Introduction

Are you curious about the intersection of technology and craftsmanship? Look no further than knife making with CNC machines! This innovative approach offers a blend of precision engineering and traditional artistry, revolutionizing the way knives are created. Let's dive into the world of CNC machines and their impact on knife making.

Understanding CNC Machines

CNC (Computer Numerical Control) machines are advanced tools that use computerized controls to operate and manipulate cutting tools. These machines offer unparalleled accuracy and consistency, making them ideal for intricate tasks like knife making.

Benefits of Using CNC Machines for Knife Making

The benefits of using CNC machines for knife making are numerous. From precise cutting to efficient production, these machines streamline the manufacturing process while maintaining exceptional quality.

Exploring the Feasibility of Making Knives with CNC Machines

With the rise of technology in manufacturing, it's natural to wonder about the feasibility of using CNC machines for crafting knives. Let's explore how these machines have transformed traditional knife making methods and opened up new possibilities in the industry.

The Basics of Knife Making with CNC

When it comes to knife making with CNC, choosing the right machine is crucial. Look for a CNC machine that offers precision cutting, durable construction, and user-friendly software for designing knife blades. With the right CNC machine, you can streamline your knife making process and produce high-quality blades with ease.

Choosing the Right CNC Machine for Knife Making

When considering a CNC machine for knife making, prioritize features like high spindle speed, rigid construction, and a robust control system. Look for a machine that offers compatibility with various materials used in knife making such as steel, titanium, and Damascus steel. A versatile CNC machine will allow you to explore different blade designs and materials without limitations. Additionally, consider the availability of software that is specifically designed for creating intricate knife blade designs. This will give you the flexibility to experiment with unique patterns and shapes, adding a personalized touch to your knife making process.

Designing Knife Blades with CNC Software

CNC software plays a crucial role in designing intricate and customized knife blades. Look for software that offers 3D modeling capabilities, precise measurement tools, and the ability to generate toolpaths for accurate cutting. With the right software, you can bring your unique knife designs to life and create one-of-a-kind blades that cater to specific customer preferences.

In addition to 3D modeling capabilities and precise measurement tools, the right CNC software should also offer a user-friendly interface that allows for easy manipulation of designs. This will enable you to make quick adjustments and refinements to your knife blade designs, ensuring that they meet your exact specifications. With intuitive software at your disposal, you can streamline the design process and bring your creative ideas to fruition with ease.

Precision Cutting with CNC Knife Cutter

The precision cutting capabilities of a CNC knife cutter are unmatched when it comes to producing consistent and high-quality knife blades. With advanced cutting technology and automated processes, you can achieve razor-sharp edges, intricate patterns, and complex geometries on your knives. This level of precision ensures that each blade meets the highest standards of craftsmanship. Furthermore, the CNC knife cutter allows for customization, enabling you to create unique and personalized designs for your knives. Whether it's a signature pattern or a specialized shape, the CNC knife cutter can bring your vision to life with impeccable accuracy.

The Profitability of Knife Making Business

When it comes to the profitability of knife making business, the answer is a resounding yes! With the rise in demand for customized CNC knife blades, there is a lucrative market waiting to be tapped into. The unique and precise designs that can be achieved with CNC technology make it possible to cater to niche markets and individual preferences, making the business highly profitable.

Is Knife Business Profitable?

The knife business is indeed profitable, especially when utilizing CNC technology for precision cutting and customization. With the ability to create unique designs and cater to specific customer needs, the market for CNC knife blades has been steadily growing. This presents a great opportunity for entrepreneurs looking to enter the industry and capitalize on this profitability.

Market Demand for Customized CNC Knife Blades

The market demand for customized CNC knife blades has been on the rise, driven by consumers seeking unique and personalized products. Whether it's custom engravings, specialized blade shapes, or intricate designs, there is a growing appetite for knives that are tailored to individual preferences. This trend presents a promising opportunity for businesses utilizing CNC technology in their knife making processes.

Exploring the Potential ROI of Knife Making Machines

When exploring the potential return on investment (ROI) of knife making machines, it's important to consider the growing demand for customized CNC knife blades. With advancements in technology and an increasing consumer interest in personalized products, businesses can expect a favorable ROI from their investment in CNC machines for knife making. The ability to cater to niche markets and deliver high-quality, customized products positions these machines as valuable assets with great potential returns.

Stay tuned as we explore more about cost considerations and advantages of using SYIL CNC machines for knife making in our upcoming sections!

Cost Considerations for CNC Knife Making

Is CNC Cutting Expensive?

When it comes to knife making, using a CNC machine for cutting can be cost-effective in the long run. While the initial investment may seem high, the precision and efficiency of CNC cutting can save money on material waste and labor costs over time.

Is it Cheaper to Build Your Own CNC?

Building your own CNC machine for knife making may seem like a budget-friendly option, but it requires technical expertise and significant time investment. Purchasing a pre-built CNC machine ensures reliability and support, which can be more cost-effective in the long term.

Cost Comparison: DIY vs Buying a CNC Machine

When comparing the costs of building your own CNC machine versus buying one, consider factors such as material quality, precision, and ongoing maintenance. While building your own may seem cheaper upfront, purchasing a high-quality pre-built CNC machine can offer better long-term value for knife making.

Advantages of Using SYIL CNC Machine for Knife Making

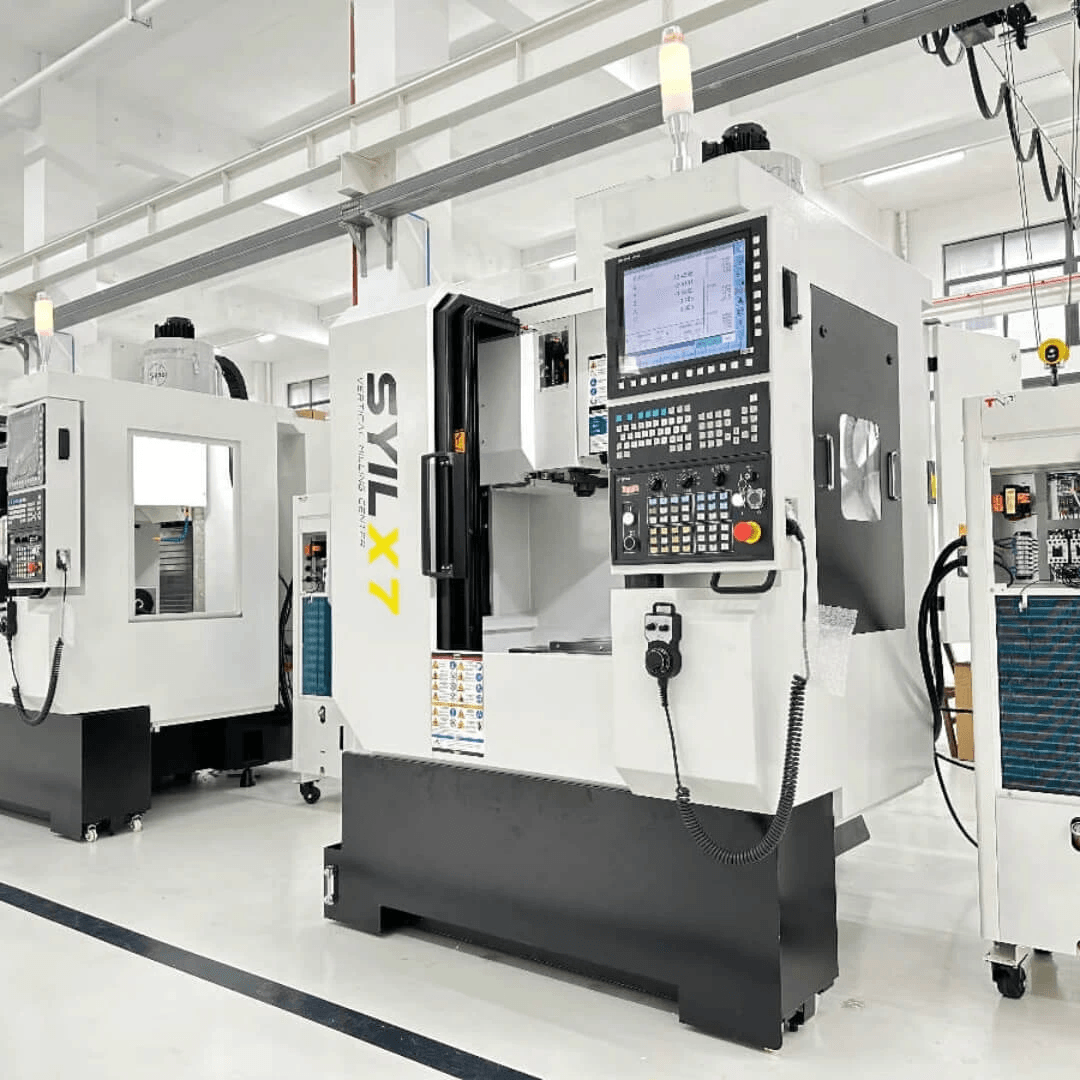

SYIL CNC Machine Features for Precision Knife Cutting

When it comes to precision knife cutting, the SYIL CNC machine offers unparalleled accuracy and consistency. With its advanced technology and high-quality materials, the SYIL CNC machine ensures that every knife blade is cut with utmost precision, resulting in a flawless end product that meets the highest standards of quality.

The SYIL CNC machine is equipped with state-of-the-art software that allows for precise programming and control of the cutting process. This ensures that each knife blade is cut to exact specifications, resulting in consistency across all products. The advanced technology also allows for intricate designs and complex shapes to be cut with ease, giving manufacturers the flexibility to create unique and innovative knife blades.

Customer Success Stories with SYIL CNC Knife Blades

Customers who have used SYIL CNC machines for knife making have reported remarkable success in their businesses. The precision and efficiency of the machines have allowed them to produce high-quality custom knife blades that cater to the growing demand in the market. These success stories are a testament to the reliability and effectiveness of SYIL CNC machines in the knife making industry.

Why Choose SYIL for Knife Making Machines

When it comes to choosing a CNC machine for knife making, SYIL stands out as a top choice due to its reputation for excellence and innovation. The company's commitment to providing state-of-the-art machinery combined with exceptional customer support makes it an ideal partner for anyone looking to venture into the profitable world of knife making with CNC technology.

Furthermore, SYIL's CNC machines are known for their precision and reliability, ensuring that each knife produced is of the highest quality. With advanced features and cutting-edge technology, SYIL's machines offer the flexibility to create intricate designs and patterns, giving knife makers the freedom to unleash their creativity. This level of precision and versatility sets SYIL apart from other manufacturers in the industry, making it the go-to choice for those who demand nothing but the best for their knife making endeavors.

Conclusion

Tips for Starting Your CNC Knife Making Business

If you're considering venturing into the knife making business with CNC machines, start by researching the market demand for custom knife blades and identifying your target audience. Invest in a high-quality CNC machine suitable for precision cutting and design, and consider offering customization options to attract more customers.

Once you have established your target audience and invested in the right CNC machine, it's time to focus on the design aspect of your custom knife blades. Consider hiring a skilled designer or learning design software yourself to create unique and attractive blade designs that will set your knives apart from the competition. Remember, a well-crafted and visually appealing design can make a significant impact on the success of your CNC knife making business.

Exploring the Future of CNC Knife Making

As technology continues to advance, the future of knife making with CNC machines looks promising. With the ability to create intricate designs and precise cuts, CNC technology opens up a world of possibilities for innovative knife designs and customization options. Keep an eye on emerging trends in the industry to stay ahead of the competition.

Embracing Innovation in Knife Making with CNC Technology

Embracing innovation is crucial for success in the knife making business, and CNC technology offers endless opportunities for creativity and efficiency. By utilizing advanced CNC software and machinery, you can streamline production processes, reduce waste, and create unique, high-quality knife blades that cater to diverse customer preferences.

Furthermore, CNC technology allows for precise customization of knife designs, enabling you to meet the unique needs of individual customers. This level of personalization can set your knife making business apart from competitors and attract a loyal customer base. With the ability to quickly adjust designs and production processes, you can stay ahead of trends and adapt to changing market demands, ensuring continued success in the industry.