Introduction

In the world of modern manufacturing, two technologies stand out for their versatility and precision: CNC machines and 3D printers. Each method offers unique advantages that cater to different needs, sparking an ongoing debate about their roles in production. As industries evolve, understanding the nuances between a CNC machine vs 3D printer becomes essential for making informed decisions.

Overview of CNC Machines and 3D Printers

CNC (Computer Numerical Control) machines have long been the backbone of precision manufacturing, using programmed commands to control tools for cutting, milling, and shaping materials into intricate designs. On the flip side, 3D printers have emerged as revolutionary devices that build objects layer by layer from digital models, offering unparalleled design freedom. Both technologies are reshaping how products are made today, but they operate on fundamentally different principles.

Key Differences in Technology

The primary distinction between a CNC machine vs 3D printer lies in their operational methodologies: CNC machines remove material to create parts while 3D printers add material through additive processes. This fundamental difference leads to variations in the types of materials used and the final characteristics of the products created. While CNC machining excels in producing robust components with tight tolerances, 3D printing shines when it comes to rapid prototyping and complex geometries.

Growing Popularity of Both Methods

As businesses seek more efficient production methods, both CNC machining and 3D printing are experiencing a surge in popularity across various sectors. Many companies are asking themselves questions like Will 3D printing replace CNC machining? or Can you use a 3D printer as a CNC? The answer often lies not in choosing one over the other but rather understanding how each can complement existing processes—leading to innovative solutions tailored to specific project needs.

Understanding CNC Machines

When diving into the world of manufacturing, understanding CNC machines is crucial. These machines have revolutionized how we create parts and products, offering precision and efficiency that traditional methods simply can't match. In this section, we'll explore what a SYIL CNC machine is, its advantages, and the various applications it serves.

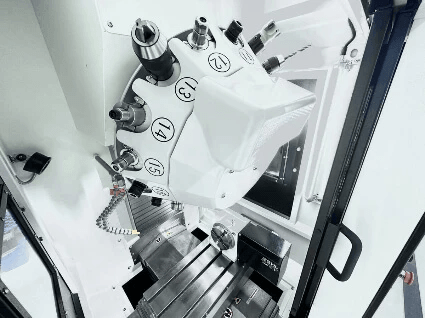

What is a SYIL CNC Machine?

A SYIL CNC machine represents the pinnacle of computer numerical control technology, designed for both hobbyists and professionals alike. These machines utilize advanced software to automate the movement of tools and materials, allowing for intricate designs to be produced with high accuracy. As we compare CNC machine vs 3D printer later on, it's essential to recognize that SYIL offers a range of models tailored for different needs—from small desktop units to larger industrial-grade machines.

Advantages of CNC Machining

CNC machining boasts several advantages that make it a go-to choice in various industries. First off, one major benefit is its unparalleled precision; these machines can achieve tolerances as tight as 0.001 inches! Secondly, durability comes into play—CNC machines can work with hard materials like metals and composites that many 3D printers struggle with. Finally, speed is an undeniable factor; once programmed, a CNC machine can produce parts quickly without sacrificing quality—making it an efficient option for large-scale production runs.

What are 3 advantages of a CNC machine? Well, you have precision machining capabilities, material versatility from metals to plastics, and high production speeds that keep projects on track without compromising quality.

Applications of CNC Technology

The applications of CNC technology are vast and varied across multiple industries. From aerospace components requiring strict adherence to safety standards to custom furniture pieces crafted with artistic flair—CNC machining has you covered! Additionally, sectors such as automotive manufacturing utilize these machines for everything from prototype development to mass production runs.

As we ponder whether 3D printing will replace CNC machining in the future or if these technologies will coexist harmoniously in manufacturing practices remains an open question—one thing's for sure: understanding the capabilities of each method is vital in choosing which is better: CNC or 3D printing?

Diving into 3D Printing

In recent years, 3D printing has emerged as a game-changing technology in the manufacturing sector, offering unique advantages that set it apart from traditional methods like CNC machining. This section will explore the various types of 3D printers, the benefits they provide, and the industries that are increasingly adopting this innovative approach. As we delve into these topics, we'll also touch on questions such as Which is better CNC or 3D printing? and whether 3D printing might eventually replace CNC machining.

Types of 3D Printers Explained

When discussing 3D printers, it's essential to recognize the different technologies available. Fused Deposition Modeling (FDM) printers are among the most common; they work by extruding melted thermoplastic filaments to create layers of material. Another popular type is Stereolithography (SLA), which utilizes a laser to cure liquid resin into solid layers—great for achieving intricate details that often surpass what you can get with a CNC machine.

There are also Selective Laser Sintering (SLS) printers that use lasers to fuse powdered materials together, enabling the creation of complex geometries without support structures. Each type has its own strengths and weaknesses; for instance, while FDM printers are more accessible and cost-effective for hobbyists, SLA machines excel in fine detail but come with higher operational costs. As we weigh these options against traditional methods like CNC machining, one might wonder if Will 3D printing replace CNC machining? The answer isn't straightforward but depends largely on specific project requirements.

Benefits of 3D Printing

One of the standout advantages of 3D printing is its ability to produce highly customized parts quickly and efficiently—perfect for prototyping or small production runs where flexibility is key. Unlike CNC machines that require specific tooling changes for different designs, a single 3D printer can switch between projects seamlessly without extensive setup time or additional costs. Moreover, this technology allows for complex geometries that would be nearly impossible—or at least prohibitively expensive—to achieve with traditional manufacturing techniques.

Another significant benefit is material efficiency; since additive manufacturing only uses material where it's needed, there's far less waste compared to subtractive processes like those employed by CNC machines. This leads many manufacturers to ask themselves What are three advantages of a CNC machine? while simultaneously recognizing how additive processes can complement their operations rather than outright replace them.

Industries Embracing 3D Printing

From aerospace to healthcare, numerous industries are embracing the capabilities offered by 3D printing technology. In aerospace engineering, companies utilize this method for rapid prototyping and creating lightweight components that enhance fuel efficiency—something traditional CNC machines struggle with due to material constraints. The medical field also benefits significantly from personalized solutions; custom prosthetics and dental implants can be produced quickly using advanced techniques.

Moreover, automotive manufacturers have begun employing additive manufacturing not just for prototyping but also for producing end-use parts in small batches—a feat that's increasingly feasible thanks to advancements in materials and printer capabilities. As diverse industries continue exploring Which is better: CNC or 3D printing?, it becomes clear that both technologies have their rightful place in modern manufacturing environments.

CNC Machine vs 3D Printer: Precision Showdown

Comparing Accuracy and Detail

Accuracy is often the first battleground in the CNC machine vs 3D printer debate. CNC machines are renowned for their exceptional precision, capable of producing intricate designs with tolerances as tight as +/- 0.005 inches. On the other hand, while modern 3D printers offer impressive detail, they can struggle with fine features or intricate geometries compared to their CNC counterparts. So when you ask which is better—CNC or 3D printing?—the answer leans towards CNC for applications requiring unparalleled accuracy.

Material Options: Strength vs Flexibility

Material selection plays a pivotal role in determining the suitability of each technology for specific projects. CNC machines can work with a wide variety of materials like metals, plastics, and wood—often resulting in stronger finished products that can withstand rigorous use. Conversely, 3D printing excels in flexibility; it allows for rapid prototyping using various polymers and composites that might not be feasible with traditional machining methods. Ultimately, if you’re after strength and durability, a CNC machine may be your best bet; however, if flexibility is key for rapid design iterations or creative projects, then 3D printing shines.

Speed of Production: Who Wins?

Speed can significantly impact project timelines and costs; thus understanding who wins this race between CNC machine vs 3D printer is crucial for manufacturers. Generally speaking, once set up correctly, CNC machines can produce parts at a faster rate than most consumer-grade 3D printers due to their automated processes and efficiency in material removal techniques. However, when it comes to low-volume production runs or one-off prototypes where setup time might not be as critical—can you use a 3D printer as a CNC? The answer is yes! Some hybrid models allow users to enjoy benefits from both worlds but still may not match the sheer speed of dedicated CNC machines.

In summary, while both technologies offer distinct advantages suited to different needs within manufacturing environments today—will 3D printing replace CNC machining? Probably not entirely; instead they will likely coexist harmoniously as industries continue evolving towards more innovative solutions.

Cost Analysis: CNC vs 3D Printing

When evaluating whether to invest in a CNC machine vs 3D printer, the cost is a pivotal factor. Both technologies come with their unique financial implications, from initial purchase prices to ongoing expenses. Understanding these costs can help businesses and hobbyists alike make informed decisions tailored to their specific needs.

Initial Investment Costs

The initial investment for CNC machines typically ranges widely based on size, capabilities, and brand—often starting from several thousand dollars and going up significantly for advanced models. In contrast, entry-level 3D printers can be found for a few hundred dollars, making them appealing for those new to additive manufacturing. However, if you’re looking at professional-grade 3D printers with high precision and speed, the costs can rival or even exceed that of CNC machines.

While comparing the two options in terms of upfront costs, it’s essential to consider what you’re getting for your money. A CNC machine offers robust capabilities and durability suited for industrial applications; meanwhile, 3D printers provide flexibility in design but may require additional investments in materials and software. The question of Which is better: CNC or 3D printing? often hinges on how much you're willing to invest initially.

Maintenance and Operational Expenses

Once you’ve made your choice between a CNC machine vs 3D printer, the ongoing maintenance costs will play a significant role in your overall budget. CNC machines usually require regular maintenance due to their mechanical components; this includes lubrication and occasional part replacements that can add up over time. On the other hand, while 3D printers have fewer moving parts, they may need frequent material changes and nozzle cleaning which also incurs costs.

Additionally, operational expenses vary widely between both technologies. For instance, materials used in CNC machining are often more expensive than plastic filaments used in most consumer-grade 3D printers but offer higher strength and durability. This leads us back to the question: “Will 3D printing replace CNC machining?” The answer largely depends on what kind of projects you're undertaking—each technology has its own set of operational challenges.

Long-Term Value Assessment

In assessing long-term value when comparing a CNC machine vs 3D printer, consider factors like production volume and material waste management. While initial costs may be lower for a 3D printer, if you're producing high volumes or complex parts consistently required by industries such as aerospace or automotive—CNC might prove more economical over time due to its efficiency and material utilization rates.

Moreover, think about scalability; as your business grows or project demands change, having robust machinery like a SYIL CNC machine could provide better longevity compared to standard consumer-level additive manufacturing options that might struggle under heavy workloads. Ultimately asking yourself What are three advantages of a CNC machine? could lead you toward recognizing its potential return on investment compared to other methods like traditional machining or even advanced forms of additive manufacturing.

Future Trends in Manufacturing

The landscape of manufacturing is rapidly evolving, fueled by technological advancements and the quest for efficiency. As we explore the future trends, one question stands out: will 3D printing replace CNC machining? While both methods have their strengths, understanding their roles in modern production is crucial for making informed decisions.

Will 3D Printing Replace CNC Machining?

The debate over whether 3D printing will replace CNC machining is ongoing and nuanced. While 3D printing offers unique advantages such as rapid prototyping and design flexibility, it doesn't necessarily mean it will completely overshadow traditional CNC methods. The reality is that each technology has its niche; for instance, CNC machines excel in producing high-precision parts from solid materials, which makes them indispensable in industries requiring tight tolerances.

Moreover, many experts believe that rather than a replacement scenario, we are more likely to see a coexistence where both technologies complement each other. As manufacturers seek to optimize production processes, they may find that using a combination of CNC machines and 3D printers can yield better results than relying on one method alone. So when pondering which is better—CNC or 3D printing—it’s essential to consider the specific needs of your project.

Innovations in CNC Technology

CNC technology continues to evolve at a rapid pace, with innovations enhancing capabilities and efficiency across various sectors. For instance, advancements like adaptive machining allow CNC machines to automatically adjust parameters based on real-time feedback during operation. This not only improves precision but also reduces waste—a significant advantage when considering what are three advantages of a CNC machine.

Additionally, the integration of AI and machine learning into CNC systems has opened new avenues for automation and predictive maintenance. These innovations ensure that manufacturers can maintain high productivity levels while minimizing downtime—a critical factor in today’s fast-paced market environment. As these technologies develop further, they will continue to solidify the role of CNC machining alongside emerging methods like 3D printing.

The Hybrid Approach: Combining Both Technologies

The hybrid approach—leveraging both CNC machining and 3D printing—is gaining traction among manufacturers seeking optimal solutions for complex projects. This synergy allows businesses to utilize the strengths of each method; for example, using a 3D printer for intricate designs while employing a CNC machine for finishing touches ensures precision without sacrificing creativity or speed. Can you use a 3D printer as a CNC? In some cases yes! Some hybrid machines combine functionalities allowing users to switch between processes seamlessly.

Furthermore, this approach enables companies to respond more effectively to market demands by offering customizable solutions without incurring excessive costs or delays associated with traditional manufacturing methods alone. By embracing this blend of technologies, businesses can stay ahead in an increasingly competitive landscape while addressing diverse customer needs efficiently—making it clear that neither method should be viewed as superior but rather as complementary tools in modern manufacturing.

Conclusion

In the ever-evolving world of manufacturing, the choice between a CNC machine vs 3D printer often hinges on project-specific needs and desired outcomes. Each technology has its unique strengths, making it essential to evaluate factors such as precision, material requirements, and production speed. Ultimately, understanding these differences will guide you in selecting the most suitable method for your next project.

Choosing Based on Your Project Needs

When deciding between a CNC machine vs 3D printer, consider the specific requirements of your project. If you need high precision and durability in materials like metal or wood, a CNC machine may be more advantageous. Conversely, if rapid prototyping and design flexibility are paramount, then opting for a 3D printer could be the way to go.

Understanding which is better—CNC or 3D printing—also depends on your production volume and complexity of designs. For intricate geometries that require less material waste, 3D printing excels; however, for large-scale production runs with stringent tolerances, CNC machining stands out as the superior choice. Thus, aligning your project's goals with each technology's capabilities is crucial for success.

Which is Better: CNC or 3D Printing?

The debate over which is better—CNC or 3D printing?—is ongoing among enthusiasts and professionals alike. While both methods have their merits, it ultimately boils down to what you're creating: if strength and finish are key factors, CNC machines typically outperform their additive counterparts in those areas. However, if rapid iteration and complex shapes are needed without extensive tooling changes, then 3D printing takes the lead.

It's also worth noting that while some may wonder if they can use a 3D printer as a CNC machine—the answer lies in hybrid technologies that blend both methodologies for optimal results. This convergence allows manufacturers to leverage strengths from both sides while mitigating weaknesses inherent to each process alone. Therefore, understanding your project's demands will help clarify which technology reigns supreme.

The Evolving Landscape of Manufacturing Solutions

As we look ahead at future trends in manufacturing solutions, one question looms large: will 3D printing replace CNC machining? The short answer is no; instead of outright replacement, we’re likely to see an integration where each method complements the other’s capabilities within various industries. Innovations in CNC technology continue to push boundaries while advancements in additive manufacturing promise exciting possibilities.

The hybrid approach offers manufacturers versatility that neither method can achieve alone; combining precision from CNC with creativity from 3D printing opens new avenues for product development and customization. As industries evolve alongside these technologies' capabilities—and as costs decrease—the landscape will undoubtedly shift toward more integrated solutions that harness the best aspects of both methods.

In conclusion, whether you're wrestling with cnc machine vs 3d printer decisions or pondering which is better overall—CNC or 3D printing—the key takeaway is clarity about your project needs will lead you towards informed choices that enhance productivity and innovation.