Introduction

CNC Machines have revolutionized the manufacturing world, offering precise and efficient machining capabilities. In this article, we will explore the basics of CNC machines, their benefits, and why they are gaining popularity in various industries. We will also introduce SYIL Machine Tools, a leading manufacturer of precision CNC machines.

Getting Started with CNC Machines

CNC machines, or Computer Numerical Control machines, are revolutionizing the manufacturing industry. These automated machines use computer programs to control their movements and execute precise cutting, milling, and drilling operations. Understanding the basics of CNC machines is crucial for beginners looking to dive into this exciting machining world.

First, CNC machines operate based on a set of instructions called G-code. This code tells the machine to move and position the cutting tool to create the desired shape or design. By understanding G-code and its syntax, beginners can effectively communicate with CNC machines and achieve accurate results.

Several factors must be considered when choosing the right CNC machine for beginners. First and foremost is the size of the machine. Beginners often prefer smaller machines that are more affordable and easier to handle. The type of materials you plan to work with is also essential in selecting a suitable CNC machine.

Safety precautions should never be overlooked when operating CNC machines. Always wear appropriate protective gear, such as safety glasses and gloves, to prevent potential injuries. Familiarizing yourself with emergency stop buttons and other safety features specific to your machine model is crucial.

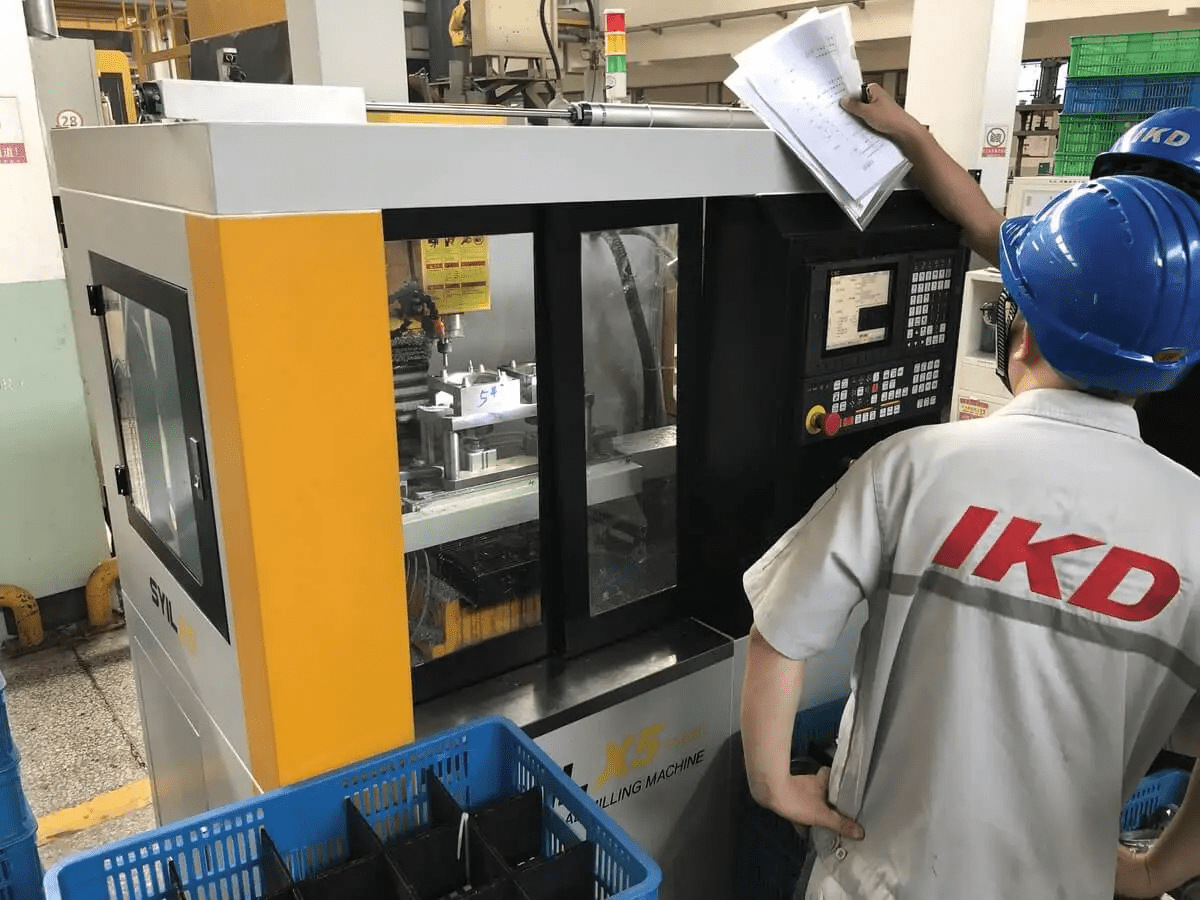

Getting familiar with SYIL CNC Machines can be an excellent choice for beginners in CNC machining. SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

By understanding the basics of CNC machines, choosing the right machine for beginners, diligently following safety precautions, and getting familiar with SYIL's range of reliable CNC machines, newcomers can confidently embark on their CNC machining journey. The next section will explore setting up your CNC machine.

Setting Up Your CNC Machine

1. Assembling the CNC Machine Components

Assembling the components of your CNC machine is like putting together a complex puzzle. Follow the manufacturer's instructions carefully to ensure proper assembly. SYIL Machine Tools provides detailed assembly guides for their machines, making it easier for beginners to get started.

2. Installing the Necessary Software and Drivers

You must install specific software and drivers on your computer to operate a CNC machine. These programs allow you to control and communicate with the machine effectively. SYIL provides user-friendly software compatible with their machines, simplifying the installation process.

2. Calibrating and Configuring Your CNC Machine

Calibrating your CNC machine is crucial for achieving accurate results. You need to calibrate various parameters such as tool offsets, axis movements, and spindle speeds. SYIL machines come with calibration instructions that help streamline this process, ensuring precise machining.

3. Troubleshooting Common Setup Issues

During setup, minor issues that can hinder the smooth operation of your CNC machine are commonly encountered. Some common problems include loose connections, incorrect settings, or software conflicts. SYIL provides troubleshooting resources to help users identify and resolve such issues quickly.

Remember that correctly setting up your CNC machine is essential for optimal performance and safety during operation. Take your time during this stage to ensure everything is in place before moving on to the next steps.

Stay tuned for our next section, where we'll discuss operating a CNC machine and explore advanced techniques in CNC machining.

Operating a CNC Machine

Operating a CNC machine requires a combination of technical knowledge and practical skills. This section will explore the key steps in operating a CNC machine, including loading and securing the material, programming the machine, initiating the cutting process, and monitoring and adjusting the machine for optimal performance.

1. Loading and Securing the Material

Before you can start machining with a CNC machine, loading and securing the material properly is crucial. This ensures stability during the cutting process and prevents accidents or errors. Begin by selecting the appropriate material for your project and ensuring it is clean and free of debris or contaminants.

Next, position your material on the CNC machine's work table, ensuring it aligns with the designated reference point. Use clamps or other securing methods to hold down the material firmly to prevent movement during machining. This step is essential for the accuracy and precision of your final product.

2. Programming Your CNC Machine

Programming is at the heart of operating a CNC machine. It involves creating instructions that tell the machine how to move and cut through your material accurately. To program your CNC machine effectively:

- Use CAD/CAM software: Utilize computer-aided design (CAD) software to create a digital model of your desired part or object. Then, use computer-aided manufacturing (CAM) software to generate toolpaths that guide the cutting tools along specific paths.

- Define tooling parameters: Specify important details such as tool dimensions, cutting speeds, feed rates, depth of cuts, and any other relevant parameters required for precise machining.

- Generate G-code: G-code is a programming language CNC machines use to execute commands. Once you have defined your toolpaths and parameters, the CAM software will generate the G-code necessary for your CNC machine.

Initiating the Cutting Process

After loading and securing the material and programming your CNC machine, it's time to begin cutting. Follow these steps:

- Set up tooling: Install and secure the cutting tools in the machine's spindle. Ensure they are properly aligned and tightened to avoid issues during machining.

- Homing: Before starting, ensure that the machine is properly homed, meaning it has accurately returned to its reference position.

- Tool touch-off: Use a tool touch-off routine to establish accurate Z-axis height reference points for each tool. This step is crucial for consistent and precise cuts.

- Run a test program: Before running your actual program, it is wise to perform a test run on a scrap piece of material to ensure everything is set up correctly and there are no unforeseen issues.

Monitoring and Adjusting the CNC Machine

While the CNC machine is in operation, it's important to monitor its performance closely and make any necessary adjustments as needed. Keep an eye on:

- Cutting conditions: Observe how well the cutting tools are performing and ensure they are not overheating or wearing out prematurely.

- Chip evacuation: Ensure that chips or debris from the cutting process are properly cleared away from the workpiece and cutting tools.

- Feed rates: Monitor feed rates during machining to ensure optimal cutting speeds without compromising quality or causing excessive tool wear.

- Surface finish: Regularly inspect the surface finish of your machined parts to identify any irregularities or defects that may require adjustments.

By actively monitoring and adjusting your CNC machine throughout the operation, you can achieve better results while minimizing errors or potential damage to your equipment and materials.

CNC machines require technical knowledge, practical skills, and attention to detail. By following these guidelines for loading and securing the material, programming the machine, initiating the cutting process, and monitoring and adjusting the machine, you can unlock the full potential of CNC machining.

Advanced Techniques and Tips for CNC Machining

CNC machining offers many possibilities for creating intricate and precise designs. To truly master the art of CNC machining, one must understand different types of tooling, implement advanced cutting strategies, maximize efficiency and accuracy, and take advantage of SYIL Machine Tools' advanced features and upgrades.

Understanding Different Types of Tooling

One crucial aspect of CNC machining is selecting the right tools for the job. Various types of tooling are available, each designed to perform specific tasks with precision.

- End mills are commonly used for milling operations

- Drills are ideal for creating holes

- Ball nose end mills are perfect for contouring and 3D machining

- Chamfer mills help create beveled edges.

Maximizing Efficiency and Accuracy

Efficiency and accuracy are paramount in CNC machining. To maximize efficiency, consider optimizing toolpaths by reducing unnecessary travel distances or using multi-axis machining techniques when applicable. This minimizes production time while maintaining precision.

To ensure accuracy, regularly calibrate your machine's axes to compensate for any deviations or inaccuracies that may occur over time. Additionally, perform routine maintenance tasks such as cleaning and lubricating to keep your CNC machine in optimal condition.

You can streamline your CNC machining processes and achieve exceptional results by focusing on efficiency and accuracy.

SYIL Machine Tools' Advanced Features and Upgrades

SYIL Machine Tools understands the evolving needs of CNC machinists and offers advanced features and upgrades to enhance your machining experience. Their machines have state-of-the-art controllers that provide intuitive user interfaces, making programming and operation a breeze.

SYIL machines also offer high-speed spindles, rigid structures, and advanced cooling systems to ensure optimal performance even during demanding operations. With its commitment to quality and sustainability, SYIL Machine Tools is a trusted brand in the industry.

By utilizing SYIL's advanced features and upgrades, you can unlock the full potential of your CNC machine and achieve remarkable precision in your machining projects.

Troubleshooting Common Issues with CNC Machines

Identifying and Resolving Minor Machine Errors

It's not uncommon to encounter minor errors that can disrupt the machining process when using CNC machines. These errors can include tool breakage, incorrect toolpath, or material misalignment. To identify and resolve these errors, it's essential to have a keen eye for detail and a good understanding of the machine's operation.

- Tool breakage can occur due to excessive cutting forces or improper tool selection. If you notice unusual sounds or vibrations during the machining process, you must stop the machine immediately and inspect the tool for any signs of damage. Replace the broken tool with a new one and ensure you use the appropriate cutting parameters for your material.

- Incorrect toolpath can result in inaccurate cuts or collisions with other machine components. To resolve this issue, carefully review your programming code and double-check that all coordinates and movements are correct. Simulating the program using CNC software before executing it on your machine is also advisable.

- Material misalignment is yet another minor error that can occur during CNC machining. This can happen when clamping or securing the material incorrectly, leading to inaccurate cuts or damage to the workpiece. Always ensure that your material is securely fastened in place before initiating the cutting process.

You can minimize downtime and maximize productivity in your CNC machining operations by staying vigilant and promptly addressing these minor machine errors.

Dealing with Software and Programming Glitches

Software glitches or programming errors can also pose challenges when operating CNC machines. These issues can range from incorrect code syntax to compatibility problems with the machine's control software. To effectively deal with software and programming glitches, it's essential to have a good understanding of CNC programming languages and troubleshooting techniques.

If you encounter code syntax errors, carefully review your program for missing or misplaced commands, incorrect parameter values, or typos. Even a small error can significantly impact the machining process. Correct any identified mistakes and retest your program to ensure it runs smoothly.

Regularly updating your machine's firmware and control software can help prevent potential glitches. Manufacturers often release updates that address known bugs or improve overall performance. Stay informed about these updates and follow the recommended update procedures provided by SYIL Machine Tools.

By proactively addressing software and programming glitches, you can ensure the smooth operation of your CNC machine and achieve accurate results in your machining projects.

SYIL Machine Tools' Customer Support and Troubleshooting Resources

When troubleshooting common issues with CNC machines, it's essential to have access to reliable customer support and troubleshooting resources. SYIL Machine Tools understands this need and provides comprehensive support services to assist users in resolving any challenges they may encounter.

SYIL Machine Tools' customer support team consists of knowledgeable experts who can provide guidance on troubleshooting various issues related to their CNC machines. Whether you need software glitches, mechanical problems, or programming errors, their support team is ready to help.

Leveraging SYIL Machine Tools' customer support and troubleshooting resources can help you overcome common issues with CNC machines more effectively, ensuring smooth and productive machining operations.

Embracing the Exciting World of CNC Machining

CNC machining has revolutionized the manufacturing industry, offering precision, efficiency, and versatility like never before. By embracing this exciting world of CNC machining, you open doors to endless possibilities in creating intricate designs and functional parts. Whether you are a hobbyist or a professional, learning to use CNC machines can unlock a new level of creativity.

Unlocking Your Creativity with CNC Machines

With CNC machines, your imagination is the only limit. From intricate carvings to complex prototypes, these machines allow you to bring your creative ideas to life precisely and accurately. By mastering the basics of machining and understanding different cutting strategies, you can unlock your creativity and explore new dimensions in design and fabrication.

SYIL Machine Tools understands the challenges beginners face when starting their journey in CNC machining. That's why they offer user-friendly machines designed specifically for beginners. With its comprehensive support and maintenance services, SYIL empowers beginners by providing them with the necessary tools and knowledge to succeed in this field.