Introduction

When it comes to metal cutting, precision is key. Choosing the right CNC metal cutting machine can make all the difference in achieving accurate and efficient results. In this article, we will explore the importance of selecting the right machine, how SYIL CNC Machines can help you get the best deal, and provide a basic understanding of CNC metal cutting machines.

The Importance of Choosing the Right CNC Metal Cutting Machine

Selecting the right CNC metal cutting machine is fundamental for any metalworking operation. It directly impacts the precision of your cuts, the quality of your finished products, and your overall efficiency. By carefully considering your needs and making an informed decision, you can ensure a machine that saves you time, money, and frustration in the long run. Here are some key factors to consider when choosing a CNC metal cutting machine:

- Material and Thickness: What types of metal will you be cutting? How thick will the material be? Different machines excel at cutting various materials and thicknesses.

- Accuracy and Precision: The detail and tolerance required in your cuts will determine the machine's necessary precision.

- Production Volume: Consider the number of parts you plan to produce and choose a machine that can handle your workload efficiently.

- Budget: CNC metal cutting machines come in various price points. Determine your budget and find a machine that offers the features you need within your financial constraints.

- Ease of Use and Operator Skills: Think about the skill level of your operators and choose a machine with a user-friendly interface and appropriate training options.

By carefully evaluating these factors, you'll be well on your way to selecting the perfect CNC metal cutting machine.

How SYIL CNC Machines Can Help You Get the Best Deal

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL CNC Machines offer advanced features that ensure precise cuts, high-speed performance, and durability. By choosing SYIL machines, you can be confident that you are getting the best deal on a CNC metal cutting machine.

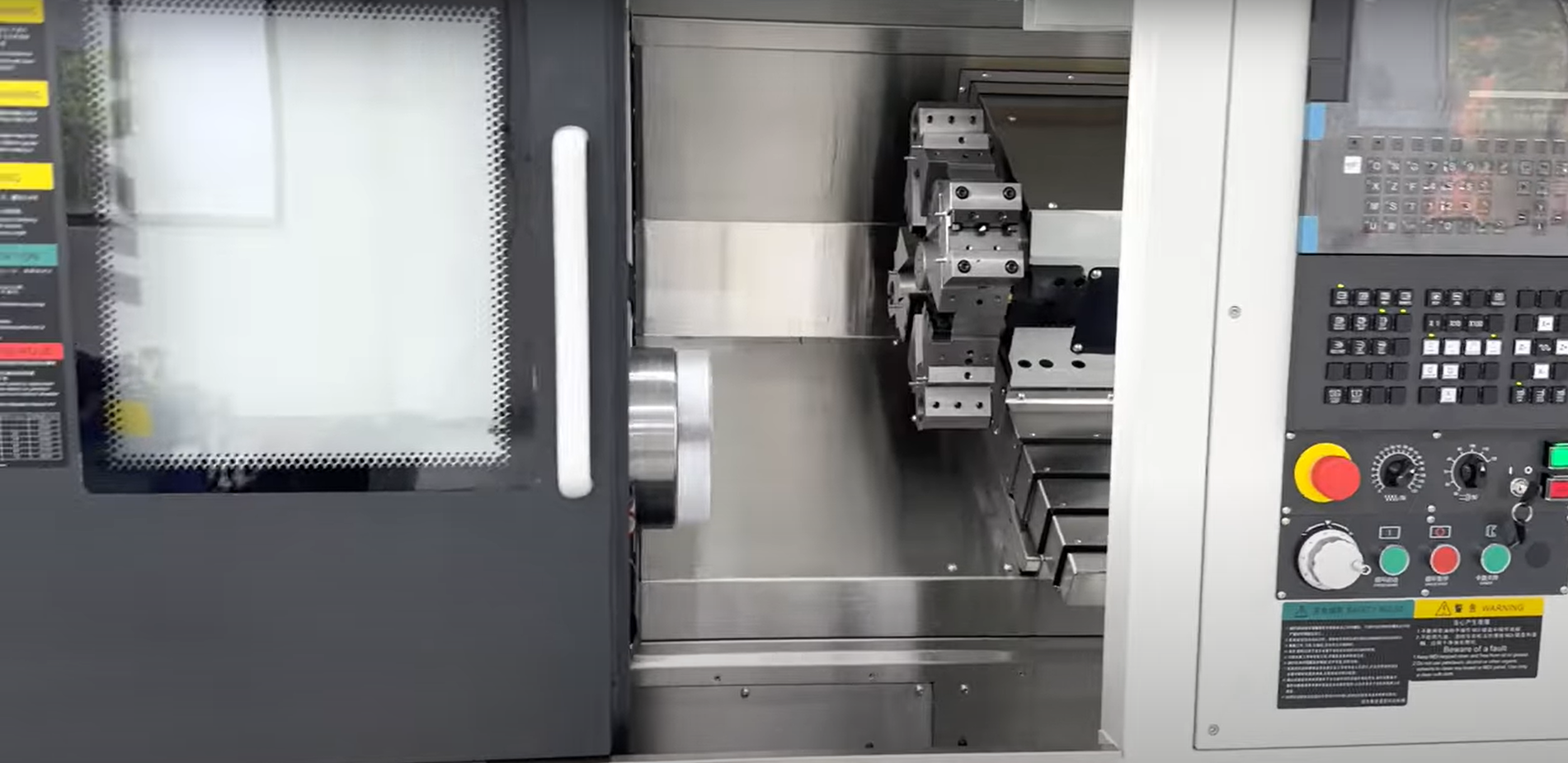

Understanding the Basics of CNC Metal Cutting Machines

CNC stands for Computer Numerical Control, which means that these machines are operated by computer programs that control their movements with utmost precision. A CNC metal cutting machine utilizes various methods, such as laser or plasma, to cut through different types of metals with accuracy and efficiency.

With this introduction in mind, let's delve deeper into exploring different types of CNC metal cutting machines to help you determine which one suits your specific needs and requirements

Types of CNC Metal Cutting Machines

CNC metal cutting machines come in various types, each with its own unique features and capabilities. Let's explore the different varieties: plasma, laser, and waterjet.

Exploring Different Varieties: Plasma, Laser, and Waterjet

1. Plasma Cutting Machines:

Plasma cutting machines use a high-velocity jet of ionized gas to cut through electrically conductive materials such as steel, aluminum, and stainless steel. They are known for their speed and affordability, making them a popular choice for industrial applications.

2. Laser Cutting Machines:

Metal laser cutting machines utilize a high-powered laser beam to melt or vaporize the cut material. This precise method is ideal for intricate designs and thin materials. It offers high accuracy and speed, making it suitable for the automotive, aerospace, and electronics industries.

3. Waterjet Cutting Machines:

Waterjet cutting machines employ a highly pressurized stream of water mixed with abrasive particles to cut through various materials. They are versatile enough to handle metals like steel and other materials like glass and stone. Waterjet cutting provides clean cuts without heat-affected zones or material distortion.

Pros and Cons of Each Type

1. Plasma Cutting Machines:

Pros:

- High cutting speed

- Affordable equipment

- Suitable for thick materials

Cons:

- Less precise compared to laser or waterjet

- Limited ability to cut complex shapes

2. Laser Cutting Machines:

Pros:

- High precision and accuracy

- Versatile in cutting various materials

- Minimal heat affected zone

Cons:

- Expensive initial investment

- Limited thickness capacity compared to plasma or waterjet

3. Waterjet Cutting Machines:

Pros:

- Can cut virtually any material

- No heat distortion or hardening of the material

Cons:

- Slower than plasma or laser cutting

- Higher operating costs due to abrasive usage

Which CNC Metal Cutting Machine Is Right for You?

Choosing the right CNC metal cutting machine depends on your specific needs and requirements. Consider factors such as the type of material you'll be working with, the desired level of precision, and your budget constraints.

A plasma cutting machine may be the best option if you prioritize speed and affordability for cutting thick materials. A laser cutting machine is ideal for intricate designs and precise cuts on thin materials. If versatility and the ability to cut various materials are important, a waterjet cutting machine would be a suitable choice.

Remember to evaluate your needs carefully and consult with experts in the field to make an informed decision.

Factors to Consider Before Purchasing

When it comes to purchasing a CNC metal cutting machine, several important factors need to be considered. By evaluating your specific needs and requirements, determining the ideal size and power capacity, and examining the precision and cutting speed, you can make an informed decision that will effectively meet your metal cutting needs.

Evaluating Your Specific Needs and Requirements

Before investing in a CNC metal cutting machine, evaluating your specific needs and requirements is crucial. Consider the type of materials you will be working with, the thickness, and the complexity of the cuts you must make. Consider whether you require additional features such as bevel cutting or multi-axis capabilities. You can choose a CNC machine tailored to meet your unique needs by understanding your unique needs.

Determining the Ideal Size and Power Capacity

A CNC metal cutting machine's size and power capacity play a significant role in its performance and efficiency. Consider the size of the materials you will be working with and ensure that the machine's bed size can accommodate them comfortably. Additionally, determine the power capacity required for your specific applications. This will depend on factors such as material thickness and cutting speed. Choosing a machine with an appropriate size and power capacity will ensure optimal performance.

Examining the Precision and Cutting Speed

Precision is crucial when it comes to CNC metal cutting machines. The accuracy of cuts directly affects the quality of your finished products. Therefore, it is essential to examine the precision capabilities of different machines before making a purchase decision. Look for machines that offer high repeatability and accuracy.

In addition to precision, consider the cutting speed of each machine option. Faster cutting speeds can significantly improve productivity by reducing production time. However, higher speeds may compromise precision in some cases.

By carefully evaluating your needs and requirements, determining the ideal size and power capacity, and examining the precision and cutting speed, you can make an informed decision when purchasing a CNC metal cutting machine. Remember, SYIL CNC Machines prioritize quality and sustainability, making them an excellent choice for your metal cutting needs.

Researching and Comparing Brands

When researching and comparing brands for CNC metal cutting machines, SYIL CNC Machines stands out with its superior features and exceptional quality. SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12,000 machines supplied globally, they prioritize quality and sustainability.

Introducing SYIL CNC Machines and Their Superior Features

SYIL CNC Machines offer a wide range of cutting-edge features, making them an excellent choice for metal cutting needs. Their machines are equipped with advanced technology, ensuring precise and efficient cuts every time. The metal laser cutting machine provided by SYIL is particularly noteworthy for its high accuracy and speed, making it ideal for various industrial applications.

One of the standout features of SYIL CNC Machines is their user-friendly interface, which allows operators to program and control the machine's movements easily. This makes it convenient even for those new to using CNC machines. Additionally, SYIL offers excellent customer support, promptly addressing any technical issues or questions.

Analyzing Other Prominent Brands in the Market

While SYIL CNC Machines offer exceptional quality, it's important to consider other prominent brands before deciding. Some notable brands include Haas Automation, Mazak Corporation, and DMG Mori.

Haas Automation is known for its reliability and durability in the industry. They offer various CNC machines suitable for various applications, including metal cutting. Mazak Corporation is another reputable brand specializing in advanced machining solutions focusing on innovation.

DMG Mori is renowned for its high-quality precision machinery and cutting-edge technology integration. It provides a comprehensive range of CNC machines designed to meet diverse manufacturing needs.

Understanding the Price-Quality Relationship

When comparing different CNC metal cutting machines brands, it's essential to consider the price-quality relationship. While some brands may offer lower prices, it's crucial to ensure that the quality and performance of the machine are not compromised.

SYIL CNC Machines strike a perfect balance between affordability and superior quality. Their machines are competitively priced without compromising on precision and durability. By choosing SYIL, you can be confident that you're getting the best value for your investment.

Finding the Best Deals

When it comes to finding the best deals on CNC metal cutting machines, there are several options to consider. Firstly, you can explore different purchase options, such as new and used machines. While new machines offer the latest technology and often come with warranties, used machines can be a more affordable option for those on a budget. However, it's important to thoroughly inspect and test used machines before purchasing to ensure they are in good working condition.

Secondly, negotiating with suppliers and dealers can also help you get the best deal. Don't be afraid to ask for discounts or additional features in the package. Suppliers and dealers are often willing to negotiate to make a sale, especially if you're purchasing multiple machines or accessories.

Lastly, financing and leasing opportunities can help ease the financial burden of purchasing a CNC metal cutting machine. Many suppliers offer financing options that allow you to pay for the machine in installments over time. Leasing is another option that allows you to use the machine for a fixed period while paying monthly fees. These options can make owning a CNC machine more accessible for businesses with limited capital.

By exploring different purchase options, negotiating with suppliers and dealers, and taking advantage of financing and leasing opportunities, you can find the best deal on a CNC metal cutting machine that fits your needs and budget.

Maximizing Your Investment

Proper maintenance and care are essential to ensure the longevity and optimal performance of your CNC metal cutting machine. Regularly inspecting and cleaning the machine, as well as lubricating moving parts, will help prevent wear and tear. Following manufacturer guidelines for scheduled maintenance and servicing is important to keep your machine in shape. By taking good care of your CNC metal cutting machine, you can avoid costly repairs and downtime.

Training and skill enhancement for operators is another crucial aspect of maximizing your investment. Investing in training programs or workshops can help operators become more proficient in operating the CNC metal cutting machine. This will improve efficiency and reduce the risk of errors or accidents. SYIL CNC Machines offers comprehensive training programs that cover both basic operation and advanced techniques, ensuring that operators are equipped with the necessary skills to operate the machines effectively.

Leveraging SYIL CNC Machine's customer support and warranty is another way to maximize your investment. SYIL provides excellent customer support, assisting customers with technical issues or questions. Their warranty ensures that any defects or malfunctions will be promptly addressed, providing peace of mind for customers. With SYIL's reliable support system, you can rest assured that you have a trusted partner who will assist you throughout the ownership of their CNC metal cutting machine.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12,000 machines supplied globally, they prioritize quality and sustainability. By choosing SYIL CNC Machines, you can trust that you're getting a reliable, high-quality machine that will meet your metal cutting needs.

Conclusion

SYIL CNC Machines: Your Path to the Best Deal on a CNC Metal Cutting Machine

When finding the best deal on a CNC metal cutting machine, SYIL CNC Machines is your go-to solution. With its commitment to quality and sustainability, SYIL Machine Tools has established itself as a leading manufacturer in the industry. Its precision CNC machines for milling and drilling have been supplied to over 12,000 customers worldwide, making it a trusted choice for businesses of all sizes.

By choosing SYIL CNC Machines, you can be confident in the performance and reliability of your metal cutting machine. Their state-of-the-art technology ensures precise cuts and efficient operation, allowing you to optimize productivity and minimize waste. With their expertise and experience, they can help you find the perfect machine that meets your specific needs and requirements.

The Future of CNC Metal Cutting Technology

As technology advances rapidly, the future of CNC metal cutting machines looks promising. Innovations such as artificial intelligence and automation are revolutionizing the industry, making machines more intelligent and efficient.

SYIL Machine Tools is at the forefront of this technological evolution. They constantly strive to integrate the latest advancements into their machines, ensuring their customers stay ahead of the competition. By investing in a SYIL CNC machine, you are getting a reliable tool for your current needs and future-proofing your business for tomorrow's challenges.

Taking the Next Step: Making an Informed Decision

Now that you have gained valuable insights into choosing the right CNC metal cutting machine, it's time to take action. Consider size, power capacity, precision, and cutting speed carefully evaluate your needs and requirements carefully.

Research different brands in the market, but remember SYIL CNC Machines' superior features and commitment to quality. Compare prices while keeping in mind the price-quality relationship. Explore different purchase options, negotiate with suppliers, and exploit financing or leasing opportunities.

Remember to maximize your investment by ensuring proper maintenance and care for your machine. Provide training and skill enhancement for operators to optimize productivity. And don't forget to leverage SYIL CNC Machine's excellent customer support and warranty.

By making an informed decision and choosing SYIL CNC Machines, you are setting yourself up for success in metal cutting. With their expertise, technology, and commitment to customer satisfaction, they will be your trusted partner every step of the way.