Introduction

Are you a budding entrepreneur looking for a lucrative business opportunity? Look no further than the knife making industry! With the rising demand for unique, handmade knives, this business has proven to be highly profitable for many artisans. From small-scale start-ups to globally recognized brands, famous knife makers have shown that success can stem from humble beginnings. To kickstart your journey into this exciting venture, it's crucial to understand the essential equipment needed for knife making.

The Profitability of Knife Making Business

The question on everyone's mind is, Is knife business profitable? The answer is a resounding yes! With the right skills and marketing strategy, you can make a substantial income from selling homemade knives. Whether you're a seasoned craftsman or just starting out, there's ample opportunity to turn your passion into a thriving business.

Famous Knife Makers Who Started Small

Curious about the potential success in this industry? Look no further than renowned names like Bob Kramer and Ken Onion who began their careers as small-scale knife makers. These trailblazers have not only achieved global recognition but have also inspired countless aspiring artisans to pursue their dreams in the world of knife making.

Essential Equipment for Knife Making

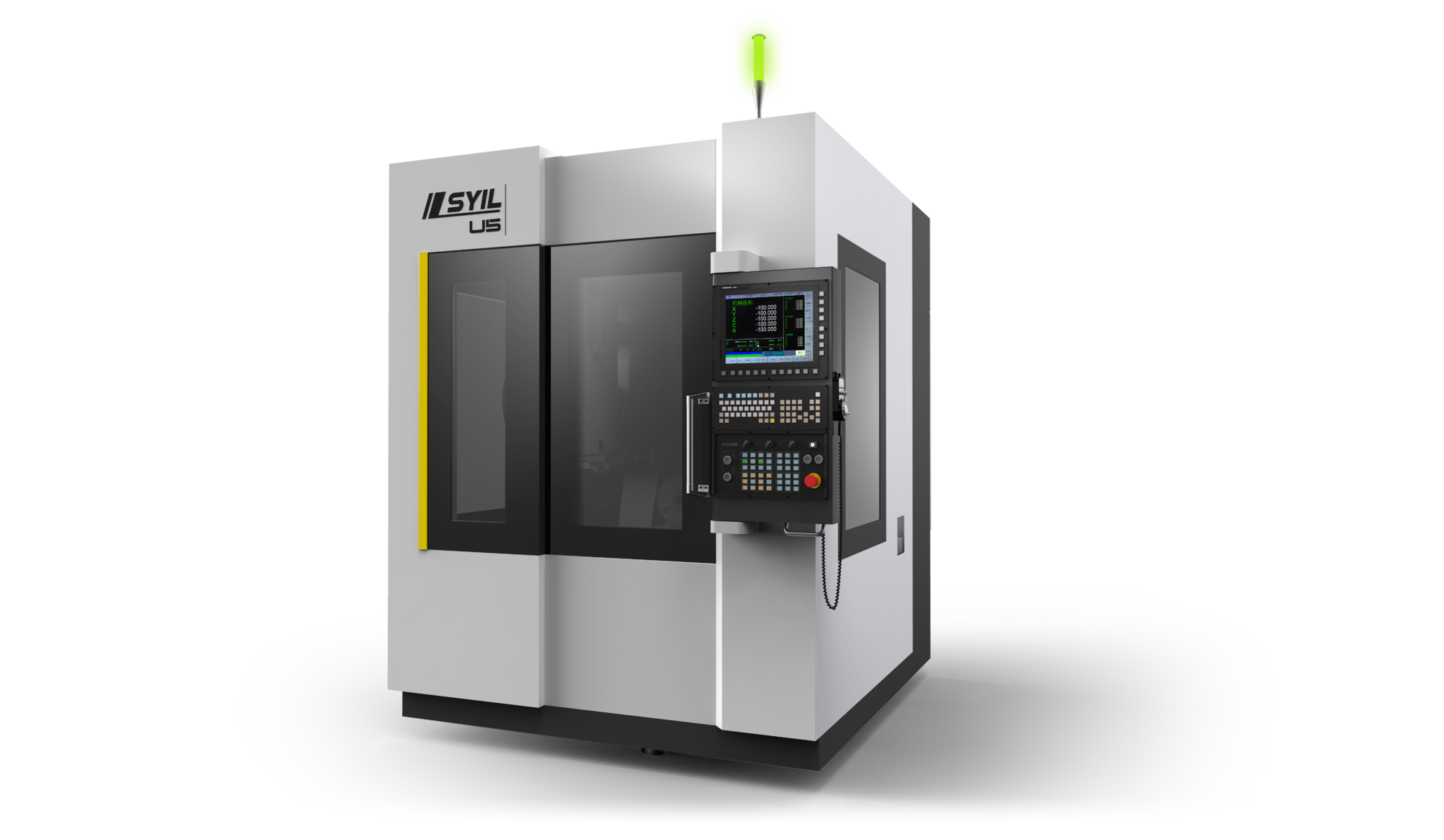

To embark on your journey as a successful knife maker, you'll need top-notch equipment such as quality steel for blades and precision tools and accessories. One game-changing addition to your arsenal is the SYIL CNC Machine - an innovative technology that revolutionizes the traditional approach to crafting knives.

Now that we've covered the basics of getting started with knife making, let's delve deeper into maximizing profit and understanding advanced technology like CNC knife cutters and blades in subsequent sections. So grab your apron and sharpen those creative skills because we're about to embark on an exciting journey into the world of knife making!

Getting Started with Knife Making

When it comes to getting started with knife making, having the right equipment is crucial. SYIL Machines For Knifemaking are a game-changer in this regard, offering precision and efficiency in creating high-quality knives. Investing in a reliable CNC machine can significantly streamline the production process and elevate the overall quality of your products.

SYIL CNC Machine: A Game Changer

SYIL Machines For Knifemaking offer a range of options for knife makers, from entry-level models to advanced systems that cater to professional craftsmen. These CNC machines provide unparalleled accuracy and speed, allowing you to create intricate designs with ease. With SYIL's user-friendly interface and robust build, you can elevate your knife-making business to new heights.

Quality Steel for Knife Blades

The quality of steel used in knife blades is paramount to the success of your craft. Investing in high-grade steel ensures that your knives are durable and long-lasting, which is essential for customer satisfaction and repeat business. When sourcing steel for your blades, prioritize factors such as hardness, toughness, corrosion resistance, and edge retention.

Knife Making Tools and Accessories

In addition to a reliable CNC machine and quality steel, having the right tools and accessories is essential for efficient knife making. From grinders and sanders to heat-treating furnaces and handle materials, equipping yourself with the necessary tools will streamline your production process and enhance the overall quality of your handmade knives.

Maximizing Profit in Knife Making Business

Finding the Right Market for Homemade Knives

One of the keys to maximizing profit in the knife making business is finding the right market for your homemade knives. Whether it's outdoor enthusiasts, chefs, or collectors, understanding your target audience will help you tailor your designs and marketing strategies to meet their specific needs and preferences. By identifying and targeting the right market, you can increase demand for your products and ultimately boost your sales.

Innovative Designs for Unique Knives

In a competitive market, standing out with innovative designs is essential for maximizing profit in knife making. Think outside the box and explore unique materials, handle designs, and blade shapes that set your knives apart from mass-produced alternatives. By offering something different and appealing to customers' desire for uniqueness, you can create a niche for yourself in the market and command higher prices for your one-of-a-kind creations.

Pricing Strategies for Handmade Knives

When it comes to pricing handmade knives, it's important to consider factors such as material costs, labor, overhead expenses, and desired profit margins. Researching similar products in the market can help you gauge appropriate price points while ensuring that you remain competitive. Additionally, offering tiered pricing options or limited edition runs can create a sense of exclusivity and justify premium pricing for your high-quality handmade knives.

By focusing on finding the right market, creating innovative designs, and implementing effective pricing strategies, you can maximize profits in the knife making business while establishing yourself as a reputable artisan in the industry.

Understanding the CNC Knife Cutter

When it comes to understanding the CNC knife cutter, it's important to recognize the many benefits of using this cutting-edge technology. With precision and accuracy, the CNC machine ensures that each knife blade is crafted to perfection, resulting in a high-quality product that customers will love. Additionally, the CNC technology allows for increased productivity and reduced waste, making it a cost-effective solution for your knife making business.

Benefits of Using CNC Technology

The benefits of using CNC technology for knife making are truly game-changing. Not only does it streamline the production process, but it also offers unmatched precision and consistency in crafting knife blades. This means that you can create high-quality knives with intricate designs and details that would be nearly impossible to achieve with traditional methods. By investing in SYIL Machines For Knifemaking, you'll be taking your business to the next level.

Production Efficiency with CNC Knife Blades

With a CNC machine, the production efficiency of creating knife blades is significantly increased. The automation and accuracy of the machine allow for faster turnaround times without sacrificing quality. This means that you can meet customer demands more effectively while maintaining a high standard for your products. As a result, you'll be able to maximize your output and profits in your knife making business.

Customization Options with CNC Machine

One of the most exciting aspects of using a CNC machine for knife making is the endless customization options it provides. Whether you want to create unique designs or personalized engravings on your knives, the CNC technology makes it all possible. This level of customization allows you to cater to specific market demands and stand out from competitors by offering one-of-a-kind products that customers can't resist.

By leveraging the benefits of using a CNC knife cutter in your business operations, you'll be able to produce high-quality knives with exceptional efficiency and customization options that set you apart from others in the market.

Monetizing Your Knife Making Skills

Diversifying Product Range for Increased Sales

To maximize your earnings as a knife maker, consider diversifying your product range to attract a wider customer base. In addition to traditional knives, you can offer custom kitchen knives, hunting knives, and even decorative knives. By catering to different needs and preferences, you can significantly boost your sales and profits.

To maximize your earnings as a knife maker, consider diversifying your product range to attract a wider customer base. In addition to traditional knives, you can offer custom kitchen knives, hunting knives, and even decorative knives. By catering to different needs and preferences, you can significantly boost your sales and profits.

Building a Strong Online Presence

In today's digital age, having a strong online presence is crucial for any business. Create a professional website to showcase your handmade knives and share the story behind each piece. Utilize e-commerce platforms to reach a global audience and make it easy for customers to purchase your products online.

In addition to a professional website, consider leveraging social media platforms to market your handmade knives. Use platforms like Instagram and Pinterest to visually showcase your products and engage with potential customers. Share behind-the-scenes content, customer testimonials, and product features to build a loyal following and drive sales.

Leveraging Social Media for Marketing

Social media platforms like Instagram, Facebook, and Pinterest are powerful tools for promoting your knife making business. Share high-quality images of your creations, engage with followers through behind-the-scenes content, and collaborate with influencers in the industry. By leveraging social media effectively, you can increase brand awareness and drive sales.

Now that we've covered how to monetize your knife making skills through diversification, online presence building, and social media marketing let's move on to understanding the CNC knife cutter technology in the next section.

Conclusion

As you scale your knife making business, consider investing in top-notch equipment like SYIL Machines for Knifemaking to streamline production and maximize profits. Take heed of tips from successful knife makers who have turned their passion into a lucrative venture. With the right tools and knowledge, you can capitalize on the profitability of the knife making business.

Scaling Your Knife Making Business

Scaling your knife making business requires strategic investments in quality equipment like CNC knife cutters and blades. Explore options for knife making equipment for sale to upgrade your production capabilities and meet growing demand. With the right tools in place, you can expand your product range and reach new markets, driving revenue growth.

Tips from Successful Knife Makers

Successful knife makers emphasize the importance of craftsmanship, innovation, and market research. To thrive in this industry, focus on creating unique designs that cater to specific customer needs while staying true to your brand identity. Additionally, leverage social media platforms for marketing to showcase your work and connect with potential buyers.

SYIL Machines For Knifemaking

SYIL Machines for Knifemaking offer precision engineering and advanced technology to elevate your craft. These cutting-edge machines enable efficient production of high-quality knives, giving you a competitive edge in the market. By incorporating SYIL CNC technology into your operations, you can enhance customization options and deliver exceptional products that command premium prices.

By embracing innovation and honing your skills as a knife maker, you can carve out a profitable niche in this industry while delighting customers with exceptional handmade knives that stand out in the market.