Introduction

When it comes to CNC machine controllers, Siemens 840D and Siemens SINUMERIK 828D are two of the most renowned names in the industry. Both offer advanced capabilities for CNC machine programming and machining automation, but they also have key differences that make them suitable for different applications. Choosing between Siemens 840D and Siemens SINUMERIK 828D requires careful consideration of factors such as performance, user-friendliness, precision, accuracy, cost, ROI, and industry-specific applications.

Understanding Siemens 840D and Siemens SINUMERIK 828D

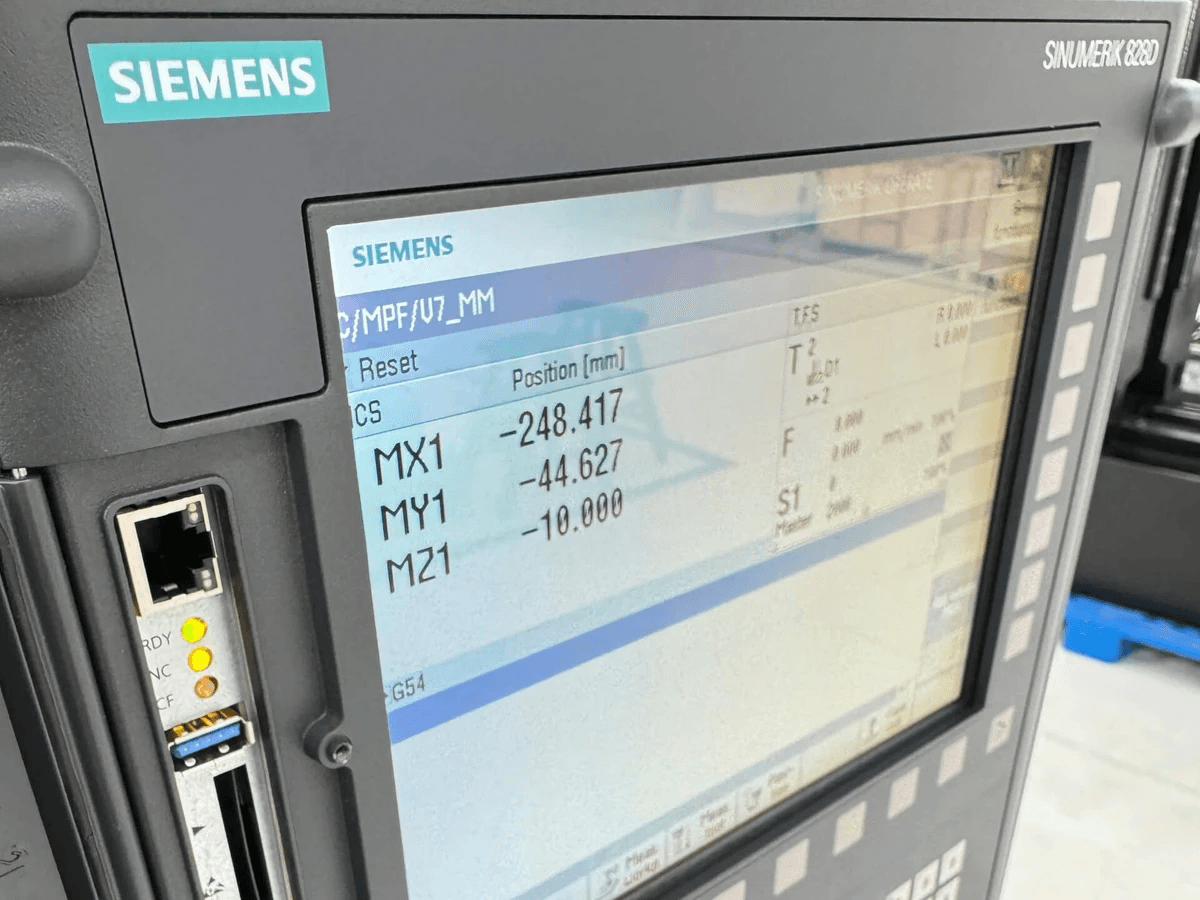

Siemens 840D is a high-end CNC machine controller known for its advanced features and capabilities in machining automation. On the other hand, the Siemens SINUMERIK 828D control system is designed to set productivity standards when it comes to milling on machines like SYIL, with its unique CNC performance.

In addition to their different focuses, another key difference between Siemens 840D and Siemens SINUMERIK 828D lies in their user interfaces. The Siemens 840D features a highly intuitive and user-friendly interface, making it easier for operators to program and control the machine. On the other hand, the SINUMERIK 828D is known for its streamlined and efficient interface, catering to the specific needs of milling operations. This difference in user interface design can greatly impact the overall user experience and productivity levels.

Key differences between Siemens 840D and Siemens SINUMERIK 828D

The key differences between these two controllers lie in their performance and capabilities, user-friendliness, precision and accuracy, cost implications, ROI potential, and industry-specific applications. Understanding these differences is crucial when deciding which controller best suits your business needs.

In addition to the key differences mentioned above, it's important to consider the level of technical support and training required for each controller. The Siemens 840D may require more specialized training and expertise due to its advanced capabilities, while the SINUMERIK 828D is designed to be more user-friendly and intuitive. This could impact the ease of implementation and ongoing maintenance for your business, so it's worth factoring in when making a decision.

Factors to consider when choosing between Siemens 840D and Siemens SINUMERIK 828D

Factors such as the specific requirements of your machining processes, the level of precision needed in your operations, the ease of operation for your machinists, as well as the potential return on investment need to be carefully evaluated before making a decision on whether to invest in a Siemens 840D or a SINUMERIK 828D.

Additionally, it's important to consider the compatibility of each system with your existing machinery and tools. The Siemens 840D may offer more advanced features, but if it doesn't integrate well with your current equipment, the transition could be costly and time-consuming. On the other hand, the SINUMERIK 828D might be a better fit for your specific setup, even if it doesn't have all the bells and whistles of the 840D. Compatibility with your current infrastructure can greatly impact the overall efficiency and effectiveness of your operations.

Performance and Capabilities

When it comes to CNC machine controllers, the Siemens 840D is a top choice for those seeking advanced features and capabilities. Known for its high-performance machining automation, the Siemens 840D offers unparalleled precision and speed in CNC machine programming. Its cutting-edge technology and user-friendly interface make it a preferred choice for industries requiring complex machining processes.

Siemens 840D: Advanced features and capabilities

The Siemens 840D CNC machine controller stands out with its exceptional precision, high-speed performance, and seamless integration of automation functions. With its advanced control algorithms and robust hardware architecture, the Siemens 840D ensures maximum dynamics and accuracy during machining operations. This makes it an ideal choice for industries demanding superior quality and efficiency in their production processes.

Furthermore, the Siemens 840D offers a user-friendly interface and intuitive programming capabilities, allowing operators to easily set up and monitor machining processes. Its seamless integration with other automation systems enables smooth communication between different manufacturing components, streamlining production and reducing downtime. Additionally, the 840D's remote monitoring and diagnostic features provide real-time feedback, enabling proactive maintenance and minimizing unexpected machine failures.

Siemens SINUMERIK 828D: Overview of performance and capabilities

On the other hand, the Siemens SINUMERIK 828D control system offers a comprehensive set of performance capabilities suitable for various machining applications. Equipped with unique CNC performance features, the SINUMERIK 828D sets productivity standards when it comes to milling on machines like SYIL. Its robust hardware architecture and intelligent control algorithms ensure maximum dynamics and precision during machining operations.

In addition, the Siemens SINUMERIK 828D control system is designed to be user-friendly, with an intuitive interface that allows for easy programming and operation. This makes it ideal for operators of all skill levels, from beginners to experienced professionals. The system also offers advanced diagnostic and maintenance features, ensuring minimal downtime and efficient troubleshooting when needed.

A comparison of performance and capabilities between Siemens 840D and Siemens SINUMERIK 828D

When comparing the performance and capabilities of the Siemens 840D with the SINUMERIK 828D, both controllers offer exceptional precision, speed, and efficiency in CNC automation. However, while the Siemens 840D is known for its advanced features tailored to complex machining processes, the SINUMERIK 828D is specifically designed to set productivity standards in milling applications on machines like SYIL. The Siemens 840D boasts a wide range of functions such as high-speed cutting, multi-channel operation, and adaptive control technology, making it ideal for intricate and demanding manufacturing tasks. On the other hand, the SINUMERIK 828D excels in providing seamless integration with milling machines, optimizing tool paths and reducing cycle times to enhance overall productivity and cost-effectiveness.

With their unique strengths in different areas of machining automation, choosing between these two controllers ultimately depends on specific industry needs and production requirements.

User-Friendliness

When it comes to user interface and ease of operation, the Siemens 840D CNC machine controller stands out with its intuitive and user-friendly design. The system offers a clear and easy-to-navigate interface, making CNC machine programming and operation more efficient for operators. With features like customizable screens and straightforward menu structures, the Siemens 840D ensures a smooth user experience.

User interface and ease of operation with Siemens 840D

The user interface of the Siemens 840D is designed to provide operators with a seamless experience. Its high-resolution display and touch panel allow for easy navigation through various functions, while the graphical representation of machining processes enhances visibility and understanding. This makes it easier for operators to monitor and control machining automation, ultimately improving productivity.

User-friendly features of Siemens SINUMERIK 828D

On the other hand, the Siemens SINUMERIK 828D also offers a user-friendly interface with its ergonomic design and intuitive controls. The system is equipped with a multi-touch screen that simplifies interaction, along with customizable soft keys for quick access to frequently used functions. These features contribute to an efficient CNC machine programming process and streamlined machining operations.

How user-friendliness impacts the choice between Siemens 840D and Siemens SINUMERIK 828D

The user-friendliness of both systems plays a crucial role in determining which CNC machine controller is best suited for specific operational needs. While the Siemens 840D excels in providing an intuitive interface for advanced machining tasks, the SINUMERIK 828D offers similar ease of use with its tailored features. Ultimately, understanding how these user-friendly aspects align with operational requirements will guide businesses in making the right choice between Siemens 840D and SINUMERIK 828D.

Precision and Accuracy

When it comes to precision and accuracy, the Siemens 840D CNC machine controller is renowned for its exceptional performance. With its advanced CNC machine programming capabilities, the Siemens 840D ensures precise and accurate machining automation, making it a top choice for industries that require high precision components. The Siemens 840D's ability to maintain tight tolerances and deliver consistent results sets it apart as a reliable and efficient CNC machine controller.

Precision and accuracy offered by Siemens 840D

The Siemens 840D's high-resolution measuring systems and intelligent control algorithms enable it to achieve remarkable precision and accuracy in machining operations. Its seamless integration with machining automation processes ensures that every movement is executed with utmost precision, resulting in superior surface finishes and dimensional accuracies. The combination of robust hardware architecture and cutting-edge control technology makes the Siemens 840D a powerhouse in delivering precise machining solutions.

Analyzing the precision and accuracy of Siemens SINUMERIK 828D

Equipped as standard on SYIL machines, the Siemens SINUMERIK 828D control system also boasts impressive precision and accuracy capabilities. With its unique CNC performance tailored for milling applications, the SINUMERIK 828D delivers exceptional results in terms of dimensional accuracy and surface finish quality. The integration of advanced drive and motor technology further enhances its ability to achieve precise machining outcomes consistently.

The importance of precision and accuracy in the decision between Siemens 840D and Siemens SINUMERIK 828D

In the decision-making process between the Siemens 840D and Siemens SINUMERIK 828D, precision and accuracy play a critical role. While both controllers offer commendable levels of precision, factors such as specific industry requirements, production volume, and desired surface finish quality should be carefully considered to determine which CNC machine controller best aligns with the business needs.

Cost and ROI

When considering the cost implications of the Siemens 840D CNC machine controller, it's important to factor in not just the initial investment, but also the long-term benefits it offers. The Siemens 840D is known for its high-performance capabilities and advanced features, which can contribute to increased productivity and efficiency in CNC machine programming and machining automation. While the initial cost may be higher, the potential return on investment (ROI) from improved production output and precision could outweigh this.

Determining the ROI potential with Siemens SINUMERIK 828D involves analyzing its unique CNC performance and productivity standards. With its robust hardware architecture and intelligent control algorithms, the SINUMERIK 828D control system offers maximum dynamics and precision during machining. This level of performance can directly impact ROI by enhancing overall production efficiency, reducing downtime, and minimizing material waste. As a result, businesses can expect a favorable ROI when utilizing this CNC machine controller for their machining operations.

The significance of cost and ROI when comparing Siemens 840D and Siemens SINUMERIK 828D lies in understanding how each system aligns with specific business needs and goals. While the cost of acquisition is a crucial consideration, it's equally important to evaluate how each system's capabilities translate into tangible ROI for your business. By weighing factors such as performance, precision, user-friendliness, industry applications, and long-term cost implications against potential returns on investment, businesses can make informed decisions about which CNC machine controller best suits their requirements.

Industry Applications

Siemens 840D: Applications in various industries

The Siemens 840D CNC machine controller is widely used in the manufacturing industry for its advanced features and capabilities. It is commonly found in industries such as aerospace, automotive, and medical equipment manufacturing. The precision and accuracy offered by the Siemens 840D make it ideal for intricate machining processes, making it a popular choice for high-precision industries.

Industry-specific benefits of Siemens SINUMERIK 828D

The Siemens SINUMERIK 828D control system, commonly used in CNC machine programming, offers specific benefits tailored to different industries. For example, in the automotive industry, its high-speed machining capabilities are highly valued for efficient production. In the medical equipment manufacturing sector, its user-friendly interface and precise control make it an excellent choice for complex part machining.

Matching industry needs with the right CNC machine: Siemens 840D vs Siemens SINUMERIK 828D

When considering which CNC automation system to choose for a specific industry application, it's essential to match the unique requirements of that industry with the capabilities of each controller. While the Siemens 840D may excel in high-precision applications, the SINUMERIK 828D's speed and efficiency may be better suited for industries with high-volume production needs.

Conclusion

Making the right choice: Siemens 840D or Siemens SINUMERIK 828D

When deciding between the Siemens 840D and the SINUMERIK 828D for your CNC machine controller, it's essential to consider the specific needs of your business. If you require advanced features and capabilities, the Siemens 840D might be the best choice. However, if user-friendliness and precision are your top priorities, the SINUMERIK 828D could be the ideal option. Ultimately, making the right choice depends on understanding your unique requirements and matching them with the strengths of each controller.

Factors to consider before investing in Siemens 840D or Siemens SINUMERIK 828D

Before investing in a CNC machine programming system such as Siemens 840D or SINUMERIK 828D, it's crucial to evaluate factors such as performance, user-friendliness, precision, industry applications, and cost implications. Understanding how these factors align with your business goals will help you make an informed decision that maximizes productivity and efficiency.

Choosing the best CNC machine for your business: Siemens 840D vs Siemens SINUMERIK 828D

In conclusion, choosing between Siemens 840D and Siemens SINUMERIK 828D comes down to understanding their unique strengths and how they align with your business needs. Whether you prioritize advanced features and capabilities or user-friendly operation and precision, both controllers offer distinct advantages that can enhance machining automation in various industries.