Introduction

Are you ready to take your knife making skills to the next level? CNC knife milling is a game-changer in the industry, offering precision and efficiency like never before. Whether you're a beginner or an experienced knife maker, understanding the ins and outs of CNC knife milling is essential for creating top-quality knives.

Understanding CNC Knife Milling

CNC knife milling involves using computer-controlled machines to precisely cut and shape materials into custom knives. This technology allows for intricate designs and consistent results that are difficult to achieve with traditional methods. With the right knowledge and equipment, you can create professional-grade knives with ease. When choosing the right CNC machine for knife milling, it's essential to consider factors such as the machine's precision, cutting speed, and compatibility with different materials. Additionally, looking for a machine with user-friendly software and good technical support can make the milling process smoother and more efficient.

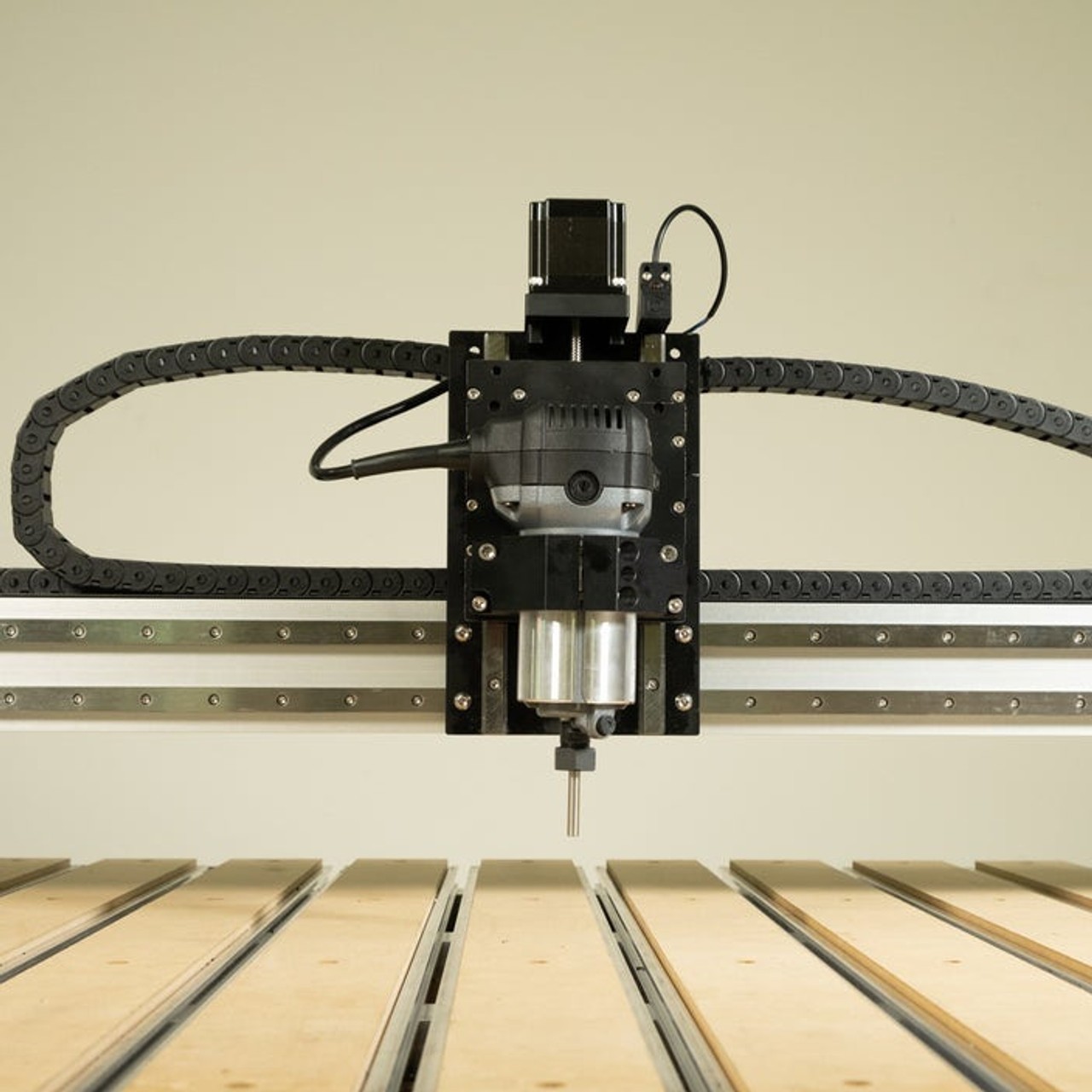

Choosing the Right CNC Machine

Selecting the right CNC machine for your knife making endeavors is crucial. Consider factors such as cutting speed, accuracy, and versatility when choosing a machine that meets your specific needs. Look for features such as high-quality spindles, rigid construction, and user-friendly controls to ensure optimal performance.

When selecting the right CNC machine for knife making, it's important to also consider the available tooling options. Look for a machine that offers a variety of tool holders and cutting tools to ensure you have the flexibility to create different types of knives. Additionally, consider the availability of software and programming options that will allow you to easily design and customize your knife patterns. Having the right tools and software can make a significant difference in the quality and precision of your knife making process.

Essential Tools for CNC Knife Making

In addition to a quality CNC machine, there are essential tools that every knife maker should have in their arsenal. From precision measuring instruments to durable cutting tools, having the right equipment on hand will streamline your knife making process and help you achieve professional results. One essential tool is a high-quality grinder, which allows you to shape and sharpen the blade with precision. Additionally, a sturdy workbench with clamps is crucial for securing your materials while you work, providing stability and accuracy. Investing in a reliable dust collection system will also keep your workspace clean and safe, ensuring that your equipment runs smoothly and lasts longer.

Getting Started with CNC Knife Milling

When it comes to getting started with CNC knife milling, it's important to master the basic techniques. Understanding how to set up your machine, input the correct measurements, and execute precise cuts is crucial for successful knife making. With the right knowledge and practice, you'll be well on your way to creating professional-grade CNC knives.

Basic Techniques for CNC Knife Milling

To begin with, familiarize yourself with the different cutting techniques such as profiling, pocketing, and drilling. These are essential for shaping and forming the blade and handle of your knife. Additionally, learning how to program tool paths and adjust cutting speeds will help you achieve the desired results. With these fundamental skills in place, you'll be able to craft high-quality CNC knives.

Once you have mastered the basic cutting techniques and programming skills, the next step is to select the right materials for your CNC knife making. Choosing high-quality steel for the blade and durable materials for the handle will ensure that your knives are not only aesthetically pleasing but also functional and long-lasting. It's important to consider factors such as hardness, corrosion resistance, and toughness when selecting materials to ensure that your CNC knives meet industry standards and customer expectations.

Selecting the Right Materials for CNC Knife Making

Choosing the right materials is key to producing durable and functional knives. Look for high-quality steel or titanium that can withstand wear and tear while maintaining sharpness. It's also important to consider handle materials such as wood or composite materials that offer both aesthetic appeal and durability. By carefully selecting your materials, you can ensure that your CNC knives are built to last.

When considering the right materials for CNC knife making, it's essential to also think about the design and functionality of the knife. Different materials can offer unique benefits, such as weight distribution, grip comfort, and overall balance. For example, a titanium handle may offer lightweight durability, while a wood handle can provide a classic aesthetic with natural grip properties. By carefully evaluating the intended use and design of your knives, you can select materials that not only enhance the overall quality but also elevate the user experience.

Understanding the SYIL CNC Machine

The SYIL CNC machine is a powerful tool for knife making enthusiasts, offering precision cutting capabilities and a user-friendly interface. With automatic tool changers and high-speed spindles, this versatile machine is ideal for crafting custom knives with intricate designs and complex cuts. In addition to its advanced control systems, the SYIL CNC machine also provides the flexibility to work with a variety of materials, allowing knife makers to explore different creative possibilities and push the boundaries of their craft.

Precision Cutting with CNC Knives

Tips for Achieving Precision Cuts

When it comes to achieving precision cuts with CNC knives, it's important to start with high-quality materials and a well-calibrated machine. Take the time to carefully program your design and double-check all measurements before starting the cutting process. Additionally, using sharp cutting tools and maintaining proper feed rates will help ensure clean and accurate cuts every time.

Maximizing Efficiency with CNC Knife Milling

To maximize efficiency with CNC knife milling, consider using nesting software to optimize material usage and reduce waste. Additionally, utilizing multi-tool capabilities can help streamline the cutting process by allowing for multiple operations within a single setup. By carefully planning your toolpaths and minimizing unnecessary movements, you can significantly improve production efficiency without sacrificing quality.

SYIL CNC Machine Features for Precision Cutting

The SYIL CNC machine offers a range of features specifically designed to enhance precision cutting for knife making. With its high-speed spindle and rigid construction, the machine provides exceptional stability and accuracy during the cutting process. Furthermore, its advanced control system allows for seamless integration of CAD/CAM software, ensuring precise execution of even the most intricate designs.

Now that we've covered some essential tips for achieving precision cuts and maximizing efficiency with CNC knife milling, let's take a closer look at the specific features of the SYIL CNC machine that make it ideal for precision cutting in knife making.

Finishing Touches for CNC Knife Making

When it comes to adding detail to your CNC knife designs, precision is key. Utilize the advanced features of your SYIL CNC machine to create intricate patterns and engravings on the blade and handle. Experiment with different design elements to make your knives stand out in a competitive market.

Adding Detail to Your CNC Knife Designs

Incorporate unique textures and patterns into your knife designs using the versatile capabilities of your CNC machine. From intricate scrollwork to personalized initials, the possibilities are endless. With the right tools and techniques, you can elevate your CNC knives from functional tools to works of art that customers will cherish.

With the right tools and techniques, you can take your CNC knife designs to the next level by experimenting with different finishing techniques. Consider adding a distressed or weathered look to your knives for a rustic appeal, or opt for a high-gloss finish for a more modern and sleek aesthetic. These finishing touches can truly enhance the overall appearance of your knives and make them stand out in the market.

Finishing Techniques for Professional Results

After milling, it's essential to refine the edges and surfaces of your CNC knives for a professional finish. Utilize sanding and polishing techniques to achieve a smooth, flawless appearance that enhances both the aesthetic appeal and functionality of your knives. Attention to detail in this stage can truly set your knives apart from others on the market.

Once you have achieved a smooth finish on your CNC knives, consider adding unique details to make them stand out. Custom engravings, etchings, or decorative patterns can add a touch of personality and individuality to your knives. These small details can make a big impact on the overall appearance and desirability of your products, setting them apart from mass-produced alternatives. By taking the time to add these special touches, you can create a truly one-of-a-kind product that will appeal to discerning customers.

SYIL CNC Machine Capabilities for Fine Detail Work

The SYIL CNC machine offers exceptional precision and control, making it ideal for fine detail work on knife designs. Its advanced cutting capabilities allow you to achieve intricate patterns and engravings with ease, while its user-friendly interface makes it accessible for beginners as well as experienced craftsmen.

The versatility of the SYIL CNC machine extends beyond just fine detail work on knife designs. With its advanced capabilities, it can also be used for precision cutting and shaping of a wide range of materials, from wood to metal. This makes it a valuable tool for craftsmen looking to expand their creative possibilities and take their designs to the next level. Additionally, the machine's intuitive interface allows for easy customization and adjustment, giving users full control over the intricacy and complexity of their projects.

Now that we've covered adding fine details to your knife designs through advanced techniques with a SYIL CNC machine, let's move on to maintenance and safety tips for efficient operation.

Maintenance and Safety Tips for CNC Knife Milling

Proper Maintenance of CNC Knife Making Equipment

When it comes to maintaining your CNC knife making equipment, regular cleaning and lubrication are key. Keep the machine free of debris and apply oil to the moving parts to ensure smooth operation. Check for any signs of wear and tear on the blades and replace them as needed to maintain precision cutting.

Safety Precautions for CNC Knife Milling

Safety should always be a top priority when working with CNC knives. Always wear protective gear such as gloves and safety goggles to prevent any accidents. Keep your work area well-ventilated, especially when using materials that produce fumes or dust. Additionally, be sure to follow proper handling procedures when changing blades or performing maintenance on the machine.

SYIL CNC Machine Safety Features

The SYIL CNC machine is equipped with a range of safety features to protect users during knife milling operations. From emergency stop buttons to protective enclosures, these features are designed to minimize the risk of accidents and ensure a safe working environment. Familiarize yourself with these safety features and make use of them to safeguard yourself while using the machine.

By following these maintenance and safety tips for CNC knife milling, you can ensure that your equipment remains in optimal condition while keeping yourself protected from potential hazards in the workshop.

Advancing Your Skills in CNC Knife Making

As you progress in CNC knife making, it's essential to explore advanced techniques for CNC knife milling. Experiment with intricate designs, complex patterns, and unique finishes to elevate your creations. Utilize specialized knife making tools for beginners to enhance your skills and create one-of-a-kind pieces that showcase your expertise.

Advanced Techniques for CNC Knife Milling

Advanced techniques for CNC knife milling involve mastering the art of intricate detailing, such as etching, engraving, and sculpting. Experiment with different blade shapes and handle designs to push the boundaries of traditional knife making. Incorporate advanced finishing methods like acid etching or Damascus steel forging to add depth and character to your creations.

Expanding Your CNC Knife Making Equipment

Expand your CNC knife making equipment by investing in precision measurement tools, specialized grinding machines, and high-quality steel blanks for creating custom blades. Consider adding a laser engraving machine to personalize your knives with logos or custom designs. Explore different handle materials such as exotic woods or carbon fiber for a unique touch.

SYIL CNC Machine Upgrades for Advanced Users

SYIL offers a range of machine upgrades tailored for advanced users in the field of CNC knife making. Upgrade to a higher horsepower spindle for increased cutting power and precision. Invest in a rotary axis attachment to create complex 3D designs on your knives with ease. Enhance your machine's capabilities with advanced software features that streamline the design process and improve efficiency.

Remember that advancing your skills in CNC knife making is an ongoing journey that requires dedication, creativity, and a willingness to push boundaries. By exploring advanced techniques, expanding your equipment, and utilizing SYIL's machine upgrades, you can take your craft to new heights and produce exceptional knives that stand out in the market.

Conclusion

Mastering CNC Knife Milling

After mastering the basic techniques and precision cutting, you will be well on your way to becoming a CNC knife making pro. With the right materials, tools, and equipment, you can create stunning knives that stand out from the rest. Keep honing your skills and experimenting with new designs to truly master the art of CNC knife milling.

Achieving Professional Results with SYIL CNC Machine

The SYIL CNC machine is a game-changer when it comes to achieving professional results in knife making. Its precision cutting capabilities and fine detail work features make it an essential tool for any serious knife maker. With this machine at your disposal, you can take your creations to the next level and produce high-quality knives that will impress even the most discerning customers.

Taking Your CNC Knife Making Skills to the Next Level

As you continue to advance in CNC knife making, consider expanding your equipment and upgrading your SYIL CNC machine for more advanced features. Explore new techniques, experiment with different materials, and push the boundaries of what is possible with CNC knife milling. With dedication and practice, you can take your skills to new heights and become a true master of the craft.