Introduction

Are you curious about the intersection of technology and jewelry making? CNC machines are revolutionizing the way jewelry is crafted, offering precision and customization like never before. With CNC technology, intricate designs and detailed pieces can be created with ease, making it a game-changer for the jewelry industry.

Introduction to CNC Machines for Jewelry Making

CNC machines, short for Computer Numerical Control machines, are automated tools that can be programmed to create complex shapes and designs with high precision. In the world of jewelry making, these machines have opened up a whole new realm of possibilities, allowing designers to bring their intricate visions to life with ease.

Benefits of Using CNC Machines for Jewelry Making

The benefits of using CNC machines for jewelry making are abundant. From precise detailing to efficient production, these machines offer unparalleled accuracy and consistency in creating jewelry pieces. Additionally, they allow for customization and versatility in design, empowering jewelers to innovate and create unique pieces that stand out in the market.

Exploring the World of Jewelry CNC

Exploring the world of jewelry CNC unveils a landscape of creativity and innovation. With the ability to cut a wide range of materials including gold and other metals, these machines have transformed traditional jewelry manufacturing processes. The future of jewelry making is being shaped by the advancements in CNC technology, paving the way for new possibilities in design and production.

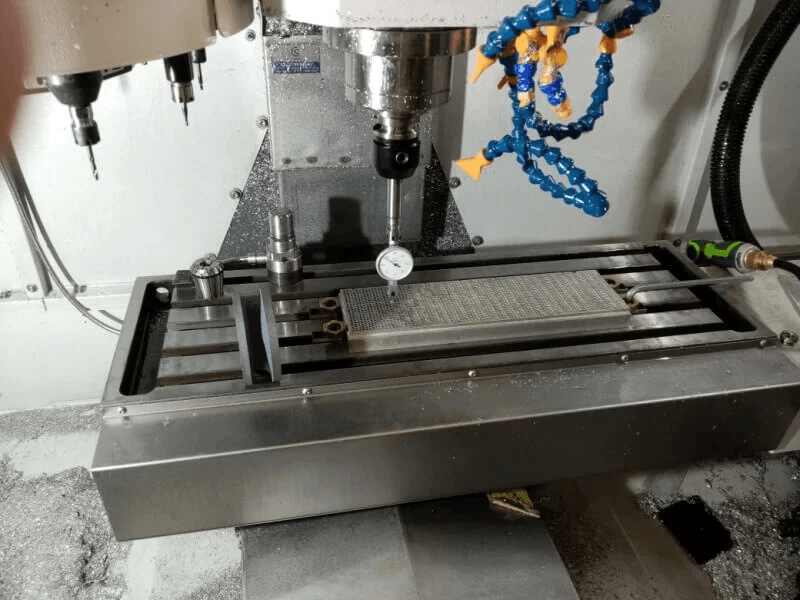

SYIL CNC Machine

When it comes to jewelry making, the SYIL CNC machine is a game-changer. This state-of-the-art machine is specifically designed for precision and intricate detailing, making it the perfect tool for crafting stunning jewelry pieces. The SYIL CNC machine offers unmatched accuracy and efficiency, allowing jewelry designers to bring their creative visions to life with ease.

Overview of SYIL CNC Machine for Jewelry Making

The SYIL CNC machine is a versatile and powerful tool that is revolutionizing the world of jewelry making. With its advanced technology and cutting-edge features, this machine offers unparalleled precision and efficiency in crafting intricate jewelry designs. Whether you're working with gold, silver, or other metals, the SYIL CNC machine delivers exceptional results every time.

Features and Capabilities of SYIL CNC Machine

The SYIL CNC machine boasts a range of impressive features and capabilities that make it ideal for jewelry making. From its high-speed spindle to its precise cutting tools, this machine is designed to handle even the most complex jewelry designs with ease. Its user-friendly interface and advanced software make it easy for designers to create custom pieces with incredible detail and accuracy.

Why SYIL CNC Machine is Perfect for Jewelry Making

The SYIL CNC machine stands out as the perfect choice for jewelry making due to its unmatched precision, versatility, and efficiency. Whether you're crafting delicate filigree earrings or bold statement necklaces, this machine can handle it all with ease. Its ability to cut a wide range of materials, including gold and other precious metals, makes it an invaluable tool for any jewelry designer.

What is CNC in Jewelry?

CNC, or Computer Numerical Control, plays a crucial role in jewelry making by automating the manufacturing process. It uses pre-programmed computer software to dictate the movement of machinery, allowing for precise and intricate designs to be created with ease.

Understanding the Role of CNC in Jewelry Making

CNC machines for jewelry making are essential as they enable designers to bring their intricate designs to life with unparalleled precision. These machines can carve, mill, and engrave various materials such as metals and gemstones, ensuring that every detail is accurately reproduced. Additionally, CNC technology allows for the production of complex and detailed designs that would be nearly impossible to achieve by hand. This opens up a world of creative possibilities for jewelry designers, allowing them to push the boundaries of traditional craftsmanship.

Advantages of Using CNC in Jewelry Manufacturing

The advantages of utilizing CNC in jewelry manufacturing are numerous. Not only does it allow for the creation of complex and detailed designs that would be nearly impossible to achieve by hand, but it also reduces production time and minimizes material wastage.

In addition to the intricate designs and reduced production time, CNC technology also allows for greater consistency in jewelry manufacturing. With computerized precision, each piece can be replicated with exacting accuracy, ensuring that every item meets the same high standards. This level of uniformity is essential for maintaining a brand's reputation and meeting customer expectations for quality and craftsmanship.

How CNC Revolutionizes the Jewelry Making Process

CNC revolutionizes the jewelry making process by streamlining production and enabling designers to experiment with innovative designs without limitations. With the ability to cut intricate patterns and shapes into various materials, CNC technology has transformed traditional jewelry making into a highly efficient and creative endeavor.

CNC technology has opened up a world of possibilities for jewelry designers by allowing them to work with a wide range of materials. From traditional metals like gold and silver to unconventional materials such as wood, acrylic, and even gemstones, CNC machines can cut and shape almost any substance with precision. This versatility not only expands the creative potential for jewelry making but also offers opportunities for sustainability by using recycled or eco-friendly materials in the process. As a result, CNC revolutionizes the jewelry making process by promoting innovation and environmental consciousness in the industry.

Materials for CNC Jewelry Making

When it comes to jewelry CNC, the choice of materials is crucial for creating stunning pieces. Can you make jewelry with a CNC machine? Absolutely! A CNC machine can cut a wide variety of metals and materials, making it an ideal tool for jewelry making.

Can a CNC Machine Cut Gold?

Yes, a CNC machine can cut gold with precision and accuracy, allowing jewelers to create intricate designs and patterns on this precious metal. The use of CNC technology has revolutionized the way gold jewelry is crafted, offering unmatched precision and detailing.

What Metals Can CNC Cut for Jewelry Making?

In addition to gold, a CNC machine can cut other metals such as silver, platinum, titanium, and stainless steel. This versatility allows jewelry designers to experiment with different materials and create unique pieces that cater to various preferences and styles. For example, titanium is known for its strength and durability, making it an excellent choice for creating modern and edgy jewelry designs. On the other hand, platinum is favored for its lustrous appearance and resistance to tarnishing, making it ideal for crafting elegant and timeless pieces that stand the test of time.

Exploring the Range of Materials for Jewelry CNC

The range of materials that can be used with jewelry CNC is vast, including gemstones, acrylics, wood, and even plastics. This flexibility opens up endless possibilities for creating custom-designed jewelry that stands out in the market.

Additionally, the use of precious metals such as gold, silver, and platinum in jewelry CNC adds a touch of luxury and elegance to custom-designed pieces. These materials allow for intricate detailing and fine craftsmanship, resulting in high-quality jewelry that appeals to discerning customers. The combination of traditional metals with modern CNC technology creates a unique blend of timeless beauty and contemporary design.

Precision and Detailing in CNC Jewelry Making

Precision and detailing are crucial aspects of jewelry CNC, as they determine the quality of the final product. With CNC machines, every cut and design is executed with utmost precision, ensuring that each piece meets the highest standards of craftsmanship.

Importance of Precision in CNC Jewelry Making

Precision is essential in jewelry CNC as it allows for accurate replication of intricate designs and patterns. Whether it's a delicate filigree or a complex geometric shape, precision ensures that every detail is faithfully reproduced, resulting in flawless jewelry pieces that exude elegance and sophistication.

Achieving Intricate Detailing with CNC Machines

CNC machines excel at achieving intricate detailing in jewelry making, thanks to their ability to execute complex designs with remarkable accuracy. From fine engravings to precise stone settings, these machines can bring even the most elaborate designs to life with unparalleled intricacy and finesse.

How CNC Enhances the Quality of Jewelry Making

CNC technology elevates the quality of jewelry making by enabling designers to create pieces with exceptional precision and detailing. This level of accuracy not only enhances the visual appeal of the jewelry but also ensures structural integrity, resulting in durable and long-lasting pieces that stand the test of time.

Customization and Versatility in Jewelry CNC

When it comes to creating unique and personalized jewelry designs, CNC machines offer unmatched customization capabilities. Jewelry designers can easily modify and adjust their designs with precision using CNC machines, allowing for endless possibilities in creating one-of-a-kind pieces that cater to individual preferences.

Customizing Jewelry Designs with CNC Machines

Jewelry designers can use CNC machines to customize intricate patterns, engravings, and shapes on various jewelry pieces, from rings to pendants. With the ability to program specific designs into the machine, it becomes effortless to produce personalized jewelry that reflects the individual style and taste of the wearer.

Furthermore, CNC machines offer jewelry designers the flexibility to experiment with different materials such as gold, silver, and platinum, allowing for the creation of unique and stunning pieces. This versatility opens up a world of possibilities for designers to push the boundaries of traditional jewelry-making techniques and explore new artistic expressions. By harnessing the power of CNC technology, designers can bring their innovative ideas to life and offer customers one-of-a-kind jewelry that cannot be replicated by traditional methods.

The Versatility of CNC in Creating Unique Jewelry Pieces

CNC technology allows for the production of a wide range of jewelry pieces, from delicate filigree earrings to bold statement necklaces. The versatility of CNC machines enables jewelry makers to experiment with different materials and styles, resulting in a diverse collection of unique and eye-catching designs that cater to a broad audience.

The versatility of CNC machines also allows jewelry designers to create intricate and detailed pieces that would be nearly impossible to achieve by hand. This technology opens up a world of possibilities for designers to push the boundaries of traditional jewelry-making techniques and explore new artistic expressions. By leveraging CNC technology, jewelry makers can bring their wildest design ideas to life, giving them the freedom to innovate and stand out in a competitive market.

How CNC Empowers Jewelry Designers to Innovate

By harnessing the power of CNC technology, jewelry designers are empowered to push boundaries and innovate in their craft. The precision and flexibility offered by CNC machines enable designers to explore new techniques, experiment with unconventional materials, and bring fresh ideas to life, ultimately driving creativity and innovation within the jewelry industry. Moreover, CNC technology allows for the creation of intricate designs that would be nearly impossible to achieve by hand, opening up a world of possibilities for designers to express their creativity in ways previously unattainable. This level of precision also ensures that each piece is consistently high quality, giving designers the confidence to take risks and push the boundaries of traditional jewelry design.

Conclusion

In conclusion, the future of jewelry making is undoubtedly intertwined with CNC technology. With the ability to create intricate designs and customize unique pieces, CNC machines are revolutionizing the jewelry manufacturing process. Embracing CNC for enhanced jewelry manufacturing allows for greater precision, versatility, and innovation in creating stunning jewelry pieces. The evolution of jewelry CNC technology continues to push boundaries and elevate the art of jewelry making to new heights.

The Future of Jewelry Making with CNC Technology

As technology continues to advance, the future of jewelry making with CNC technology looks extremely promising. With the ability to seamlessly blend traditional craftsmanship with modern precision, CNC machines offer endless possibilities for creating exquisite jewelry pieces that were once thought impossible.

Embracing CNC for Enhanced Jewelry Manufacturing

Embracing CNC for enhanced jewelry manufacturing opens up a world of opportunities for designers and manufacturers alike. The precision and detailing capabilities of CNC machines allow for the creation of intricate designs that were previously unattainable through traditional methods.

The Evolution of Jewelry CNC Technology

The evolution of jewelry CNC technology has come a long way, from basic cutting capabilities to advanced customization features. As more materials become compatible with CNC machines, including gold and other precious metals, the potential for creating stunning jewelry pieces continues to expand.

Remember that in today's fast-paced world, staying ahead in the competitive field of jewelry making means embracing innovative technologies like never before. With its ability to cut various metals including gold and create intricate designs with unparalleled precision, it's clear that there's no limit to what can be achieved with a quality SYIL CNC machine in hand!