Introduction

The CNC machine operator profession is an integral part of modern manufacturing, crucial in ensuring precision and efficiency in the production process. With the increasing reliance on CNC machines, there is a growing demand for skilled operators who can operate and maintain these advanced tools effectively.

In this article, we will explore the salary trends for CNC machine operators and discuss the factors that influence variations in their pay scale. We will also delve into the job outlook for CNC machine operators in 2023, considering the effects of automation and advancements in CNC technology on job opportunities and requirements.

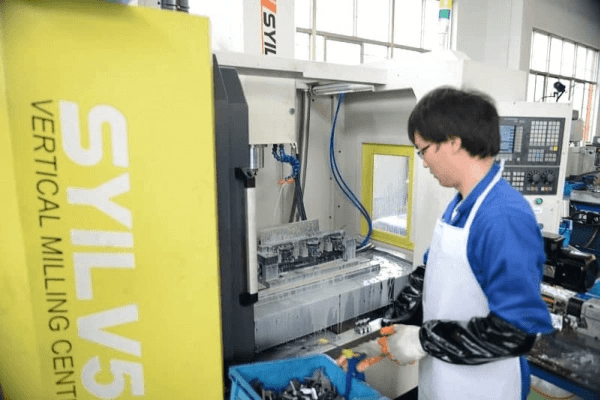

Before we dive into these topics, let's take a moment to introduce SYIL Machine Tools and their range of CNC machines. SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability.

Salary Trends for CNC Machine Operators

CNC machine operators are crucial in manufacturing and operating computer-controlled machines to produce precision parts. As the demand for CNC machines continues to grow, so does the need for skilled operators who can effectively operate and maintain these machines.

Current Average Salary For CNC Machine Operators

One of the most common questions aspiring CNC machine operators have is, How much does a CNC machine operator make? The current average salary for CNC machine operators varies depending on factors such as experience, location, and industry.

According to recent data, the average salary for CNC machine operators ranges from $35,000 to $60,000 per year. However, it's important to note that entry-level positions may offer lower salaries initially but can increase with experience and additional skills.

Factors Influencing Salary Variations

Several factors can influence the salary variations among CNC machine operators. One of the primary factors is experience. As an operator gains more experience and expertise in operating different types of CNC machines, their value in the job market increases, leading to higher salaries.

Location also plays a significant role in determining salaries. Areas with high manufacturing demand or industries relying heavily on CNC machines tend to offer higher wages due to increased competition for skilled operators.

The type of industry also impacts salary variations. Industries such as aerospace and automotive often require highly specialized skills from their CNC machine operators, leading to higher pay scales than other industries.

Projected Salary Growth For CNC Machine Operators

The future looks promising for individuals pursuing a career as a CNC machine operator. With advancements in technology and an increasing demand for precision manufacturing, salaries for these professionals are projected to continue to grow.

By 2023, it is estimated that the average salary range for experienced CNC machine operators will be between $45,000 and $75,000 per year. This projected growth is driven by the need for skilled operators who can adapt to evolving technologies and contribute to the efficiency of manufacturing processes.

Benefits And Perks Offered By Employers

In addition to competitive salaries, CNC machine operators enjoy various benefits and perks their employers offer. These benefits may include health insurance, retirement plans, paid time off, and opportunities for career advancement.

Employers recognize the importance of attracting and retaining skilled CNC machine operators, so they strive to provide attractive benefits. These benefits enhance job satisfaction and contribute to the overall well-being of operators and their families.

Job Outlook for CNC Machine Operators in 2023

Increased Automation And Its Effects On Job Opportunities

With rapid technological advancements, automation has become a key factor in the manufacturing industry. This has led to concerns about job opportunities for CNC machine operators. However, automation has created new opportunities for skilled operators rather than eliminating jobs. While certain tasks may be automated, human intervention and expertise are still crucial to ensure smooth operations and maintain quality control.

Advancements In CNC Technology And Its Impact On Job Requirements

The continuous advancements in CNC technology have significantly impacted the job requirements for CNC machine operators. Today, operators are expected to possess a broader skill set that includes operating machines and programming and troubleshooting them. The ability to interpret technical drawings, perform precision measurements, and understand complex machining processes is essential in this evolving field.

Skills And Qualifications In Demand For CNC Machine Operators

To thrive in the competitive job market of CNC machine operation, some certain skills and qualifications are highly sought after by employers. These include proficiency in CAD/CAM software, knowledge of different machining techniques, strong problem-solving abilities, attention to detail, and excellent communication skills. Additionally, certifications from reputable training programs demonstrate a commitment to professional development and enhance employability.

Opportunities For Career Advancement And Specialization

The field of CNC machine operating offers numerous opportunities for career advancement and specialization. As operators gain experience and expand their skill set, they can progress into supervisory roles or transition into related fields such as engineering or quality control. Specializing in specific industries or types of machines can also open up new avenues for growth.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC machines are designed to meet the demands of the evolving industry and provide operators with the tools they need to excel in their careers.

Training and Education for CNC Machine Operators

CNC machine operators play a crucial role in modern manufacturing, ensuring the efficient operation of computer numerical control (CNC) machines. Formal training and certifications are essential to excel in this profession.

Importance Of Formal Training And Certifications

Formal training programs provide aspiring CNC machine operators with the knowledge and skills to operate these complex machines effectively. These programs cover blueprint reading, machine setup, programming, tooling, and quality control.

Certifications validate the competency of CNC machine operators and enhance their employability. Industry-recognized certifications, such as those offered by the National Institute for Metalworking Skills (NIMS), demonstrate proficiency in specific areas like CNC milling or turning.

SYIL Machine Tools' Commitment To Providing Training Resources

SYIL Machine Tools recognizes the importance of proper training for CNC machine operators. They offer comprehensive training resources to support their customers throughout their career journey.

From online tutorials to hands-on workshops, SYIL provides a range of educational materials designed to enhance operators' knowledge and skills. Their commitment to continuous learning ensures that operators stay updated with industry trends and advancements in CNC technology.

Skills And Knowledge Acquired Through Training Programs

Training programs equip CNC machine operators with diverse skills necessary for success in their profession. These include proficiency in reading technical drawings, understanding geometric dimensions and tolerances, operating various types of CNC machines, performing routine maintenance tasks, troubleshooting issues that may arise during operations, and ensuring quality control standards are met.

Additionally, operators gain valuable knowledge about machining techniques, tool selection strategies, programming languages like G-code or M-code, and efficient production planning methods.

Continuous Learning And Staying Updated With Industry Trends

In the rapidly evolving field of manufacturing technology, continuous learning is vital for CNC machine operators to remain competitive. Staying updated with industry trends allows them to adapt quickly to new technologies and techniques, improving their efficiency and productivity.

Attending trade shows, participating in workshops or seminars, and engaging with online forums are excellent ways for CNC machine operators to stay informed about the latest advancements. SYIL Machine Tools actively encourages operators to embrace lifelong learning, providing access to resources that facilitate their professional growth.

As CNC machines continue to revolutionize the manufacturing industry, the demand for skilled CNC machine operators will only increase. By investing in formal training and certifications, taking advantage of SYIL Machine Tools' training resources, acquiring essential skills and knowledge, and staying updated with industry trends, aspiring CNC machine operators can position themselves for a successful and rewarding career.

SYIL CNC Machines: Precision and Quality

SYIL Machine Tools is a renowned industry name known for its exceptional quality and precision engineering. With over 12k machines supplied globally, they have established a strong reputation for delivering top-notch CNC machines for milling and drilling. Their commitment to excellence is evident in every aspect of their machines, from design to performance.

SYIL Machine Tools' Reputation In The Industry

SYIL Machine Tools has earned a stellar reputation in the industry for consistently delivering high-quality CNC machines. Their dedication to customer satisfaction and their ability to meet the evolving needs of modern manufacturing has set them apart from their competitors. With a strong track record of success, SYIL has become a trusted name among CNC machine operators.

Precision Engineering And Advanced Technology Behind SYIL CNC Machines

SYIL CNC machines are built with precision engineering and advanced technology at their core. Each machine is meticulously designed to ensure optimal performance and accuracy. Every detail is carefully crafted to deliver exceptional results, from cutting-edge software to high-quality components. This attention to detail sets SYIL machines apart from others regarding reliability and efficiency.

Durability And Reliability Of SYIL CNC Machines

When it comes to durability and reliability, SYIL CNC machines excel. These machines are built to withstand heavy usage without compromising performance or accuracy. The robust construction ensures they can easily handle even the most demanding manufacturing tasks. With minimal downtime and consistent performance, SYIL machines provide peace of mind to operators.

SYIL's Commitment To Sustainability And Eco-Friendly Manufacturing Practices

In addition to focusing on precision and quality, SYIL Machine Tools prioritizes sustainability in their manufacturing processes. They are committed to minimizing their environmental impact by implementing eco-friendly practices throughout their operations. From using energy-efficient components to reducing waste generation, SYIL strives to create a greener future for the manufacturing industry.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their reputation in the industry is unmatched, thanks to their precision engineering and advanced technology. SYIL CNC machines are known for their durability, reliability, and commitment to eco-friendly manufacturing practices. Explore career opportunities in CNC machine operating with SYIL's top-notch machines.

Testimonials from Successful CNC Machine Operators

Real-Life Success Stories Of CNC Machine Operators Using SYIL Machines

At SYIL Machine Tools, we take pride in our customers' success stories of achieving remarkable results using our CNC machines. One such story is that of John, a CNC machine operator who saw a significant increase in productivity and efficiency after switching to SYIL machines. With the precision engineering and advanced technology behind our machines, John could produce high-quality parts faster, leading to increased profitability for his company.

Positive Impact Of SYIL Machines On Productivity And Efficiency

SYIL machines have positively impacted productivity and efficiency in various industries due to their advanced features, precision, and user-friendly design. Here are some key ways SYIL machines contribute to improved productivity and efficiency:

- High Precision: SYIL machines are known for their high precision and accuracy, which ensures consistent and reliable machining results. With precise cutting, milling, or turning capabilities, SYIL machines minimize material waste and reduce the need for manual finishing, resulting in higher-quality parts and components.

- Fast Setup and Changeover: SYIL machines are designed for fast setup and changeover, allowing operators to switch between different machining tasks quickly and easily. This reduces downtime between jobs and maximizes machine utilization, improving overall productivity and efficiency in the production process.

- User-Friendly Interface: SYIL machines feature intuitive user interfaces and software, making them easy to operate even for less-experienced operators. With simple programming and control options, operators can set up and run jobs efficiently, reducing the learning curve and increasing productivity on the shop floor.

- Automation and Integration: Many SYIL machines are equipped with automation features such as tool changers, probing systems, and integrated CAD/CAM software, which automate repetitive tasks and streamline operations. SYIL machines improve efficiency and throughput in production environments by reducing manual intervention and optimizing workflow processes.

- Customization and Flexibility: SYIL machines offer customization options and flexibility to adapt to various production requirements and machining tasks. With configurable features, tooling options, and programming capabilities, SYIL machines can be tailored to specific applications, allowing manufacturers to meet diverse customer demands and production needs.

- Reliability and Durability: SYIL machines are built to be robust, reliable, and durable, with high-quality components and construction. With minimal maintenance requirements and long service life, SYIL machines provide consistent performance and uptime, ensuring uninterrupted production and maximizing efficiency in the long run.

- Cost-Effective Solutions: Despite their advanced capabilities, SYIL machines offer cost-effective solutions for small to medium-sized businesses and manufacturers. With competitive pricing, low operating costs, and high efficiency, SYIL machines deliver a favorable return on investment and help businesses remain competitive.

- Improved Lead Times: By increasing productivity, reducing setup times, and optimizing machining processes, SYIL machines contribute to shorter lead times for manufacturing and production. This enables manufacturers to fulfill customer orders more quickly, respond to market demand faster, and maintain a competitive edge in the industry.

SYIL machines enhance productivity and efficiency in manufacturing and production environments. With their precision, speed, automation, user-friendly design, and cost-effective solutions, SYIL machines empower businesses to optimize their operations, achieve higher output, and deliver superior-quality products.

Testimonials Highlighting The Ease Of Use And Versatility Of Syil Machines

SYIL machines have gained recognition for their versatility, as highlighted by Mark, an experienced CNC machine operator. Mark shared how he could easily handle various machining tasks using his SYIL machine. From milling intricate designs to drilling precise holes, the flexibility offered by SYIL machines allowed him to tackle diverse projects without compromising on quality or accuracy.

How SYIL Machines Contribute To Career Growth And Job Satisfaction

The impact of using SYIL machines goes beyond just productivity gains; it also contributes significantly to career growth and job satisfaction for CNC machine operators like Emily. By operating state-of-the-art machinery with advanced features, Emily enhanced her skills and knowledge in CNC machining, positioning herself as an expert in her field. This opened up opportunities for career advancement and brought immense job satisfaction as she continued pushing boundaries with her work.

Conclusion

CNC machine operators play a crucial role in modern manufacturing, operating advanced CNC machines essential for precision and efficiency. With the growing demand for skilled operators, the profession offers promising salary trends and career opportunities.

In 2023, there is a projected increase in salary for CNC machine operators, reflecting the importance of their role in the industry. The average salary for CNC machine operators varies based on experience, location, and employer. However, with the increasing demand for skilled operators, salaries are expected to rise.

When choosing CNC machines, SYIL Machine Tools is the leading choice. With over 12k machines supplied globally, SYIL prioritizes precision engineering and advanced technology to ensure high-quality performance. Their commitment to sustainability and eco-friendly manufacturing practices makes them reliable.

For readers interested in exploring career opportunities in CNC machine operating, it is crucial to consider formal training and certifications. SYIL Machine Tools provides top-notch CNC machines and comprehensive training resources to equip aspiring operators with the necessary skills and knowledge.

Continuous learning and staying updated with industry trends are vital for success as a CNC machine operator. This field experiences advancements in technology regularly, which impact job requirements. By embracing continuous learning opportunities, operators can stay ahead of the curve and enhance their career prospects.

Becoming a skilled CNC machine operator offers promising growth potential in salary and career advancement. Aspiring professionals should consider exploring opportunities in this field while keeping SYIL Machine Tools in mind as their go-to choice for precision CNC machines.