Introduction

In CNC machining, spindle manufacturing is crucial for ensuring efficiency and optimal performance. A high-quality spindle is essential for the smooth operation of milling and drilling processes, making it a key component in CNC machines. SYIL Machine Tools, a leading manufacturer in the industry, understands the significance of spindle manufacturing and prioritizes both quality and sustainability in its products.

The Importance of Spindle Manufacturing in CNC Machine Efficiency

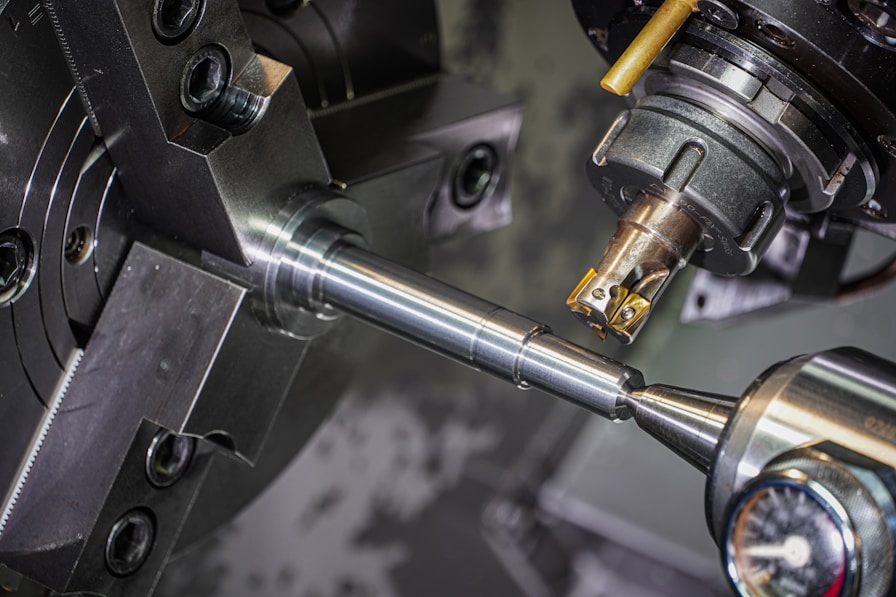

CNC machines are the workhorses of modern manufacturing, but their efficiency hinges on a crucial component: the spindle. This part rotates the cutting tool and transmits power, allowing for precise milling and drilling. Here's how high-quality spindle manufacturing contributes to overall CNC machine performance:

- Smooth Motion and Reduced Vibration: A well-made spindle minimizes friction and maintains perfect balance, leading to smoother tool rotation and less vibration. This translates to cleaner cuts and improved surface finishes on your workpieces.

- High Precision and Accuracy: Tight tolerances and robust spindle construction ensure the cutting tool moves exactly as programmed. This minimizes errors and guarantees consistent, high-precision results for every part you produce.

- Increased Productivity and Reduced Downtime: Reliable spindles are less prone to breakdowns and require less maintenance. This translates to fewer production delays and keeps your CNC machine running smoothly for longer stretches.

By investing in well-manufactured spindles, you're investing in your CNC machines' overall efficiency and productivity.

How SYIL Machine Tools Prioritize Quality and Sustainability

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their commitment to excellence is reflected in their meticulous approach to spindle manufacturing. They understand that durable spindles improve machine performance and reduce waste by minimizing downtime due to repairs or replacements.

The Role of Spindle Manufacturer in CNC Machine Performance

The Function of a Spindle in Milling and Drilling Processes

The spindle is a critical component in CNC machines, particularly in milling and drilling. The rotating axis holds the cutting tool, allowing it to spin at high speeds while maintaining stability and precision. By securely gripping the tool, the spindle ensures efficient material removal and precise shaping of workpieces. Without a reliable spindle, the performance of milling machines would be severely compromised.

Key Factors Affecting CNC Machine Efficiency

Several factors influence the efficiency of CNC machines, with the spindle being one of the most significant ones. The quality and design of the spindle directly impact cutting speed, accuracy, and surface finish. Factors such as spindle speed, power transmission capability, vibration reduction, and thermal stability are crucial in determining overall machine efficiency. Choosing a reputable spindle manufacturer with expertise in optimizing these factors is essential for achieving optimal machine performance.

SYIL's Commitment to Precision and Reliability

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling applications. With over 12k machines supplied globally, they prioritize quality and sustainability. SYIL understands that precision is paramount regarding spindles' performance in CNC machines. Their commitment to using advanced technologies ensures that their spindles deliver exceptional accuracy, reliability, and longevity.

Understanding the Different Types of Spindles

1. Milling Spindles: Enhancing Cutting Performance

Milling spindles are crucial in CNC machines, as they enhance cutting performance. These spindles are designed to rotate at high speeds and provide the necessary power to remove material efficiently during milling processes. With SYIL Machine Tools' precision CNC machines, the milling spindles are engineered to deliver exceptional performance, ensuring smooth and accurate cuts every time.

2. Spindle Shaft: Transmitting Power and Reducing Vibration

The spindle shaft is another essential component of a CNC machine's spindle system. It is the main power transmission element, transferring rotational energy from the motor to the cutting tool. Additionally, it plays a vital role in reducing vibration during machining operations, resulting in improved surface finishes and extended tool life. SYIL's CNC machines feature high-quality spindle shafts carefully designed for optimal power transmission and minimal vibration.

3. Spindle Tool: Versatile Solutions for Various Applications

The spindle tool is a versatile component that allows CNC machines to perform various applications beyond milling and drilling. It enables the use of different tools such as taps, reamers, and countersinks, expanding the machine's capabilities for diverse machining tasks. SYIL Machine Tools offers a wide range of spindle tools that can be easily interchanged, allowing users to easily adapt their CNC machines to different projects.

4. Grinding Spindles: Achieving High Precision and Surface Quality

Grinding spindles are designed for precision grinding operations requiring exceptionally smooth surfaces and tight tolerances. These spindles provide high rotational speeds and precise control over grinding forces, resulting in superior workpiece surface quality. SYIL's CNC machines incorporate grinding spindles that ensure exceptional accuracy and surface finishes, making them ideal for applications that demand the highest level of precision.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC machines are equipped with high-performance spindles, including milling spindles for enhanced cutting performance, spindle shafts for power transmission and vibration reduction, versatile spindle tools for various applications, and grinding spindles for high precision and surface quality. Trust SYIL as your partner in precision CNC machining to harness the power of spindle manufacturing for optimal performance.

Factors to Consider When Choosing a Spindle Manufacturer

Several factors should be considered when selecting a spindle manufacturer for your CNC machine to ensure optimal performance and efficiency.

1. Quality Standards and Certifications

One crucial aspect is the manufacturer's adherence to quality standards and certifications. A reputable spindle manufacturer will have certifications such as ISO 9001, guaranteeing their manufacturing processes meet international quality management standards. By choosing a manufacturer with these certifications, you can be confident in the quality and reliability of their spindle solutions.

2. Customization Options for Specific Requirements

Every CNC machine has unique requirements based on its intended applications. Therefore, choosing a spindle manufacturer that offers customization options is essential. Whether you need specific dimensions, power ratings, or specialized features, a manufacturer like SYIL Machine Tools can tailor their spindles to meet your specific needs. This level of customization ensures that your CNC machine operates at its highest efficiency.

3. Durability and Longevity of Spindle Solutions

Durability and longevity are critical factors when selecting a spindle manufacturer. The lifespan of the spindle directly impacts the overall efficiency and productivity of your CNC machine. A reliable manufacturer will use high-quality materials and advanced manufacturing techniques to create durable spindles capable of withstanding demanding milling or drilling processes without compromising performance.

SYIL's Extensive Experience in the CNC Machine Industry

When choosing a spindle manufacturer, considering their experience in the CNC machine industry is vital. SYIL Machine Tools has over 12k machines supplied globally, showcasing their expertise in precision CNC machining solutions. With years of experience, they understand the intricacies of spindle manufacturing and can provide reliable solutions that enhance the efficiency of your CNC machine.

How Spindle Manufacturing Impacts CNC Machine Efficiency

Spindle manufacturing plays a crucial role in determining the efficiency of CNC machines, such as milling machines. Enhancing spindle speed and power can enhance productivity, resulting in faster and more accurate machining processes.

Optimizing Spindle Speed and Power for Enhanced Productivity

One key factor impacting CNC machine efficiency is spindle speed. The spindle manufacturer must carefully design and manufacture spindles that can operate at high speeds without compromising accuracy or stability. By utilizing advanced technologies and materials, SYIL Machine Tools ensures that its milling machine spindles are capable of achieving optimal speed for maximum productivity.

In addition to speed, power is another essential aspect of spindle manufacturing. A powerful spindle allows efficient material removal rates, reduces machining time, and increases overall productivity. SYIL's commitment to quality ensures that its spindles deliver the necessary power while maintaining precision and reliability.

By optimizing both speed and power, SYIL's CNC machines equipped with high-quality spindles can complete machining operations more quickly, improving efficiency and reducing production times.

Maintaining Spindle Accuracy and Stability for Consistent Results

Another critical factor in CNC machine efficiency is the accuracy and stability of the spindle during operation. The spindle manufacturer must ensure that their products can maintain precise tolerances over extended periods of use.

SYIL understands the importance of spindle accuracy for achieving consistent results in milling processes. Their milling machine spindles are designed precisely, utilizing advanced bearing systems and rigid construction to minimize runout and vibration.

SYIL's spindles maintain excellent accuracy throughout the machining process by reducing runout and vibration, resulting in high-quality finished products with tight tolerances. This level of consistency is crucial for industries such as aerospace or automotive, where precision is paramount.

SYIL's Focus on Efficiency and Performance Improvement

SYIL Machine Tools is a trusted spindle manufacturer dedicated to continuously improving the efficiency and performance of its CNC machines. It invests in research and development to stay at the forefront of spindle technology and materials.

By incorporating advancements in spindle technology, such as ceramic bearings or hybrid designs, SYIL's spindles offer improved speed, power, and durability performance. These advancements enhance efficiency by reducing machining time while maintaining accuracy and stability.

SYIL also focuses on sustainability in its manufacturing processes. By utilizing eco-friendly materials and energy-efficient production methods, they minimize their environmental impact without compromising the quality or performance of their spindles.

The Future of Spindle Manufacturing and CNC Machines

Advancements in Spindle Technology and Materials

In the ever-evolving world of CNC machines, spindle technology continues to push boundaries and redefine possibilities. As a leading spindle manufacturer, SYIL Machine Tools stays at the forefront of these advancements, ensuring their customers benefit from cutting-edge technology.

One significant advancement is the development of high-speed milling spindles. These spindles allow for faster feed rates, increasing productivity and reducing machining time. SYIL's expertise in milling machine spindle manufacturing allows them to provide customers with these advanced solutions to enhance their machining capabilities.

Another area where advancements are being made is the materials used for spindle shafts. By utilizing innovative materials such as ceramic or carbon fiber composites, manufacturers can achieve higher stiffness and lower weight, resulting in improved performance and reduced vibration. SYIL understands the importance of these developments and incorporates them into its spindle manufacturing processes to deliver superior-quality products.

Industry Trends and Innovations Shaping CNC Machines

The CNC machine industry constantly evolves, driven by technological advancements and changing market demands. One significant trend is the increasing demand for multi-axis machining capabilities. Manufacturers are now looking for machines that can perform complex operations with fewer setups, saving time and increasing efficiency. SYIL Machine Tools offers a range of spindles specifically designed for multi-axis machining applications to meet this demand.

Another trend shaping CNC machines is the integration of automation and smart technologies. Manufacturers are embracing automation to improve productivity and reduce human error. SYIL understands this shift towards automation and develops spindles that seamlessly integrate with automated systems, allowing for efficient operation and enhanced overall performance.

SYIL's Sustainable Approach to Manufacturing and Development

As an advocate for sustainability, SYIL Machine Tools takes a responsible approach to manufacturing and development. They prioritize energy efficiency by incorporating advanced spindle designs that minimize power consumption without sacrificing performance. This commitment to sustainability benefits the environment and helps customers reduce their operational costs.

Choosing the Right Spindle Manufacturer for CNC Machine Efficiency

When optimizing CNC machine efficiency, selecting the right spindle manufacturer is crucial. The spindle plays a significant role in the performance of milling and drilling processes, affecting factors such as cutting performance, power transmission, vibration reduction, precision, and surface quality.

SYIL Machine Tools: A Trusted Partner in Precision CNC Machining

SYIL Machine Tools has established itself as a trusted partner in precision CNC machining. With its commitment to quality and sustainability, it has become a leader in the industry. With over 12k machines supplied globally, SYIL prioritizes delivering high-quality products that meet customer requirements.

Harnessing the Power of Spindle Manufacturing for Optimal Performance

CNC machines can achieve optimal performance by harnessing the power of spindle manufacturing. Spindles with optimized speed and power enhance productivity by reducing machining time. Maintaining spindle accuracy and stability ensures consistent results, improving overall efficiency.

In conclusion, selecting a reputable spindle manufacturer is vital for maximizing CNC machine efficiency. SYIL Machine Tools stands out as a reliable partner in precision CNC machining. Their focus on quality and sustainability ensures customers receive high-performing machines tailored to their specific requirements. By leveraging advanced spindle manufacturing techniques, SYIL empowers businesses to achieve optimal performance and stay ahead in today's competitive market.