Introduction

Advanced machinery spindle systems are crucial in optimizing performance in machining operations. These systems are responsible for cutting tools' smooth and efficient rotation, ensuring precision and productivity. One company that specializes in developing high-quality spindle systems is SYIL Machine Tools. With over 12k machines supplied globally, they have established themselves as a trusted name in the industry.

SYIL's CNC machines are equipped with advanced spindle systems that offer numerous benefits, making them an ideal choice for businesses seeking to enhance their machining capabilities.

The Role of Spindle Systems in Performance Optimization

Understanding The Function Of Spindle Systems

Spindle systems play a crucial role in the performance optimization of machining operations. These systems rotate the cutting tools, enabling them to remove material from workpieces efficiently. Spindle systems ensure precise and accurate cuts by achieving high rotational speeds and providing stability. They are the heart of any CNC machine, allowing for smooth and efficient operation.

Benefits Of Using Advanced Spindle Systems In Machining

Advanced spindle systems offer several advantages that can significantly improve the efficiency and accuracy of your machining operations. Here are some of the key benefits:

- Increased Productivity: Advanced spindle systems enable high-speed cutting and milling, allowing you to complete more work in less time. Faster rotational speeds translate to faster material removal, increasing production output.

- Enhanced Accuracy and Precision: These systems improve stability and rigidity, minimizing deflection and vibration during machining. This leads to more consistent and precise cuts, ensuring that your products meet the desired specifications with greater accuracy.

Incorporating advanced spindle systems into your machining processes can significantly improve your finished products' productivity, accuracy, and overall quality.

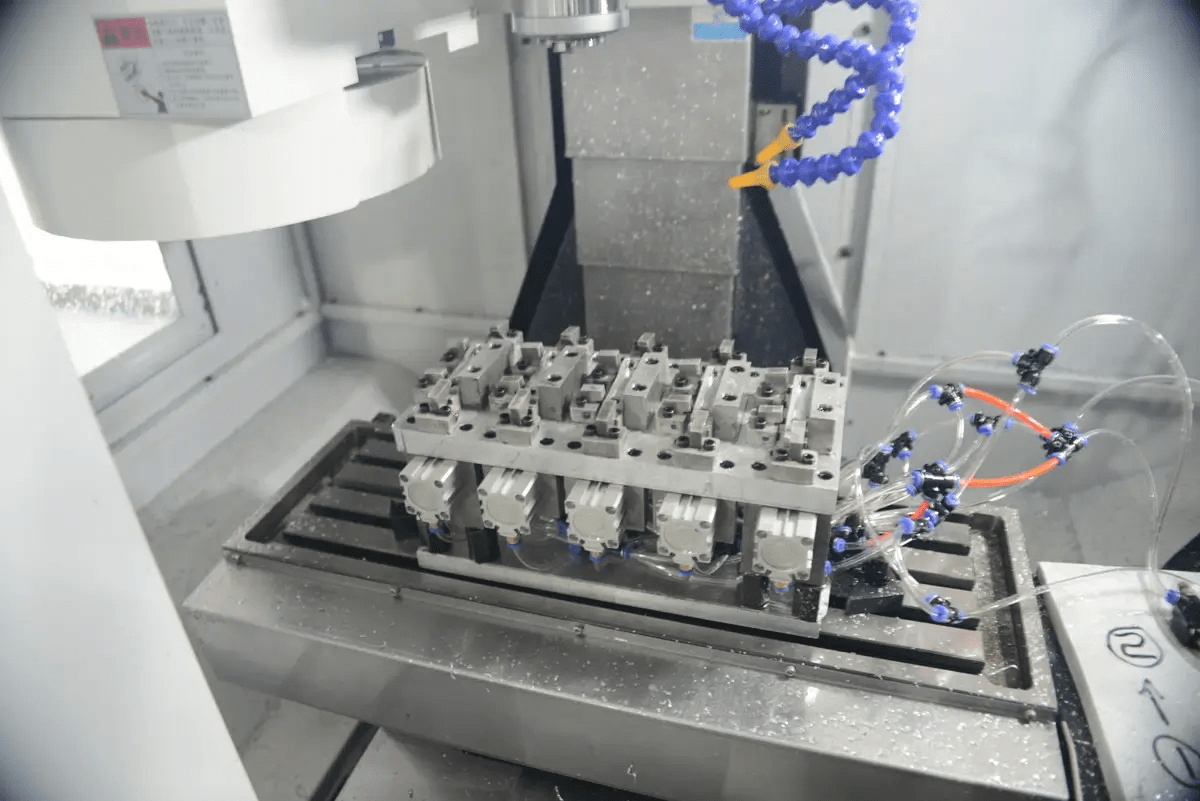

How SYIL's CNC Machines Incorporate Advanced Spindle Systems

SYIL Machine Tools understands the importance of incorporating advanced spindle systems into CNC machines for optimal performance. Their CNC machines have high-quality CNC spindle motors specifically designed for precision machining tasks. These motors offer exceptional reliability and durability while delivering high torque and rotational speeds required for efficient cutting and milling operations.

Maximizing Productivity And Precision With SYIL'S Spindle Systems

SYIL's CNC machines maximize productivity and precision through their state-of-the-art spindle systems. These machines can achieve faster cutting rates by utilizing high-speed spindles without compromising accuracy or surface finish quality. The enhanced stability and rigidity provided by SYIL's advanced spindles ensure consistent results even when working with challenging materials or complex geometries.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. By incorporating advanced spindle systems into their CNC machines, SYIL ensures optimal performance, maximizing productivity and precision in machining operations. Their commitment to excellence makes them ideal for businesses seeking reliable and high-quality machinery spindle solutions.

Key Features of SYIL's CNC Machines for Performance Optimization

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. Their CNC machines offer a range of key features that optimize performance in machining operations.

1. High-Speed Spindles For Efficient Cutting And Milling

SYIL's CNC machines have high-speed spindles that enable efficient cutting and milling processes. These spindles can rotate at high speeds, allowing for faster material removal and increased productivity. With their advanced technology, SYIL's high-speed spindles ensure precise and accurate results, even when operating at high velocities.

2. Enhanced Stability And Rigidity For Improved Accuracy

Stability and rigidity are crucial factors to achieve optimal performance in machining operations. SYIL's CNC machines are designed with enhanced stability and rigidity to ensure improved accuracy in every cut or mill. The robust construction of these machines minimizes vibrations, resulting in superior surface finishes and precise dimensional control.

3. Advanced Cooling Systems For Temperature Control

Temperature control is essential in machining operations to prevent heat-related issues that can affect the quality of the final product. SYIL's CNC machines feature advanced cooling systems that effectively dissipate heat generated during cutting or milling processes. These cooling systems maintain a stable temperature, ensuring consistent performance and prolonging the lifespan of the machine components.

4. Compatibility With Various Materials And Applications

SYIL's CNC machines are versatile tools that handle various materials and applications. Whether aluminum, steel, wood, or plastic, these machines deliver exceptional results across different industries. The compatibility with various materials allows manufacturers to expand their capabilities without compromising on performance or precision.

SYIL's CNC machines provide the ideal solution for performance optimization in machining operations. These machines deliver efficient and accurate results with features such as high-speed spindles, enhanced stability, advanced cooling systems, and compatibility with various materials. Manufacturers can rely on SYIL Machine Tools for their precision CNC machine needs, ensuring productivity and quality in their machining processes.

Sustainable Practices and Performance Optimization

SYIL Machine Tools is committed to sustainability in CNC machine manufacturing, ensuring their machines are designed with eco-friendly practices. By prioritizing sustainability, SYIL aims to reduce the environmental impact of its operations and contribute to a greener future.

Energy-efficient spindle systems are one of the key ways that SYIL achieves reduced power consumption in their CNC machines. These advanced spindle systems are designed to minimize energy wastage while maintaining optimal performance. Using energy-efficient spindle motors, SYIL's machines help businesses save on electricity costs and reduce their carbon footprint.

In addition to energy efficiency, SYIL's machines are built with longevity and durability in mind. The precision spindle manufacturers at SYIL understand the importance of reducing waste in machining operations. By creating machines built to last, they minimize the need for frequent replacements or repairs, resulting in less waste generated over time.

SYIL's commitment to sustainability extends beyond its manufacturing processes. Their CNC machines contribute to eco-friendly machining operations by optimizing performance and reducing material waste. With features like high-speed spindle technology and enhanced stability, SYIL's machines help businesses achieve efficient cutting and milling processes, reducing material wastage.

SYIL Machine Tools develops and manufactures precision CNC machines for milling and drilling. With over 12k machines supplied globally, they prioritize quality and sustainability. By incorporating sustainable practices such as energy-efficient spindle systems and durable machine construction, SYIL contributes to eco-friendly machining operations while optimizing performance for businesses worldwide.

Technological Advancements in Spindle Systems

In the ever-evolving world of machining, technological advancements in spindle systems have played a crucial role in optimizing performance levels. SYIL Machine Tools, a leading manufacturer of precision CNC machines, has been at the forefront of these innovations, constantly pushing the boundaries to deliver higher performance and efficiency.

Innovations In Spindle Design For Higher Performance Levels

SYIL Machine Tools understands that the heart of any machining operation lies within the spindle system. That's why they have invested heavily in developing cutting-edge designs that can handle even the most demanding tasks. Their machinery spindles are engineered with precision and durability in mind, ensuring smooth and reliable operation throughout.

One notable innovation is their advanced cooling system integrated into their spindle design. By effectively managing temperature control during operations, SYIL's spindles minimize thermal expansion and maintain optimal working conditions for improved accuracy and longevity.

Integration Of Smart Technologies For Enhanced Automation

SYIL has embraced smart technologies that facilitate enhanced automation to optimize performance further. Their CNC spindle motors have intelligent features such as automatic tool changers and adaptive control systems. These advancements streamline machining processes by reducing manual intervention and maximizing productivity.

By integrating smart technologies into their spindle systems, SYIL enables operators to achieve higher levels of efficiency while maintaining precision. This saves time and reduces human error, resulting in consistent quality output.

SYIL's Focus On Research And Development For Continuous Improvement

SYIL Machine Tools is committed to staying ahead of the competition by continuously investing in research and development efforts. They understand that technological advancements are not a one-time achievement but an ongoing process.

Through rigorous testing and analysis, SYIL's team of experts constantly seeks ways to improve the performance capabilities of their machinery spindles. This commitment to innovation ensures that customers benefit from state-of-the-art solutions that meet their evolving needs.

Staying Ahead In The Industry With Cutting-Edge Spindle Systems

SYIL Machine Tools has established itself as a leader in the industry by consistently delivering cutting-edge spindle systems. With a focus on precision, reliability, and efficiency, their high-speed spindle technology sets new benchmarks for performance optimization.

By staying at the forefront of technological advancements, SYIL's CNC machines offer customers a competitive edge. Whether it's precision spindle manufacturers or those seeking efficient machine tool spindles, SYIL's commitment to continuous improvement ensures they are always one step ahead.

Case Studies of Performance Optimization with SYIL's CNC Machines

Successful Implementation of SYIL's Spindle Systems in Manufacturing Industries

SYIL Machine Tools has successfully implemented its advanced spindle systems in various manufacturing industries, revolutionizing performance optimization. By integrating high-speed spindle technology and precision spindle manufacturers, SYIL's CNC machines have significantly improved productivity and efficiency in machining operations. With their expertise in machinery spindles and spindle repair services, SYIL ensures that their machines deliver exceptional performance and reliability.

One notable case study involves a leading automotive parts manufacturer that adopted SYIL's CNC machines with state-of-the-art spindle systems. The company experienced a remarkable increase in production output thanks to the high-speed spindles that enabled efficient cutting and milling processes. This resulted in reduced cycle times and improved overall productivity for the manufacturer.

Increased Productivity and Cost-Effectiveness Achieved with SYIL's Machines

SYIL Machine Tools' CNC machines have proven instrumental in increasing productivity and cost-effectiveness for businesses across various industries. These machines offer enhanced stability and rigidity by incorporating advanced spindle systems, ensuring precise machining operations.

In one case study involving a furniture manufacturing company, implementing SYIL's CNC machines significantly reduced production costs. The high-speed spindles allowed for faster material cutting, resulting in shorter lead times and reduced labor expenses. Additionally, the compatibility of SYIL's machines with various materials and applications allowed the company to meet diverse customer demands.

Testimonials from Satisfied Clients Regarding Performance Optimization

SYIL Machine Tools takes pride in its ability to optimize outstanding performance through CNC machines' advanced spindle systems. Numerous satisfied clients have shared testimonials highlighting the exceptional results achieved with SYIL's machinery.

One client from the aerospace industry expressed their satisfaction with the precision provided by SYIL's CNC machine tool spindles. The client mentioned that the spindle systems' accuracy and reliability allowed them to achieve intricate machining tasks easily. This testimonial emphasizes the crucial role of SYIL's machines in meeting the demanding requirements of industries that rely on precision engineering.

Real-World Examples Showcasing the Capabilities of SYIL's CNC Machines

Real-world examples are tangible evidence of SYIL Machine Tools' CNC machines' capabilities in performance optimization. One example involves a medical device manufacturer integrating SYIL's CNC machines into their production line. The advanced cooling systems incorporated in these machines ensured precise temperature control during machining processes, resulting in high-quality and consistent medical devices.

Another example showcases a metal fabrication company utilizing SYIL's CNC machines for diverse projects. The compatibility with various materials allowed the company to handle different metal alloys efficiently, improving their overall productivity and expanding their customer base.

Conclusion

One of the key advantages of SYIL's CNC machines is the reliability and quality of their spindle systems. With precision spindle manufacturers at the helm, SYIL Machine Tools ensures their machines are equipped with top-notch CNC motors. This commitment to excellence translates into consistent and dependable performance for machinists across various industries.

For those seeking high-speed spindle technology and superior machine tool spindles, SYIL's CNC machines are the go-to choice. Their advanced cooling systems provide effective temperature control during machining operations, allowing optimal performance even in demanding applications. Additionally, these machines are compatible with various materials and can be customized to meet specific machining needs.

SYIL Machine Tools also prioritizes sustainability in its CNC machine manufacturing process. By incorporating energy-efficient spindle systems, they reduce power consumption without compromising performance. Furthermore, the longevity and durability of SYIL's contribute to reduced waste in the long run, making them an eco-friendly choice for machining operations.

With a focus on technological advancements in spindle systems, SYIL stays ahead by continuously improving its machines. Innovations in spindle design and integration of smart technologies enable enhanced automation and efficiency. Through ongoing research and development efforts, SYIL Machine Tools ensures its customers access cutting-edge spindle systems for optimal performance.

Real-world case studies demonstrate the effectiveness of SYIL's CNC machines in achieving performance optimization. Industries across the globe have successfully implemented these machines, resulting in increased productivity and cost-effectiveness. Testimonials from satisfied clients attest to the capabilities of SYIL's spindle systems in delivering exceptional results.

Optimizing performance in machining operations is essential, and SYIL's CNC machines offer the ideal solution. With their advanced spindle systems, reliability, and commitment to sustainability, SYIL Machine Tools develops and manufactures precision CNC machines that meet the diverse needs of machinists worldwide. Explore SYIL's CNC machines today to unlock the full potential of your machining operations.