Introduction

CNC machines have revolutionized various industries with their precision and efficiency. These machines can perform complex tasks with minimal human intervention, making them indispensable in today's manufacturing world. This article will explore the different types of CNC machines and their importance in different industries. We will also briefly mention SYIL Machine Tools, a leading industry manufacturer.

CNC stands for Computer Numerical Control, which refers to the automation of machine tools through the use of computers. These machines are programmed to perform precise movements and operations on various materials such as metal, wood, and plastic. CNC machines have become a cornerstone of modern manufacturing processes by eliminating human error and ensuring consistent results.

Several categories of CNC machines are available today, each designed for specific applications and materials. These include milling machines, turning machines, drilling machines, plasma cutting machines, laser cutting machines, routers, engraving machines, and more. Each type offers unique capabilities that cater to diverse manufacturing needs.

Types of CNC Milling Machines

CNC milling machines are crucial to the manufacturing industry, offering precision and efficiency in various applications. Several types of CNC milling machines cater to different needs and requirements. Let's explore the different categories of CNC milling machines:

1. Horizontal Milling Machines

Horizontal milling machines are known for their versatility and ability to handle complex tasks. Their horizontal spindle orientation allows for removing material from the workpiece horizontally. This type of machine is commonly used for heavy-duty machining operations and is ideal for industries such as aerospace and automotive.

2. Vertical Milling Machines

Vertical milling machines are another popular choice in the world of CNC machining. Unlike horizontal milling machines, vertical mills have a vertical spindle orientation, enabling them to remove material from the workpiece in a vertical direction. These machines are widely used for tasks like drilling, tapping, and slotting operations.

3. Bed-Type Milling Machines

Bed-type milling machines offer exceptional stability and precision due to their robust construction. These machines have a stationary worktable on a rigid bed, providing increased support during machining operations. Bed-type milling machines are commonly used in industries that require high-precision components, such as toolmaking and moldmaking.

4. Gantry Milling Machines

Gantry milling machines feature an overhead gantry structure that supports the spindle head, allowing for extended reach and flexibility during machining operations. These machines simultaneously handle large workpieces or multiple smaller parts with high accuracy and efficiency.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

Manufacturers can choose the most suitable option for their needs by understanding the different types of CNC milling machines. Each type offers unique advantages and capabilities, whether horizontal, vertical, bed-type, or gantry milling machines. Selecting the right CNC milling machine is crucial to achieving efficient and accurate machining results.

Now that we have explored the variations of CNC milling machines, it's evident that these advanced tools play a vital role in modern manufacturing processes. SYIL Machine Tools' commitment to quality and sustainability makes them a reliable choice for businesses seeking top-notch CNC machines. So why not delve into the world of CNC machines and unlock endless possibilities for your manufacturing endeavors?

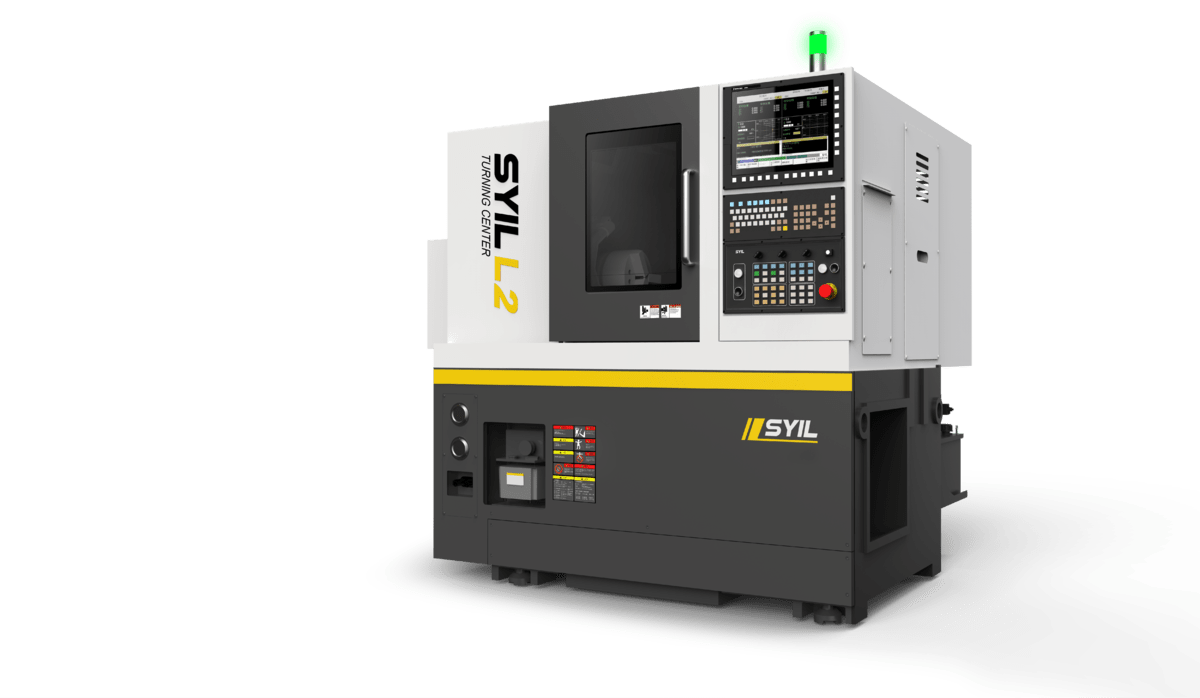

Types of CNC Turning Machines

CNC turning machines play a crucial role in the manufacturing industry, allowing for precise and efficient production of cylindrical components. There are several types of CNC turning machines, each with unique capabilities and advantages.

1. CNC Lathe Machines

CNC lathe machines are the most common turning machines used in various industries. These machines use computer-controlled systems to rotate the workpiece while cutting tools shape it into the desired form. CNC lathe machines offer high precision and versatility, making them suitable for various applications.

2. Swiss-Type CNC Machines

Swiss-type CNC machines are specialized turning centers that excel at producing small, intricate parts with high precision. These machines feature a sliding headstock, allowing simultaneous machining operations on multiple axes. Swiss-type CNC machines are commonly used in watchmaking, medical device manufacturing, and electronics industries.

3. Multi-Axis Turning Centers

Multi-axis turning centers, also known as multi-tasking or mill-turn machines, combine the capabilities of a lathe and a milling machine into one powerful unit. These advanced machines can perform turning and milling operations on complex workpieces with multiple features. Multi-axis turning centers enhance productivity and reduce setup time by eliminating the need for multiple machine setups.

4. Vertical Turning Lathes

Vertical turning lathes (VTLs) are designed to handle large, heavy workpieces that horizontal lathes cannot accommodate. These robust machines have a vertical spindle orientation, allowing for easy loading and unloading of heavy components. VTLs are commonly used in the aerospace, automotive, and energy industries.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

Types of CNC Drilling Machines

CNC drilling machines are crucial in various industries for creating precise holes in different materials. Several types are available, each with unique features and applications.

1. Radial Drilling Machines

Radial drilling machines are versatile tools that can drill holes at various angles and positions. Their radial arm can be adjusted to reach different areas on the workpiece. These machines are commonly used in the construction, metalworking, and automotive manufacturing industries.

Radial drilling machines offer flexibility and precision, making them suitable for projects requiring multiple hole sizes and depths. They also have advanced features like automatic feed control and coolant systems, ensuring efficient drilling operations.

2. CNC Deep Hole Drilling Machines

CNC deep-hole drilling machines specialize in creating deep holes with high precision. These machines use specialized tools and techniques to achieve accurate results even at extreme depths. They are commonly used in industries such as aerospace, oil and gas, and mold making.

With their advanced cooling systems and chip removal mechanisms, CNC deep-hole drilling machines can handle challenging materials like hardened steel or titanium alloys. They also offer automated processes for increased efficiency and reduced operator intervention.

3. Gun Drilling Machines

Gun drilling machines are specifically designed for long, straight holes with small diameters. These machines use a single cutting edge to create precise holes with minimal deviation from the intended path. Gun drilling is commonly employed in industries such as medical device manufacturing, firearms production, and automotive fuel injection systems.

Gun drilling machines provide excellent chip evacuation capabilities through the tool's hollow design, allowing for continuous coolant flow during the process. Their ability to produce accurate holes with high surface finish makes them ideal for critical applications requiring tight tolerances.

4. Benchtop Drilling Machines

Benchtop drilling machines are compact versions of larger CNC drills that can be placed on a workbench or table. These machines are commonly used in small-scale workshops, educational institutions, and hobbyist settings. They offer convenience and versatility for drilling tasks on smaller workpieces.

Despite their smaller size, benchtop drilling machines still provide precise drilling capabilities and often come with features like variable speed control and depth adjustment. They are an excellent choice for those with limited space or budget constraints.

So whether you're working on large-scale industrial projects or pursuing hobbies at home, a CNC drilling machine can meet your specific requirements. Explore the world of CNC machines today to unlock endless possibilities in precision engineering.

Other Types of CNC Machines

CNC machines are not limited to just milling, turning, and drilling. Various other types of CNC machines cater to different industrial needs. Let's explore some of these machines in detail.

1. CNC Plasma Cutting Machines

CNC plasma cutting machines precisely cut metal sheets using a high-temperature plasma torch. These machines are widely used in the automotive, construction, and metal fabrication industries. They offer fast and accurate cutting with minimal waste.

2. CNC Laser Cutting Machines

CNC laser cutting machines utilize a powerful laser beam to cut through various materials such as metal, wood, plastic, and fabric. These versatile machines are commonly used in industries like signage making, aerospace engineering, and jewelry manufacturing. They provide clean and precise cuts with high speed.

3. CNC routers

CNC routers are primarily used for shaping and carving materials like wood, plastic, and foam. They remove material from the workpiece using rotating cutting tools controlled by computer programs. These machines find applications in woodworking, sign-making, and prototyping industries.

4. CNC engraving machines

CNC engraving machines specialize in creating detailed designs or inscriptions on various materials. They use rotating cutting tools to etch patterns or text onto surfaces. These machines are commonly used in industries such as jewelry making, trophy manufacturing, and customization of personal items.

SYIL Machine Tools also offers a range of CNC milling and drilling machines. Their expertise extends to plasma, laser, routing, and engraving machines. SYIL is becoming a recognized brand globally with its commitment to quality and sustainability.

By exploring the world of CNC machines, businesses can find the perfect match for their specific needs. Whether precision cutting with plasma or intricate carving with lasers, there is a CNC machine for every application. Choose wisely and unlock the potential for increased productivity and efficiency.

Remember, SYIL Machine Tools offers reliable and innovative solutions when considering different types of CNC machines. So why wait? Dive into the world of CNC machines and revolutionize your manufacturing processes today!

Factors to Consider When Choosing a CNC Machine

When it comes to selecting the right CNC machine for your needs, there are several factors that you should consider. These factors will help you make an informed decision and ensure that the machine you choose best fits your requirements.

1. Purpose And Application Of The Machine

First and foremost, you need to determine the purpose and application of the CNC machine. Different types of CNC machines are designed for specific tasks, such as milling, turning, drilling, cutting, or engraving. Understanding your specific needs will help you narrow your options and choose a machine that can effectively perform the desired tasks.

2. Size And Capacity Requirements

The size and capacity of the CNC machine are crucial considerations. You need to assess the dimensions of your workpieces and determine whether the machine's working area can accommodate them. Consider the machine's weight limitations if you're working with heavy or large-scale projects. Choosing a machine with sufficient size and capacity ensures that it can handle your intended workload.

3. Automation And Efficiency Features

Automation and efficiency features significantly enhance productivity and reduce manual labor. Look for CNC machines with advanced automation capabilities, such as tool changers, automatic material handling systems, or robotic integration. These features streamline operations and improve accuracy and consistency in production processes.

4. Budget Considerations

Last but not least, budget considerations are essential when choosing a CNC machine. Determine how much you are willing to invest in acquiring a CNC machine while considering long-term maintenance costs. It's crucial to balance affordability and quality to ensure you get value for your money.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

Conclusion

This article explored the various types of CNC machines used in industries today. We discussed the four main categories: milling machines, turning machines, drilling machines, and other specialized machines like plasma cutters and engraving machines.

Importance Of Selecting The Right CNC Machine

Choosing the right CNC machine for your needs is crucial to ensure optimal performance and productivity. Each type of machine offers unique capabilities and advantages depending on the application. When deciding, it is essential to consider factors such as purpose, size requirements, automation features, and budget.

SYIL Machine Tools' Commitment To Quality And Sustainability

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

The world of CNC machines is vast and ever-evolving. These powerful tools have revolutionized industries worldwide, from simple milling tasks to intricate engraving projects. I encourage you to delve deeper into this fascinating field and discover how CNC machines can enhance your business or personal projects.