solid block of metal or other materials. This level of precision and accuracy allows for the creation of complex shapes and intricate details that would be difficult or impossible to achieve by hand. Additionally, CNC machines can produce multiple copies of the same design with minimal variation, ensuring uniformity across a collection of jewelry items.

The process of creating jewelry with a CNC machine

The process of creating jewelry with a CNC machine begins with designing the piece using specialized software. Once the design is complete, it is then translated into a set of instructions that guide the CNC machine's movements as it carves, cuts, or shapes the metal into the desired form.

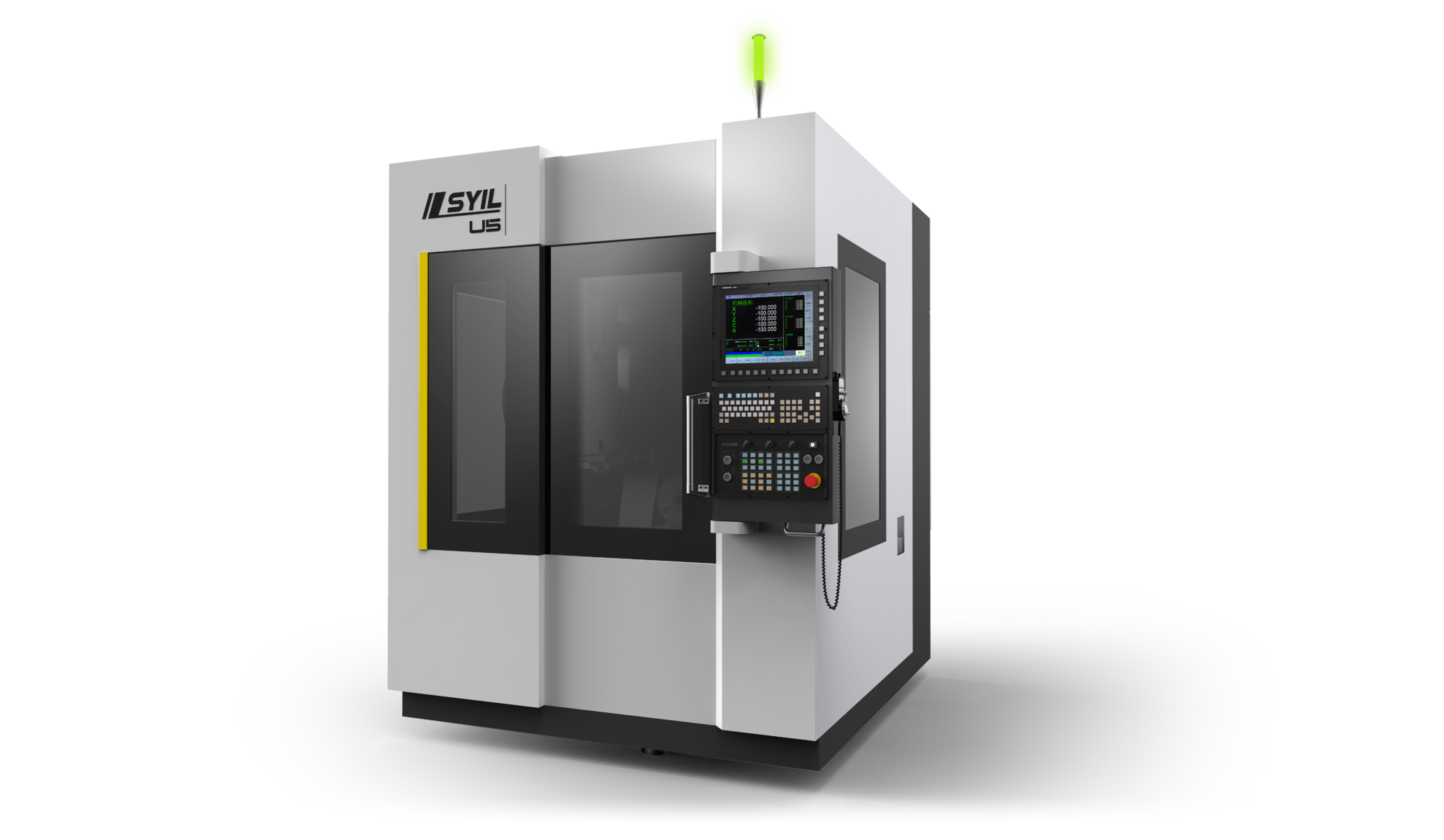

Advantages of using SYIL CNC machine for jewelry production

Using a SYIL CNC machine for jewelry production offers numerous advantages. These machines provide unparalleled precision and accuracy, allowing for complex designs to be crafted with ease. Additionally, SYIL CNC machines offer flexibility and customization options, making them ideal for producing unique and intricate jewelry pieces.

SYIL CNC machines also offer a high level of consistency and repeatability, ensuring that each jewelry piece is produced with the same level of precision and quality. This is essential for maintaining brand standards and meeting customer expectations. Furthermore, the speed and efficiency of SYIL CNC machines allow for faster production times, enabling jewelry makers to meet demand and fulfill orders in a timely manner. With these advantages, using a SYIL CNC machine can significantly enhance productivity and profitability in the jewelry production process.

Designing Intricate Jewelry with CNC Machines

When it comes to creating intricate and unique jewelry designs, CNC machines are the perfect tool for the job. With their precise cutting and shaping capabilities, these machines can bring even the most complex designs to life with incredible detail and precision. Whether it's delicate filigree work or intricate patterns, a CNC machine can handle it all with finesse.

Creating intricate and unique jewelry designs

Using a CNC machine for jewelry making allows artisans to push the boundaries of design, creating pieces that were once thought impossible to produce by hand. The level of intricacy and detail that can be achieved is truly remarkable, opening up a world of creative possibilities for jewelry makers.

Precision and accuracy in jewelry crafting with CNC machines

One of the key benefits of using a CNC machine for jewelry production is the unparalleled precision and accuracy it offers. Every cut, every curve, and every detail is executed with exacting perfection, ensuring that each piece meets the highest standards of craftsmanship.

In addition to precision and accuracy, CNC machines also offer unparalleled flexibility and customization in jewelry making. With the ability to program intricate designs and patterns, artisans have the freedom to create unique pieces that cater to individual tastes and preferences. Whether it's a one-of-a-kind engagement ring or a personalized pendant, CNC machines enable craftsmen to bring their clients' visions to life with unmatched precision and attention to detail.

Flexibility and customization in jewelry making with CNC machines

CNC machines also provide an unmatched level of flexibility and customization in jewelry making. Whether it's adapting existing designs or creating entirely new ones, these machines allow artisans to easily tweak and adjust their creations to suit their vision without compromising on quality.

Efficiency and Cost-Effectiveness of CNC-Made Jewelry

When it comes to jewelry making, the question of whether it's cheaper to build or buy a CNC machine is often debated. The initial investment in purchasing a CNC machine may seem high, but the long-term cost savings in production and labor make it a worthwhile investment for jewelry manufacturers. By automating the manufacturing process, businesses can reduce production costs and increase their profit margins.

Is it cheaper to build or buy a CNC machine for jewelry making?

Building your own CNC machine for jewelry making can be a cost-effective option if you have the technical expertise and resources to do so. However, for most jewelry makers, purchasing a pre-built CNC machine is more practical and efficient. This allows them to focus on their craft and production without the added time and effort required to build a machine from scratch.

Maximizing profits with CNC machining in jewelry production

CNC machining offers significant opportunities for maximizing profits in jewelry production. With its precise and efficient manufacturing capabilities, businesses can increase their output while maintaining high quality standards. This results in higher productivity, reduced material waste, and ultimately, greater profitability for jewelry makers.

Economic benefits of using CNC machines for jewelry manufacturing

The economic benefits of using CNC machines for jewelry manufacturing are numerous. From reducing labor costs to minimizing errors in production, CNC machining offers a cost-effective solution for creating high-quality jewelry pieces. By streamlining the manufacturing process and optimizing resources, businesses can achieve greater efficiency and profitability in the competitive jewelry market.

Quality Control and Consistency in CNC-Made Jewelry

When it comes to CNC-made jewelry, ensuring consistent quality is of utmost importance. With the use of advanced CNC machines, jewelry manufacturers can achieve unparalleled precision and uniformity in their creations. This allows for the production of flawless pieces that meet the highest standards of craftsmanship and design.

Ensuring consistent quality in CNC-made jewelry

CNC machines play a crucial role in maintaining consistent quality in jewelry production. By utilizing computer-controlled technology, manufacturers can execute intricate designs with absolute accuracy, resulting in uniformity across all pieces. This level of precision ensures that every piece of jewelry meets the exacting standards expected by both artisans and customers alike.

Maintaining high standards in jewelry production with CNC machines

The use of CNC machines elevates the standard of jewelry production by enabling manufacturers to uphold stringent quality control measures. These machines allow for meticulous attention to detail, ensuring that every facet and contour is executed with precision. As a result, the finished products exhibit a level of craftsmanship that is unmatched by traditional methods.

Furthermore, CNC machines also offer the advantage of consistency in production. With precise programming and automated processes, manufacturers can replicate intricate designs and patterns with minimal variation across multiple pieces. This level of uniformity is crucial in meeting customer expectations for high-quality, flawless jewelry. Additionally, the use of CNC machines allows manufacturers to explore more complex and innovative designs that were previously unattainable through traditional methods, further enhancing the appeal and uniqueness of their products.

Meeting customer expectations with precision and perfection

With CNC-made jewelry, customers can expect nothing short of perfection. The ability to consistently produce flawless pieces not only meets but exceeds customer expectations for quality and precision. This level of consistency assures customers that each piece they acquire is a true work of art, crafted with the utmost care and attention to detail. Furthermore, the use of CNC technology allows for intricate and complex designs that would be nearly impossible to achieve through traditional methods. This opens up a whole new world of possibilities for jewelry makers and ensures that customers will always have access to unique and innovative pieces.

The Future of Jewelry Making: Innovations in CNC Technology

As technology continues to advance, so does the potential for innovation in jewelry making with CNC machines. The latest advancements in CNC technology for jewelry making have revolutionized the way intricate and unique designs are crafted. With improved precision and efficiency, CNC machines are paving the way for the future of jewelry crafting.

Advancements in CNC technology for jewelry making

The advancements in CNC technology for jewelry making have led to the development of more sophisticated and precise machines that can create intricate designs with unparalleled accuracy. These technological breakthroughs have also resulted in faster production times and increased efficiency, allowing jewelers to bring their creative visions to life with greater ease and speed.

Embracing the future of jewelry crafting with SYIL CNC machines

SYIL's state-of-the-art CNC machines are at the forefront of the future of jewelry crafting, offering unparalleled precision, flexibility, and customization options. By embracing SYIL CNC machines, jewelers can take their craftsmanship to new heights, exploring endless design possibilities and pushing the boundaries of traditional jewelry making.

Expanding possibilities in jewelry design and production with CNC technology

The expansion of possibilities in jewelry design and production with CNC technology has opened up a world of creative opportunities for artisans and designers. From creating intricate filigree patterns to producing custom-made pieces, CNC machines have transformed the landscape of jewelry making by enabling makers to explore new techniques and push the boundaries of traditional craftsmanship.

Conclusion

The use of CNC machines in jewelry making has revolutionized the industry, elevating craftsmanship to new heights. With the ability to create intricate and unique designs, CNC machines have opened up endless possibilities for jewelry production.

Elevating Jewelry Craftsmanship with CNC Machines

CNC machines have elevated jewelry craftsmanship by allowing for the creation of intricate and detailed designs that were once thought impossible. The precision and accuracy of CNC technology ensure that each piece is crafted with the utmost care and attention to detail, resulting in stunning works of art that are truly one-of-a-kind.

Embracing the Future of Jewelry Making with SYIL CNC

As we embrace the future of jewelry making, it's clear that SYIL CNC machines are at the forefront of innovation in the industry. Their advanced technology and capabilities have paved the way for new possibilities in design and production, allowing artisans to push boundaries and explore new creative avenues.

The Artistry and Precision of CNC-Made Jewelry

The artistry and precision of CNC-made jewelry speak for themselves. With the ability to create custom designs with unparalleled accuracy, CNC machines have redefined what is possible in jewelry making. From delicate filigree work to bold statement pieces, there's no limit to what can be achieved with a CNC machine.

By embracing this cutting-edge technology, artisans can unlock their full creative potential while meeting customer demand for high-quality, bespoke pieces. As we look towards the future, it's clear that CNC machines will continue to shape the landscape of jewelry making, offering endless opportunities for innovation and excellence.