Introduction

In the ever-evolving world of manufacturing, CNC machines have revolutionized how we approach precision engineering and design. Among these machines, the debate between the CNC mill vs CNC router often arises, sparking curiosity about their unique capabilities and applications. Understanding these differences is crucial for selecting the right tool for your projects, whether you're a hobbyist or an industry professional.

Understanding CNC Machines

CNC, or Computer Numerical Control, machines automate complex machining processes through programmed commands, allowing for high precision and repeatability. These machines can manipulate tools to cut, shape, and form various materials into intricate designs that would be challenging to achieve manually. By grasping the fundamentals of CNC technology, you can better appreciate how specific models like the CNC milling machine and CNC router machine fit into this landscape.

Key Differences Between CNC Mill and Router

When comparing a CNC mill vs a CNC router, it's essential to recognize their distinctive features tailored for different tasks. While both utilize computer programming to control movements and operations, a milling machine typically focuses on harder materials like metals with superior precision. In contrast, a router cutting machine excels in softer materials such as wood or plastic, offering versatility in design but generally at lower precision levels than its milling counterpart.

Applications and Industries

The applications of these machines span various industries—from aerospace to jewelry making—each benefiting from the unique strengths of either a CNC milling machine or a CNC router machine. For instance, intricate components in aerospace engineering require the high precision that only a mill can provide. Meanwhile, artisans crafting bespoke wooden furniture often turn to routers for their ability to handle detailed carvings effortlessly while accommodating larger workpieces.

Overview of CNC Machines

When diving into the world of CNC machines, it’s essential to understand their core functionalities and differences. The CNC milling machine and the CNC router machine are two primary types that cater to various needs in the machining industry. Each has its strengths, making them suited for distinct applications, from intricate designs to robust manufacturing processes.

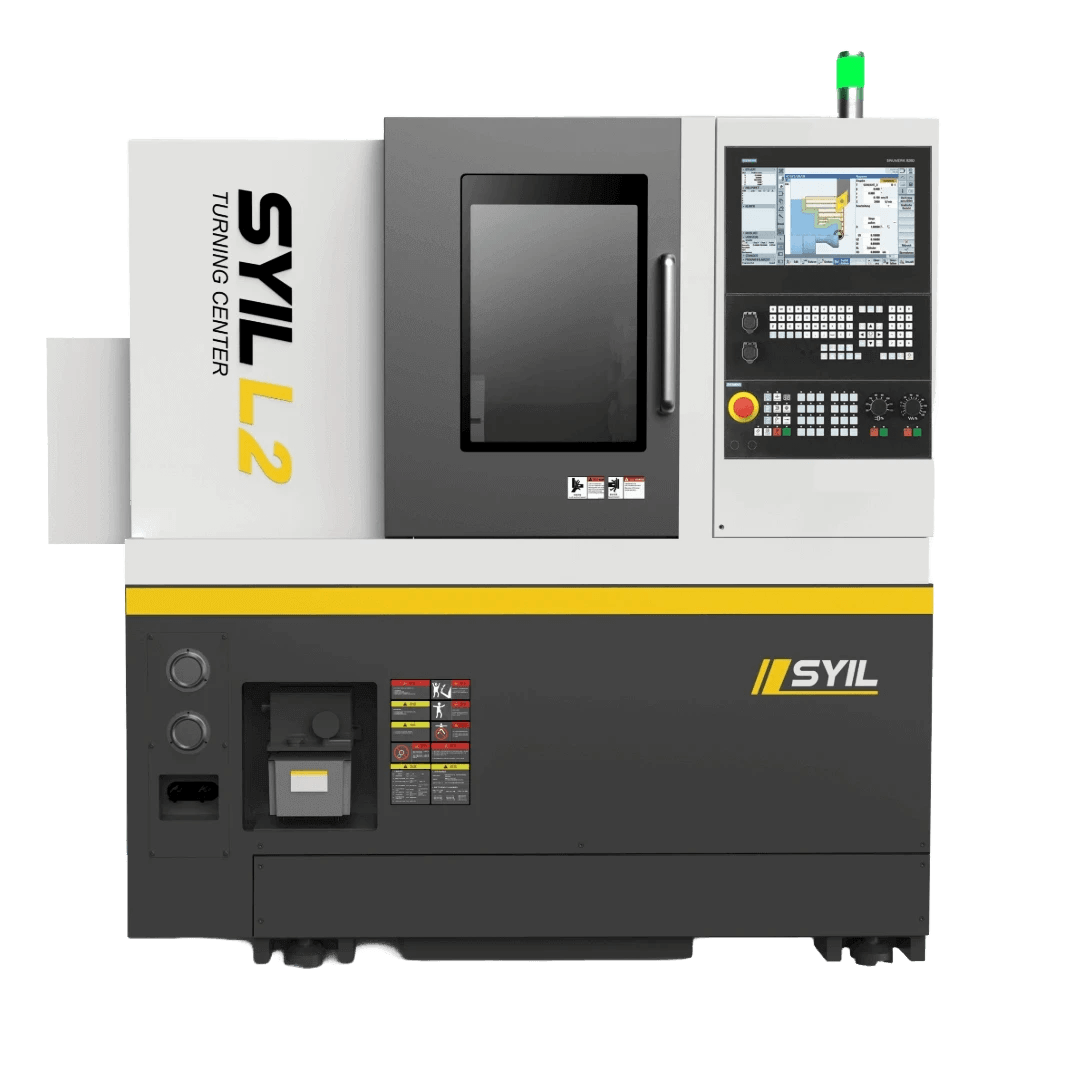

What is a CNC Milling Machine?

A CNC milling machine is a powerhouse in precision machining, designed to shape materials through rotary cutting tools. It operates on multiple axes, allowing for complex geometries and detailed features that are often required in industries like aerospace and automotive. With its ability to handle hard materials such as metals and alloys, the CNC mill excels where high precision is paramount, making it a go-to choice for engineers and manufacturers alike.

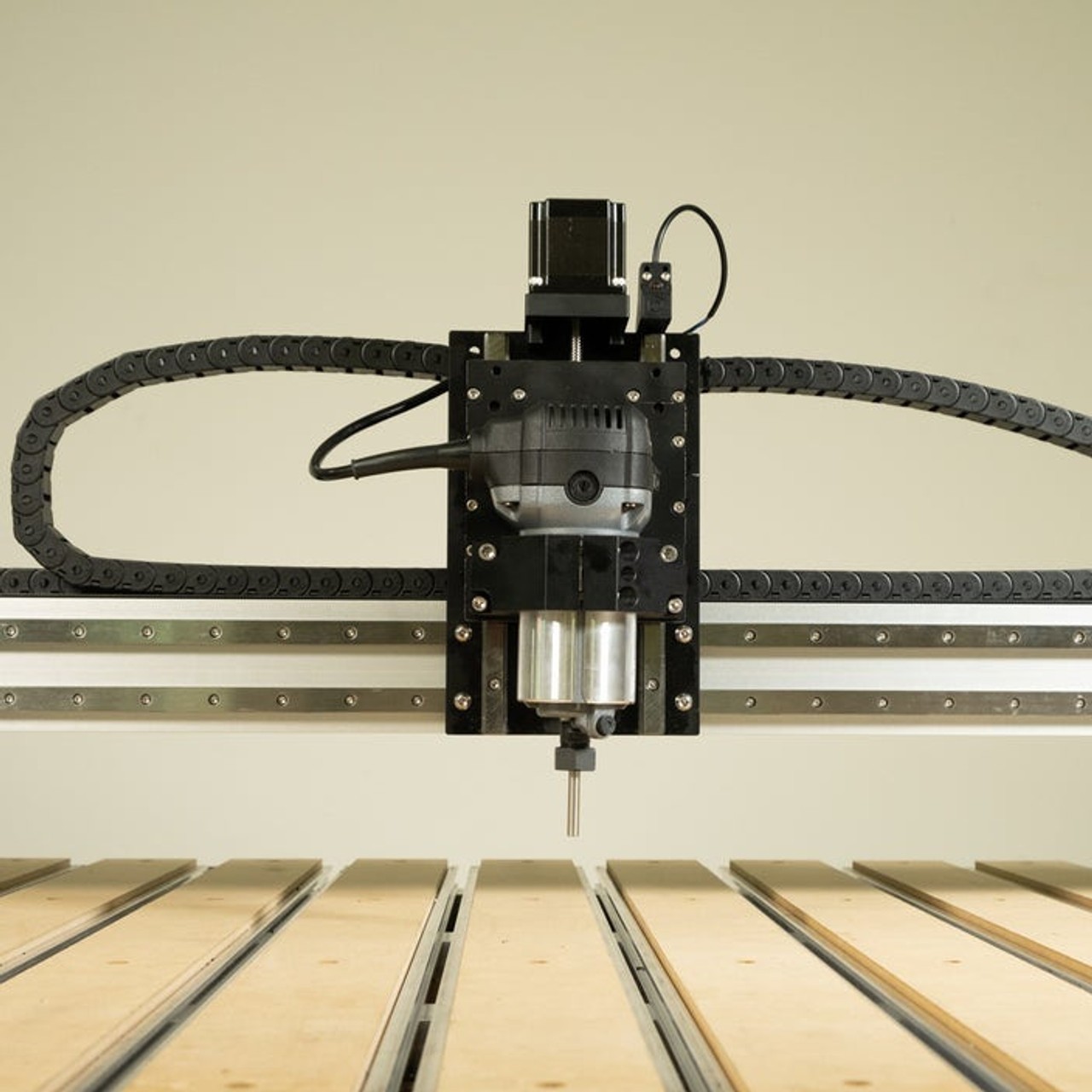

What is a CNC Router Machine?

In contrast, the CNC router machine specializes in softer materials like wood, plastics, and composites. This versatile tool utilizes high-speed spinning bits to carve out intricate designs with remarkable speed and efficiency. While it may not achieve the same level of precision as a CNC milling machine in hard materials, its adaptability makes it ideal for applications ranging from furniture crafting to signage production.

How CNC Router Parts Differ from Mill Parts

The parts of a CNC router differ significantly from those found in a milling machine due to their intended use and material handling capabilities. For instance, while both machines share some fundamental components like motors and controllers, routers typically have lighter frames designed for rapid movement across softer substrates. Additionally, the cutting tools used in cnc parts machining vary; routers employ straight bits or spiral bits optimized for cutting wood or plastic while mills utilize end mills tailored for metalworking tasks.

Precision and Detail

CNC Mill: High Precision for Complex Parts

CNC milling machines are renowned for their high precision, making them ideal for creating complex parts that require tight tolerances. These machines utilize advanced cutting tools that move along multiple axes, allowing intricate designs to be machined with exceptional accuracy. If your project involves detailed components such as gears or automotive parts, the CNC mill will likely be your best bet due to its superior ability to handle complex geometries.

The precision of a CNC mill stems from its robust construction and sophisticated software controls, ensuring consistent results across multiple production runs. This high level of detail not only enhances the functionality of parts but also minimizes waste during the cnc parts machining process. Consequently, choosing a CNC mill can ensure that your projects meet stringent quality standards while maintaining efficiency.

CNC Router Cutting Machine: Versatile Yet Accurate

On the other hand, a CNC router cutting machine offers versatility combined with respectable accuracy—making it an excellent choice for various applications like woodworking or sign-making. While it may not achieve the same level of precision as a milling machine in some cases, modern CNC routers have advanced significantly in terms of accuracy and can handle intricate designs effectively. The flexibility in material compatibility allows users to work with wood, plastics, and soft metals without compromising on quality.

CNC routers employ different types of bits that can easily switch out depending on the desired finish or material type being used. This adaptability makes them popular among hobbyists and professionals alike who need to create detailed designs quickly without sacrificing too much on precision compared to traditional methods. However, if you're working on projects requiring extreme detail or engineering-grade components, you might want to reconsider whether a cnc router machine fits those specific demands.

Choosing Based on Required Detail

Ultimately, choosing between a cnc mill vs cnc router boils down to understanding your project's requirements regarding detail and complexity. If you're focused on producing highly intricate parts with tight tolerances—like those found in aerospace or medical applications—a CNC milling machine is likely more suitable due to its unparalleled precision capabilities. Conversely, if you need versatility in materials while still achieving good levels of accuracy—such as creating custom furniture or decorative items—a cnc router cutting machine could serve you well.

Before making any decisions about which machine aligns best with your goals, take stock of what materials you'll be working with and how intricate your designs will be over time; this evaluation will guide you toward selecting either cnc router parts or milling tools that suit your needs perfectly! Remember that investing wisely now ensures smoother operations later down the line.

Material Compatibility

CNC Milling Machine for Hard Materials

CNC milling machines are engineered to tackle tough materials like metals, hard plastics, and dense composites. The robust construction and powerful spindle of a CNC milling machine allow for precise machining of complex shapes and intricate details in hard materials. This makes the CNC mill an ideal choice for industries such as aerospace, automotive, and manufacturing where durability and precision are non-negotiable.

In contrast, if you were to use a CNC router for these harder materials, you might find it lacking in both power and precision. While some high-end routers can manage softer metals or plastics, they typically won’t deliver the same level of detail as a dedicated milling machine. Thus, when working with hard materials, it's clear that the CNC milling machine reigns supreme in this cnc mill vs cnc router debate.

CNC Router for Wood and Composites

On the other hand, when it comes to softer materials like wood or composite materials, the CNC router shines brightly. The design of a CNC router cutting machine allows it to efficiently carve intricate designs into wood while maintaining speed and accuracy—perfect for furniture making or decorative items. Additionally, its lighter build means it's easier to maneuver around larger sheets of material without compromising quality.

The versatility of a CNC router also extends to various composite materials used in industries like signage or architectural modeling. With specialized cnc router parts designed for cutting soft substrates efficiently, this type of machinery offers flexibility that makes it appealing for hobbyists and professionals alike. So if your project involves wood or composites rather than metals or ceramics, leaning towards a cnc router would be wise!

Exploring Material Options: Which Fits Your Needs?

Ultimately, determining which machine fits your needs boils down to understanding your specific projects' material requirements. If you're primarily working with hard metals requiring high precision machining—look no further than the reliable capabilities of a cnc milling machine! However, if your focus is on woodworking or crafting with softer composites—then investing in a quality cnc router should be at the top of your list.

Before making any decisions about which machinery suits you best within this ongoing cnc mill vs cnc router conversation; consider not only what you're cutting but also how often you'll be switching between different materials! Understanding these factors will guide you toward selecting the right equipment that aligns perfectly with both current demands and future aspirations in your crafting journey.

Cost Analysis

When considering a CNC machine for your projects, understanding the cost implications is crucial. The financial aspect encompasses initial investments, operational costs, and long-term maintenance expenses. Let's dive into these factors to help you navigate the cnc mill vs cnc router debate with confidence.

Initial Investment: CNC Mill vs CNC Router

The initial investment in a CNC milling machine typically surpasses that of a CNC router machine. This difference stems from the complexity and precision required for milling operations, which often necessitate more advanced technology and robust components. However, while a cnc router may have a lower entry price point, it's essential to assess the long-term value based on your specific needs in cnc parts machining.

For hobbyists or small businesses focusing on wood or softer materials, the affordability of a cnc router cutting machine can be enticing. Yet, if your projects demand high precision and the ability to work with harder materials like metals, investing in a quality CNC mill may yield better returns over time. Ultimately, weighing these initial costs against your intended applications will guide you toward making an informed decision.

Operational Costs of CNC Machines

Operational costs play a significant role in determining the overall expense of owning either type of machine. For instance, while both machines require electricity and tooling costs for operation, the cnc milling machine often incurs higher tooling expenses due to its more complex cutting processes and tool wear rates associated with harder materials. In contrast, operational costs for a cnc router are generally lower since they primarily work with softer materials like wood and plastics.

Maintenance requirements also differ between these two types of machines; while both need regular upkeep to ensure optimal performance, mills may require more frequent servicing due to their intricate mechanisms and heavier workloads. Additionally, consider factors such as software licensing fees for CAD/CAM programs that are compatible with each type of machine when evaluating ongoing expenses. Understanding these operational costs will help you make an educated choice between a cnc mill vs cnc router based on your budget constraints.

Longevity and Maintenance for Each Type

Longevity is another critical factor when assessing your investment in either a CNC mill or router machine. Generally speaking, well-maintained machines can last many years; however, their lifespans can vary significantly depending on usage intensity and maintenance practices. A properly maintained CNC milling machine can serve industrial applications effectively over time but may require more frequent repairs compared to its counterpart due to its demanding nature.

On the other hand, while cnc routers tend to be less complex mechanically—which can lead to lower maintenance demands—they also face limitations in terms of material compatibility that could affect longevity if misused or overworked beyond their designed capabilities. Investing time into routine maintenance checks—like lubricating moving parts or calibrating tools—can enhance both types' durability significantly regardless of whether you choose a cnc mill or router cutting machine.

In conclusion, weighing initial investments against operational costs alongside longevity considerations will ultimately steer you toward selecting the right machinery suited for your specific needs within the realm of cnc parts machining.

Ideal Use Cases

When it comes to choosing between a CNC mill and a CNC router, understanding their ideal applications can help you make the right decision. Each machine shines in specific areas, making them indispensable tools in various industries. Let’s explore some of the best use cases for both types of CNC machines.

SYIL X5 Mini CNC Machine for Prototyping

The SYIL X5 Mini CNC machine is an excellent choice for prototyping due to its compact size and high precision capabilities. This CNC milling machine allows engineers and designers to create intricate parts with exceptional detail, making it ideal for testing new designs before full-scale production. In the debate of CNC mill vs CNC router, the X5 stands out as a go-to option for those needing accuracy in small-scale projects.

Prototyping often requires rapid iterations and modifications, which is where this mini CNC machine excels. Its user-friendly interface simplifies programming tasks, allowing users to focus on creativity rather than getting bogged down by complex setups. Thus, when considering cnc parts machining for prototyping needs, the SYIL X5 Mini offers a blend of efficiency and reliability that few can match.

Jewelry Making with CNC Router Machines

CNC router machines have revolutionized jewelry making by enabling artisans to craft intricate designs with ease and precision. The versatility of a cnc router cutting machine allows jewelers to work with various materials such as metals, plastics, and wood while achieving stunning results that would be difficult or impossible by hand. In contrast to a traditional milling approach, routers provide greater flexibility in design execution without sacrificing quality.

Jewelry makers benefit from the ability to produce multiple pieces quickly while maintaining high standards of detail—a crucial factor in this competitive industry. The lightweight nature of many cnc router parts means that they can be adapted easily for different tasks or materials without requiring extensive downtime between jobs. This adaptability makes cnc routers particularly appealing when crafting custom pieces or limited-edition collections.

Industrial Applications for CNC Milling

CNC milling machines are indispensable in industrial applications where precision is paramount—think aerospace components or automotive parts manufacturing! These robust machines are designed specifically for working with hard materials like metals that require detailed machining processes not suited for routers. When comparing cnc mill vs cnc router capabilities in an industrial context, mills clearly take the lead due to their strength and accuracy.

In large-scale production environments, operational efficiency is critical; hence investing in a reliable cnc milling machine pays off over time through reduced waste and increased output quality. Moreover, advancements in technology mean modern mills come equipped with sophisticated software that enhances productivity while minimizing errors during production runs—making them essential assets on any factory floor! As industries continue evolving towards automation and higher demands on quality control processes, the role of these machines will only grow more significant.

Conclusion

In the world of CNC machining, making the right choice between a CNC mill and a CNC router can be pivotal for your projects. Understanding the unique capabilities and applications of each machine ensures you select the right tool for your specific needs, whether you're crafting intricate parts or shaping large sheets of material. As you weigh the options, consider not only your immediate requirements but also how these machines can evolve with your business.

Making the Right Choice for Your Projects

When deciding between a CNC milling machine and a CNC router machine, it's essential to evaluate the materials you'll be working with and the precision required. A CNC mill is ideal for hard materials and complex geometries, while a CNC router cutting machine excels at handling softer substrates like wood or composites. By analyzing your project specifications and future needs, you can make an informed decision that maximizes efficiency and quality.

Future Trends in CNC Machinery

The landscape of CNC machinery is continually evolving, with innovations enhancing both performance and usability. Emerging technologies such as automation, AI integration, and advanced software are set to redefine how we approach cnc parts machining in various industries. Keeping an eye on these trends will not only help you stay competitive but also open up new avenues for creativity in design and manufacturing processes.

Recap: CNC Mill vs CNC Router Insights

To sum it up, understanding the distinctions between a cnc mill vs cnc router is crucial for optimizing your manufacturing processes. Each machine has its strengths: while cnc milling machines offer high precision for complex parts, cnc routers provide versatility for larger-scale projects involving softer materials. By recognizing their unique capabilities and applications, you're better equipped to make choices that propel your projects forward.