Introduction

CNC machines have revolutionized the manufacturing industry, providing unprecedented precision and efficiency. This article will explore the different types of CNC machines and their significance in various industries. We will also briefly examine SYIL Machine Tools, a leading manufacturer in this field. Let's dive in and discover the world of CNC machines!

Overview of CNC Machines

CNC stands for Computer Numerical Control, which refers to the automation of machine tools through computer programming. These machines can execute complex tasks with high precision and repeatability, making them indispensable in modern manufacturing processes.

Importance of CNC Machines in Various Industries

CNC machines are vital across multiple industries, including automotive, aerospace, electronics, and medical equipment manufacturing. Their ability to produce intricate parts with minimal human intervention ensures consistent quality and reduces production time.

Brief mention of SYIL Machine Tools and its expertise

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

Preview of the Different Types of CNC Machines to be Discussed

This article will delve into various types of CNC machines such as milling, lathe, drilling, plasma, and laser cutting machines. Each type has unique features and applications contributing to diverse manufacturing processes.

Milling Machines

Milling machines are versatile tools used in manufacturing processes to shape and cut materials precisely. They are essential in various automotive, aerospace, and construction industries. These machines utilize rotating cutting tools to remove material from a workpiece, resulting in the desired shape or form.

One of the key advantages of using milling machines in manufacturing is their ability to produce complex and intricate parts with high accuracy. This precision is crucial for industries that require tight tolerances and fine details in their products. Additionally, milling machines offer excellent repeatability, ensuring consistent results throughout the production process.

There are different types of milling machines available, each designed for specific applications. Vertical milling machines have a vertically oriented spindle that moves up and down along the Z-axis. They are commonly used for tasks such as drilling holes or cutting slots.

Horizontal milling machines have a horizontally oriented spindle that moves along the X-axis. Due to their robust construction, these machines are ideal for producing large, heavy parts.

Gantry milling machines feature a bridge-like structure that supports the spindle and simultaneously allows movement along multiple axes. This design provides enhanced stability and flexibility, making them suitable for machining large workpieces.

SYIL Machine Tools has significantly contributed to the development of precision milling machines. With their expertise in CNC technology, they have created innovative solutions that improve accuracy, speed, and efficiency in machining operations. SYIL's commitment to quality ensures that its milling machines deliver exceptional performance while meeting industry standards.

Lathe Machines

Lathe machines are essential tools in the manufacturing industry. They are used for shaping and cutting materials such as metal, wood, and plastic. The machine rotates the workpiece on its axis while various cutting tools are applied to shape it into the desired form.

These versatile machines find applications in a wide range of industries, including automotive, aerospace, and construction. In the automotive industry, lathe machines are used to create precision parts such as crankshafts and camshafts. In aerospace, they play a crucial role in manufacturing turbine blades and engine components. Additionally, lathe machines are employed to create musical instruments like drums and flutes.

Different types of lathe machines cater to specific needs and requirements. The most common type is the center lathe, which is manually operated and suitable for small-scale production or hobbyist use. On the other hand, CNC lathes offer advanced automation capabilities with computer-controlled operations, enabling precise and complex machining tasks.

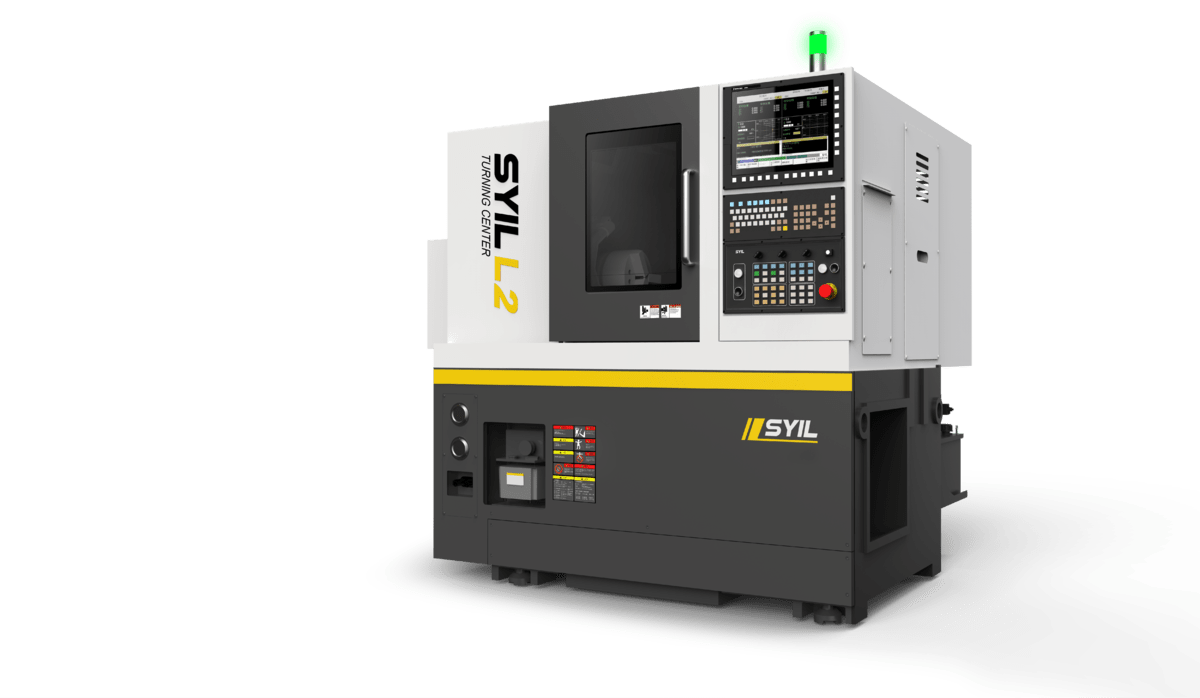

SYIL Machine Tools has established itself as a leading manufacturer of high-quality lathe machines. With their commitment to excellence and precision engineering, SYIL produces reliable machines that meet the demands of various industries. Their CNC lathe machines incorporate cutting-edge technology to deliver superior performance and accuracy.

Drilling Machines

Drilling machines are essential tools in metalworking processes. They create holes of various sizes and depths in different materials. They are commonly utilized in construction, manufacturing, and automotive industries.

The importance of drilling machines in metalworking processes cannot be overstated. They enable precise hole drilling, which is crucial for assembling parts and components. These machines provide accuracy and consistency, ensuring that the desired specifications are met for each hole drilled.

There are different types of drilling machines available, each with unique features and capabilities.

- Vertical drilling machines, as the name suggests, have a vertically oriented spindle that moves up and down to drill holes.

- Horizontal drilling machines have a horizontally oriented spindle that moves left to right or vice versa.

- Radial arm drilling machine has an arm that can be rotated around a column to reach different workpiece areas. This versatility allows for greater flexibility in hole placement.

SYIL Machine Tools is dedicated to producing efficient drilling machines that meet the needs of various industries. Their machines are designed with precision and reliability, ensuring consistent performance and accurate results.

Plasma Cutting Machines

Plasma cutting machines are a vital tool in the world of fabrication and metalworking. These machines utilize a high-velocity jet of ionized gas, known as plasma, to cut through various materials with precision and efficiency.

Definition and Uses of Plasma Cutting Machines

Plasma cutting machines are specifically designed to cut through electrically conductive materials such as steel, aluminum, brass, and copper. The process involves creating an electrically ionized gas (plasma) channel between the electrode and the workpiece. This intense heat melts the material, while a high-velocity gas jet blows away the molten metal.

Advantages of Using Plasma Cutting Machines in Fabrication

Plasma cutting machines offer several advantages that make them indispensable in the field of fabrication. First, they provide exceptional precision and accuracy, allowing for intricate cuts and detailed designs. Additionally, these machines can effortlessly cut through thick materials, making them ideal for heavy-duty applications.

Another significant advantage is their versatility. Plasma cutting machines can handle various materials and thicknesses, making them suitable for various industries such as automotive manufacturing, construction, shipbuilding, and metal fabrication.

Furthermore, plasma cutting is faster than traditional methods like sawing or shearing. It significantly reduces production time while maintaining excellent quality standards. This efficiency translates into cost savings for businesses, increasing productivity without compromising precision.

Different Types Of Plasma Cutting Machines (e.g., manual, CNC)

There are two main types of plasma cutting machines:

- Manual plasma cutters

- CNC (Computer Numerical Control) plasma cutters

Manual plasma cutters require operators to guide the machine manually along the desired cutting path using handheld torches. These portable devices are commonly used in small-scale operations or on-site projects where mobility is essential.

On the other hand, CNC plasma cutters offer automated precision cuts by following pre-programmed instructions. These machines utilize computer-controlled systems to guide the torch along the designated cutting path. CNC plasma cutters are highly efficient and suitable for large-scale industrial applications where accuracy and repeatability are paramount.

Laser Cutting Machines

Laser cutting machines have revolutionized the manufacturing industry with their precision and versatility. These machines utilize a high-powered laser beam to cut through various materials, offering numerous advantages over traditional cutting methods. From intricate designs to rapid production, laser-cutting machines have become indispensable in diverse industries.

Overview of Laser Cutting Machines and Their Capabilities

Laser cutting machines use a focused laser beam to cut through materials accurately. The intensity of the laser beam melts, vaporizes, or burns away the material, leaving a clean and precise cut. This technology allows for intricate designs and complex shapes that would be challenging to achieve with conventional cutting tools.

Applications of Laser Cutting Machines in Diverse Industries

Laser-cutting machines have applications in various industries, including automotive, aerospace, electronics, and fashion. In the automotive sector, these machines precisely fabricate car parts and components. In aerospace, they aid in manufacturing lightweight structures with intricate details. The electronics industry benefits from laser-cut circuit boards and precise engraving on electronic devices. Additionally, fashion designers utilize laser-cutting machines to create unique fabric patterns.

Different Types of Laser Cutting Machines (e.g., CO2, fiber)

There are different types of laser-cutting machines available in the market today. One popular type is CO2 lasers, which use carbon dioxide gas as the medium for generating the laser beam. These versatile lasers can cut through materials, such as wood, acrylics, plastics, and fabrics.

Another type is fiber lasers which use optical fibers doped with rare-earth elements like erbium or ytterbium as the medium for generating the laser beam. Fiber lasers are known for their high energy efficiency and are primarily used for metal-cutting applications.

Conclusion

CNC machines have revolutionized various industries with their precision and efficiency. Throughout this article, we have explored the different types of CNC machines and their applications. SYIL Machine Tools, a leading manufacturer in the industry, has played a significant role in the development of these machines.

Recap of the Various Types of CNC Machines Discussed

We discussed milling machines used for shaping solid materials, which come in different variations such as vertical, horizontal, and gantry mills. We also explored lathe machines, which can rotate a workpiece on its axis to perform various operations. Different types of lathe machines include center lathe and CNC lathe.

Drilling machines were highlighted for their importance in metalworking processes. They come in vertical, horizontal, and radial arm forms to cater to drilling needs. Plasma cutting machines were also mentioned for their ability to cut through electrically conductive materials using plasma torches. Manual and CNC plasma cutting machines are available.

Lastly, laser cutting machines were introduced as versatile tools used across diverse industries for precise cutting operations. CO2 and fiber laser cutting machines are commonly used variations.

SYIL Machine Tools' Contributions to the Industry

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Operating in multiple countries, SYIL is becoming a recognized brand in the industry.

By adopting CNC technology, businesses can enhance the productivity, accuracy, and efficiency of their manufacturing processes. The use of CNC machines eliminates human error while increasing production capacity. It is crucial for readers to explore these benefits further to stay competitive in today's market.

Final thoughts on the future of CNC machine development

As technology advances rapidly, we can expect further innovation and development in CNC machines. The future holds exciting possibilities for increased automation, improved precision, and enhanced functionality. It is an exciting time for the industry, and SYIL Machine Tools is at the forefront of these advancements.