Introduction

Are you a knifemaker looking to take your craft to the next level? If so, exploring CNC knife making could be the game-changer you've been searching for. By understanding the process and benefits of using a CNC machine, you can elevate your knifemaking skills to new heights.

Exploring CNC Knife Making

When it comes to knife making, precision is key. The CNC milling of knives offers unparalleled accuracy and efficiency, making it an attractive option for knifemakers looking to streamline their process and achieve consistent results.

Precision in knife making is essential for creating high-quality, durable products that meet the needs of customers. CNC milling technology allows for intricate designs and precise cutting, ensuring that each knife is crafted with the utmost accuracy. This level of precision not only enhances the overall quality of the knives but also saves time and reduces material waste, making it a cost-effective solution for knifemakers.

Understanding the Process

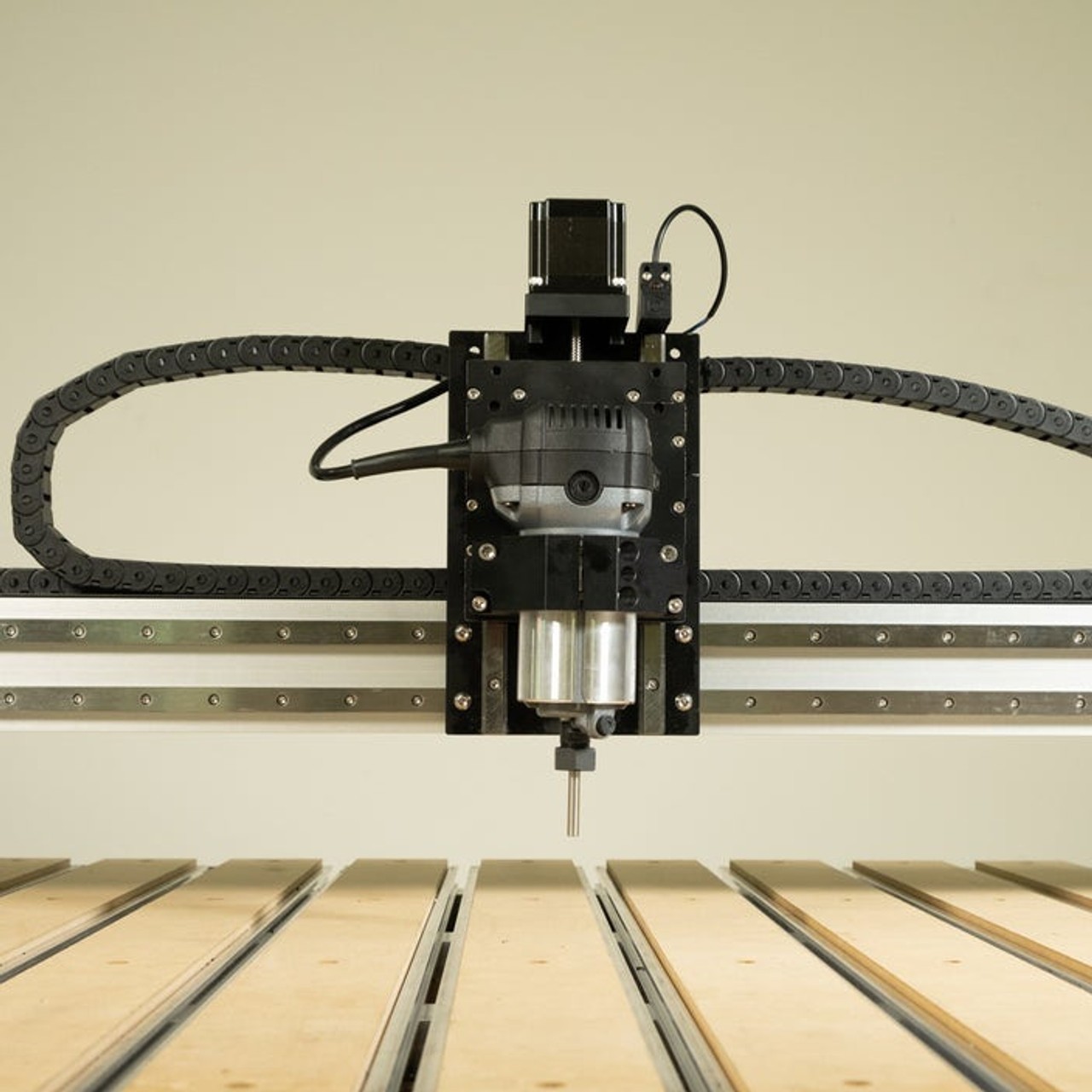

CNC milling machines provide a versatile and automated approach to crafting knives, allowing for intricate designs and complex shapes that may be challenging to achieve through traditional methods. This technology opens up new possibilities for knifemakers seeking to push the boundaries of their craft.

CNC milling machines offer a level of precision and consistency that is difficult to achieve by hand. This means that knifemakers can create identical knives with intricate designs and complex shapes, ensuring that each product meets the highest standards of quality. Additionally, the automated nature of CNC machines allows for increased efficiency in production, saving time and labor costs for knifemakers.

Benefits of Using a CNC Machine

The benefits of using a CNC machine for knife making are numerous. From increased productivity and reduced material waste to enhanced precision and repeatability, this innovative approach revolutionizes the way knifemakers bring their designs to life.

In addition to the efficiency and precision benefits, using a CNC machine for knife making also allows for greater design flexibility. Knifemakers can easily experiment with different shapes, sizes, and textures, bringing a new level of creativity to their craft. This versatility opens up a world of possibilities for creating unique and custom knives that stand out in the market. With the ability to quickly iterate and refine designs, knifemakers can stay ahead of trends and meet the demands of their customers with ease.

Choosing the Right CNC Milling Machine

When it comes to choosing the right CNC milling machine for knifemaking, it's essential to research SYIL machines specifically designed for this craft. SYIL offers a range of machines tailored to the needs of knifemakers, providing precision and efficiency in the milling process.

Researching SYIL Machines for Knifemaking

SYIL machines are renowned for their reliability and performance in the field of knifemaking. With a focus on quality and precision, these machines are equipped with features that cater to the intricate nature of knife design and production. Researching SYIL machines ensures that you find a reliable and efficient tool for your craft.

Evaluating CNC Options for Knife Making

In addition to SYIL machines, it's important to evaluate other CNC options available for knife making. Consider factors such as spindle speed, cutting capabilities, and overall build quality when comparing different machines. Look for models that offer versatility and ease of use in creating custom knives.

Quality Factors to Consider

When choosing a CNC milling machine for knife making, quality should be at the forefront of your decision-making process. Look for sturdy construction, precise controls, and advanced features that contribute to the overall accuracy of your knife production. Investing in a high-quality machine will ultimately enhance the craftsmanship of your creations.

Remember that finding the right CNC milling machine is crucial in achieving exceptional results in knifemaking. By thoroughly researching and evaluating various options available, you can ensure that your investment leads to superior craftsmanship and efficiency in producing custom knives.

Designing Your Knife

When it comes to designing your own knife, the art of knifemaking is a timeless craft that allows for personal expression and creativity. Whether you're a seasoned knifemaker or just starting out, customizing your knife design is an exciting process that allows you to create a one-of-a-kind piece that reflects your individual style and preferences. With the help of CAD software for precision, you can bring your unique vision to life with intricate details and precise measurements.

The Art of Knifemaking

The art of knifemaking dates back centuries, with skilled craftsmen using traditional techniques to forge blades by hand. Today, modern technology has revolutionized the process, making it more accessible than ever before. With CNC milling machines, knifemakers can now achieve unparalleled precision and consistency in their designs, while still embracing the time-honored traditions of the craft.

Customizing Your Knife Design

One of the most exciting aspects of knifemaking is the ability to customize every aspect of your knife design. From choosing the type of steel for the blade to selecting unique handle materials, every decision contributes to the overall look and feel of the finished product. With CNC options for knife making, you have complete control over every detail, allowing you to create a truly bespoke piece that reflects your personality and preferences.

CAD Software for Precision

CAD software plays a crucial role in the knifemaking process, enabling you to design intricate patterns and shapes with utmost precision. By utilizing CAD software, you can visualize your design in 3D and make adjustments as needed before bringing it to life with a CNC milling machine. This level of accuracy ensures that each knife produced is consistent in quality and meets your exact specifications.

CNC Milling Process

Now that you have your design ready, it's time to dive into the CNC milling process. With SYIL machines for knifemaking, you can easily bring your custom knife design to life. The CNC milling of knives is a precise and efficient process that ensures accuracy and quality in every cut.

Step-by-Step Milling Guide

To start the CNC milling process, secure your material onto the machine bed and load your CAD design into the software. Set up the cutting tools and calibrate the machine for precision. Then, initiate the milling process and watch as your custom knife design takes shape with each carefully calculated cut.

Precision Cutting Techniques

SYIL machines for knifemaking offer advanced cutting techniques that allow for intricate designs and fine details to be accurately milled into your material. The CNC milling of knives requires precision cutting techniques to ensure that every curve, edge, and angle of your knife design is executed flawlessly.

Ensuring Quality and Accuracy

Throughout the CNC milling process, it's crucial to constantly monitor the machine's performance to ensure quality and accuracy in every cut. SYIL machines for knifemaking are equipped with advanced technology that guarantees precise results, giving you peace of mind as you watch your custom knife take shape before your eyes.

Finishing Touches

After the CNC milling process, it's time to focus on the finishing touches of your custom knife. Polishing and sharpening are crucial steps to ensure a high-quality end product. With the precision of a CNC machine, you can achieve a flawless blade edge and a pristine finish that will make your knife stand out.

Polishing and Sharpening

Using specialized tools and techniques, you can polish and sharpen the blade of your knife to perfection. The CNC milling process ensures precise angles and edges, making it easier to achieve a razor-sharp finish. Whether you prefer a mirror-like polish or a more rustic look, the CNC machine allows for complete control over the final outcome.

Custom Handle Options

When it comes to custom handle options, the possibilities are endless with CNC technology. From traditional wood or bone handles to modern materials like G10 or carbon fiber, you can create a handle that perfectly complements your blade design. The CNC milling machine provides the accuracy needed to craft intricate handle designs with ease.

With CNC technology, you can also experiment with unconventional handle shapes and textures that may not be achievable through traditional methods. Whether you want a handle with intricate patterns, unique contours, or a combination of different materials, CNC milling allows for endless customization options. This level of personalization ensures that your knife not only performs well but also reflects your individual style and preferences.

Personalizing Your Creation

With CNC technology, personalizing your knife creation is easier than ever. Whether you want to add custom engravings, etchings, or even inlays, the precision of the CNC machine ensures that every detail is executed flawlessly. Your unique touch will make your knife truly one-of-a-kind. In addition to personalizing the design of your knife, CNC technology also allows for precise customization of the handle shape and size. This means you can create a knife that fits perfectly in your hand, making it not only aesthetically unique but also ergonomically tailored to your grip.

Remember that when considering The CNC milling of knives, SYIL Machines for Knifemaking offer reliable options for bringing your custom knife designs to life with precision and efficiency.

Conclusion

CNC technology has revolutionized the art of knifemaking, offering precision, efficiency, and endless design possibilities. With the rise of new knifemaking workshops for CNC, knifemakers can explore the CNC milling of knives with SYIL machines specially designed for knifemaking. The question Can you make a knife with a CNC machine? has been answered with a resounding yes, as CNC milling machines provide the perfect platform for creating custom knives with unparalleled accuracy and quality.

New Knifemaking Workshop for CNC

The emergence of new knifemaking workshops specifically tailored for CNC technology has opened up exciting opportunities for both seasoned and aspiring knifemakers. These workshops offer hands-on training, expert guidance, and access to state-of-the-art SYIL machines designed for precision knife making. Aspiring knifemakers can now delve into the world of CNC milling of knives with confidence and skill.

With the increasing popularity of custom knives, the demand for skilled knifemakers has never been higher. These new workshops provide a platform for aspiring knifemakers to hone their craft and learn from experienced professionals in the industry. By offering access to cutting-edge CNC technology, these workshops are equipping the next generation of knifemakers with the tools and knowledge they need to succeed in this competitive field.

The CNC Milling of Knives, Knifemaker

The CNC milling of knives has transformed the traditional knifemaking process, allowing knifemakers to achieve intricate designs and flawless finishes with ease. With SYIL machines designed for knifemaking, knifemakers can explore a wide range of options for customizing their creations, from blade shapes to handle materials. The marriage of advanced CNC technology and traditional craftsmanship has elevated the art of knife making to new heights.

The CNC milling of knives has revolutionized the way knifemakers approach their craft. With the precision and versatility of SYIL machines, knifemakers can unleash their creativity and bring their unique designs to life. The ability to customize blade shapes, handle materials, and intricate details has opened up a world of possibilities for both amateur and professional knifemakers alike. As a result, the art of knife making has evolved into a seamless blend of innovation and tradition, pushing the boundaries of what is possible in this timeless craft.

Can You Make a Knife with a CNC Machine?

The answer is a resounding yes - not only can you make a knife with a CNC machine, but you can also elevate your craft to unprecedented levels of precision and quality. SYIL machines for knifemaking offer unparalleled accuracy in cutting techniques, ensuring that every detail of your design is brought to life with perfection. With the right combination of CAD software and CNC milling machine, the possibilities for creating custom knives are endless.

With the precision and accuracy of a CNC machine, you can create intricate designs and patterns on your custom knives that would be nearly impossible to achieve by hand. This opens up a world of creative possibilities for knifemakers, allowing them to experiment with new shapes, textures, and finishes. Whether you're looking to make a sleek chef's knife or a rugged hunting blade, the precision of a CNC machine ensures that every cut is made with the utmost care and attention to detail.