Introduction

Are you looking to take your manufacturing to the next level? Investing in a 5-axis CNC machine could be the game-changer your business needs. With its ability to move in five different axes simultaneously, this cutting-edge technology offers unparalleled precision and efficiency, revolutionizing how you approach production. But before you decide, it's crucial to understand the key features of a 5-axis CNC machine and what factors to consider when buying one.

The Benefits of Investing in a 5 Axis CNC Machine

Unleash the potential of your manufacturing with a 5-axis CNC machine. This innovative technology offers a multitude of advantages that can transform your business.

Here are the key benefits of investing in a 5-axis CNC machine:

- Boosted Productivity: By machining complex parts in a single setup, 5-axis machines significantly reduce turnaround times and streamline your workflow.

- Reduced Setup Times: Eliminate the need for multiple setups and repositioning with 5-axis machining's ability to reach all sides of a workpiece.

- Enhanced Accuracy and Surface Finish: The precise control of 5 axes ensures unmatched precision and superior surface finishes on your parts.

- Conquer Complex Designs: Fabricate intricate geometries and challenging shapes easily, thanks to the 5-axis approach to machining.

- Gain a Competitive Edge: Investing in a 5-axis CNC machine positions your business at the forefront of manufacturing technology, allowing you to take on previously impossible projects.

Embrace the future of manufacturing and unlock a new level of efficiency and precision with a 5-axis CNC machine.

Understanding the Key Features of a

5-Axis CNC Machine

A 5-axis CNC machine provides unmatched flexibility and versatility, allowing for more complex machining operations than traditional 3-axis or 4-axis machines. Its ability to move along multiple axes simultaneously enables it to reach areas that would otherwise be inaccessible, resulting in faster cycle times and higher accuracy. Understanding these key features is essential when evaluating which model suits your production needs.

What to Consider When Buying a

5-Axis CNC Machine

When purchasing a 5-axis CNC machine, several factors must be considered. It's important to weigh all options carefully, from the size and capacity that best aligns with your production requirements to the overall price range that fits within your budget. Additionally, understanding what sets different models apart and how they can benefit your business is crucial in making an informed decision.

Evaluating Your Production Needs

When evaluating your production needs for a 5-axis CNC machine, it's crucial to consider the right size and capacity for your business. With SYIL's range of 5-axis CNC machines, you can choose from compact models suitable for small workshops to larger machines designed for industrial-scale production. By understanding the space available in your facility and the volume of work you need to handle, you can decide on the size and capacity that best fits your operations.

Determining the Right Size and Capacity for Your Business

SYIL offers a variety of 5-axis CNC machines that cater to different production needs. Whether you require a small 5-axis CNC machine for intricate projects or a larger model for heavy-duty manufacturing, SYIL has options to suit your business requirements. By assessing the scope of your work and projecting future growth, you can ensure that the size and capacity of the machine align with your long-term production goals.

Assessing the Precision and Accuracy Requirements

Precision and accuracy are paramount when selecting a 5-axis CNC milling machine. SYIL's advanced technology ensures high levels of precision, allowing you to achieve intricate designs with exceptional accuracy. Whether you're working on prototypes or complex components, SYIL's 5-axis CNC machines deliver outstanding precision, resulting in superior finished products that meet even the most stringent quality standards.

Understanding the Speed and Efficiency of Different Models

In addition to precision, speed, and efficiency are key factors in evaluating a 5-axis CNC machine. SYIL's range includes models with varying spindle speeds and rapid traverse rates, enabling you to optimize production processes based on your specific requirements. Whether you need high-speed machining capabilities or efficient material removal rates, SYIL has a 5-axis CNC machine tailored to enhance productivity while maintaining exceptional quality standards.

With SYIL's comprehensive range of 5-axis CNC machines designed to meet diverse production needs, businesses can confidently invest in cutting-edge technology that maximizes efficiency without compromising precision or performance.

Researching Top Brands and Models

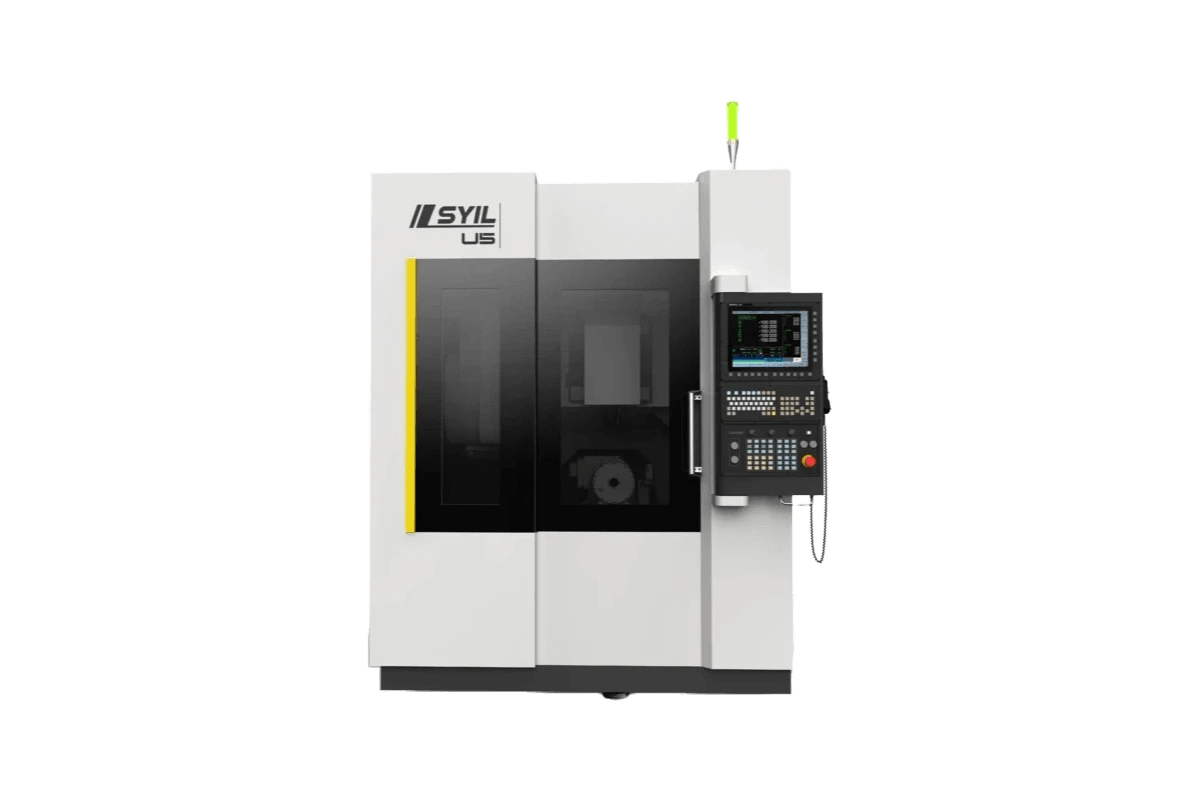

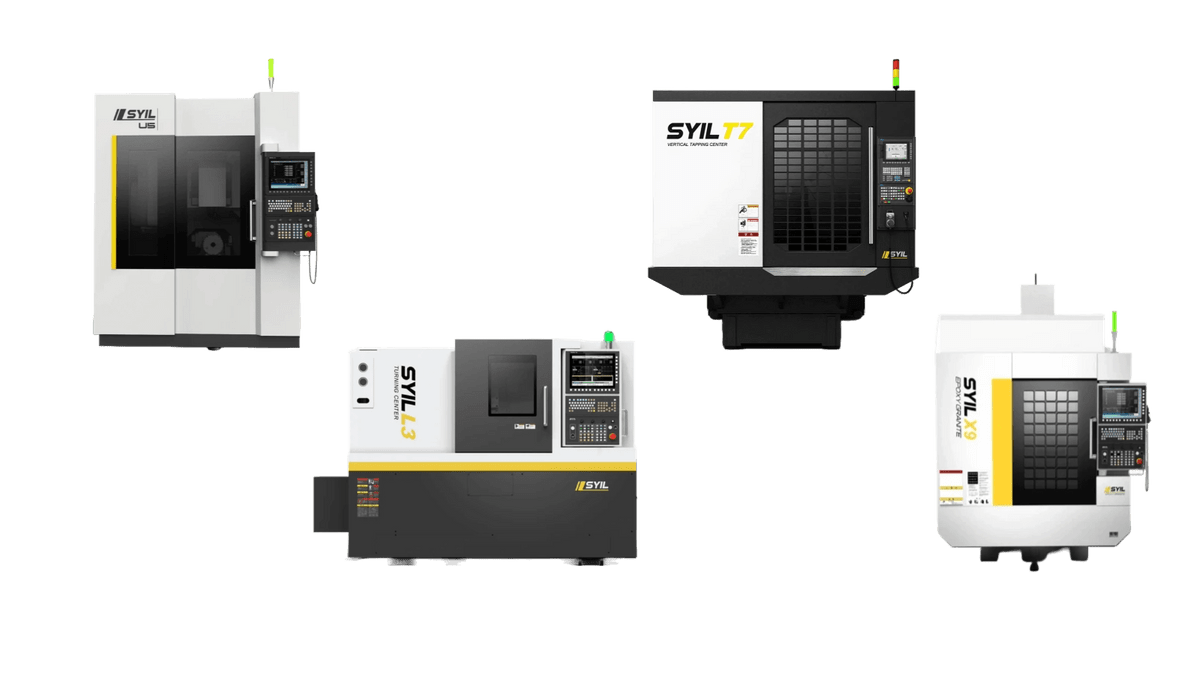

Exploring SYIL CNC Machine's Range of

5-Axis CNC Machines

Regarding 5-axis CNC machines, SYIL offers a diverse range of high-quality models designed to meet the needs of various industries. From small 5-axis CNC machines to larger industrial models, SYIL's selection ensures that businesses of all sizes can find the perfect fit for their production requirements.

Comparing Prices and Features of Different

5-Axis CNC Machines

SYIL's 5-axis CNC machine price range is competitive, offering excellent value for money without compromising on quality or performance. When comparing prices and features, it's clear that SYIL stands out as a top choice for businesses looking to invest in a reliable and efficient 5-axis CNC milling machine.

Reading Customer Reviews and Testimonials

Customer reviews and testimonials consistently praise SYIL's 5-axis CNC machines for their precision, reliability, and user-friendly design. Businesses that have invested in a SYIL 5-axis CNC machine report increased productivity, exceptional accuracy, and overall satisfaction with their purchase.

By exploring SYIL's range of 5-axis CNC machines, comparing prices and features, and reading customer reviews and testimonials, businesses can make an informed decision when investing in this advanced technology. With SYIL's reputation for quality and performance, choosing a SYIL 5-axis CNC machine is a smart investment in enhancing production capabilities.

Understanding the Total Cost of Ownership

When considering the total cost of ownership for a 5-axis CNC machine, it's crucial to factor in maintenance and service costs. SYIL CNC machines are known for their durability and reliability, which can help minimize maintenance expenses over time. Additionally, regular servicing by experienced technicians ensures optimal performance and longevity for your investment.

Factoring in Maintenance and Service Costs

SYIL's range of 5-axis CNC machines is designed with longevity in mind, reducing the frequency and cost of maintenance. With high-quality components and precision engineering, these machines are built to withstand heavy usage without compromising on performance. By investing in a SYIL 5-axis CNC machine, you can minimize ongoing maintenance costs while maximizing productivity and efficiency.

Exploring Financing Options for Your

5-Axis CNC Machine

SYIL offers flexible financing options to make owning a 5-axis CNC machine more accessible for businesses of all sizes. Whether you're looking to purchase outright or explore lease-to-own arrangements, financing solutions are available to suit your specific budget and requirements. This makes it easier for businesses to invest in cutting-edge technology without straining their financial resources.

Calculating the Return on Investment for Your Purchase

Investing in a SYIL 5-axis CNC machine is not just an expense – it's an opportunity to enhance your production capabilities and drive profitability. By calculating the return on investment (ROI) based on increased productivity, precision, and reduced lead times, businesses can quantify the long-term benefits of integrating a 5-axis CNC machine into their operations. With SYIL's reputation for quality and performance, the ROI on these machines often exceeds expectations.

Businesses can make informed decisions that drive growth and success by carefully considering maintenance costs, exploring financing options, and calculating ROI when purchasing a 5-axis CNC machine from SYIL.

Choosing the Right Supplier

When it comes to investing in a 5-axis CNC machine, finding a reputable and reliable supplier is crucial. Look for a supplier with a proven track record of delivering high-quality machines at competitive prices. SYIL CNC Machine is a top choice, offering a wide range of 5-axis CNC machines to suit different production needs.

Finding a Reputable and Reliable CNC Machine Supplier

When searching for a supplier, consider factors such as industry experience, customer reviews, and the range of machines offered. SYIL CNC Machine is a trusted supplier known for its commitment to quality and customer satisfaction. With an extensive selection of 5-axis CNC machines, they can cater to various business requirements.

Evaluating After-Sales Support and Warranties

After-sales support, and warranties are essential when purchasing a 5-axis CNC machine. Choose a supplier that offers comprehensive support services and generous warranty packages. SYIL CNC Machine provides excellent after-sales support, ensuring customers can access technical assistance and maintenance services when needed.

Ensuring On-Time Delivery and Installation Services

Timely delivery and professional installation services are critical for minimizing downtime and maximizing productivity. When you choose SYIL CNC Machine as your supplier, you can expect on-time delivery of your 5-axis CNC machine and expert installation assistance to ensure seamless integration into your production workflow.

By partnering with SYIL CNC Machine as your supplier for a 5-axis CNC machine, you can be confident in receiving top-notch equipment and exceptional customer service throughout the purchasing process and beyond.

Optimizing Your Workspace for a 5 Axis CNC Machine

When planning for space, power, and safety requirements for your 5-axis CNC machine, consider the size and layout of your workshop to ensure enough room for the machine and its operation. Additionally, you must assess the power supply needed to run the machine efficiently and safely. Safety measures such as proper ventilation and protective gear should also be considered to create a secure working environment for your team.

Planning for Space, Power, and Safety Requirements

Setting up your workshop for a 5-axis CNC machine requires planning to optimize its performance and ensure safety. Here are some key considerations:

- Ample Workspace: Provide sufficient space around the machine for operation and maintenance. You'll need room to load materials, maneuver tools, and perform routine cleaning.

- Reliable Power Source: Ensure a power supply meets the machine's energy demands. These machines can be power-hungry, so consult an electrician to ensure your workshop has the appropriate capacity.

- Proper Ventilation: Implement adequate ventilation systems to remove dust and fumes. Dust particles can irritate the lungs and pose a fire hazard, while fumes from certain materials can be toxic.

- Safety Equipment: Provide your team with necessary personal protective equipment (PPE). Depending on the specific materials and processes used, this may include safety glasses, ear protection, respirators, and gloves.

Following these guidelines, you can create a safe and efficient workspace that allows your 5-axis CNC machine to thrive.

Training Your Team for Efficient Operation and Maintenance

To maximize the efficiency of your 5-axis CNC machine, it's important to invest in training programs that will equip your team with the skills needed to operate and maintain the equipment effectively. Proper training will enhance productivity and minimize downtime due to operational errors or maintenance issues. SYIL offers comprehensive training resources to ensure your team is well-prepared to confidently handle their 5-axis CNC milling machine.

Integrating Your

5-Axis CNC Machine into Your Production Workflow

Integrating a 5-axis CNC machine into your production workflow requires careful planning and coordination with existing processes. Consider how this advanced technology can streamline production tasks while maintaining quality standards. SYIL's range of 5-axis CNC machines offers seamless integration capabilities, allowing you to optimize your production workflow without disrupting existing operations.

SYIL's range of 5-axis CNC machines provides unmatched precision and efficiency at competitive prices, making them an ideal choice for businesses looking to elevate their manufacturing capabilities. By carefully planning space, power, and safety requirements, training your team effectively, and integrating this advanced technology into your production workflow, you can unlock the full potential of a 5-axis CNC machine while maximizing efficiency in your operations.

Maximize Efficiency and Precision with the Right 5 Axis CNC Machine

Investing in a 5-axis CNC Machine can be a game-changer for your business, and making an informed decision is essential. By carefully evaluating your production needs, researching top brands and models, understanding the total cost of ownership, choosing the right supplier, and optimizing your workspace, you can unlock your business's potential with the right 5-axis CNC Machine.

Making an Informed Decision for Your 5 Axis CNC Machine Purchase

When considering purchasing a 5-axis CNC Machine, it's crucial to weigh the benefits against the price. SYIL CNC Machines offer a range of options at competitive prices, ensuring that you get the best value for your investment. With their advanced features and precision engineering, SYIL's 5-axis CNC Machines are designed to meet the demands of modern manufacturing.

Unlocking the Potential of Your Business with a

5-Axis CNC Machine

A 5-axis CNC Machine opens up endless possibilities for your business by enabling complex and intricate machining operations. Whether in aerospace, automotive, or any other industry requiring high-precision parts production, a 5-axis CNC Milling Machine can take your business to new heights. SYIL's small 5-axis CNC machine is perfect for businesses looking to maximize efficiency without compromising quality.

With its advanced capabilities and versatility, a 5-axis CNC machine offers unparalleled speed and accuracy in machining complex parts. SYIL's range of 5-axis CNC machines ensures maximum efficiency and precision in every operation. By investing in the right equipment from a reputable supplier like SYIL, you can stay ahead of the competition and achieve remarkable results.