Introduction

CNC lathe machines are essential tools in the manufacturing industry, revolutionizing how we produce intricate parts and components. Learning how to work on a CNC lathe machine is not only valuable for professionals in the field but also for beginners looking to enhance their skills.

In this article, we will explore the critical aspects of CNC lathe machine operation and provide five tips to optimize your performance. Additionally, we will briefly mention SYIL Machine Tools, a leading manufacturer known for their precision CNC machines. Let's dive into the world of CNC lathe machines and discover how to unlock their full potential.

We will also provide you with five valuable tips that will help you excel in CNC lathe machine operation. From mastering CNC programming to proper tool selection, material machining techniques, maintenance, and more, these tips will enhance your skills and maximize the potential of your CNC lathe machine.

Stay tuned for the upcoming sections where we delve into each tip in detail.

Understanding the CNC Lathe Machine

CNC lathe machines are complex tools for precision turning operations in various industries. To fully comprehend their operation, it is essential to understand the basic components, familiarize oneself with the machine, utilize high-performance CNC machines like those offered by SYIL, and prioritize safety precautions.

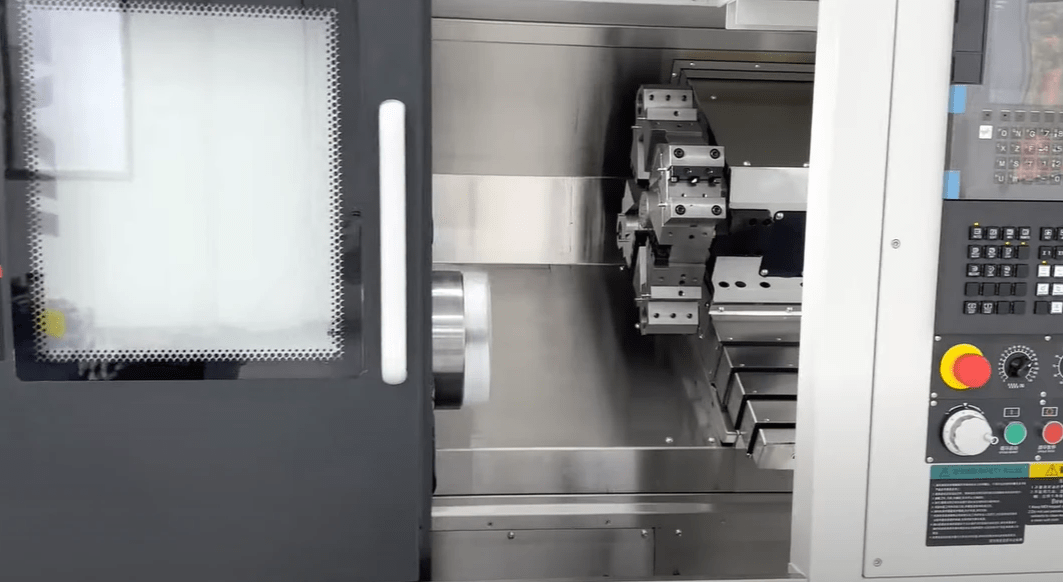

Basic Components of CNC Lathe Machine

A CNC lathe machine has several key components that work together to facilitate turning operations. These include the bed, headstock, tailstock, carriage, chuck, and tool turret.

- The bed provides a stable base for the machine and houses the main components.

- The headstock contains the spindle motor and gearbox responsible for rotating the workpiece.

- The tailstock supports long workpieces and offers additional stability during machining.

- The carriage moves along the bed and holds various cutting tools while engaging with the workpiece.

- The chuck securely clamps the workpiece, allowing for precise rotation during machining.

- The tool turret holds multiple cutting tools that can be automatically indexed into position.

Importance of Machine Familiarity

Before operating a CNC lathe machine, it is crucial to become familiar with its various functions and controls. This familiarity ensures efficient operation and reduces the risk of errors or accidents during machining processes. By understanding how each component works together and how to navigate through different settings on the control panel, operators can optimize their workflow and consistently achieve desired results.

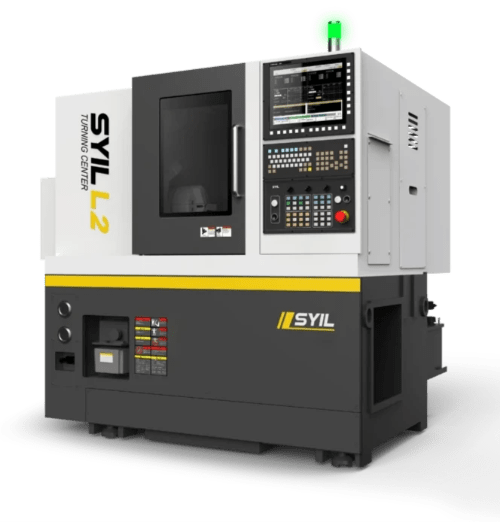

Utilizing SYIL CNC Machines for Optimal Performance

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling purposes globally. With over 12,000+ machines supplied worldwide, they prioritize quality and sustainability in their products. Operating in multiple countries, SYIL has become a recognized brand in the industry due to its commitment to delivering reliable machines that enhance productivity on a CNC lathe machine.

Safety Precautions and Considerations

Working with any machinery requires strict adherence to safety measures, and CNC lathe machines are no exception.

- Operators should always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, to protect themselves from potential hazards.

- It is crucial to follow proper machine setup procedures, secure workpieces correctly, and avoid loose clothing or accessories that could get caught in moving parts.

- Regular maintenance checks and inspections should be conducted to ensure the machine is in optimal working condition.

Tip 1: Mastering CNC Programming

To excel in operating a CNC lathe machine, mastering CNC programming is essential. Let's explore the importance of learning G-code and M-code, utilizing software and programming languages, SYIL's user-friendly interface, and debugging and troubleshooting common programming errors.

Importance of Learning G-code and M-code

G-code and M-code are the two primary languages used in CNC programming. G-code controls the machine's movements, while M-code manages auxiliary functions like coolant or tool changes. Understanding these codes allows operators to communicate precise instructions to the machine.

By learning G-code and M-code, operators can create complex programs that automate machining operations. This knowledge lets them control spindle speed, tool movement, coolant flow, and more. It empowers operators to optimize their workflow, reduce errors, and enhance productivity on a CNC lathe machine.

Utilizing Software and Programming Languages

In addition to G-code and M-code, operators can utilize specialized software and programming languages to streamline their CNC programming tasks. These tools offer intuitive interfaces that simplify the process of creating programs.

Software such as CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems enables operators to design parts digitally and generate corresponding machining instructions automatically. This integration between design and manufacturing facilitates efficient production on CNC lathe machines.

Programming languages like C++ or Python provide advanced capabilities for creating customized programs tailored to specific machining requirements. These languages allow operators to implement complex algorithms or logic into their programs for enhanced precision and efficiency.

SYIL's User-Friendly Programming Interface

SYIL Machine Tools recognizes the importance of user-friendly programming interfaces for beginners in CNC lathe machine operation. Their machines are equipped with intuitive control panels that simplify program creation.

SYIL offers a comprehensive software package with a graphical interface for designing parts, generating toolpaths, simulating machining operations, and converting designs into G-code. This user-friendly programming interface minimizes the learning curve for operators, enabling them to adapt to CNC lathe machine programming quickly.

Debugging and Troubleshooting Common Programming Errors

Even with a good understanding of CNC programming, errors can still occur. Debugging and troubleshooting skills are crucial for identifying and rectifying these issues promptly.

Operators should familiarize themselves with common programming errors such as syntax mistakes, incorrect toolpath generation, or improper parameter settings. By reviewing the program code line by line and using simulation tools, operators can identify potential errors before running the program on the CNC lathe machine.

SYIL provides comprehensive documentation and support to help operators resolve programming errors efficiently. Their technical team is readily available to provide guidance and assistance whenever needed.

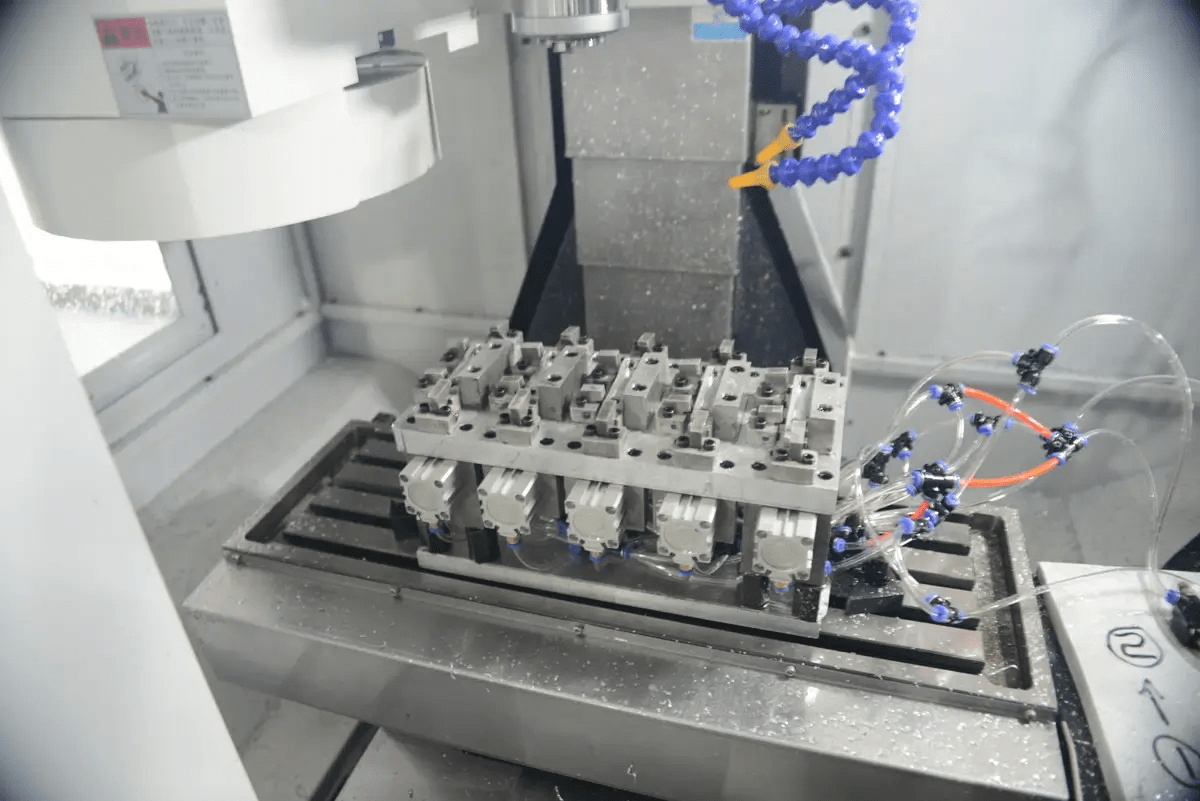

Tip 2: Proper Tool Selection and Setup

When working on a CNC lathe machine, proper tool selection and setup are crucial in achieving optimal results. Let's dive into the essential aspects of this tip to enhance productivity and precision.

Overview of Essential Lathe Tools

You must be familiar with the essential lathe tools to operate a CNC lathe machine effectively. These include:

- turning tools

- boring bars

- threading tools

- parting tools

- grooving tools

Each tool serves a specific purpose in the machining process and contributes to the machine's overall performance.

Understanding Tool Materials and Geometry

Understanding the materials and geometry of lathe tools is key to maximizing their efficiency. Different materials such as carbide, high-speed steel (HSS), and ceramic offer varying levels of durability and cutting performance. Additionally, tool geometry, including rake angle, clearance angle, and cutting-edge shape, affects chip formation and surface finish.

Importance of Accurate Tool Setup and Alignment

Accurate tool setup and alignment are critical for achieving precise machining results. Improper alignment can lead to excessive tool wear or damage to the workpiece or machine. It is crucial to ensure that the tools are properly secured in their holders and aligned with respect to the workpiece dimensions.

SYIL's Tooling Solutions for Precision Turning

SYIL Machine Tools understands the importance of precision turning on a CNC lathe machine. They offer a wide range of tooling solutions to enhance accuracy and productivity. With SYIL's high-quality tool holders, cutting inserts, and other accessories, operators can achieve exceptional results while maintaining efficiency.

Tip 3: Material Selection and Machining Techniques

Choosing the right materials for CNC lathe machining is crucial to achieving optimal results. Different materials have varying properties, and selecting the appropriate one can significantly impact the quality of your finished product. When working on a CNC lathe machine, consider the following factors when choosing materials:

Choosing the Right Materials for CNC Lathe Machining

The first step in material selection is understanding your project's specific requirements. Consider factors such as strength, durability, heat resistance, and machinability. Common materials used in CNC lathe machining include aluminum, steel, brass, and plastics.

Choosing materials compatible with a CNC lathe machine's capabilities enhances productivity. SYIL Machine Tools offers various CNC machines that efficiently handle various materials.

Importance of Proper Feeds and Speeds

Feeds and speeds refer to the rate at which the cutting tool moves across the material and rotates during machining. Optimizing feeds and speeds is crucial to achieving desired results while ensuring efficient operation.

By adjusting feeds and speeds appropriately, you can prevent issues like tool breakage or excessive wear. It also helps maintain surface finish quality and dimensional accuracy throughout the machining process.

Optimizing surface finish and dimensional accuracy

Surface finish plays a vital role in determining the overall quality of your machined parts. A smooth surface finish enhances aesthetics while reducing friction or wear in functional components.

Dimensional accuracy ensures that your finished parts meet precise specifications. It guarantees compatibility with other components or assemblies they will be used with.

To optimize surface finish and dimensional accuracy on a CNC lathe machine, pay attention to tool selection, feeds, and speed settings, as well as proper techniques for finishing operations like facing or turning.

SYIL's advanced machining techniques and recommendations

SYIL Machine Tools understands the importance of material selection and machining techniques for CNC lathe operations. Their machines are designed to handle various materials, from soft plastics to tough metals.

SYIL's advanced machining techniques include precision cutting, high-speed machining, and multi-axis operations. These techniques enable users to achieve intricate designs, complex geometries, and superior surface finishes.

By following SYIL's recommendations and utilizing their advanced machining techniques, you can enhance productivity and maximize the capabilities of your CNC lathe machine.

Tip 4: Maintenance and Machine Care

Regular machine maintenance is essential for the optimal performance and longevity of a CNC lathe machine. Neglecting maintenance can decrease productivity, increase downtime, and cause costly repairs. By following proper cleaning, lubrication, and inspection procedures, operators can ensure their machines' smooth operation.

Importance of Regular Machine Maintenance

Regular maintenance helps prevent wear and tear on the CNC lathe machine's components. It allows for early detection of potential issues, minimizing the risk of major breakdowns and expensive repairs. Operators can keep their machines running smoothly and avoid unexpected downtime by implementing a routine maintenance schedule.

Cleaning, Lubrication and Inspection Procedures

Proper cleaning is crucial to remove debris, chips, and coolant residue that may accumulate during operation. Regular lubrication ensures that all moving parts are well-oiled for smooth movement and reduced friction. Inspections should be conducted regularly to identify signs of wear or damage in components such as belts, gears, bearings, and tool holders.

Troubleshooting Common Machine Issues

Even with regular maintenance, CNC lathe machines may encounter common issues such as tool chatter or misalignment. Operators should familiarize themselves with troubleshooting techniques to identify and resolve these problems quickly. This may involve adjusting tool offsets or realigning components to ensure accurate machining results.

SYIL's Commitment to Reliable and Durable Machines

SYIL Machine Tools understands the importance of reliable CNC lathe machines in enhancing productivity. With their commitment to quality and sustainability, SYIL develops precision machines built to last. Their focus on durability ensures that operators can rely on their SYIL CNC lathe machines for consistent performance over an extended period.

Conclusion

In conclusion, mastering the operation of a CNC lathe machine requires a combination of knowledge, practice, and the right tools. By following the five tips outlined in this article, beginners can enhance their productivity and efficiency on a CNC lathe machine.

Recap of the 4 Tips for Beginners

Firstly, mastering CNC programming is essential. Learning G-code and M-code, using software and programming languages, and taking advantage of SYIL's user-friendly programming interface can significantly improve programming skills.

Secondly, proper tool selection and setup are vital to achieving accurate results. Familiarizing oneself with essential lathe tools, understanding tool materials and geometry, and utilizing SYIL's tooling solutions for precision turning are key factors in successful machining.

Thirdly, material selection and machining techniques should be considered carefully. Choosing the right materials for CNC lathe machining, optimizing feeds and speeds, and focusing on surface finish and dimensional accuracy are crucial to master.

Lastly, regular maintenance and machine care are essential for prolonging the lifespan of a CNC lathe machine. Following cleaning, lubrication, inspection procedures diligently can prevent common machine issues. SYIL's commitment to reliable and durable machines ensures long-term performance.