Introduction

A VMC machine, also known as a vertical machining center, is a type of CNC milling machine that utilizes vertical spindle orientation for cutting and shaping various materials. These machines offer numerous benefits, including increased precision, higher productivity, and reduced labor costs. This article will explore the different types of VMC machines, their applications in various industries, and why the SYIL U5 Vertical Machining Center stands out among its competitors.

What is a VMC machine?

A VMC machine is a computer-controlled milling machine that uses a rotating cutter to remove material from a workpiece. It operates on three axes (X, Y, and Z) for precise vertical cutting operations. This type of machine is commonly used in manufacturing processes to create intricate parts with high accuracy.

The Benefits of Using VMC Machines

VMC machines are a powerful technology used in modern manufacturing, offering several key benefits:

- Increased Precision and Accuracy: VMC machines utilize computerized control for precise positioning and cutting movements, resulting in highly accurate finished products compared to conventional machining methods.

- Higher Productivity and Efficiency: Automation is a major advantage of VMC machines. They can perform multiple tasks simultaneously and complete complex machining operations quickly, boosting overall productivity and efficiency.

In conclusion, VMC machines are vital in modern manufacturing because they deliver greater precision, increased efficiency, and faster production times.

Overview of Different Types of VMC Machines

There are various types of VMC machines available in the market today. The most common ones include the Vertical Machining Center (VMC), Horizontal Machining Center (HMC), Five-Axis Machining Center, High-Speed Machining Center, and Double Column Machining Center. Each type has its unique features and capabilities suited for different applications.

How VMC Machines are Used in Various Industries

VMC machines are used in several industries, including aerospace, automotive, medical equipment manufacturing, electronics production, and mold-making. They are used for tasks ranging from prototyping to mass production. Their ability to accurately machine complex parts makes them indispensable in modern manufacturing.

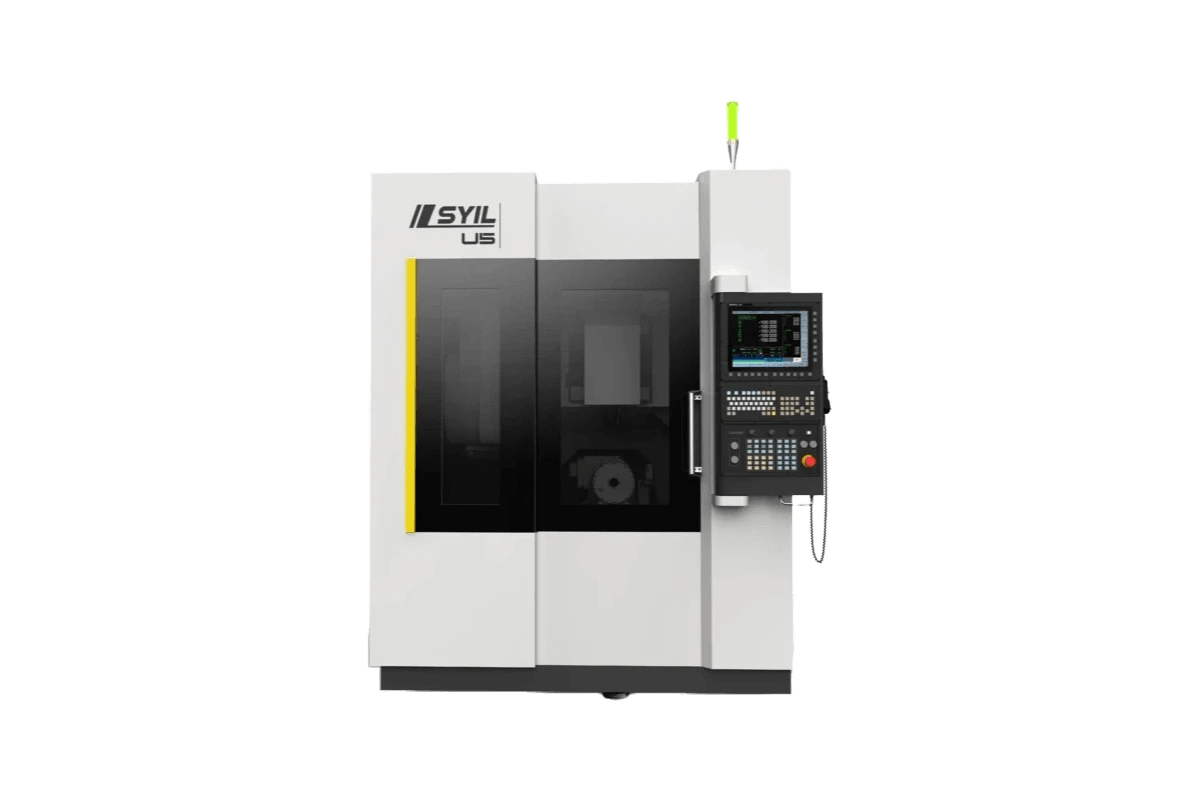

Why SYIL U5 Vertical Machining Center Stands Out

Among the various VMC machines available, the SYIL U5 Vertical Machining Center stands out for its exceptional performance and user-friendly operation. It offers unparalleled precision and productivity, making it the ideal choice for industrial machinists looking to boost their productivity. With its advanced capabilities and reliable support, the SYIL U5 is a top-notch option for machining needs.

Understanding VMC Machines

Definition and Function of VMC Machines

A VMC machine, also known as a vertical machining center, is a type of CNC (Computer Numerical Control) milling machine that utilizes a vertically oriented spindle to remove material from a workpiece. It is widely used in various industries for precision cutting, drilling, and shaping operations. The primary function of a VMC machine is to automate the manufacturing process and produce complex parts with high accuracy and efficiency.

Components and Structure of a VMC Machine

Understanding the Key Components of a Vertical Machining Center (VMC)

A Vertical Machining Center (VMC) is a powerful machine tool for various machining tasks. To achieve precise and efficient operation, several key components work in unison. Here's a breakdown of these essential elements:

- Spindle: This is the heart of the VMC, which is responsible for rotating the cutting tool at high speeds to remove material from the workpiece.

- Worktable: This sturdy platform securely holds the workpiece in place during machining.

- Tool Changer: This automated system allows for the swift swapping of cutting tools for various machining operations.

- Control Panel: The control panel is the operator's hub, where they can program machining jobs, monitor progress, and make necessary adjustments.

The robust construction of a VMC, typically made from high-quality cast iron or steel, ensures stability and rigidity throughout operation, minimizing vibrations and maintaining machining accuracy.

Key Features and Capabilities of VMC Machines

VMC machines offer a range of features and capabilities that make them highly versatile and efficient in modern manufacturing environments. These include advanced CNC controls that enable precise positioning and movement of the cutting tool; multiple-axis capabilities (typically 3-axis or 5-axis) for complex machining operations; high spindle speeds for fast material removal rates; automatic tool changers for increased productivity; and coolant systems for efficient chip evacuation and temperature control.

Types of VMC Machines

Vertical Machining Center (VMC)

The vertical machining center, commonly known as VMC, is a type of vertical milling machine that operates. Its spindle moves up and down, allowing the cutting tool to make precise cuts in various directions. Due to its versatility and accuracy, the VMC machine is widely used in the automotive, aerospace, and electronics industries.

Horizontal Machining Center (HMC)

Unlike the vertical machining center, the horizontal machining center operates horizontally, with its spindle positioned horizontally. This type of machine is suitable for heavy-duty machining operations and is often used in industries such as automotive and aerospace for tasks like milling large components or parts.

Five-Axis Machining Center

The five-axis machining center is a highly advanced VMC machine offering greater flexibility and precision. It can move the cutting tool along five axes simultaneously, allowing complex shapes and angles to be easily achieved. This type of machine is commonly used in industries like aerospace and mold-making.

High-Speed Machining Center

As the name suggests, the high-speed machining center is designed to perform machining operations at significantly higher speeds than conventional machines. It utilizes advanced technology to reduce cycle times while maintaining accuracy and surface finish quality. The high-speed machining center finds applications in industries where time efficiency is crucial, such as automotive and electronics.

Double Column Machining Center

The double-column machining center features a robust structure with two columns supporting the crossbeam on which the spindle moves horizontally. This design provides enhanced stability and rigidity, making it suitable for heavy-duty cutting operations on large workpieces or molds. Industries like aerospace and die-making benefit from this type of VMC machine.

Applications of VMC Machines

Aerospace Industry

VMC machines are crucial in the aerospace industry, where precision and reliability are paramount. These machines manufacture complex components such as turbine blades, engine parts, and aircraft structures. With their advanced capabilities, VMC machines ensure high accuracy and tight tolerances required in aerospace applications. The SYIL U5 Vertical Machining Center is the perfect choice for aerospace manufacturers looking to enhance their production efficiency and achieve superior quality.

Automotive Industry

VMC machines are widely used in the automotive industry to produce components like engine blocks, transmission parts, and brake systems. Because they can perform multiple operations in one setup, these machines streamline the manufacturing process and improve productivity. The SYIL U5 CNC mill offers exceptional precision and speed, making it an ideal solution for automotive manufacturers seeking to optimize their production lines.

Medical Industry

The medical industry relies on VMC machines to manufacture intricate medical devices such as implants, surgical instruments, and prosthetics. These machines enable precise machining of complex shapes with tight tolerances required in the medical field. The SYIL U5 Vertical Machining Center provides unmatched accuracy and surface finish quality needed for producing high-quality medical components.

Electronics Industry

In the electronics industry, VMC machines produce circuit boards, connectors, and other electronic components with high precision requirements. These machines ensure accurate drilling of tiny holes and precise milling of intricate patterns on delicate materials like PCBs (Printed Circuit Boards). The SYIL U5 CNC mill offers advanced features like high-speed spindle rotation and rapid tool change that enhance productivity in electronic component manufacturing.

Mold and Die Industry

The mold and die industry heavily relies on VMC machines to create molds used in various manufacturing processes, such as injection molding or die casting. These machines provide the necessary precision to produce intricate mold cavities with tight tolerances. The SYIL U5 Vertical Machining Center offers exceptional rigidity and stability, making it an excellent choice for mold and die manufacturers looking to achieve superior mold quality.

Advantages of VMC Machines

Increased Precision and Accuracy

VMC machines, such as the SYIL U5 Vertical Machining Center, offer increased precision and accuracy in machining operations. With advanced CNC technology and precise control systems, these machines can achieve tight tolerances and consistently produce high-quality parts. The cutting tool's ability to precisely position allows for intricate and complex machining tasks with minimal errors or deviations.

Higher Productivity and Efficiency

Vertical Machining Centers (VMCs) are revolutionizing manufacturing by boosting productivity and streamlining processes. Here's how VMCs achieve this:

- Multi-Axis Machining: Unlike traditional machines, VMCs possess multiple axes that can perform various machining operations simultaneously. This eliminates the need for multiple setups and drastically reduces cycle times.

- Enhanced Efficiency: VMCs prioritize efficiency with features like powerful spindle motors that expedite material removal and rapid tool change systems that minimize downtime between operations.

For instance, the SYIL U5 Vertical Machining Center exemplifies these advantages with its robust motor and lightning-fast tool-changing capabilities.

By incorporating VMCs into your production line, you can unlock a new efficiency level and propel your manufacturing to new heights.

Flexibility and Versatility

VMC machines offer a wide range of flexibility and versatility in machining applications. They can handle various materials, including metals, plastics, composites, etc. With their multi-axis capabilities, these machines can perform complex milling operations such as contouring, drilling, tapping, threading, and pocketing. The SYIL U5 Vertical Machining Center provides even greater flexibility with its customizable options for different workpiece sizes and configurations.

Cost-Effectiveness and Reduced Labor

Investing in a VMC machine like the SYIL U5 can lead to significant cost savings in the long run. These machines automate repetitive tasks that would otherwise require manual labor, reducing labor costs while improving overall efficiency. Additionally, the precision of VMC machines minimizes material waste by optimizing cutting paths and reducing errors or rework.

In conclusion, VMC machines, such as the SYIL U5 Vertical Machining Center, offer unparalleled precision, productivity, flexibility, and cost-effectiveness advantages. Their advanced capabilities and user-friendly operation are essential tools for modern manufacturing industries. Whether for aerospace, automotive, medical, electronics, or mold and die applications, the SYIL U5 VMC machine is an ideal choice to boost productivity and achieve superior machining results.

Choosing the Right VMC Machine

When it comes to selecting a VMC machine, there are several factors that you need to consider.

Factors to Consider when Selecting a VMC Machine

Choosing the Right Vertical Machining Center (VMC) for Your Needs

Selecting the right VMC is crucial for efficient and successful machining operations. Here are some key factors to consider when making your decision:

- Machining Requirements: First, assess your specific needs. Consider the size and complexity of the parts you'll work with and your production volume. This will help determine the machine size and capacity best suits your workflow.

- Spindle Speed and Power: Evaluate the VMC's spindle speed and power. Higher spindle speeds translate to faster-cutting speeds and greater productivity. Additionally, a powerful spindle ensures efficient material removal for tougher jobs.

- Control System: Consider the type of control system used in the VMC. A CNC (Computer Numerical Control) system offers greater precision and flexibility than manual controls. This allows for intricate machining of complex parts and facilitates programming for consistent results.

By carefully considering these factors, you can select a VMC that meets your needs and helps you achieve optimal machining performance.

Evaluating the Specific Needs and Requirements

Evaluating your needs and requirements is crucial to choosing the right VMC machine. Consider factors such as desired accuracy, surface finish quality, and complexity of parts.

Consider whether you require additional features such as automatic tool changers or coolant systems. These features can significantly enhance productivity and efficiency in your machining operations.

Comparing Different Models and Brands

It is essential to compare different models and brands before making a decision. Look for reputable manufacturers with a proven record of producing high-quality VMC machines.

Compare specifications such as maximum workpiece size, table load capacity, tool magazine capacity, and available customization options. This will help you find a machine that meets all your requirements.

Understanding the Importance of Reliability and Support

When investing in a VMC machine, reliability is key. Look for machines built with durable components and a reputation for long-term performance.

Additionally, consider the level of technical support the manufacturer or distributor provides. A reliable support system ensures that issues or concerns can be addressed promptly, minimizing downtime and maximizing productivity.

SYIL U5 Vertical Machining Center is a top choice in the market, offering unmatched reliability and support. Its advanced features and user-friendly interface make it the ideal machine for any industrial machinist.

Conclusion

In conclusion, VMC machines play a crucial role in modern manufacturing processes. They offer unparalleled precision and efficiency, making them essential for the aerospace, automotive, medical, electronics, and mold and die industries. VMC machines' versatility allows for a wide range of applications, while their advanced capabilities ensure higher productivity and accuracy.

When choosing the right VMC machine, consider specific requirements, reliability, and support. Comparing different models and brands is also crucial in making an informed decision.

One standout option is the SYIL U5 Vertical Machining Center. This CNC mill offers unmatched precision and productivity. Its user-friendly operation makes it ideal for industrial machinists looking to boost efficiency. With its advanced features and capabilities, the SYIL U5 is a reliable investment for any manufacturing operation.

Investing in a VMC machine like the SYIL U5 can revolutionize your manufacturing process by increasing precision and accuracy while improving productivity and efficiency. Don't miss out on the benefits that these versatile machines can offer.