Introduction

In today's fast-paced and competitive manufacturing industry, efficiency and precision are key factors for success. That's where CNC metal cutter machines come into play. These advanced machines have revolutionized the metal cutting process, offering unparalleled accuracy and versatility. One company that stands out in this field is SYIL CNC Machine, which has been at the forefront of developing cutting-edge technology for metal cutting. Investing in a CNC metal cutter machine offers numerous benefits, from cost savings to improved productivity. This article will explore the evolution of CNC metal cutter machines, how SYIL is revolutionizing metal cutting, and the advantages of investing in these machines.

The Evolution of CNC Metal Cutter Machines

Over the years, CNC metal cutter machines have undergone significant advancements in technology and design. From manual operations to computer-controlled systems, these machines have transformed how metal cutting is done. Gone are the days of relying on human operators to make precise cuts; now, with CNC technology, every movement is meticulously calculated and executed accurately.

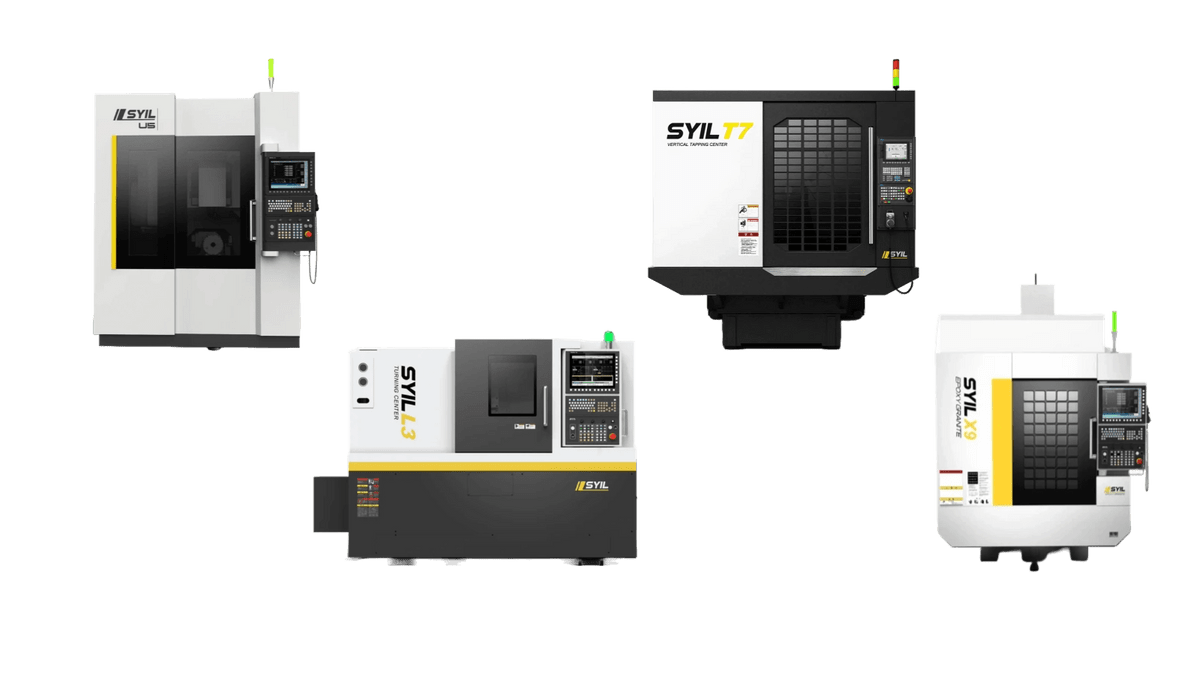

How SYIL CNC Machine is Revolutionizing Metal Cutting

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their state-of-the-art CNC metal cutter machine is no exception. It combines cutting-edge technology with user-friendly controls to deliver exceptional results.

The Benefits of Investing in a CNC Metal Cutter Machine

CNC metal cutting machines are revolutionizing metal fabrication and manufacturing. Here's how they elevate your business:

- Unmatched Accuracy and Consistency: CNC technology eliminates human error, guaranteeing precise cuts every time. This translates to parts that meet even the strictest tolerances, reducing rework and wasted materials.

- Boosted Efficiency: CNC machines optimize cutting paths, minimizing material waste. Additionally, their fast setup times keep production flowing smoothly.

- Versatility Across Materials: (This point can be merged with the promotional sentence about SYIL) SYIL machines handle a broad spectrum of metals, from steel and aluminum to more specialized alloys, ensuring your projects are completed with exceptional performance and reliability.

Investing in a CNC metal cutter gives you a powerful tool for achieving superior quality, efficiency, and versatility in your metalworking operations.

In the next section, we will delve deeper into understanding CNC metal cutter machines, how they work, and explore different types of these machines. Stay tuned to discover the features and capabilities of SYIL CNC metal cutter machine that set it apart from the competition.

Understanding CNC Metal Cutter Machines

CNC metal cutter machines have revolutionized the metal cutting industry with their precision and efficiency. These machines utilize computer numerical control (CNC) technology to automate the cutting process, resulting in accurate and consistent cuts every time.

What is a CNC Metal Cutter Machine?

A CNC metal cutter machine is a powerful tool for cutting various types of metals with precision and speed. It is equipped with a computer-controlled system that directs the movement of the cutting tool based on pre-programmed instructions. This allows for complex shapes and designs to be accurately cut from metal sheets or blocks.

How Does a CNC Metal Cutter Machine Work?

The operation of a CNC metal cutter machine begins with creating a digital design or model using CAD (Computer-Aided Design) software. The design is then converted into instructions, known as G-code, which specify the toolpath and cutting parameters.

Once the G-code program is loaded into the machine's control system, the operator sets up the workpiece on the table or bed. The cutting tool, typically a rotating blade or laser beam, is positioned above the workpiece.

As the machine starts running, it follows the G-code instructions precisely, moving along multiple axes to cut through the metal according to the programmed design. The operator can monitor and adjust various parameters during operation to ensure optimal results.

Exploring Different Types of CNC Metal Cutter Machines

There are several types of CNC metal cutter machines available in the market, each designed for specific applications and materials:

- Plasma Cutters: These machines use ionized gas (plasma) to cut through electrically conductive materials such as steel and aluminum.

- Laser Cutters: Laser technology is employed in these machines to achieve high-precision cuts on various metals, including stainless steel and brass.

- Waterjet Cutters: Waterjet machines utilize a high-pressure stream of water mixed with an abrasive substance to cut through metals like titanium and copper.

- Milling Machines: CNC milling machines are versatile tools that can perform both cutting and drilling operations on various metals, including steel and aluminum.

By understanding the different types of CNC metal cutter machines available, businesses can choose the most suitable option based on their specific requirements and budget.

The Features and Capabilities of SYIL CNC Metal Cutter Machine

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC metal cutter machines offer a range of features and capabilities that make them stand out in the market.

1. Precision and Accuracy: The Key Features of SYIL CNC Machine

SYIL's CNC metal cutter machine is known for its exceptional precision and accuracy. Advanced technology and high-quality components ensure that every cut is made with utmost precision, resulting in perfectly finished products. Whether you're working on intricate designs or large-scale projects, SYIL's CNC machine delivers consistent accuracy to meet your requirements.

2. Versatility: Cutting Various Materials with Ease

One of the key advantages of SYIL's CNC metal cutter machine is its versatility in cutting various materials. From steel to aluminum, brass to titanium, this machine can easily handle a wide range of materials. Whether in the automotive industry or involved in architectural projects, SYIL's CNC machine can efficiently cut through different metals, providing you with endless possibilities for your applications.

3. Efficiency: Reducing Material Waste and Enhancing Productivity

SYIL's CNC metal cutter machine is designed to optimize efficiency by reducing material waste and enhancing productivity. Its precise cutting capabilities minimize errors and ensure that every piece is cut accurately, eliminating the need for rework or additional material usage. This saves costs and increases productivity by reducing downtime and maximizing output.

By investing in a SYIL CNC metal cutter machine, businesses can unlock efficiency and precision like never before. With its key features of precision and accuracy, versatility in cutting various materials, and efficiency in reducing material waste and enhancing productivity, SYIL's CNC machine is the perfect choice for businesses to streamline their metal cutting processes.

Next, we will explore the advantages of investing in a CNC metal cutter machine, including cost savings, time savings, and quality output. Stay tuned to discover how SYIL's CNC machine can revolutionize metal cutting operations.

The Advantages of Investing in a CNC Metal Cutter Machine

Investing in a CNC metal cutter machine offers numerous advantages that can greatly benefit your business. Let's explore some of these advantages below:

1. Cost Savings: Eliminating Human Error and Increasing Efficiency

One of the key advantages of investing in a CNC metal cutter machine is its cost savings. By eliminating human error, these machines ensure precise and accurate cuts every time, minimizing material waste and reducing production costs. With manual cutting methods, errors can occur due to human limitations, leading to costly mistakes and rework. However, with a CNC metal cutter machine, you can rely on its automated processes to consistently deliver high-quality results without the risk of human error.

2. Time Savings: Achieving Faster Turnaround Times

Time is money in any business, and investing in a CNC metal cutter machine can significantly speed up your production processes. These machines are designed for efficiency, allowing faster turnaround times than traditional cutting methods. With their automated capabilities, CNC metal cutter machines can execute complex cutting patterns and designs precisely and consistently. This saves time, enables you to meet tight deadlines, and increases overall productivity.

3. Quality Output: Ensuring High Precision and Consistency

Precision is crucial for achieving high-quality results when it comes to metal cutting. A CNC metal cutter machine offers exceptional accuracy and consistency throughout the cutting process. These machines are equipped with advanced technology that ensures precise measurements and cuts, resulting in superior quality output every time. Whether you're working on intricate designs or large-scale projects, investing in a CNC metal cutter machine guarantees the highest precision and consistency.

By investing in SYIL's CNC metal cutter machine specifically, you can unlock even more advantages for your business:

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC metal cutter machines are no exception, offering exceptional performance and reliability.

Applications of CNC Metal Cutter Machines

CNC metal cutter machines have a wide range of applications across various industries. Let's explore some key sectors where these machines are making a significant impact.

1. Automotive and Aerospace Industries: Meeting High Standards and Specifications

In the automotive and aerospace industries, precision and accuracy are paramount. CNC metal cutter machines are crucial in meeting the high standards and specifications required for manufacturing components such as engine parts, brackets, and structural elements. These machines ensure consistent quality, tight tolerances, and efficient production processes, resulting in reliable and durable products that meet industry regulations.

2. Architecture and Construction: Precision Cutting for Complex Designs

In architecture and construction, intricate designs often require precise cutting of materials like steel, aluminum, or brass. CNC metal cutter machines excel in delivering accurate cuts for complex shapes, allowing architects and builders to bring their creative visions to life with ease. From decorative elements to structural components, these machines offer the versatility to achieve intricate designs while maintaining precision.

3. Metal Fabrication and Manufacturing: Enhancing Production Processes

Metal fabrication and manufacturing industries heavily rely on CNC metal cutter machines to enhance their production processes. These machines streamline operations by reducing material waste through optimized cutting paths, resulting in cost savings. Their ability to cut through various metals efficiently enables manufacturers to achieve higher productivity levels while maintaining consistent quality across large-scale production runs.

SYIL Machine Tools, a leading manufacturer of CNC machines, offers state-of-the-art solutions that cater to the diverse needs of these industries. Focusing on precision, quality, and sustainability, SYIL CNC machines provide businesses with the tools they need to stay competitive in today's demanding market.

Choosing the Right CNC Metal Cutter Machine for Your Business

When it comes to selecting a CNC metal cutter machine for your business, there are several factors that you should consider. First and foremost, you need to determine the specific requirements of your operations. Are you looking for a machine that can handle heavy-duty cutting tasks or one that is more suitable for smaller-scale projects? Understanding your needs will help you narrow your options and find the perfect fit.

The SYIL CNC Machine Difference: Why Choose SYIL Over Competitors?

When comparing different brands of CNC metal cutter machines, it's clear that SYIL stands out from its competitors in several ways. Firstly, SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling with over 12k machines supplied globally. This extensive experience speaks volumes about their expertise in the industry.

SYIL prioritizes quality and sustainability in all aspects of their manufacturing process. Their commitment to producing durable machines ensures long-term reliability for businesses investing in their products.

Moreover, SYIL offers excellent customer support throughout the purchasing process. Their team of experts is readily available to provide guidance and assistance, ensuring that customers have a smooth experience.

SYIL CNC Machine Testimonials: Real Experiences from Satisfied Customers

Don't just take our word for it - hear what our satisfied customers have to say about SYIL CNC metal cutter machines:

- We have been using SYIL machines for several years, and we couldn't be happier with their performance. The precision and accuracy of these machines are unmatched, allowing us to deliver high-quality products to our clients. - John Smith, Metal Fabrication Company

- Investing in a SYIL CNC metal cutter machine has been a game-changer for our business. Not only has it improved our productivity, but it has also reduced material waste significantly. We highly recommend SYIL machines to anyone in the manufacturing industry. - Sarah Johnson, Manufacturing Company

- SYIL's customer support is top-notch. From the initial consultation to after-sales service, they have been there every step of the way. Their team is knowledgeable and always ready to assist with any queries or concerns we may have. - Mark Davis, Aerospace Industry Supplier

These testimonials highlight the positive experiences that customers have had with SYIL CNC metal cutter machines. Their satisfaction speaks volumes about the quality and reliability of these machines.

Unlock Efficiency and Precision: The Power of SYIL CNC Metal Cutter Machine

Investing in a CNC metal cutter machine can unlock unparalleled efficiency and precision in your metal cutting processes. SYIL CNC Machine, with its advanced features and capabilities, takes this power to the next level. By harnessing the precision and accuracy of SYIL CNC Machine, you can achieve flawless cuts that meet even the most demanding specifications. With its versatility in cutting various materials and reducing material waste, SYIL CNC Machine ensures optimal productivity and cost savings for your business.

Investing in the Future: Why SYIL CNC Machine is the Right Choice

When investing in a CNC metal cutter machine, choosing SYIL is the right choice for securing your future success. With over 12k machines supplied globally, SYIL Machine Tools has established itself as a trusted brand in precision CNC machines for milling and drilling. The commitment to quality and sustainability sets them apart from competitors. By investing in a SYIL CNC Machine, you are getting a reliable and efficient tool and contributing to a greener future.