Introduction

Precision cutting is crucial in various industries, such as manufacturing and fabrication, where accuracy and efficiency are paramount. To meet these requirements, a metal cutting CNC machine has become essential. These machines utilize computer numerical control (CNC) technology to automate the cutting process, ensuring precise and consistent results.

One notable player in the CNC machine industry is SYIL Machine Tools. With their commitment to reliability and sustainability, SYIL CNC machines offer reliable solutions for metal cutting needs. Their machines are designed to deliver high-quality performance while minimizing environmental impact.

Metal cutting CNC machines offer a range of benefits that revolutionize metal fabrication. Here's how:

- Enhanced Accuracy and Consistency: CNC machines rely on programmed instructions, eliminating human error and ensuring precise, consistent cuts across every piece.

- Tackling Complex Designs: Unlike manual processes, CNC machines can easily handle intricate designs and complex cuts, expanding your design possibilities.

- Boosted Productivity: CNC machines minimize setup time and often have multitasking capabilities, significantly increasing production output.

Metal cutting CNC machines bring precision, versatility, and efficiency to metalworking, making them a valuable asset for any fabrication project.

By investing in a metal cutting CNC machine from SYIL Machine Tools, businesses can benefit from precise cuts, increased efficiency, and sustainable solutions that align with their environmental goals.

In this article, we will explore the importance of metal cutting CNC machines for precision cutting and delve into their advantages. We will also discuss how SYIL CNC machines stand out as reliable and sustainable solutions in the market. Let's dive into the world of precision cutting with SYIL!

Choosing the Right Metal Cutting CNC Machine

When it comes to selecting a metal-cutting CNC machine, several important factors must be considered. First and foremost, you need to assess your specific requirements and determine the size and type of machine that will best suit them. Then, consider the maximum cutting capacity, spindle speed, and tool changer capacity that you require for your projects.

SYIL CNC Machines offers various options to cater to different needs. Whether you are looking for a compact shop CNC machine or a larger industrial-grade model, SYIL covers you. Their machines are known for their reliability, precision, and durability.

Machine precision is crucial in metal cutting operations as it directly affects the quality of the finished product. A high-quality CNC machine like SYIL offers exceptional precision in every cut. This level of accuracy is vital for industries such as aerospace, automotive, and medical where tight tolerances are required.

By investing in a SYIL metal cutting CNC machine, you can optimize your workflow and achieve higher efficiency in your operations. These machines have advanced automation features that streamline the production process and minimize errors. With reduced downtime and increased productivity, you can meet deadlines more effectively.

Regular maintenance is essential to ensure the longevity and optimal performance of your metal-cutting CNC machine. SYIL provides simple maintenance tips to help you keep your machine running smoothly for years. Regular cleaning and lubrication techniques are crucial to prevent wear and tear on the components.

Inevitably, issues may arise during operation that require troubleshooting or repairs. When faced with common problems in CNC machining, it's crucial to identify them promptly and find quick solutions to avoid costly delays. SYIL offers comprehensive support for troubleshooting and repairs, ensuring minimal disruption to your production schedule.

Investing in a metal-cutting CNC machine is a wise choice for precision cutting. SYIL Machine Tools, with its commitment to quality and sustainability, is your ideal partner in providing reliable CNC solutions. Master the art of metal cutting with SYIL CNC machines and experience the difference in precision and efficiency.

Safety Measures for Operating a Metal Cutting CNC Machine

When operating a metal-cutting CNC machine, safety should always be the top priority. Proper safety protocols are essential to ensure a secure working environment and prevent accidents. SYIL CNC Machines understands the importance of safety and has built its machines with advanced features for peace of mind.

One of the main reasons why proper safety protocols are crucial when operating a CNC machine is the high-speed nature of these machines. Metal cutting CNC machines utilize sharp tools and powerful motors to cut through various materials precisely. Operators can risk injury from flying debris or accidental contact with moving parts without the necessary safety measures.

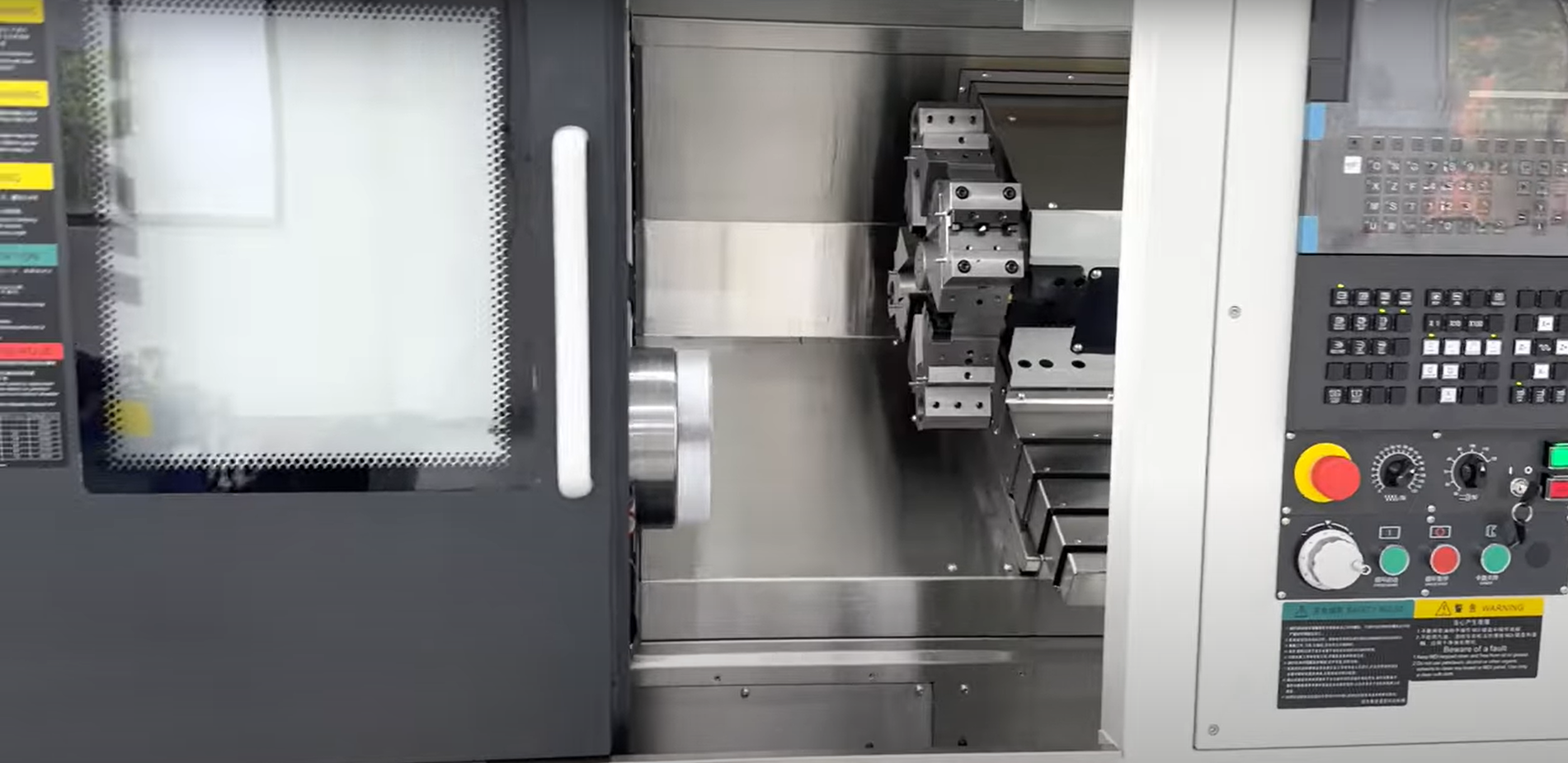

SYIL CNC Machines are designed with advanced safety features to mitigate these risks. They incorporate protective enclosures that cover the cutting area, preventing operators from coming into direct contact with the moving parts during operation. Additionally, SYIL machines are equipped with emergency stop buttons that allow operators to immediately halt operations in case of unforeseen circumstances.

Ensuring operator safety during metal cutting operations goes beyond relying on machine features. Operators must also be properly trained to use the machine safely and follow established protocols at all times. This includes wearing appropriate personal protective equipment (PPE) such as goggles, gloves, and ear protection.

By promoting proper safety practices and providing reliable machines with built-in safety features, SYIL Machine Tools prioritizes operator well-being while delivering efficient and precise metal cutting solutions.

Optimizing Efficiency with a Metal Cutting CNC Machine

Metal cutting CNC machines are essential for maximizing efficiency and productivity in any machining shop. With the advanced technology offered by SYIL CNC machines, businesses can reduce downtime and streamline their workflow to achieve optimal results. By automating processes and incorporating smart features, SYIL CNC machines enhance efficiency and minimize errors in metal cutting operations.

Maximizing Productivity by Reducing Downtime with SYIL CNC Machines

One key advantage of using SYIL metal cutting CNC machines is their ability to significantly reduce downtime. With their precision engineering and robust construction, these machines ensure uninterrupted operation and minimize unforeseen breakdowns or maintenance issues. Businesses can meet deadlines effectively and increase their output by maximizing productivity through reduced downtime.

Streamlining Workflow and Minimizing Errors in Metal Cutting

SYIL CNC machines are designed to streamline workflow and minimize errors in metal cutting processes. These machines offer high accuracy and precision, ensuring that every cut is executed perfectly. The intuitive control systems allow operators to create complex designs effortlessly, reducing the chances of human error. This streamlining of workflow not only saves time but also improves the overall quality of the final product.

SYIL CNC Machines: Automation and Smart Features to Enhance Efficiency

SYIL CNC machines have automation features that enhance efficiency in metal cutting operations. These smart features automate repetitive tasks, allowing operators to focus on more critical aspects of production. Additionally, these machines offer advanced software integration that simplifies programming and significantly reduces setup time. The combination of automation and smart features SYIL provides ensures maximum efficiency throughout the machining process.

Maintaining and Caring for a Metal Cutting CNC Machine

Regular maintenance is crucial for ensuring the longevity of your metal-cutting CNC machine. By following simple maintenance tips, you can keep your machine running smoothly and avoid costly repairs. SYIL CNC Machines offer reliable solutions designed to withstand heavy usage and require minimal maintenance.

Importance of Regular Maintenance for Prolonged Machine Lifespan

Regular maintenance is essential to prolong the lifespan of your metal cutting CNC machine. You can identify potential issues before they escalate into major problems by conducting routine inspections. This helps prevent unexpected breakdowns and ensures uninterrupted productivity in your shop. Neglecting regular maintenance can lead to decreased performance, increased downtime, and costly repairs.

SYIL CNC Machines: Simple Maintenance Tips to Ensure Longevity

SYIL CNC Machines are built with durability in mind, but they still require regular upkeep to maintain optimal performance. Here are some simple maintenance tips to ensure the longevity of your machine:

- Keep the workspace clean: Regularly clean the surrounding area of your machine to prevent dust, debris, and metal shavings from accumulating. This helps prevent damage to sensitive components and ensures smooth operation.

- Lubricate moving parts: Apply lubrication as the manufacturer recommends to reduce friction between moving parts. This prevents excessive wear and tear and extends the lifespan of critical components.

- Check belts and pulleys: Inspect belts and pulleys regularly for signs of wear or damage. Replace any worn-out belts or damaged pulleys promptly to avoid unnecessary downtime.

- Calibrate regularly: Regularly calibrate your machine using precision measuring tools to ensure accurate cutting results. This helps maintain the quality and precision of your metal cutting operations.

- Follow manufacturer guidelines: Refer to the manufacturer's guidelines for specific maintenance instructions tailored to your SYIL CNC Machine model.

Effective Cleaning and Lubrication Techniques for Metal Cutting CNC Machines

Cleaning and lubrication are vital aspects of maintaining a metal cutting CNC machine. Here are some effective techniques to keep your machine in top condition:

- Cleaning: Use compressed air or a vacuum cleaner to remove dust and debris from the machine's components, including the spindle, tool holders, and coolant system. Wipe down surfaces with a clean cloth and mild detergent to remove any stubborn dirt.

- Lubrication: Apply lubricants to designated points as recommended by the manufacturer. This includes lubricating ball screws, linear guides, and other moving parts that require regular maintenance.

- Coolant system maintenance: Regularly check the coolant levels and ensure proper filtration to prevent contamination. Clean or replace filters as necessary to maintain optimal coolant performance.

By following these cleaning and lubrication techniques, you can ensure that your metal cutting CNC machine operates smoothly and efficiently for years.

Troubleshooting Common Issues with a Metal Cutting CNC Machine

When operating a metal cutting CNC machine, it is important to know common problems that may arise during the machining process. Identifying and resolving these issues promptly can help minimize downtime and ensure smooth operations.

Identifying and Resolving Common Problems in CNC Machining

One common problem in CNC machining is tool breakage or wear. This can occur due to improper tool selection, incorrect feeds, and speeds, or excessive cutting forces. To address this issue, operators should regularly inspect tools for signs of wear and replace them as needed. Optimizing cutting parameters based on the machined material can also help prevent tool breakage.

Another issue that may arise is poor surface finish on machined parts. This can be caused by incorrect tool geometry, inadequate coolant or lubrication, or improper machine setup. To resolve this problem, operators should ensure proper tool selection and geometry for the desired surface finish. Additionally, using appropriate coolant or lubrication during machining can help improve surface quality.

SYIL CNC Machines: Comprehensive Support for Troubleshooting and Repairs

SYIL CNC Machines understands the importance of promptly addressing troubleshooting and repairs to minimize disruptions in production. With its comprehensive support system, it offers timely assistance to customers facing issues with its metal-cutting CNC machines.

SYIL's team of experts is well-equipped to handle various troubleshooting scenarios and provide effective solutions to resolve any problems encountered during CNC machining operations. Whether assisting with tool selection or providing guidance on optimizing cutting parameters, SYIL offers comprehensive support every step of the way.

Avoiding Costly Delays with Quick Solutions to Machine Malfunctions

If not addressed promptly, machine malfunctions can lead to costly delays in production schedules. SYIL CNC Machines prioritizes minimizing these delays by offering quick solutions to machine malfunctions.

With their advanced technology and smart features, SYIL CNC Machines are designed to detect and diagnose issues in real-time. This allows operators to quickly identify the source of the problem and take appropriate action to resolve it. SYIL CNC Machines help businesses stay on track with their production targets by minimizing downtime and maximizing machine uptime.

Conclusion

Investing in a Metal Cutting CNC Machine: A Wise Choice for Precision Cutting

Investing in a metal cutting CNC machine is a wise choice for precision cutting. These machines offer unparalleled accuracy and efficiency, allowing you to achieve the highest quality results in your metal cutting projects. With advanced technology and innovative features, SYIL CNC machines are the perfect partner for quality and sustainable CNC solutions.

SYIL CNC Machines: Your Partner for Quality and Sustainable CNC Solutions

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL CNC machines are designed to deliver reliable performance while minimizing environmental impact. By choosing SYIL as your partner, you can trust that you are investing in a machine that will meet your needs and exceed your expectations.

Mastering the Art of Metal Cutting with SYIL CNC Machines

With SYIL CNC machines, you can master the art of metal cutting. These machines offer a wide range of options to suit your specific needs, whether you are working on small-scale projects or large-scale production runs. By utilizing the automation and smart features of SYIL CNC machines, you can enhance efficiency and streamline workflow, ultimately maximizing productivity.

In conclusion, investing in a metal cutting CNC machine is essential for precision cutting. SYIL CNC machines provide reliable and sustainable solutions that enable you to achieve accurate results while optimizing efficiency. With their advanced safety features, easy maintenance tips, and comprehensive support for troubleshooting and repairs, SYIL is your trusted partner in metal cutting. Choose SYIL today and experience the difference they can make in your machining operations.