Introduction

In the world of manufacturing and woodworking, precision is paramount, and CNC routers have emerged as the champions of accuracy. These machines are not just tools; they are gateways to a new era of industrial production where complex designs come to life with unparalleled finesse. As we delve into the realm of CNC technology, it becomes clear that discovering the best industrial CNC router can significantly elevate your production capabilities.

Discovering Precision in CNC Routers

CNC routers are engineered for precision, making them indispensable in various industries. The best industrial CNC router can carve intricate patterns in wood, metal, and other materials while maintaining exact specifications. Whether you're crafting furniture or creating detailed prototypes, understanding what makes a CNC machine stand out will guide you towards achieving remarkable results.

The Rise of Industrial CNC Technology

The evolution of industrial CNC technology has transformed how manufacturers approach production processes. What is the best CNC machine in the world? This question often leads to discussions about advanced features and capabilities that enhance efficiency and reduce waste. With an increasing demand for high-quality products, investing in robust machinery has never been more critical for staying competitive.

Why Invest in a Quality CNC Router

Investing in a quality CNC router means committing to longevity and performance that pays off over time. When considering what is the lifespan of a CNC router, many users find that premium models offer years of reliable service when properly maintained. Furthermore, choosing the best industrial CNC router for metal can open up lucrative avenues; after all, what is the most profitable CNC project to sell? With the right equipment at your disposal, your creative potential knows no bounds.

Understanding CNC Technology

CNC (Computer Numerical Control) technology has revolutionized the manufacturing landscape, bringing precision and efficiency to various industries. It enables machines to operate with remarkable accuracy, transforming digital designs into tangible products. In this section, we will explore what makes CNC routers stand out, including the best industrial CNC router options available today.

What is the Best CNC Machine in the World?

When it comes to determining what is the best CNC machine in the world, opinions vary based on specific needs and applications. However, many industry experts often point to high-end models from brands like Haas Automation and Biesse as frontrunners due to their reliability and precision. Ultimately, the best industrial CNC router for your needs will depend on factors such as material type, project complexity, and budget considerations.

In addition to performance metrics like speed and accuracy, user-friendliness plays a crucial role in defining the best machine. Many operators prefer machines that come equipped with intuitive software interfaces that simplify programming tasks. So whether you’re looking for a robust solution for metalwork or a versatile router for woodworking projects, understanding individual requirements is key.

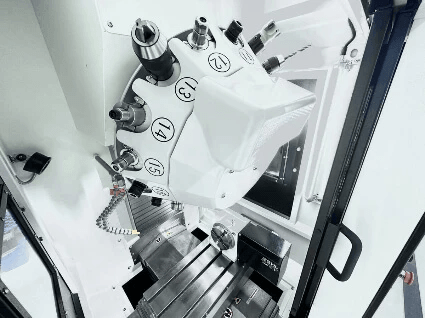

Key Features of Industrial CNC Routers

Industrial CNC routers are equipped with features designed to enhance performance and efficiency across various applications. One standout feature is high-speed spindle motors that allow for faster cutting speeds without sacrificing quality—essential for industries where time equals money. Additionally, advanced motion control systems ensure smooth operation while reducing wear on critical components.

Another significant aspect of industrial routers is their ability to handle diverse materials ranging from wood to metal composites effortlessly. This versatility makes them ideal candidates for anyone asking what is the most profitable CNC project to sell; they can tackle everything from intricate carvings to robust signage with ease. Moreover, many models offer customizable tooling options that allow users to adapt their machines according to specific project requirements.

Lastly, durability cannot be overlooked when evaluating these machines; many industrial routers are built from heavy-duty materials designed to withstand rigorous use over extended periods—an essential factor when considering what is the lifespan of a CNC router? Investing in quality machinery often pays off in reduced downtime and maintenance costs over time.

How CNC Routers Enhance Precision

CNC routers enhance precision through advanced computer algorithms that dictate every movement of the cutting tool with pinpoint accuracy. This level of control minimizes human error significantly compared to traditional machining methods—ensuring consistent results regardless of complexity or scale of production runs. With features like automatic tool changers and real-time monitoring systems integrated into modern designs, achieving high-quality outputs has never been easier.

Moreover, many top-tier models utilize closed-loop systems that provide feedback on position and speed during operation; this ensures that even minute adjustments can be made instantly for optimal performance—making them some of the best industrial CNC routers available today! Such enhancements not only lead directly into better product quality but also contribute positively towards overall operational efficiency.

Finally, by leveraging sophisticated software solutions alongside hardware advancements found in these routers—like laser alignment tools or 3D modeling capabilities—users can push boundaries previously thought unattainable within their respective crafts! As industries continue evolving toward greater automation levels while demanding higher standards than ever before; investing wisely in these technologies becomes imperative if one wishes not just keep pace but thrive amidst fierce competition.

Top Brands for Industrial CNC Routers

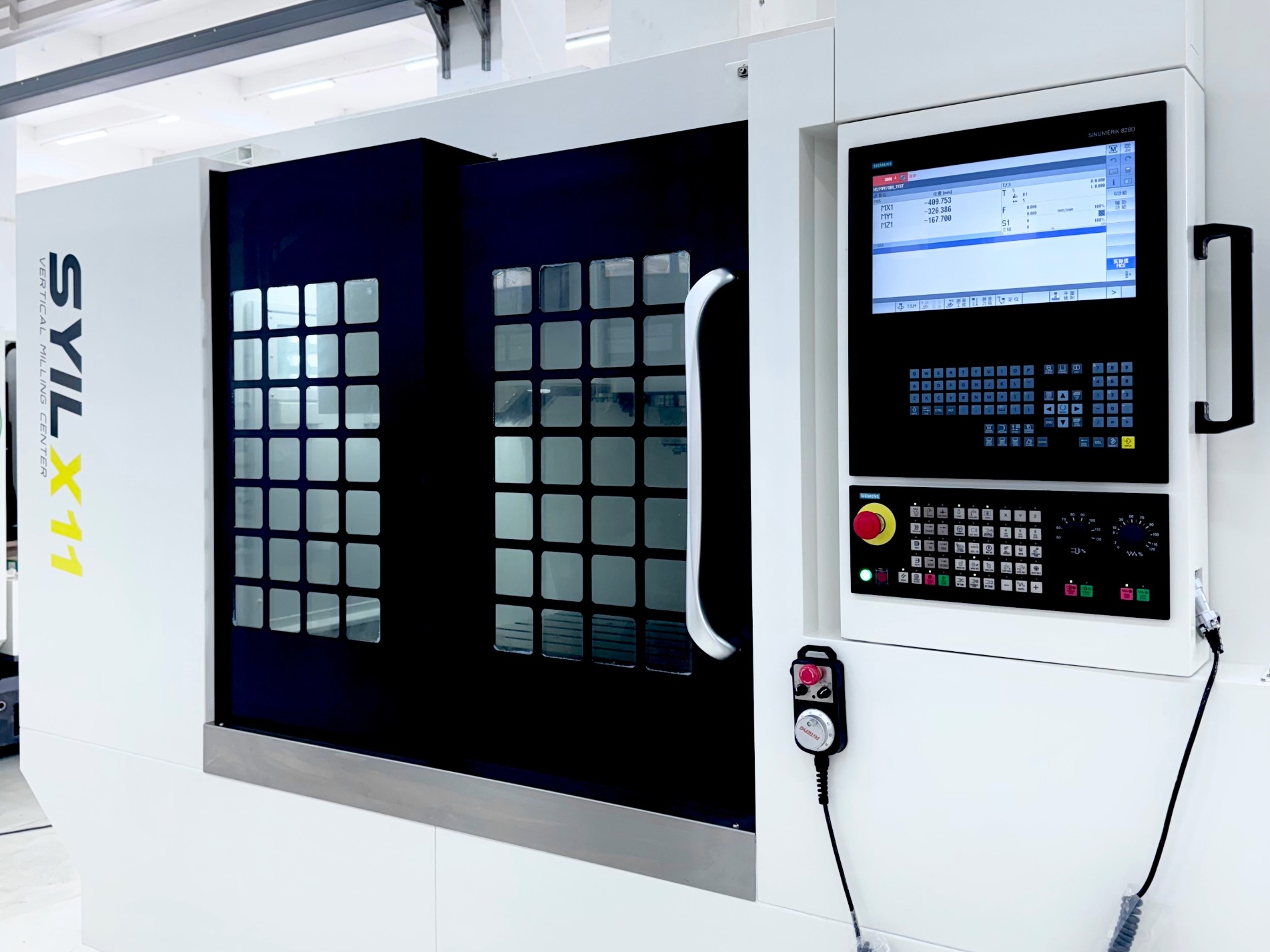

Evaluating SYIL CNC Machines

SYIL CNC machines are often hailed as some of the best industrial CNC routers available today. Known for their robust construction and precision engineering, these machines cater to various applications, including metalworking and woodworking. If you're asking yourself, What is the best CNC machine in the world? you might find that SYIL's offerings consistently rank high due to their combination of performance and affordability.

One of the key advantages of investing in a SYIL machine is their impressive lifespan, which can exceed many competitors when properly maintained. Understanding what is the lifespan of a CNC router is crucial for any business looking to invest wisely; with SYIL, users often report years of reliable service before needing significant repairs or replacements. Furthermore, if you're on the hunt for the best industrial CNC router for metalwork, SYIL's models are engineered specifically to handle tough materials without compromising on precision.

In addition to durability and functionality, SYIL also provides excellent customer support—a factor that can greatly influence your overall experience with any industrial equipment. For those considering cost versus value when choosing their machinery, it's worth noting that many users deem SYIL as offering the best industrial CNC router for the money spent. The blend of high-quality engineering with competitive pricing makes them an attractive option in today’s market.

When exploring profitable ventures within this technology sphere, one might wonder: What is the most profitable CNC project to sell? Many entrepreneurs have found success by utilizing SYIL machines' capabilities to create intricate designs or custom parts that are highly sought after in various industries.

In summary, if you’re looking into where industrial CNC routers are made or which brands consistently deliver value over time, consider adding SYIL to your shortlist—your future projects may just thank you!

Key Applications of CNC Routers

CNC routers are revolutionizing various industries with their precision and versatility. From woodworking to metal fabrication, understanding the key applications of CNC routers can help businesses maximize their productivity and profitability. This section will explore the best industrial CNC router for metal, profitable projects to consider, and how CNC technology enhances prototyping.

Best Industrial CNC Router for Metal

The best industrial CNC router for metal combines power, precision, and durability to handle tough materials like aluminum, steel, and titanium. Brands like SYIL have gained recognition in this area by producing machines that boast advanced features such as high-speed spindles and robust build quality.

Investing in a reliable machine not only improves efficiency but also expands your capabilities. Many users ask, What is the best CNC machine in the world? when searching for options that can cut through metals with ease while maintaining accuracy. With a solid choice in an industrial CNC router for metal, you can take on complex projects that demand both strength and finesse.

Most Profitable CNC Projects to Sell

Exploring what is the most profitable CNC project to sell can open up new revenue streams for your business or hobbyist endeavors. Popular projects include custom furniture pieces, intricate signs, personalized gifts, and even automotive parts—all of which can fetch a good price if crafted well using a quality router. By leveraging the capabilities of a top-tier machine like the best industrial CNC router for the money, you can create unique products that stand out in today’s competitive market.

Additionally, trends often shift toward bespoke items; therefore, investing time into understanding customer preferences is key to maximizing profits from your creations. Remember that successful projects often come from combining creativity with precise machining techniques provided by advanced CNC technology. With each product sold reflecting your craftsmanship aided by an exceptional router, you’ll likely see returns on your investment grow.

Enhancing Prototyping with CNC Technology

CNC routers play a pivotal role in enhancing prototyping processes across various industries. The precision offered by these machines allows designers and engineers to create accurate models quickly—essentially cutting down lead times significantly compared to traditional methods. Whether you're working on complex designs or simple prototypes, knowing where are industrial CNC routers made can provide insight into their reliability based on manufacturing standards.

Moreover, many professionals wonder about the lifespan of a CNC router when considering long-term investments in prototyping tools; generally speaking, well-maintained machines last several years before requiring major overhauls or replacements. Therefore investing wisely in durable equipment ensures that you have reliable tools at hand throughout multiple project iterations while maintaining high levels of accuracy needed during development phases.

Lifespan and Maintenance of CNC Routers

When considering the best industrial CNC router, understanding its lifespan and maintenance requirements is crucial for maximizing your investment. A well-maintained CNC router can significantly enhance productivity and precision, allowing businesses to thrive in competitive markets. Knowing how to care for your machine not only extends its life but also ensures it operates at peak performance.

What is the Lifespan of a CNC Router?

The lifespan of a CNC router can vary widely based on factors such as usage, maintenance, and build quality. Generally speaking, high-quality industrial models can last anywhere from 10 to 20 years if properly cared for. For those wondering “What is the best CNC machine in the world?”, it’s important to note that machines with robust construction and advanced technology tend to offer longer lifespans.

Regular usage can affect longevity; frequent operation without adequate maintenance may lead to wear and tear that shortens a machine’s life. Additionally, the environment where industrial CNC routers are used—such as humidity levels or exposure to dust—can impact their durability. Thus, investing in the best industrial CNC router for metal or other materials should come with an understanding of its expected lifespan.

Essential Maintenance Tips for Longevity

To ensure your CNC router stands the test of time, implementing essential maintenance practices is key. Regular cleaning of components helps prevent debris buildup that can hinder precision; this includes keeping rails free from dust and lubricating moving parts as needed. It’s also advisable to perform routine inspections on critical components like bearings and spindles—after all, catching issues early can save you from costly repairs later.

Another important aspect involves software updates; staying current with firmware ensures optimal performance features are utilized effectively. Operators should also familiarize themselves with their specific model's manual since different brands may have unique requirements—especially when considering where industrial CNC routers are made and how they’re designed for various applications. By following these tips, you’ll be well on your way to having one of the best industrial CNC routers available.

Understanding Wear and Tear in CNC Parts

Wear and tear are inevitable in any machinery over time, including top-tier options like the best industrial CNC router available today. Understanding how different parts wear out helps operators make informed decisions about replacements before they become critical failures; this knowledge is crucial if you're looking into what is the most profitable CNC project to sell or aiming for long-term production efficiency.

Common areas subject to wear include belts, bearings, and cutting tools—their condition directly impacts precision machining capabilities. Regularly monitoring these components allows you not only to maintain accuracy but also to plan budget allocations more effectively when considering factors influencing cost versus value in your investment choices.

Ultimately, being proactive about wear management contributes significantly toward achieving optimal performance from your equipment while minimizing downtime—a key consideration when weighing options like the best industrial cnc router for money spent on maintaining production flow.

Cost vs. Value: Making the Right Choice

When it comes to investing in a CNC router, understanding the balance between cost and value is crucial. With many options available, determining which offers the best industrial CNC router for the money can save you time and resources in the long run. This section will help you navigate through key considerations to ensure you make an informed decision.

Best Industrial CNC Router for the Money

Finding the best industrial CNC router for your budget often feels like searching for a needle in a haystack. However, brands such as SYIL and ShopSabre consistently rank high in terms of performance and reliability without breaking the bank. When evaluating options, consider features like precision, speed, and durability; these factors greatly influence whether you're getting good value for your investment.

Many users wonder what is the best CNC machine in the world? While opinions may vary based on specific needs, models that combine advanced technology with user-friendly interfaces tend to shine above others. Remember that while cost is essential, investing in a machine that meets your production demands will yield better returns over time.

Factors Influencing Cost and Precision

The price of an industrial CNC router can fluctuate based on several key factors including size, capabilities, and brand reputation. A robust machine designed for heavy-duty tasks typically comes with a higher price tag but offers superior precision—essential when working on projects like metal fabrication or intricate wood designs. Understanding what influences these costs helps you identify where to allocate your budget effectively.

Additionally, where are industrial CNC routers made? The origin can impact quality control standards and overall build quality; machines manufactured in regions known for engineering excellence often provide better longevity and performance. Ultimately, balancing these factors against your project requirements will guide you toward making sound financial decisions.

Investing Wisely in CNC Technology

Investing wisely in CNC technology means looking beyond just initial costs; consider long-term savings from reduced maintenance needs and higher productivity levels too! A well-maintained machine not only lasts longer but also retains its precision over time—so knowing “what is the lifespan of a CNC router?” becomes pivotal when weighing options during purchase decisions.

Moreover, exploring profitable projects such as custom furniture or signage can help offset initial costs by generating income through skilled craftsmanship using your new equipment. If you're curious about what is the most profitable CNC project to sell?, think about high-demand items that resonate with local markets or niche industries.

In conclusion, making an informed choice about purchasing an industrial CNC router involves more than just comparing prices; it requires assessing how each option aligns with your business goals while ensuring optimal performance at every turn.

Conclusion

In the world of precision machining, selecting the right CNC router can be a game-changer for your business. Whether you're pondering what is the best CNC machine in the world or simply trying to find the best industrial CNC router for metal, understanding your specific needs is crucial. Investing wisely in a quality machine ensures you maximize productivity and efficiency, ultimately leading to greater profitability.

Choosing the Right CNC Router for You

It's essential to consider not just what is available but also what aligns with your operational goals and project requirements. For instance, if you're looking at what is the most profitable CNC project to sell, having a versatile machine that can handle various materials will give you an edge in today's competitive market.

The Impact of CNC Routers on Production

CNC routers have revolutionized production processes across various industries by enhancing precision and reducing waste. With capabilities that allow for intricate designs and consistent output, these machines significantly improve production timelines compared to traditional methods. As manufacturers increasingly turn towards automation and high-quality results, understanding where are industrial CNC routers made becomes relevant; many top brands are committed to precision engineering that boosts overall productivity.

Future Trends in CNC Technology and Precision

Looking ahead, trends in CNC technology suggest an exciting evolution towards smarter machines equipped with advanced features like AI integration and IoT connectivity. These innovations promise not only improved accuracy but also enhanced maintenance capabilities—addressing concerns about what is the lifespan of a CNC router. As we continue to explore automation's potential impact on manufacturing processes, finding the best industrial CNC router for the money will become even more critical as businesses strive for both quality and cost-effectiveness.