Introduction

In the world of manufacturing and fabrication, entry level CNC machines have emerged as game-changers for hobbyists and aspiring machinists alike. These machines offer a gateway into the intricate realm of computer numerical control, allowing users to produce precise parts and prototypes without needing extensive experience. For those curious about how much an entry level CNC machine costs, or what it takes to become a level 1 CNC machinist, this guide will illuminate your path to CNC mastery.

Understanding Entry Level CNC Machines

Entry level CNC machines are designed with beginners in mind, providing an accessible introduction to the world of machining. They typically feature user-friendly interfaces and simplified controls that make it easier for novices to learn the ropes without feeling overwhelmed. By understanding these machines' capabilities and limitations, you can better appreciate their role in shaping your journey into the manufacturing industry.

Key Features of the SYIL X5

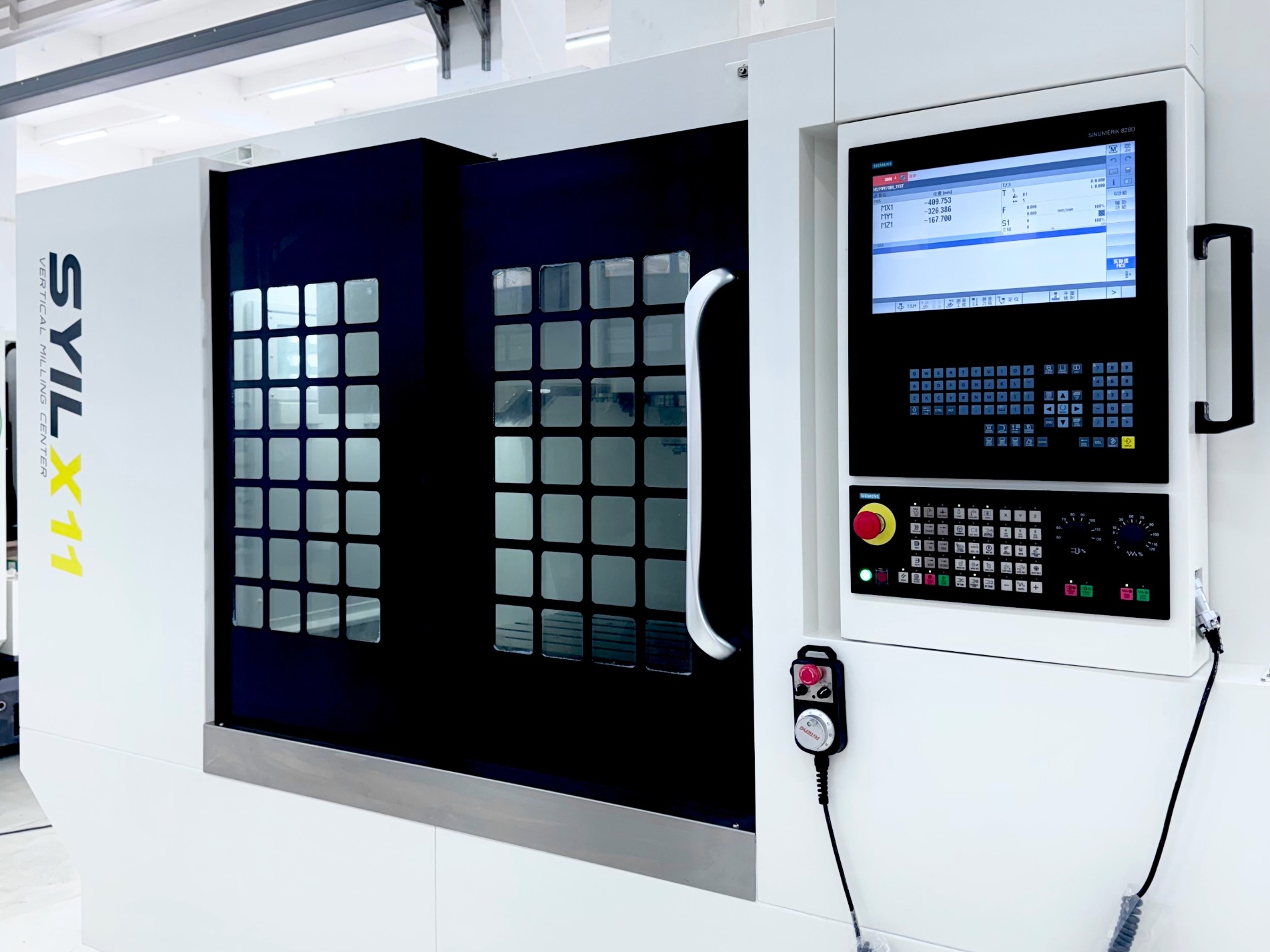

The SYIL X5 stands out among entry level CNC machines due to its robust construction and impressive specifications. With a compact design ideal for small workshops or home use, this machine offers precision machining capabilities that rival more advanced models. Features like a high-speed spindle and versatile tooling options allow users to explore various applications while honing their skills in a supportive environment.

Benefits of Starting with Entry Level CNC

Starting with an entry level CNC machine like the SYIL X5 presents numerous advantages for budding machinists. For one, it allows you to develop essential skills without the steep learning curve associated with more complex equipment. Additionally, many people wonder: can you make money with a small CNC machine? The answer is yes! By leveraging your newfound skills on projects or even starting a small business, you can turn your passion for machining into profit while exploring creative opportunities along the way.

Capabilities of Entry Level CNC Machines

Entry level CNC machines, like the SYIL X5, are surprisingly capable tools that can handle a variety of projects with finesse. These machines are designed to be user-friendly while still delivering impressive results, making them perfect for both hobbyists and budding professionals. Whether you're looking to create intricate designs or simple parts, an entry level CNC machine can rise to the occasion.

Versatility in Project Types

One of the standout features of an entry level CNC machine is its versatility in project types. From woodworking to metalworking, these machines can tackle a wide range of materials and applications. This flexibility allows users to experiment with various projects, whether it's crafting custom furniture or producing small mechanical components.

For those asking How much is an entry level CNC machine?, it's worth noting that their affordability often comes with a broad spectrum of capabilities. You don't need a hefty budget to dive into multiple project types; many entry level options offer great value without compromising on functionality. This adaptability opens doors for creativity and innovation, making it easier for users to explore their interests.

Precision and Detail in Fabrication

Precision is key when it comes to CNC machining, and entry level machines deliver impressive accuracy that rivals their more expensive counterparts. With advanced software and reliable hardware, you can achieve detailed cuts and intricate designs consistently every time you use your machine. This precision is crucial for anyone looking to create professional-grade prototypes or custom pieces.

As you delve deeper into what it means to be a level 1 CNC machinist, you'll discover that mastering precision techniques is essential for success in this field. Learning how to fine-tune your settings will allow you not only to produce high-quality work but also gain confidence as you progress in your skills. Ultimately, the ability to fabricate with detail will set your projects apart from the rest.

Ideal for Prototyping and Customization

Entry level CNC machines are particularly well-suited for prototyping and customization projects due to their ease of use and adaptability. Whether you're developing new product concepts or personalizing items for clients, these machines provide an efficient way to bring ideas into reality quickly. Their design allows users at any skill level—especially beginners—to experiment without overwhelming complexity.

If you're wondering How do I start a career in CNC?, consider focusing on prototyping as a key area where entry-level skills shine brightly. The ability to swiftly create prototypes not only enhances your portfolio but also makes you more attractive in the job market as companies seek individuals who can innovate rapidly while maintaining quality standards. Plus, this hands-on experience builds valuable skills that translate well into other areas within the industry.

Cost Considerations

When exploring the world of entry level CNC machines, understanding the cost is crucial for anyone looking to dive into this exciting field. The price of an entry level CNC machine can vary significantly based on features, capabilities, and brand reputation. Therefore, it's essential to do your homework and consider not just the initial investment but also what you’ll gain in terms of skills and potential income.

How Much Is an Entry Level CNC Machine?

So, how much is an entry level CNC machine? Generally, you can expect to pay anywhere from $2,000 to $10,000 for a decent model that offers a range of functions suitable for beginners. While it might seem like a hefty price tag at first glance, remember that investing in a reliable machine lays the groundwork for your future projects and career in CNC machining.

If you're asking yourself what is a level 1 CNC machinist? It's someone who operates basic CNC machines with limited programming knowledge—perfectly aligned with what you can achieve using an entry level CNC machine. This makes it easier to break into the industry without needing extensive experience or training upfront.

Comparing Prices and Features

When comparing prices and features of various entry level CNC machines, it’s important to look beyond just the cost. Some models may be cheaper but lack essential features like precision tooling or software compatibility; conversely, pricier options might offer advanced capabilities that are unnecessary for beginners. Make sure to assess factors such as build quality, ease of use, support resources available from manufacturers, and customer reviews before making your decision.

Additionally, consider how these features align with your goals—whether you're focused on prototyping or custom projects will influence which model suits you best. If you're keen on starting a career in CNC machining or wondering how do I start a career in CNC?, choosing the right machine can set you up for success right out of the gate.

Long-Term Value of Investing

Investing in an entry level CNC machine isn't just about immediate costs; it’s about long-term value as well. While your initial expenditure may seem significant now, think about how this tool can help you develop valuable skills over time that are highly sought after in various industries. Moreover, many people wonder if they can make money with a small CNC machine—absolutely! With creativity and some business acumen, you could turn that investment into a profitable venture through custom jobs or even selling unique products online.

In essence, while evaluating cost considerations is key when purchasing an entry-level machine like the SYIL X5 or similar models; remember that this investment could open doors to numerous opportunities down the line—both personally and professionally.

Skills Required for Entry Level CNC Operations

When diving into the world of CNC machining, understanding the skills required for entry-level positions is crucial. With the rise of entry level CNC machines, more individuals are looking to start their journey in this field. Whether you're curious about how much an entry level CNC machine costs or what it takes to be a successful machinist, this section has you covered.

What Is a Level 1 CNC Machinist?

A Level 1 CNC machinist is essentially the starting point for anyone entering the world of CNC operations. These professionals typically operate entry level CNC machines and are responsible for basic tasks such as setting up machines, loading materials, and monitoring production runs. If you're asking yourself, What is a level 1 CNC machinist? think of them as the backbone of manufacturing processes, ensuring that everything runs smoothly and efficiently.

Level 1 machinists usually work under the supervision of more experienced operators or engineers to learn essential practices and protocols. This hands-on experience is invaluable as it lays the foundation for future growth in your career. With dedication and skill development, you can advance quickly from this initial position.

Essential Skills for Beginners

To thrive as a beginner in the realm of entry level CNC machines, certain essential skills are necessary. First and foremost is familiarity with basic machining concepts—this includes understanding blueprints and technical drawings which are fundamental in guiding your work process. Additionally, having good mathematical skills helps when making precise measurements and calculations during fabrication.

Another critical skill set includes problem-solving abilities; issues can arise unexpectedly during operations, so being able to troubleshoot effectively will save time and resources. Lastly, attention to detail cannot be overstated; even minor mistakes can lead to significant errors in production quality or safety hazards. By honing these essential skills early on, you'll set yourself up for success in your journey toward becoming a proficient machinist.

Training and Resources Available

If you're pondering How do I start a career in CNC? there are plenty of training programs available that cater specifically to beginners interested in operating entry level CNC machines. Community colleges often offer courses on basic machining principles where you can gain hands-on experience with various types of equipment including mills and lathes. Online platforms also provide valuable resources like tutorials or certification courses that fit around your schedule.

Moreover, many companies offer apprenticeships which combine on-the-job training with classroom instruction—perfect if you're eager to learn while earning at the same time! For those wondering about long-term prospects like Can you make money with a small CNC machine?, gaining foundational knowledge through these training avenues will enhance your ability to monetize your skills effectively later on.

Pathways to a CNC Career

Embarking on a career in CNC (Computer Numerical Control) machining can be an exciting venture, especially with the accessibility of entry level CNC machines like the SYIL X5. Whether you're looking to create custom projects or delve into manufacturing, understanding how to start is crucial. Let's explore the steps and resources that can pave your way into this dynamic field.

How Do I Start a Career in CNC?

To kickstart your journey in the world of CNC machining, you should begin by familiarizing yourself with entry level CNC machines and their functionalities. Many aspiring machinists wonder, “How do I start a career in CNC?” The answer lies in gaining hands-on experience; consider working at a local machine shop or enrolling in workshops that focus on operating these machines.

Next, it's beneficial to learn about the various types of machinery used in the industry. This knowledge will not only help you understand what is required from an entry level position but also prepare you for more advanced roles as you progress. Remember, starting with an entry level CNC machine allows you to build foundational skills that can lead to greater opportunities down the line.

Educational Programs and Certifications

While practical experience is vital, formal education can significantly enhance your prospects as a Level 1 CNC machinist. Numerous community colleges and technical schools offer programs specifically designed for aspiring machinists—many even provide certifications upon completion. These programs often cover essential topics such as blueprint reading, programming basics, and safe machine operation.

You might be asking yourself: “How much is an entry level CNC machine?” Well, investing in education typically costs less than purchasing high-end machinery upfront! Moreover, obtaining certifications demonstrates your commitment and expertise to potential employers, setting you apart from other candidates who may lack formal training.

Real-World Experience Opportunities

Gaining real-world experience is crucial for anyone seeking to make their mark as a Level 1 CNC machinist. Consider internships or apprenticeships at local manufacturers; these positions often provide invaluable insights into daily operations while allowing you to work directly with experienced professionals. Additionally, many companies are willing to train individuals who show enthusiasm for learning about entry level CNC machines.

Don’t overlook online platforms offering freelance projects where you can utilize your skills—yes, you really can ask yourself: “Can you make money with a small CNC machine?” The answer is yes! By taking on small jobs or personal projects using an entry level machine like the SYIL X5, you'll not only hone your craft but also start building a portfolio that showcases your abilities.

Monetizing Your CNC Skills

In today’s digital age, the question on many aspiring machinists' minds is: can you make money with a small CNC machine? The answer is a resounding yes! Entry level CNC machines, like the SYIL X5, offer an affordable and effective way to turn your passion for machining into a profitable venture. With the right strategies and creativity, you can easily transform your skills into a sustainable income source.

Can You Make Money with a Small CNC Machine?

Absolutely! Many people have successfully turned their entry level CNC machine into a money-making asset. Whether you’re crafting custom parts or unique art pieces, there’s demand for high-quality machined products in various industries. Plus, as you gain experience and refine your skills—what is a level 1 CNC machinist if not someone who learns quickly?—you’ll discover even more lucrative opportunities.

Business Ideas for Entry Level CNC Users

If you're wondering how much an entry level CNC machine can help in launching your business ideas, consider these options: personalized gifts like engraved plaques or custom signs are always in demand. You could also venture into prototyping for local businesses needing small batch runs of parts or components. The beauty of starting with an entry level CNC machine is that it allows you to explore different niches without breaking the bank.

Maximizing Profit with Creative Projects

To truly maximize profit with creative projects using your entry level CNC machine, think outside the box! Consider creating bespoke furniture pieces or intricate home decor items that appeal to niche markets online. Additionally, leveraging social media platforms to showcase your work can attract clients and increase sales; remember that every post is an opportunity to say: “Can you make money with a small CNC machine?”

Conclusion

The world of CNC machining is brimming with opportunities, especially for those starting out with an entry level CNC machine. These machines are more than just tools; they represent a gateway into a dynamic field where creativity meets precision engineering. By exploring the potential of entry level CNC technology, individuals can unlock new avenues for innovation and productivity.

Exploring the Potential of Entry Level CNC

Entry level CNC machines serve as an excellent introduction to the world of computer numerical control machining. With capabilities that allow for versatility in project types, these machines can handle everything from simple designs to intricate prototypes. As you delve deeper into what an entry level CNC machine can do, you'll find that it not only enhances your skills but also ignites your passion for fabrication and design.

Understanding how much an entry level CNC machine costs is crucial for anyone considering this path. Prices vary widely based on features and capabilities, yet the investment often pays off in terms of skill development and creative potential. The ability to create custom pieces or prototypes opens up exciting possibilities that can lead to personal satisfaction or even entrepreneurial ventures.

Career Opportunities in CNC Machining

For those wondering what is a level 1 CNC machinist, it’s essentially someone who has just begun their journey in this field but possesses essential skills that make them valuable in various industries. Career opportunities abound—from working in manufacturing plants to specializing in custom fabrication shops—making it a versatile choice for job seekers. Moreover, as you gain experience and expertise, you’ll find numerous pathways leading to advanced positions within the industry.

If you're asking yourself how do I start a career in CNC? The answer lies in education and hands-on experience through apprenticeships or training programs. Many community colleges offer courses tailored specifically for aspiring machinists which cover everything from basic operations to advanced techniques; these are invaluable stepping stones toward building a successful career.

Start Your Journey with the SYIL X5

The SYIL X5 stands out as one of the best entry level CNC machines available today, perfect for both beginners and seasoned hobbyists alike. With its user-friendly interface and robust features, it simplifies the learning curve while providing ample room for growth as your skills develop over time. Whether you're looking to prototype new ideas or explore creative projects, starting with the SYIL X5 could be your best decision yet.

If you're curious about whether you can make money with a small CNC machine, rest assured that many have turned their passion into profit by creating unique products tailored to niche markets. From personalized gifts to small-batch production runs, there are countless business ideas waiting at your fingertips once you master your entry level CNC machine skills. So why wait? Dive into this exciting world today!