Introduction

In today's fast-paced manufacturing industry, precision and efficiency are crucial. That's where CNC metal cutting machines come into play. These advanced machines offer many benefits that revolutionize the metal cutting process.

The Benefits of Using a CNC Metal Cutting Machine

CNC metal cutting machines provide unparalleled accuracy and consistency in cutting various types of metals. They eliminate the need for manual labor, reducing human error and increasing productivity. With their automated features, these machines can easily execute complex designs, resulting in intricate and precise cuts.

SYIL CNC Machines: Affordable Metal Cutting

When it comes to affordable yet high-quality CNC metal cutting machines, SYIL Machine Tools is a name you can trust. With over 12k machines supplied globally, SYIL prioritizes quality and sustainability in their precision CNC machines for milling and drilling.

Cut Metal for Less Than $400 with a CNC Machine

Cutting metal doesn't have to break the bank. SYIL CNC machines offer cost-effective solutions that allow you to cut metal for less than $400. By combining affordability with precision, these machines make it accessible for small businesses and hobbyists alike to achieve professional-level results without compromising on quality.

With SYIL's precision CNC machines, you can elevate your metal cutting capabilities while staying within budget constraints. Embrace the efficiency and accuracy of CNC technology by choosing SYIL Machine Tools as your trusted partner in achieving exceptional results in metal fabrication.

Understanding CNC Metal Cutting

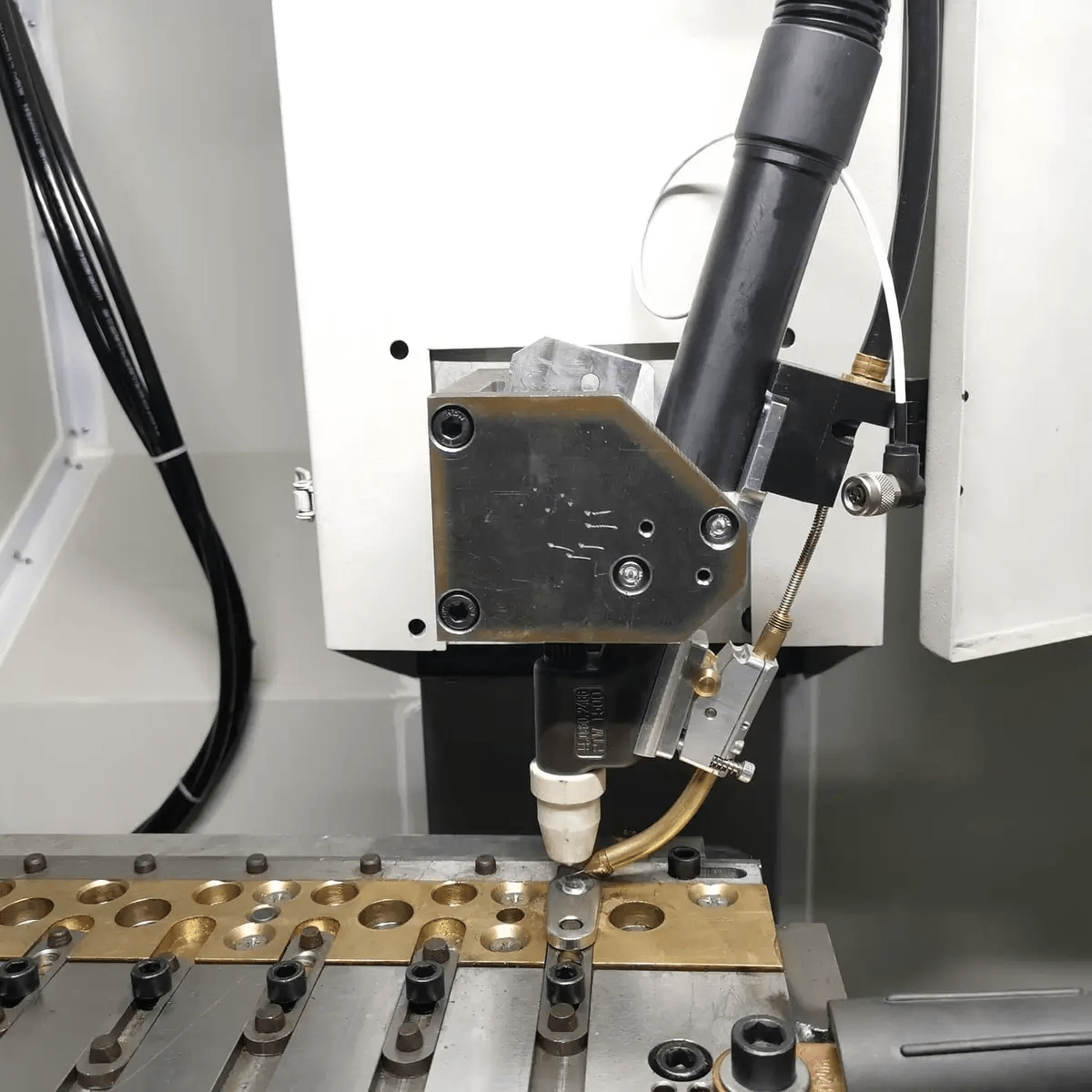

CNC cutting, also known as computer numerical control cutting, is a process that utilizes automated machines to cut and shape metal materials precisely. It works by following programmed instructions that control the movement of the cutting tool. This technology allows for high accuracy and repeatability in metal cutting processes.

One key advantage of using a CNC metal cutting machine is its ability to produce intricate and complex designs with great precision. CNC cutting's automated nature eliminates human errors and ensures consistent results, making it ideal for industries that require high-quality cuts, such as aerospace, automotive, and manufacturing.

SYIL CNC machines offer precision and quality at an affordable price. With over 12k machines supplied globally, SYIL Machine Tools has established itself as a trusted manufacturer in the industry. Their CNC metal cutting machines are designed to deliver exceptional performance while maintaining affordability.

By investing in a SYIL CNC machine, you can benefit from its advanced features, such as high-speed machining, multi-axis capabilities, and efficient tool management systems. These features enhance productivity and enable faster turnaround times for your projects.

SYIL Machine Tools understands the importance of precision in metal cutting processes. Their CNC machines are built with robust construction and utilize state-of-the-art technology to ensure accurate cuts every time. Whether you need to cut through steel, aluminum, or other metals, SYIL CNC machines can easily handle the task.

Understanding CNC metal cutting is crucial for industries that require precise and efficient fabrication processes. By utilizing a CNC cutter like those offered by SYIL Machine Tools, you can achieve exceptional results while staying within your budget. Embrace the precision and efficiency of CNC metal cutting with SYIL Machine Tools today.

Choosing the Right CNC Cutter

When selecting a CNC metal cutting machine, several factors must be considered. First and foremost, you need to determine the specific requirements of your metal cutting projects. Consider the size and thickness of the materials you will be working with and the intricacy of the cuts needed. Additionally, consider your budget and how much you are willing to invest in a CNC cutter.

SYIL CNC machines offer a wide range of options to meet your needs. Whether you are a hobbyist or a professional, they have machines suitable for various applications. From small desktop models to larger industrial-grade machines, SYIL has it all. Their machines are known for their precision and quality, ensuring accurate and clean cuts every time.

When looking for an affordable CNC cutter, you should prioritize certain features. First, consider the machine's cutting capacity and speed. Look for a cutter that can handle your desired materials efficiently without compromising quality. Additionally, check if the machine offers automatic tool changing capabilities, which can greatly improve productivity.

Another vital feature to look for is ease of use and setup. SYIL CNC machines have user-friendly setup instructions that make assembly and calibration a breeze. This ensures that even beginners can quickly start their metal cutting projects without hassle.

Choosing the right CNC cutter is crucial for successful metal cutting projects. Consider factors such as your specific requirements, budget, and desired features when making your decision. SYIL Machine Tools offers a wide range of options catering to different needs while prioritizing precision and quality in CNC machines.

Setting Up Your CNC Metal Cutting Machine

Assembling and calibrating your CNC machine is crucial in ensuring its proper functioning and accuracy. SYIL CNC machines provide user-friendly setup instructions, making the process seamless and efficient. Additionally, it is essential to follow safety precautions when operating a CNC cutter to prevent accidents and ensure the well-being of operators.

When setting up your CNC metal cutting machine, carefully assemble all the components according to the manufacturer's instructions. This may involve attaching the frame, installing the control panel, and connecting various cables and wires. Pay attention to details such as proper alignment and secure fastening to ensure stability during operation.

Once assembled, calibration is necessary to ensure precise cutting. This involves setting up the machine's coordinate system and establishing the reference point for all subsequent movements. Calibration may include homing the machine, zeroing out axes, and adjusting tool offsets. SYIL CNC machines offer intuitive calibration processes that simplify this task for users.

SYIL CNC machines provide user-friendly setup instructions that guide operators through each process step. These instructions are designed to be easily understood by users of varying experience levels. With clear diagrams and concise explanations, even beginners can set up their machines quickly and efficiently.

Safety precautions must always be observed when operating a CNC cutter. Operators should wear appropriate protective gear, such as safety glasses or goggles, to shield their eyes from flying debris. They should also keep hands clear of moving parts during operation and avoid wearing loose clothing or jewelry that could get caught in the machine.

By following proper setup procedures and adhering to safety guidelines, operators can ensure optimal performance while minimizing risks associated with operating a CNC metal cutting machine.

In conclusion, setting up a CNC metal cutting machine involves assembling and calibrating the components, following user-friendly setup instructions provided by SYIL CNC machines, and prioritizing safety precautions. Operators can achieve accurate cuts and maintain a safe working environment by doing so. SYIL Machine Tools' commitment to quality and sustainability makes them an excellent choice for those seeking precision CNC machines for metal cutting.

Tips for Efficient Metal Cutting

Maximizing the capabilities of your CNC metal cutting machine

Understanding your CNC metal cutting machine's features and functionalities is important to maximizing its capabilities. SYIL CNC machines offer advanced features that enhance efficiency and precision in metal cutting. With their high-speed spindles and rigid construction, SYIL machines can easily handle various types of metals. Their automatic tool changers also allow for seamless transitions between different cutting tools, optimizing productivity. By utilizing the full potential of your CNC machine, you can achieve faster and more accurate metal cutting results.

SYIL CNC machines: advanced features for efficient cutting

SYIL CNC machines have advanced features that contribute to efficient metal cutting. Their servo motors provide precise movement control, ensuring accurate cuts every time. The machines also have built-in coolant systems that help dissipate heat generated during the cutting process, preventing damage to both the tool and the workpiece. Moreover, SYIL machines come with user-friendly software interfaces that allow operators to easily program complex cutting paths. These advanced features make SYIL CNC machines a reliable choice for efficient metal cutting.

Optimizing tool paths and cutting strategies

Optimizing tool paths and cutting strategies is crucial to optimizing the efficiency of your metal cutting process. SYIL CNC machines offer software solutions that enable users to generate optimized tool paths based on specific requirements. These optimized tool paths can significantly improve overall productivity by minimizing unnecessary tool movements and reducing idle times. Additionally, selecting the appropriate cutting strategy based on material type and thickness can enhance efficiency. Utilizing these optimization techniques allows you to achieve faster production times while maintaining high-quality cuts.

Maximizing the capabilities of your CNC metal cutting machine is essential for efficient and precise metal cutting. SYIL CNC machines offer advanced features that enhance efficiency, such as high-speed spindles and automatic tool changers. By optimizing tool paths and cutting strategies, you can further improve productivity. With SYIL Machine Tools' commitment to quality and sustainability, their CNC machines are reliable for achieving efficient metal cutting results. Embrace the precision and efficiency of CNC metal cutting with SYIL Machine Tools.

Troubleshooting and Maintenance

When it comes to CNC metal cutting, it's important to be prepared for any issues. Understanding common problems and their solutions can help you maintain your CNC cutter's performance. SYIL CNC machines are known for their reliable performance and easy maintenance, making them a great choice for hassle-free metal cutting. Additionally, proper care and maintenance can significantly prolong your machine's lifespan.

Common Issues And Solutions in CNC Metal Cutting

CNC metal cutting offers a precise and efficient way to create complex metal parts. However, even the most advanced machines can encounter occasional issues. Here are some common problems and solutions to keep your CNC metal cutting operation running smoothly:

- Tool Breakage: This can occur due to improper tool selection (using a drill bit for milling) or excessive feed rates (pushing the tool too fast). Solution: Choose the right tool for the job and adjust feed rates to match the material and desired cut. If a tool breaks, replace it immediately to prevent further damage to the machine.

- Poor Surface Finish: Incorrect cutting parameters, such as spindle speed, feed rate, or worn-out tools, can lead to a rough cut. Solution: Ensure you have set the correct cutting parameters for the material and application. Regularly inspect your tools for signs of wear and replace them when necessary.

Addressing these common issues can help you maintain optimal performance and produce high-quality metal parts with your CNC machine.

SYIL CNC Machines: Reliable Performance and Easy Maintenance

SYIL CNC machines are designed with reliability in mind, ensuring consistent performance throughout your metal cutting operations. With over 12k machines supplied globally, SYIL Machine Tools has established itself as a trusted brand in the industry.

Thanks to their user-friendly design, SYIL CNC machines are straightforward to maintain. Operators can easily perform tasks such as lubricating moving parts and cleaning out debris without extensive technical knowledge. Additionally, SYIL provides comprehensive documentation and support to assist users in troubleshooting any issues they may encounter.

Proper Care and Maintenance For Prolonged Machine Lifespan

Regular maintenance is key to ensuring your CNC metal cutting machine operates smoothly and efficiently for years. Here's a breakdown of essential steps to take:

- Inspection and Cleaning: Regularly inspect your machine for any accumulated debris that may be hindering performance. Clean the machine thoroughly according to the manufacturer's instructions.

- Lubrication: Lubricate moving parts as recommended by the manufacturer's manual. This reduces friction and wear, ensuring smooth operation.

- Manufacturer's Maintenance Schedule: Follow the recommended maintenance schedule provided by SYIL Machine Tools. This might include checking and adjusting belt tension, inspecting electrical connections, and replacing worn-out components.

By following these simple steps and staying proactive with maintenance, you can avoid costly repairs and get the most out of your CNC metal cutter.

Conclusion

Achieving affordable metal cutting with SYIL CNC machines is now within reach for individuals and small businesses. With their precision and quality at an affordable price, SYIL CNC machines offer a cost-effective solution for cutting metal. The future of CNC metal cutting technology looks promising, with advancements in efficiency and precision. Embrace the precision and efficiency of CNC metal cutting with SYIL Machine Tools, a trusted manufacturer in the industry.