Introduction

In the ever-evolving world of manufacturing, the 4 axis CNC machine stands out as a game changer, offering versatility that transforms how we approach complex machining tasks. As industries demand precision and efficiency, understanding what is 4-axis CNC becomes crucial for those looking to enhance their production capabilities. With its ability to perform intricate cuts and designs, the 4 axis CNC router has become an essential tool in various sectors, pushing the boundaries of traditional machining.

Exploring the Versatility of 4 Axis CNC

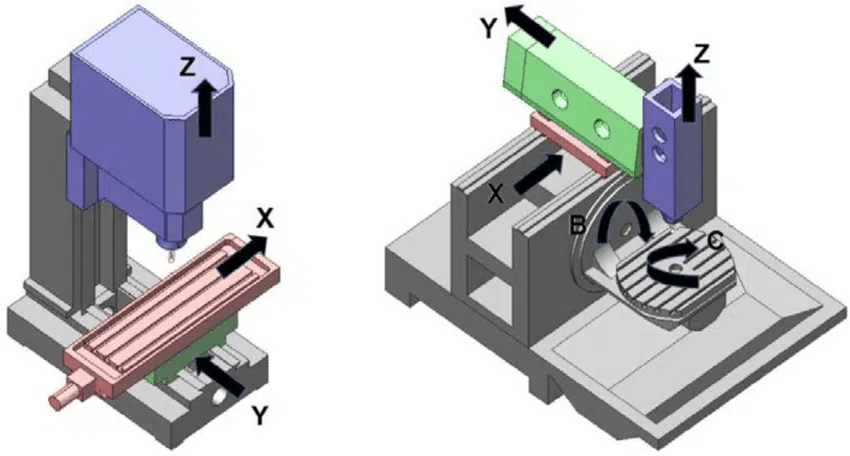

The versatility of 4 axis CNC technology is a significant draw for manufacturers seeking to optimize their operations. Unlike its 3-axis counterpart, which can only move along three linear axes (X, Y, and Z), a 4 axis CNC machine adds an additional rotational axis—allowing for more complex geometries and angles to be machined with ease. This added functionality opens up new possibilities for creating intricate designs that would otherwise be difficult or impossible with a standard setup.

The Advantages Over 3 Axis CNC Machining

When comparing what is the difference between 3-axis and 4-axis CNC machines, several advantages come to light. The primary benefit lies in efficiency; a 4-axis system can complete tasks in fewer setups by allowing workpieces to be rotated during machining—resulting in time savings and improved accuracy. Furthermore, this capability reduces manual handling of parts, minimizing potential errors while enhancing overall production speed.

Applications That Benefit from 4 Axis CNC

Various industries have embraced the capabilities of 4 axis CNC technology due to its adaptability across numerous applications. From aerospace components requiring precise tolerances to custom jewelry design where intricate detailing is paramount, the versatility of these machines shines through. Additionally, automotive manufacturing relies heavily on this technology for producing complex parts that meet stringent quality standards—demonstrating just how beneficial a robust tool like a 4 axis CNC router can be.

What is 4 Axis CNC?

When diving into the world of CNC machining, the term 4 axis CNC often pops up, and for good reason. It represents a significant evolution from traditional 3-axis CNC machines, allowing for more intricate designs and complex geometries. But what exactly is 4-axis CNC? Let’s break it down.

Understanding the Basics

At its core, a 4 axis CNC machine adds an additional rotational axis to the standard three linear axes found in conventional machines. This extra axis allows for movement around the X, Y, and Z axes while simultaneously rotating the workpiece or tool on a fourth axis—typically referred to as the A-axis. This capability opens up a whole new realm of possibilities for creating detailed parts that would be challenging or impossible with just a 3-axis setup.

Understanding what is 4-axis CNC means recognizing its role in enhancing productivity and precision in manufacturing processes. It’s especially beneficial for industries requiring complex shapes or features that need to be machined from multiple angles without having to reposition the workpiece repeatedly. In summary, 4-axis machining streamlines operations by reducing setup times and improving accuracy.

How 4 Axis CNC Machines Operate

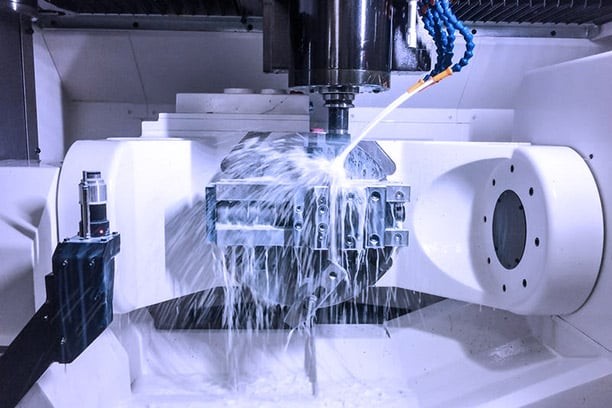

The operation of a 4 axis CNC machine involves sophisticated programming that coordinates all four axes during machining processes. The machine interprets G-code instructions, which dictate movements along each axis while managing tool paths effectively. This integration allows for seamless transitions between different machining operations—like drilling holes at various orientations or contouring complex surfaces.

Unlike traditional machines where operators might need to pause and reposition components manually, a 4 axis CNC router can handle tasks autonomously once programmed correctly. This not only speeds up production but also minimizes human error—a win-win situation in any manufacturing environment! As we delve deeper into what is the difference between 3-axis and 4-axis CNC machines, it becomes clear how this added functionality can significantly enhance operational efficiency.

Key Features of 4 Axis CNC

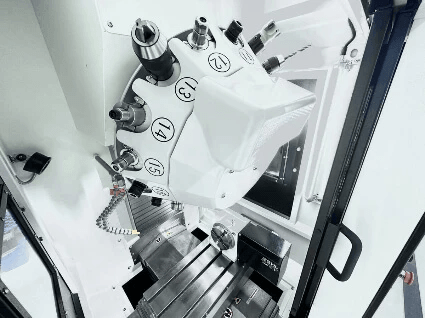

Several key features distinguish a typical 4 Axis CNC from its less advanced counterparts. First off, the ability to rotate around an additional axis allows users to achieve undercuts and intricate details that are simply unattainable with only three axes at play. Moreover, many modern models come equipped with advanced software capabilities that facilitate easier programming through user-friendly interfaces.

Another notable feature includes enhanced tooling options; many manufacturers provide specialized tools designed specifically for use with their machines—enabling users to tackle diverse materials ranging from metals to plastics seamlessly. Additionally, when considering factors like price versus performance in relation to features such as speed and precision—it's evident why investing in quality equipment like SYIL's offerings can yield substantial returns over time.

In conclusion, understanding what is 5-axis CNC technology further expands on this topic by showcasing even more advanced capabilities available today; however, mastering the fundamentals of a robust and versatile system like a 4 Axis CNC remains essential for anyone looking to elevate their machining game!

What is the Difference Between 3-Axis and 4-Axis CNC Machines?

Both types of machines serve distinct purposes, yet the leap from 3-axis to 4-axis CNC opens up a world of enhanced functionality. In this section, we will delve into their movement capabilities, efficiency in complex designs, and cost considerations.

Comparing Movement Capabilities

The primary distinction between a 3-axis CNC and a 4-axis CNC machine lies in their movement capabilities. A 3-axis system operates along three linear axes—X, Y, and Z—allowing for horizontal and vertical cuts on flat surfaces. In contrast, a 4-axis CNC adds an additional rotational axis (often referred to as the A-axis), enabling the machine to rotate around one of its existing axes for more intricate shapes and features.

This added rotation capability allows for more complex machining operations that would be impossible or highly inefficient with just three axes. For instance, while a 3-axis system can create simple parts like brackets or plates, a 4 axis CNC router can handle cylindrical components or multi-sided parts without requiring multiple setups or fixtures. This flexibility makes the transition from what is 4-axis CNC to implementing it in practical applications an exciting venture for manufacturers seeking precision.

Efficiency in Complex Designs

When discussing efficiency in complex designs, it's clear that moving from a standard setup to what is the difference between a 3-axis and 4-axis CNC machine offers substantial benefits. The ability of a 4 axis CNC machine to perform simultaneous operations on multiple sides of a workpiece drastically reduces production time compared to traditional methods that might require repositioning or re-clamping parts during machining.

Moreover, this increased efficiency translates directly into cost savings over time by minimizing labor hours needed for setup and reducing material waste through more precise cuts. Industries focusing on intricate designs—like aerospace components or custom jewelry—find that leveraging the advanced capabilities of a 4 axis CNC router enhances both quality and speed without sacrificing accuracy.

Cost Considerations

Cost is always an essential factor when deciding between different types of machinery; thus understanding how it plays into your choice between these two systems is crucial. Generally speaking, while the initial investment for a quality 4 Axis CNC machine price may be higher than that of its 3-axis counterpart, the long-term benefits often outweigh these initial costs.

Investing in what is now widely recognized as superior technology means not only enhanced productivity but also lower operational costs due to reduced cycle times and less material waste over time. Additionally, businesses looking at future scalability may find that opting for advanced machines like those equipped with both four- and five-axes (yes folks! Is there even such thing as a seven axis CNC machine?) positions them better against competitors who are still using outdated methods.

Real-World Applications of 4 Axis CNC Machining

The versatility of 4 axis CNC machining has led to its widespread adoption across various industries. From the aerospace sector, where precision is paramount, to the intricate world of custom jewelry design, the applications are as diverse as they are innovative. Understanding these real-world applications can help businesses leverage the full potential of a 4 axis CNC machine.

Aerospace Industry Innovations

In the aerospace industry, innovations are driven by the need for lightweight yet durable components that meet strict safety standards. 4 axis CNC machines excel in producing complex geometries that are often required in aircraft components, such as turbine blades and structural parts. With their ability to handle multi-dimensional designs, these machines ensure high precision and efficiency in manufacturing processes.

Moreover, using a 4 axis CNC router allows for enhanced flexibility when creating prototypes or small batches of specialized parts. This capability is crucial in an industry where rapid advancements demand quick turnaround times without compromising quality. As aerospace technology continues to evolve, so does the reliance on advanced machining solutions like 4 axis CNC.

Automotive Component Manufacturing

The automotive sector also benefits significantly from 4 axis CNC machining by enabling manufacturers to create intricate components with ease and accuracy. What is 4-axis CNC? Simply put, it refers to machines capable of moving along four different axes—three linear axes plus one rotational axis—allowing for complex part designs that traditional methods struggle with. This capability translates into improved performance and reduced weight for automotive parts.

Additionally, manufacturers can streamline their production processes by utilizing a single setup on a 4 axis CNC machine instead of multiple setups needed for a standard 3-axis system. This efficiency not only saves time but also minimizes material waste—an essential consideration in today’s eco-conscious market. The automotive industry’s embrace of this technology demonstrates its vital role in enhancing both productivity and innovation.

Custom Jewelry Design

Custom jewelry design is another area where 4 axis CNC machining shines brightly, allowing artisans to transform creative visions into reality with precision and flair. Jewelers can use a 4 axis CNC machine to carve intricate patterns into precious metals or stones that would be nearly impossible to achieve by hand alone. The ability to produce highly detailed designs makes it an invaluable tool for creating bespoke pieces tailored to individual client preferences.

What is the difference between a 3-axis and a 4-axis CNC machine? While both types have their merits, the added rotational movement offered by a fourth axis enables jewelers to work on multiple facets simultaneously—resulting in faster production times without sacrificing detail or quality. As demand for unique jewelry continues to rise, integrating advanced technologies like a 4 axis cnc router becomes increasingly essential for staying competitive in this artistic field.

Exploring 5-Axis CNC Technology

When it comes to CNC machining, the evolution from 4-axis to 5-axis technology represents a significant leap forward in precision and versatility. While 4-axis CNC machines have revolutionized various industries, the introduction of 5-axis CNC provides even more capabilities for complex designs and intricate shapes. This section will dive into what exactly constitutes a 5-axis CNC machine, its advantages over its predecessor, and where it's typically utilized.

What is 5-Axis CNC?

So, what is 5-axis CNC? In simple terms, it's a type of machining that allows for movement along five different axes simultaneously—X, Y, Z, and two rotational axes (A and B). This capability enables the cutting tool to approach the workpiece from virtually any angle, enhancing precision and reducing setup time. Unlike traditional setups that might require multiple fixtures or repositioning of the workpiece—common in both 3-axis and even 4-axis CNC operations—5-axis systems streamline production processes significantly.

Advantages of 5-Axis Over 4 Axis CNC

The advantages of using a 5-axis CNC machine over a standard 4 Axis CNC are substantial. First off, it offers greater flexibility in design; intricate geometries can be achieved with minimal part handling or repositioning. Additionally, because the cutting tools can access more angles during machining processes, manufacturers often see improved surface finishes and reduced cycle times—making it not just an upgrade in capability but also an enhancement in efficiency.

Moreover, while considering factors such as cost versus performance when looking at your options between a 4 axis cnc router or a full-fledged 5-axis system might seem daunting at first glance; users often find that increased productivity offsets higher initial investments over time.

Typical Use Cases for 5-Axis CNC

So where does this advanced technology shine? Typical use cases for a 5-axis CNC include aerospace components where precision is paramount; automotive parts that require complex geometries; and custom tooling applications that demand high levels of accuracy. Industries like medical device manufacturing also benefit greatly from this technology due to the intricate details required in their products.

Considerations for 4 Axis CNC Machine Price

When diving into the world of 4-axis CNC machines, understanding the price tags attached can be a bit of a maze. The cost of a 4-axis CNC machine isn’t just a number; it reflects various factors such as capabilities, precision, and even brand reputation. As you explore what is 4-axis CNC technology, keep in mind that investing in these machines can lead to significant advancements in your machining processes.

Factors Influencing Pricing

Several elements come into play when determining the price of a 4-axis CNC router or machine. Firstly, the complexity of the machine itself plays a huge role; more advanced features often mean higher costs. Additionally, brand reputation and customer support services can also influence pricing—premium brands may charge more due to their reliability and after-sales service.

Another key factor is the level of automation integrated within the machine. A fully automated 4-axis CNC system will typically carry a heftier price tag compared to manual or semi-automated options. Lastly, materials used in construction and additional features like software packages will also affect overall costs; high-quality components usually reflect higher prices but can lead to better performance and longevity.

Analyzing Cost vs. Benefit

When considering whether to invest in a 4-axis CNC machine, it's crucial to weigh cost against potential benefits comprehensively. While you might find lower-priced options on the market, they may not offer the same efficiency or versatility that comes with more expensive models. Understanding what is the difference between 3-axis and 4-axis CNC machines can help you appreciate why some machines command higher prices—they provide enhanced capabilities for complex designs.

Moreover, consider how much time and labor savings you could achieve with superior machinery; faster production times often translate into increased profits over time. For businesses focused on custom projects or intricate designs—like those found in aerospace or jewelry—investing in quality equipment pays off significantly by improving precision and reducing waste.

Investment in Quality: SYIL CNC Machines

When it comes to choosing reliable machinery, SYIL has made quite an impression in the realm of 4 axis CNC solutions. Known for their robust build quality and innovative design features, SYIL's offerings provide excellent value for both small shops and large manufacturers alike. Investing in quality means fewer breakdowns and maintenance costs down the line—a vital consideration when evaluating your options.

With SYIL's range of products tailored specifically for diverse applications—from automotive parts to intricate jewelry design—you'll find that their pricing reflects not just functionality but also durability and support services that enhance user experience over time. If you're curious about what is 5-axis CNC technology as well, SYIL offers models that expand beyond just four axes while maintaining competitive pricing structures.

In conclusion, while exploring your options for purchasing a 4 axis CNC machine or router, remember that upfront costs are only part of the equation; long-term benefits are where true value lies.

Conclusion

In the ever-evolving world of manufacturing, CNC technology continues to push the boundaries of what is possible. The future of CNC machining looks promising, with advancements in automation and precision driving innovations across various industries. As we explore new technologies, such as 5-axis CNC and even 7-axis machines, the versatility and efficiency of systems like 4 axis CNC will remain at the forefront.

The Future of CNC Machining

The future is bright for 4 axis CNC machines, as they offer enhanced capabilities that are increasingly in demand. With industries constantly seeking ways to improve production efficiency and reduce costs, understanding what is 4-axis CNC becomes crucial for businesses looking to stay competitive. As manufacturers embrace smart technology and IoT integration, 4 axis CNC solutions will play a pivotal role in shaping the next generation of machining.

Why Opt for 4 Axis CNC Solutions

Choosing a 4 axis CNC machine can be a game-changer for many companies involved in complex manufacturing processes. What is the difference between a 3-axis and a 4-axis CNC machine? The added rotational capability allows for more intricate designs without needing multiple setups or additional fixtures, making it an ideal choice for those who value precision and efficiency. Additionally, when considering options like a 4 axis cnc router, users can achieve superior results with less time spent on retooling.

Making Informed Decisions in CNC Tools

When investing in machinery like a 4 axis CNC machine or exploring its price points, it's essential to weigh cost against benefits carefully. By analyzing factors such as production needs and potential ROI, businesses can make informed decisions that align with their operational goals. Whether you're contemplating upgrading to a more advanced system or just starting with basic models like those found in the realm of what is 5-axis CNC technology, thorough research will guide you toward optimal choices.