Introduction

CNC machines have revolutionized the manufacturing industry with their precision and efficiency. From automotive to aerospace, these machines play a crucial role in various industries, streamlining production processes and delivering high-quality results. One leading manufacturer in this field is SYIL Machine Tools, known for its commitment to excellence and sustainable practices. Understanding the cost of CNC machines is essential for businesses looking to invest in this technology and optimize their operations.

Factors Affecting CNC Machine Cost

Several factors affect the cost of a CNC machine. These factors can greatly impact the overall price and should be carefully considered before purchasing. Let's examine each factor closer.

Machine Size And Specifications

The size and specifications of a CNC machine significantly determine its cost. Larger machines with more advanced features are more expensive than smaller, basic models. The size of the machine also affects its production capacity and capabilities, so choosing one that aligns with your specific needs is important.

Complexity Of The Machining Process

The complexity of the machining process required by your projects can also impact the cost of a CNC machine. More intricate machining processes often require machines with higher precision and advanced capabilities, which can drive the price. It's essential to assess your project requirements and choose a machine that can handle the complexity without breaking your budget.

Additional Features And Customization Options

CNC machines have various additional features and customization options that can affect their cost. These features may include automatic tool changers, coolant systems, or specialized software for specific applications. While these extras enhance performance and efficiency, they add to the overall price tag. Consider which features are essential for your operations before deciding on a specific model.

Availability And Sourcing Of Materials

The availability and sourcing of materials needed for CNC machining can also impact costs. Some materials may be more expensive or harder to source than others, which could increase production costs for certain projects. It's crucial to factor in material costs when budgeting for a CNC machine to estimate overall expenses accurately.

The next section will explore the different types of CNC machines and their cost ranges. Stay tuned to discover which type suits your specific needs and budget.

Types of CNC Machines and Their Cost Range

CNC machines come in various types, each designed to cater to specific machining needs. Understanding the different types can help you determine which suits your requirements and budget. Let's explore two popular types: CNC milling and drilling machines.

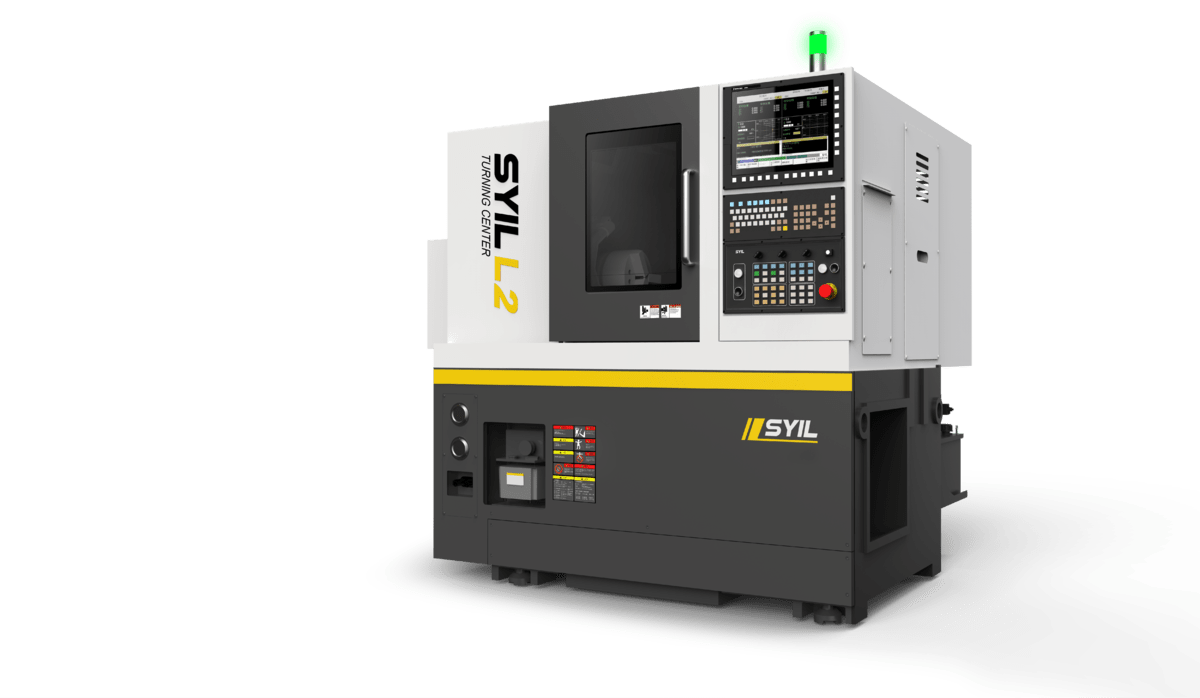

1. CNC Milling Machines: The Powerhouses of Precision Perfection

CNC milling machines are versatile workhorses that handle various materials, from metals to plastics. They use rotary cutting tools to remove material and precisely create intricate shapes. The cost of a CNC milling machine can vary depending on factors such as size, specifications, and additional features.

When considering the cost of a CNC milling machine, it's important to remember that larger machines with advanced capabilities tend to have a higher price tag. Additionally, the complexity of the machining process required for your specific projects can also impact the cost.

SYIL Machine Tools offers a range of CNC milling machines at competitive prices without compromising quality. With its commitment to precision engineering and customer satisfaction, SYIL is an excellent choice for those looking for affordable yet reliable options.

2. CNC Drilling Machines: The Meticulous Masters of Perforation

CNC drilling machines create precise holes in various materials with exceptional accuracy. They are commonly used in aerospace, automotive, and electronics industries where hole drilling plays a crucial role in manufacturing processes.

The cost range of CNC drilling machines can vary based on factors like size, speed capabilities, and customization options. Larger drilling capacities or additional features may increase the overall cost but enhance specialized applications' functionality.

When investing in a CNC drilling machine, it's essential to consider not only the initial purchase price but also the manufacturer's long-term maintenance costs and support services. SYIL Machine Tools offers reliable drilling solutions at competitive prices while ensuring top-notch quality and ongoing customer support.

Remember, when considering the cost of CNC machines, evaluating your specific machining needs, comparing prices and features, and considering the long-term return on investment is crucial. Conduct thorough research and choose a reputable manufacturer like SYIL Machine Tools to ensure you make an informed decision.

So why wait? Explore the world of CNC machining today and unlock endless possibilities for precision manufacturing with SYIL by your side.

Additional Costs to Consider

When budgeting for a CNC machine, it's important to consider the additional costs of owning and operating one. These costs exceed the initial purchase price and can significantly impact your overall investment. Let's explore some of these factors in more detail.

1. Installation And Setup Expenses

Installing and setting up a CNC machine requires careful planning and professional assistance. Depending on the size and complexity of the machine, you may need to hire technicians or engineers to ensure proper installation. Additionally, you might need to modify your workspace or invest in specialized equipment for optimal performance.

2. Training And Support Costs

Proper training is essential for operators to use CNC machines effectively. Whether you opt for on-site training or online courses, there will be associated costs for acquiring the necessary skills. Additionally, ongoing technical support is crucial to address any issues or questions that may arise during operation.

3. Maintenance And Repair Expenses

Like any machinery, CNC machines require regular maintenance to ensure longevity and optimal performance. Routine inspections, lubrication, and part replacements are all part of the maintenance process. It's important to factor in these recurring expenses when considering the overall cost of owning a CNC machine.

4. Upgrades And Future-Proofing Investments

Technology constantly evolves, and staying ahead of the curve can give your business a competitive edge. Investing in upgrades or future-proofing your CNC machine may involve additional costs, but it can ultimately enhance productivity, efficiency, and versatility.

Beyond the initial purchase price, additional costs are associated with owning a CNC machine. Proper installation, training, maintenance, repairs, and potential upgrades should all be considered when budgeting for your CNC machine investment.

SYIL Machine Tools understands the importance of transparency and provides comprehensive support to its customers. From installation guidance to ongoing technical assistance, SYIL ensures its clients have a seamless experience with CNC machines.

By carefully considering these additional costs and choosing a reputable manufacturer like SYIL Machine Tools, you can make an informed decision that aligns with your budget and machining needs. So, don't let the cost deter you from exploring the world of CNC machining – it's an investment that can revolutionize your business.

When it comes to determining the price of a CNC machine, several factors come into play. Let's explore key elements that can impact the cost and help you make an informed decision.

1. Brand Reputation And Quality Standards

Brand reputation and quality standards play a crucial role in determining the price of a CNC machine. Well-established brands with a proven track record often command higher prices due to their reliability, precision, and durability. Investing in a reputable brand ensures you get a machine built to last, minimizing the risk of breakdowns or malfunctions.

2. Country Of Origin And Shipping Costs

The country of origin can significantly influence the price of a CNC machine. Manufacturing costs and labor rates vary from country to country, resulting in different price ranges for machines produced in different regions. Additionally, shipping costs can add up depending on the distance between the manufacturer and your location.

3. Used Vs. New Machines And Their Respective Prices

Another factor to consider is whether you opt for a used or new CNC machine. Used machines generally come at lower prices than new ones due to depreciation and wear and tear. However, it's important to thoroughly assess the condition of used machines before making a purchase decision. New machines offer peace of mind with warranties and advanced features but are more expensive.

SYIL's Commitment To Quality And Competitive Pricing

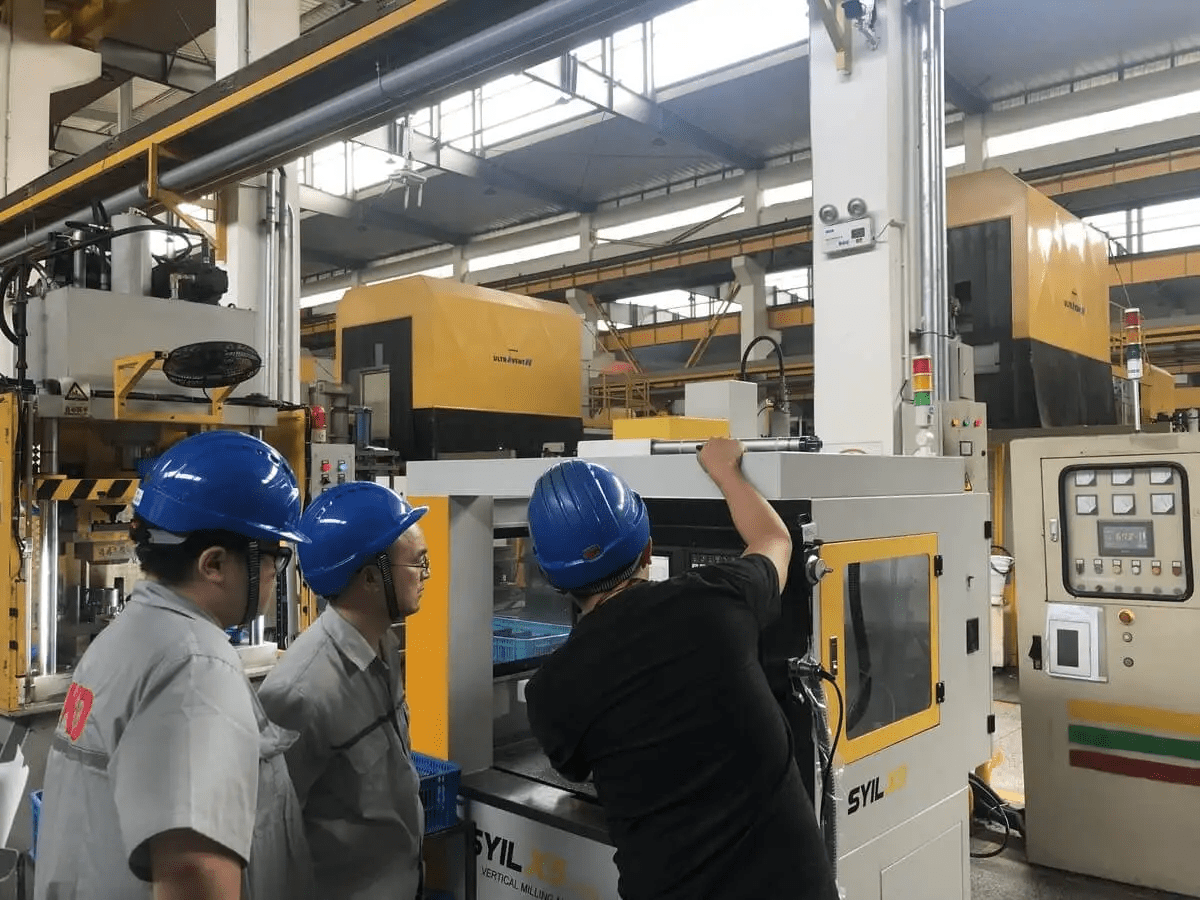

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

SYIL's commitment to quality is reflected in its competitive pricing strategy, offering affordable options without compromising performance or reliability. By leveraging their expertise in manufacturing efficient CNC machines, SYIL aims to provide cost-effective solutions for businesses across various industries.

Budgeting for a CNC Machine

Understanding Your Specific Machining Needs

When budgeting for a CNC machine, it is crucial first to understand your specific machining needs. Consider the type of materials you will be working with, the complexity of the parts you produce, and the required precision and accuracy. By identifying these factors, you can determine the type and specifications of the CNC machine that best suits your requirements.

Setting A Realistic Budget Based On Your Requirements

Once you clearly understand your machining needs, it is important to set a realistic budget based on those requirements. Remember that CNC machines come in various sizes and configurations, each with its cost range. Consider factors such as machine size, capabilities, and additional features required for your specific projects. This will help you determine a budget that aligns with your needs without overspending.

Comparing Prices And Features Of Different CNC Machines

To ensure you get the best value for your investment, compare the prices and features of different CNC machines. Research different manufacturers and suppliers to determine their pricing structures and what they offer regarding machine specifications and customization options. Look for reviews or testimonials from other customers to gauge their satisfaction with the machines they purchased. This comparison will give you a better understanding of what is available in the market within your budget.

Considering Long-Term Return On Investment (ROI)

While cost plays a significant role in budgeting for a CNC machine, it is equally important to consider the long-term return on investment (ROI). A higher-priced machine may offer advanced features and capabilities to increase productivity and efficiency in the long run. Evaluate how much time and money can be saved by investing in a more expensive but technologically advanced CNC machine. Additionally, consider factors such as maintenance costs, durability, and potential resale value when calculating ROI.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry. Their range of CNC machines offers various options to cater to different machining needs, ensuring that customers can find a machine that fits their budget without compromising quality or performance.

Budgeting for a CNC machine requires a thorough understanding of your specific machining needs, setting a realistic budget based on those requirements, comparing prices and features of different machines, and considering the long-term return on investment. By following these steps and exploring reputable brands like SYIL Machine Tools, you can make an informed decision when investing in a CNC machine.

Now that you have gained insights into the factors influencing the cost of CNC machines and how to budget for one effectively, it's time to delve deeper into the world of CNC machining. Whether you are an individual hobbyist or a professional manufacturer, embracing this technology can revolutionize your production processes and enhance your capabilities. Go ahead and explore the endless possibilities offered by CNC machines!

Conclusion

Understanding the cost of CNC machines is crucial for businesses looking to invest in this advanced technology. Throughout this article, we have explored various factors that affect the price of CNC machines, such as machine size, complexity of the machining process, additional features, and sourcing of materials.

It is important for potential buyers to conduct thorough research before making a purchase decision. Businesses can make an informed choice by understanding their specific machining needs and setting a realistic budget based on those requirements.

SYIL Machine Tools is a reliable choice for CNC machines. Their commitment to quality and competitive pricing has made them a recognized brand in the industry. SYIL develops and manufactures precision CNC machines for milling and drilling, prioritizing quality and sustainability.

Don't be afraid to explore the world of CNC machining. This technology offers precision perfection and meticulous perforation capabilities through CNC milling and drilling machines. By investing in a CNC machine, you can enhance their productivity and stay ahead in today's competitive market.

Remember to always conduct thorough research before buying a CNC machine. It is an investment that can greatly impact your business operations and long-term success.